Options for Electric Power Steering Modules a Reliability ... - Danfoss

Options for Electric Power Steering Modules a Reliability ... - Danfoss

Options for Electric Power Steering Modules a Reliability ... - Danfoss

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

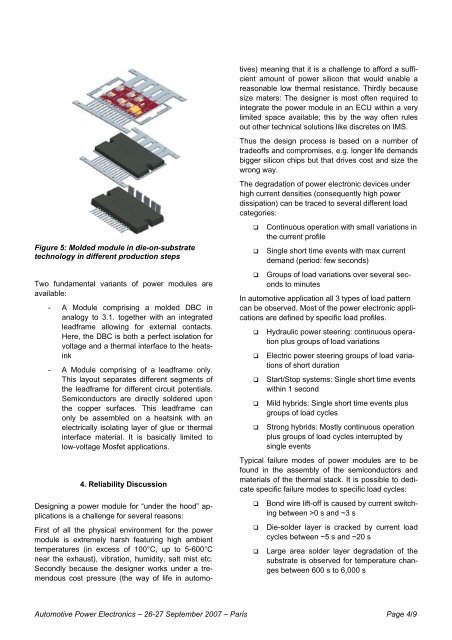

Figure 5: Molded module in die-on-substrate<br />

technology in different production steps<br />

Two fundamental variants of power modules are<br />

available:<br />

- A Module comprising a molded DBC in<br />

analogy to 3.1. together with an integrated<br />

leadframe allowing <strong>for</strong> external contacts.<br />

Here, the DBC is both a perfect isolation <strong>for</strong><br />

voltage and a thermal interface to the heatsink<br />

- A Module comprising of a leadframe only.<br />

This layout separates different segments of<br />

the leadframe <strong>for</strong> different circuit potentials.<br />

Semiconductors are directly soldered upon<br />

the copper surfaces. This leadframe can<br />

only be assembled on a heatsink with an<br />

electrically isolating layer of glue or thermal<br />

interface material. It is basically limited to<br />

low-voltage Mosfet applications.<br />

4. <strong>Reliability</strong> Discussion<br />

Designing a power module <strong>for</strong> “under the hood” applications<br />

is a challenge <strong>for</strong> several reasons:<br />

First of all the physical environment <strong>for</strong> the power<br />

module is extremely harsh featuring high ambient<br />

temperatures (in excess of 100°C, up to 5-600°C<br />

near the exhaust), vibration, humidity, salt mist etc.<br />

Secondly because the designer works under a tremendous<br />

cost pressure (the way of life in automo-<br />

tives) meaning that it is a challenge to af<strong>for</strong>d a sufficient<br />

amount of power silicon that would enable a<br />

reasonable low thermal resistance. Thirdly because<br />

size maters: The designer is most often required to<br />

integrate the power module in an ECU within a very<br />

limited space available; this by the way often rules<br />

out other technical solutions like discretes on IMS.<br />

Thus the design process is based on a number of<br />

tradeoffs and compromises, e.g. longer life demands<br />

bigger silicon chips but that drives cost and size the<br />

wrong way.<br />

The degradation of power electronic devices under<br />

high current densities (consequently high power<br />

dissipation) can be traced to several different load<br />

categories:<br />

� Continuous operation with small variations in<br />

the current profile<br />

� Single short time events with max current<br />

demand (period: few seconds)<br />

� Groups of load variations over several seconds<br />

to minutes<br />

In automotive application all 3 types of load pattern<br />

can be observed. Most of the power electronic applications<br />

are defined by specific load profiles.<br />

� Hydraulic power steering: continuous operation<br />

plus groups of load variations<br />

� <strong>Electric</strong> power steering groups of load variations<br />

of short duration<br />

� Start/Stop systems: Single short time events<br />

within 1 second<br />

� Mild hybrids: Single short time events plus<br />

groups of load cycles<br />

� Strong hybrids: Mostly continuous operation<br />

plus groups of load cycles interrupted by<br />

single events<br />

Typical failure modes of power modules are to be<br />

found in the assembly of the semiconductors and<br />

materials of the thermal stack. It is possible to dedicate<br />

specific failure modes to specific load cycles:<br />

� Bond wire lift-off is caused by current switching<br />

between >0 s and ~3 s<br />

� Die-solder layer is cracked by current load<br />

cycles between ~5 s and ~20 s<br />

� Large area solder layer degradation of the<br />

substrate is observed <strong>for</strong> temperature changes<br />

between 600 s to 6,000 s<br />

Automotive <strong>Power</strong> Electronics – 26-27 September 2007 – Paris Page 4/9