Expand your options. - Gerber Technology

Expand your options. - Gerber Technology

Expand your options. - Gerber Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

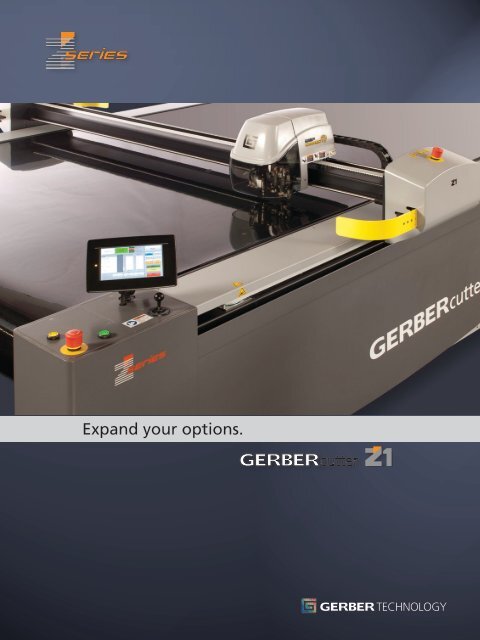

<strong>Expand</strong> <strong>your</strong> <strong>options</strong>.

Software that gives you the power of speed and information. Simplified expandability.<br />

At the heart of the GERBERcutter ® Z1 is state-ofthe-art<br />

Axis software, a Windows ® -based system<br />

that is easy to use and delivers significant productivity<br />

enhancements:<br />

• Comprehensive reports that help you take<br />

control of <strong>your</strong> business. Analyze system<br />

throughput, material yield, processing times,<br />

individual job statistics and more. Discover<br />

opportunities to make cutter operators more<br />

efficient and to optimize <strong>your</strong> cutting process.<br />

• Job queue enables simultaneous loading of all<br />

jobs to be cut during an entire shift or day’s<br />

work.<br />

• Job recovery functionality helps you resume the<br />

cutting process at the precise point the job was<br />

interrupted due to a power outage, for example.<br />

• Wizards automate repetitive processes and<br />

accelerate preparation of the cut job.<br />

• Users are able to monitor and electronically<br />

regulate the pressure of the knife to optimize<br />

the accuracy of cut parts.<br />

The GERBERcutter Z1 is built upon a new distributed<br />

control system, the foundation upon which many<br />

powerful <strong>options</strong> like inkjet-printed part identification<br />

and <strong>Gerber</strong>’s ContourVision scan-to-cut system<br />

can be added. By distributing the intelligence away<br />

from the main controller, the system is more modular<br />

and flexible, installation is simplified, processing<br />

power is significantly improved and the system is<br />

more reliable.<br />

Define cutting parameters such as tool pressure,<br />

vacuum levels and cutting speed on the cutter’s<br />

portable workstation and easily adjust them using<br />

the touch screen directly at the cutter.<br />

Energy efficient.<br />

Because the GERBERcutter Z1 is designed for maximum<br />

efficiency, it’s equipped with an intelligent<br />

variable vacuum regulator. Simply input the optimum<br />

vacuum levels to cut and convey <strong>your</strong> materials. The<br />

system regulates vacuum levels according to the task<br />

at hand – even minimizing vacuum when the cutter is<br />

idle to conserve electricity.

A<br />

B<br />

C<br />

D<br />

The state-of-the-art cutting head accommodates<br />

up to three cutting tools and a pen for annotation<br />

enabling you to customize tools according to<br />

<strong>your</strong> application.<br />

Control cut jobs using a touch screen directly<br />

on the cutter. Here you can adjust tool pressure,<br />

vacuum levels and cutting speed.<br />

GERBERconnect remote diagnostics monitors the<br />

status of <strong>your</strong> cutting system via a secure Internet<br />

connection so <strong>Gerber</strong> service professionals can<br />

ensure it’s always in optimum working condition.<br />

A new distributed control system improves<br />

processing power and reliability and enables you<br />

to easily add <strong>options</strong> to <strong>your</strong> system.<br />

GERBERcutter Z1 is the next generation computer-controlled, automated cutting<br />

system and the optimal solution for single- and low-ply cutting of a wide range of<br />

challenging composite materials, upholstery fabric and technical textiles.<br />

Rely on it to maximize <strong>your</strong> productivity and profitability, reduce work in process,<br />

shorten lead times and ensure precisely cut parts.<br />

F<br />

B<br />

E<br />

C<br />

D<br />

A<br />

F G<br />

E<br />

F<br />

G<br />

The conveyorized cutting belt is designed<br />

with a patented sign wave that delivers<br />

more accurately cut parts and prolongs the<br />

life of the belt. It also eliminates the need<br />

for plastic overlay and paper underlay.<br />

Safety paddles installed on the cutting<br />

beam and four emergency stop buttons<br />

located at each corner of the cutting<br />

system uphold the safety of operators.<br />

Powerful Axis software delivers comprehensive<br />

reports, simplifies re-cutting of<br />

parts and delivers multiple productivity<br />

enhancements.

Customizable.<br />

Slash the amount of time it takes to prepare <strong>your</strong><br />

cut jobs. When you determine the optimum settings<br />

for <strong>your</strong> specific materials, save them to re-use time<br />

after time.<br />

The GERBERcutter Z1 operates according to <strong>your</strong><br />

workflow. Choose to cut materials either in sections<br />

or continuously to maximize <strong>your</strong> productivity.<br />

An optional workstation enables the operator to<br />

identify cut parts quickly, streamlining the kitting and<br />

bundling process. On the workstation’s touch screen,<br />

users can also select parts that require recutting,<br />

automatically re-nest them and quickly re-cut them.<br />

The system accommodates three cutting tools to<br />

minimize tool changes and a pen for annotation.<br />

Choose from a wheel cutter, drag blade and a variety<br />

of notch and punch tools to best suit <strong>your</strong> cutting<br />

application. Quickly set the cutting origin using the<br />

system’s laser pointer.<br />

Safe.<br />

With <strong>Gerber</strong> <strong>Technology</strong>, operator safety is always a<br />

primary concern. The GERBERcutter Z1 is equipped<br />

with emergency stop buttons in multiple locations<br />

and safety paddles that immediately halt the cutting<br />

beam if it comes into contact with an operator.<br />

The system is UL listed and complies with CE safety<br />

standards.<br />

Remote diagnostics.<br />

The GERBERcutter Z1 is equipped with GERBERconnect <br />

remote diagnostics. In addition to automatically detecting<br />

<strong>your</strong> cutter’s status, GERBERconnect enables<br />

<strong>Gerber</strong> service professionals to analyze <strong>your</strong> system<br />

via a secure Internet connection and to take steps<br />

to ensure it’s always in optimum working condition.<br />

Service and support you can trust.<br />

With reliable service from <strong>Gerber</strong> <strong>Technology</strong>, you’ll<br />

protect <strong>your</strong> investment.<br />

<strong>Gerber</strong> <strong>Technology</strong> has a global network of highlyskilled<br />

applications and technical support specialists.<br />

And we offer the highest quality consumables and<br />

aftermarket products available.

Take comfort in our experience.<br />

The GERBERcutter Z1 was designed and engineered by the manufacturer that invented automated cutting.<br />

<strong>Gerber</strong> <strong>Technology</strong> has been leading innovation for more than 40 years. During this time, we’ve worked sideby-side<br />

with thousands of customers around the world.<br />

Today, <strong>Gerber</strong> <strong>Technology</strong> draws upon its decades of experience to deliver the most reliable computer-driven<br />

cutting technology and the most advanced software in the industry.<br />

Contact us today to discuss <strong>your</strong> needs. You’ll find the dedicated business partner you deserve.<br />

+1 860 871 8082<br />

USA: 1 800 826 3243<br />

www.gerbertechnology.com

![Download Fast Facts [PDF] - Gerber Technology](https://img.yumpu.com/8694541/1/190x245/download-fast-facts-pdf-gerber-technology.jpg?quality=85)

![Descargar información de la empresa [PDF] - Gerber Technology](https://img.yumpu.com/8670734/1/190x245/descargar-informacian-de-la-empresa-pdf-gerber-technology.jpg?quality=85)