Free to Download - SCLG

Free to Download - SCLG

Free to Download - SCLG

- TAGS

- download

- sclg

- sclgme.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

40 CITYPULSE JULY 09

AD<br />

Page 2

EDITOR’S NOTE<br />

EDITORIAL<br />

Group Managing Edi<strong>to</strong>r<br />

Vigyan Arya<br />

vigyan@groupinfinity.com<br />

Edi<strong>to</strong>r<br />

Patrick Francis<br />

patrick@groupinfinity.com<br />

Contributing Edi<strong>to</strong>rs<br />

Priya Kumar<br />

Eric Francis<br />

Savio Pimenta<br />

Saida Samai<br />

Edi<strong>to</strong>rial Assistant<br />

Jessel Tan<br />

ART / PRODUCTION<br />

Aslam A.K<br />

Boban K.V<br />

Pho<strong>to</strong>grapher<br />

Amaresh<br />

Advertising & Marketing<br />

sales@groupinfinity.com<br />

4 Link January 2011<br />

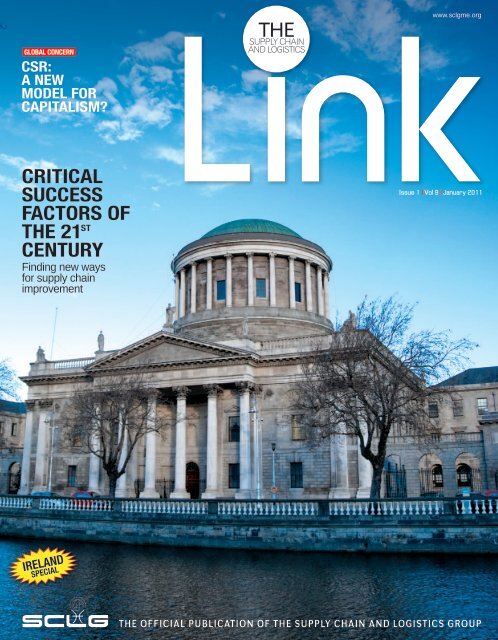

Image: Four Courts, Dublin<br />

Issue 1 Vol 9 Jan 2011<br />

The Link is the official publication<br />

of <strong>SCLG</strong>ME. The opinions<br />

and views contained in this<br />

publication are not necessarily<br />

those of the <strong>SCLG</strong>ME as<br />

publishers. Readers are advised<br />

<strong>to</strong> seek special advice before<br />

acting on information contained<br />

in this publication, which is for<br />

general use and may not be<br />

appropriate for the reader’s<br />

particular circumstances. No part<br />

of this publication or any part<br />

of its contents thereof may be<br />

reproduced in any form without<br />

the permission of the publishers<br />

in writing.<br />

EDITORIAL PRODUCTION<br />

AND CONTENT PROVIDER<br />

Group Infinity FZC;<br />

P.O. Box 9733, Sharjah;<br />

United Arab Emirates<br />

Ph: 06-5571646; Fax: 06-5571656<br />

Email: link@groupinfinity.com<br />

Cover Design by Aslam AK<br />

Dear <strong>SCLG</strong> Members,<br />

Again a new year has started and first and foremost, on behalf of<br />

the <strong>SCLG</strong> Leadership Team, I would like <strong>to</strong> wish all of you the very<br />

best for yourselves, your families and your business. May 2011 be<br />

a year of health and prosperity.<br />

While 2010 was a year of<br />

recovery in most businesses,<br />

2011 will be a year of transition,<br />

not only for our industry, that has<br />

<strong>to</strong> transform <strong>to</strong> more sustainable<br />

models, methods and processes<br />

<strong>to</strong> ensure business continuity, but<br />

also for the <strong>SCLG</strong> <strong>to</strong> adapt the way<br />

it interacts with its members, the<br />

industry, government departments,<br />

other industry groups and the public<br />

at large.<br />

With Social Media and networking driving the modern<br />

interaction between individuals, the <strong>SCLG</strong> also has <strong>to</strong> embrace<br />

these <strong>to</strong>ols and communicate in different ways. We increasingly<br />

use information and publications from the internet and find<br />

ourselves ‘linked’ <strong>to</strong> other professionals and part of industry<br />

groups. This year the Executive Committee will focus on<br />

communication through these platforms and keep current and in<br />

<strong>to</strong>uch, wherever and whenever, even whilst on the move.<br />

We will also strive <strong>to</strong> transition more of our Student and Young<br />

Professional members in<strong>to</strong> our activities. They represent our<br />

future and come with great ideas and enthusiasm <strong>to</strong> progress and<br />

bring innovation <strong>to</strong> the industry.<br />

Last but not least, we want <strong>to</strong> ensure international expansion<br />

and facilitate relations across borders and in<strong>to</strong> other continents<br />

for our members. In an increasingly Global and Integrated Supply<br />

Chain environment we need <strong>to</strong> open dialog with our partners in<br />

the rest of the world.<br />

I look forward <strong>to</strong> being in <strong>to</strong>uch with all of you throughout this<br />

coming year and working with you <strong>to</strong> continue the success of the<br />

<strong>SCLG</strong> group.<br />

Warmest regards,<br />

André N. Verdier<br />

President, Executive Committee <strong>SCLG</strong>

INSIDE<br />

Contents<br />

15 IRELAND SPECIAL<br />

Value for Money – The Road <strong>to</strong> Success<br />

Our success in achieving Value for Money (VFM) will only be fully<br />

achieved when we have the processes in place <strong>to</strong> consistently<br />

measure savings across multiple agencies<br />

30<br />

ISSUES<br />

Cutting Freight Costs when<br />

Fuel Keeps Rising<br />

It would take a brave soul <strong>to</strong> predict relief in<br />

the medium or even long term on fuel prices<br />

REGULAR FEATURES<br />

10 GCC - NEWS<br />

Embraer names new executive jets service<br />

center in Middle East<br />

6 Link January 2011<br />

32<br />

OVERVIEW<br />

Goods shipments: A two-speed<br />

sec<strong>to</strong>r<br />

Goods shipments play a large role in<br />

operating in a real-time complex system<br />

26<br />

46<br />

FINANCE<br />

Bank investments in private<br />

equity: An unfair advantage?<br />

Private sec<strong>to</strong>r, government and logistics<br />

industry collaboration are vital <strong>to</strong> realize<br />

potential economic success<br />

CASE STUDY<br />

Predictive Demand, Planning<br />

and Demand Sensing<br />

Supply chain network optimization is a core<br />

competency in the North Pole<br />

42 IN FOCUS - MANAGEMENT 52 INTERNATIONAL - NEWS<br />

The Asian region is better equipped <strong>to</strong><br />

handle recession than European countries<br />

Malaysia’s CIMB seeks <strong>to</strong> boost its Gulf<br />

business with new offers

Membership<br />

Corporate Membership<br />

Membership with the Supply Chain and<br />

Logistics Group (<strong>SCLG</strong>) is open <strong>to</strong> all<br />

organisations. Corporate members may<br />

nominate four <strong>to</strong> six members, depending<br />

on the category of membership – basic,<br />

privileged or premier – they opt for.<br />

All nominated members shall be allowed<br />

<strong>to</strong> vote at the Annual General Meeting<br />

(AGM) and at any Extraordinary General<br />

Meetings. The Board of Direc<strong>to</strong>rs (BoD) and<br />

Executive Committee (EC) members shall<br />

decide the annual fees for membership.<br />

Individual Membership<br />

This is open <strong>to</strong> any individual from any<br />

part of the world. The annual subscription<br />

shall be set from time-<strong>to</strong>-time as deemed<br />

necessary by the BoD and EC members.<br />

Student Membership<br />

Only full-time students can be <strong>SCLG</strong><br />

members, but this membership does not<br />

convey voting rights <strong>to</strong> the individual. The<br />

annual fee shall be set from time-<strong>to</strong>-time<br />

as deemed necessary by the BoD and EC<br />

members.<br />

Why be an <strong>SCLG</strong> Member<br />

A membership allows access <strong>to</strong> educational<br />

training, seminars and networking evenings<br />

at concessional and rebated rates. It<br />

also provides rebates on subscription<br />

of membership <strong>to</strong> <strong>SCLG</strong>’s international<br />

partners. There is also a certificate that<br />

distinguishes a member as a professionally<br />

focused individual or enterprise committed <strong>to</strong><br />

the cause of the supply chain and logistics<br />

industry.<br />

For more details, please visit our website<br />

on www.sclgme.org. If you wish <strong>to</strong> volunteer<br />

<strong>to</strong> help us foster a better supply chain and<br />

logistics community, please contact Kanchan<br />

Vora on admin@sclgme.org.<br />

The <strong>SCLG</strong> Middle East is a non-profit<br />

organization working under the umbrella<br />

GLOBAL THOUGHT AND INDUSTRY LEADERS<br />

Shashi Shekhar<br />

Founder & Group<br />

President <strong>SCLG</strong><br />

Mohammed Sharaf<br />

DP World<br />

Michael Proffitt<br />

Fadi Ghandour<br />

Aramex<br />

Saadi Al Rais<br />

RHS Logistics<br />

Clifford Cuttelle David Wild<br />

Sanjay Naik<br />

Emirates Group<br />

Jinendra Sancheti<br />

TNT Express<br />

Dr. John Gat<strong>to</strong>rna<br />

Mishal Hamed Kanoo<br />

Kanoo Group<br />

Essa Al Saleh<br />

Agility<br />

Hamdi Osman<br />

FedEx<br />

<strong>SCLG</strong> INFO<br />

www.sclgme.org

<strong>SCLG</strong> INFO<br />

REGIONAL DEVELOPMENT<br />

COMMITTEE<br />

www.sclgme.org<br />

Dr. K. M. Madrecha<br />

Abu Dhabi<br />

Municipality<br />

Dr. Ernst Schmied<br />

East Europe, CIS,<br />

Russia<br />

Dr. Dermot Carey<br />

UK & Ireland<br />

Usha Kaul<br />

University of Dubai<br />

Ravi Kashyap<br />

Steinweg Sharaf<br />

Dirk Van Doorn<br />

DHL<br />

Mark Millar<br />

Asia Pacific<br />

Johnson Soans<br />

Extron Electronics<br />

Jassim Saif<br />

Emirates SkyCargo<br />

Pradeep<br />

Melakandy<br />

Pan-Pacific<br />

Logistics<br />

Dave Tootle<br />

Southern Africa<br />

Dany Vermeulen<br />

Australia & New<br />

Zealand<br />

Tom Nauwelaerts<br />

Al-Futtaim Group<br />

of the Dubai Chamber of Commerce<br />

and Industry <strong>to</strong> promote the cause of the<br />

supply chain and logistics industry. It brings<br />

opportunities for personal and professional<br />

development through networking prospects<br />

among like-minded professionals and<br />

corporations on a global basis.<br />

The <strong>SCLG</strong> was founded with the help<br />

of senior management professionals<br />

representing a wide spectrum of industries<br />

in the supply chain. It strives <strong>to</strong> bring the<br />

BOARD OF DIRECTORS<br />

Tayssir Awada<br />

FedEx<br />

Roy Patterson<br />

UTi<br />

Geoff Wheatley<br />

SSI Schaefer (ME)<br />

Dr. Satish Mapara<br />

GlobeApex<br />

Management<br />

Consultants<br />

Madhav Kurup<br />

Hellman Worldwide<br />

Logistics<br />

Capt. Arup Gupta<br />

Retail Logistics<br />

Nigel Moore<br />

Logistics<br />

Recruitment<br />

Sanjay Babur<br />

Cosmos Insurance<br />

Graham Burne<br />

best in education, seminars and interaction<br />

through partnerships and alliances with a<br />

variety of similar bodies across the globe.<br />

The group’s official magazine, The Supply<br />

Chain and Logistics Link, addresses the<br />

needs of the supply chain professionals in<br />

the Middle East. It presents news, views,<br />

developments and information drawn from<br />

industry experts.<br />

The first of its kind in the region, The Link<br />

aspires <strong>to</strong> be a benchmark for the industry<br />

community, offering valuable insights<br />

and information <strong>to</strong> the target market. The<br />

M I S S I O N<br />

The group aims <strong>to</strong> provide an accessible<br />

and dynamic networking environment<br />

that facilitates the achievements of its<br />

members in a community that encourages<br />

professional development and diversity<br />

in the logistics and supply chain<br />

management.<br />

CONSULTATIVE COMMITTEE<br />

Dr. Dermot Carey<br />

MRM Global<br />

UK & Ireland<br />

Reinhard Wind<br />

Jasamin Fichte<br />

Fitche & Co Legal<br />

Consultancy<br />

Michael S<strong>to</strong>ckdale<br />

Dr. Cedwyn<br />

Fernandes<br />

University of<br />

Middlesex<br />

Andreas Dur<br />

Xvise Logistics<br />

Mohsen Al Awadhi<br />

Dubai Logistics City<br />

Melvin Varghese<br />

Argonaut S.E.A.<br />

Private Limited<br />

Brian Forbes<br />

DHL Express<br />

Stephen Cross<br />

ATMS<br />

Naveen Arun<br />

Hemant Barke<br />

Prudence<br />

Insurance<br />

Brokers<br />

Soma Shekhar<br />

TrackIT<br />

Sebastian Thomas<br />

ZAFCO<br />

John Halpin<br />

AVT International<br />

Group<br />

Ayman Abouseif<br />

On-Track Arabia<br />

magazine’s articles and news features cover<br />

innovative supply chain practices, emerging<br />

technologies, e-commerce and market<br />

information from industry leaders.

EXECUTIVE COMMITTEE<br />

Andre Verdier<br />

President,<br />

Executive<br />

Committee<br />

Juergen Hirsch<br />

Agility (UAE<br />

Kamel El<br />

Ghoussaini<br />

Span<br />

Kinsella Paul<br />

Chep ME Fzco<br />

Pritesh P. N.<br />

Modern Freight<br />

Sigi Gruber<br />

SSSI Schaefer<br />

LLC<br />

Ravi Subramaniam<br />

Launchpad<br />

Consultants<br />

Vinod Jayan<br />

Al Futtaim<br />

Retail Division<br />

Iyad Moussa<br />

TNT<br />

International<br />

Express<br />

Krishna Prasad<br />

Aster Marine<br />

Cargo (UAE)<br />

O B J E C T I V E S<br />

ËTo promote the cause of the supply<br />

chain and logistics industry and raise the<br />

standards of all industries on end-<strong>to</strong>-end<br />

supply chain<br />

ËTo protect the interests of member<br />

organisations and support government<br />

bodies in the formulation of policy<br />

frameworks for logistics organisations<br />

ËTo encourage the free exchange of<br />

knowledge and skills relating <strong>to</strong> supply<br />

chain and logistics among its members<br />

ËTo provide members the opportunity<br />

<strong>to</strong> network among one another and <strong>to</strong><br />

help facilitate an efficient commercial<br />

environment<br />

ËTo undertake studies and gather<br />

information, statistical data and official<br />

documents relevant <strong>to</strong> the industry<br />

Dr. Dermot Carey<br />

Ireland<br />

Dr. Ernst Schmied<br />

Austria<br />

Khalid Bichou<br />

Morocco<br />

Mark Millar<br />

Asia Pacific<br />

Paul Lim<br />

Singapore<br />

Alan Waller<br />

UK<br />

Tim Sensenig<br />

USA<br />

Dr. Craig Voortman<br />

South Africa<br />

Prof Donald Tham<br />

Canada<br />

Tom <strong>Free</strong>se<br />

USA<br />

Mahendra Agarwal<br />

Singapore<br />

Vineet Agarwal<br />

India<br />

ËTo establish and maintain good relations<br />

with similar international organisations<br />

and other professional groups, and <strong>to</strong><br />

provide members the opportunity <strong>to</strong><br />

network with like-minded organisations<br />

ËTo conduct training courses, seminars,<br />

conferences and studies relating <strong>to</strong><br />

logistics and supply chain and <strong>to</strong> establish<br />

a library and research centre <strong>to</strong> expand<br />

the knowledge base information on the<br />

industry<br />

ËTo promote the cause of education in<br />

supply chain and logistics among the UAE<br />

nationals, thereby contributing <strong>to</strong> build a<br />

cadre of professionals and highly-skilled<br />

citizens <strong>to</strong> take up current and future<br />

challenges in the industry.<br />

INTERNATIONAL ADVISORS<br />

Dominique De<br />

Froberville<br />

Mauritius<br />

Horst Deffner<br />

Brazil<br />

Dr. Ganesh<br />

Natrajan<br />

India<br />

Edward Sweeney<br />

Ireland<br />

Dimitriy Bulaenko<br />

Ukraine<br />

Igor Hribar<br />

Slovenia<br />

Dr. Tom Gulledge<br />

USA<br />

Terry Lee<br />

Taiwan<br />

An<strong>to</strong>ny Walford<br />

Switzerland<br />

Ferenc Kovacs<br />

Hungary<br />

Dr. John Paul<br />

Singapore<br />

Win<strong>to</strong>n Myers<br />

South Africa<br />

Dr. Heinrich Frye<br />

Germany<br />

Matthieu Gasselin<br />

Italy<br />

Andrew Saliba<br />

Malta<br />

Gerald M.<br />

Mukyenga<br />

Uganda<br />

Dr. Jorg Rissiek<br />

Germany<br />

<strong>SCLG</strong> INFO<br />

www.sclgme.org

GCC News<br />

Al Jaber Aviation and Airbus showcase the<br />

new A318 Elite Plus at MEBA 2010<br />

The Al Jaber Aviation (AJA)<br />

A318 Elite plus aircraft is on<br />

display as the ideal design model<br />

for corporate jets by Airbus, an<br />

EADS company and leading aircraft<br />

manufacturer at the ongoing Middle<br />

East Business Aviation (MEBA)<br />

2010 event in Dubai.<br />

AJA, the new pinnacle of<br />

VIP aviation and part of the Al<br />

Jaber Group based in Abu Dhabi<br />

will showcase the elegant and<br />

comfortable ergonomic cabins<br />

of the Airbus 318 that have been<br />

designed <strong>to</strong> accommodate up <strong>to</strong> 19<br />

passengers and two crew members.<br />

With long haul capability, the A318 Elite<br />

plus will be able <strong>to</strong> cater <strong>to</strong> requirements<br />

from Heads of States, Rulers, VIPs and<br />

those who wish <strong>to</strong> fly in comfort <strong>to</strong> far<br />

destinations. The A318 aircraft is a more<br />

viable option than traditional business jets<br />

as it can fly larger groups making it ideal for<br />

big companies and government delegations.<br />

10 Link January 2011<br />

This is further supported by the aircraft<br />

offering cargo capability.<br />

“The Middle East is a growing market<br />

for business jets and is set <strong>to</strong> expand 15-<br />

20% per annum over the next four years <strong>to</strong><br />

become a $1bn-per-year industry. We are<br />

looking <strong>to</strong> secure a slice of this lucrative<br />

segment and our aircraft are ready <strong>to</strong> cater<br />

<strong>to</strong> this growth,” said Mohammed Al Jaber,<br />

Petrochemical production in Gulf set <strong>to</strong> rise <strong>to</strong> $80b<br />

Chemical production in the Gulf will rise<br />

from $40 billion (Dh146 billion) <strong>to</strong> $80<br />

billion by 2020 but that will not be enough<br />

<strong>to</strong> achieve a major share of global output<br />

in the sec<strong>to</strong>r, a senior industry professional<br />

said yesterday.<br />

“I would like <strong>to</strong> see the year 2020 value<br />

hit the $120 billion <strong>to</strong> $150 billion per annum<br />

range,” Saudi Aramco President and Chief<br />

Executive Khalid A. Al Falih said at the fifth<br />

Annual Forum of the Gulf Petrochemicals<br />

and Chemicals Association (GPCA) in<br />

Dubai.<br />

“The strategic challenge for the region’s<br />

chemical industry is not <strong>to</strong> grow from $40<br />

billion <strong>to</strong> $50 billion in per-annum revenue<br />

but <strong>to</strong> fundamentally alter its economic<br />

role within the region... <strong>to</strong> leapfrog other<br />

regions within the global petrochemicals<br />

landscape,” Al Falih said.<br />

Aramco will bring Wasit, its largest gas<br />

plant, online in 2013, a year earlier than<br />

expected, Al Falih said. The company<br />

completed a crude expansion programme<br />

last year that <strong>to</strong>ok its oil production capacity<br />

<strong>to</strong> 12 million barrels per day.<br />

Petrochemical production increased by<br />

an average of 3.7 per cent in the Gulf last<br />

year, with Saudi Arabia posting an increase<br />

of 6.3 per cent; the UAE 4.4 per cent;<br />

Kuwait 3.2 per cent and Qatar 7.4 per cent.<br />

Global apprehension<br />

“Last year at this time there was global<br />

apprehension about economic recovery,”<br />

said Mohammad H. Al Mady, Vice-<br />

Chairman and Chief Executive of the Saudi<br />

Basic Industries Corporation (Sabic) and<br />

chairman of GPCA.<br />

“Thankfully, <strong>to</strong>day, there is more<br />

optimism about growth. But this is no time<br />

for complacency,” he said.<br />

Al Mady said he sees expanded margins<br />

for petrochemicals as increased demand<br />

comes from emerging economies such as<br />

China, India, South Korea and Indonesia.<br />

Concerns for 2011 include excess<br />

capacity in the Gulf and the possibility of<br />

CEO of AJA.<br />

The Airbus 318 Elite plus is the<br />

newest Airbus Corporate Jet, and<br />

features a stylish and practical<br />

single-aisle cabin created by<br />

Lufthansa Technik. All equipment<br />

and seats have been designed <strong>to</strong><br />

be very simple <strong>to</strong> use, and <strong>to</strong> offer<br />

the most comfort and generous<br />

s<strong>to</strong>rage in a VIP charter aircraft.<br />

The A318 aircraft boasts<br />

mood-lighting system, new <strong>to</strong>uchscreen<br />

technology, and advanced<br />

passenger entertainment and<br />

communications - including<br />

a PFIS (Passenger Flight<br />

Information System), Internet and audio and<br />

video on-demand. The cabin cross-section<br />

is almost twice as wide as that of traditional<br />

business jets. The benefits <strong>to</strong> cus<strong>to</strong>mers<br />

include robust long-lasting airframe<br />

and reliable systems and an advanced<br />

aerodynamic design powered by modern<br />

and efficient engines.<br />

asset price bubbles in the global economy,<br />

especially in commodities and metals, Al<br />

Mady said.<br />

Shaikha Lubna Bint Khalid Al Qasimi,<br />

UAE Minister of Foreign Trade, said<br />

the Gulf’s leading position in the global<br />

petrochemical industry is expected <strong>to</strong> grow<br />

as capacity increases.<br />

“Expansion of capacity continued even<br />

in the <strong>to</strong>ugh economic environment [in the<br />

past two years].<br />

“It will be accelerated by increased<br />

foreign investment in the sec<strong>to</strong>r,” she said.<br />

The UAE’s Borouge, for example, will<br />

triple capacity <strong>to</strong> 4.5 million <strong>to</strong>nnes per<br />

annum by the end of 2013. By 2015, nine<br />

new crackers and downstream plants<br />

will come online across the Gulf, giving<br />

the region a 20 per cent share of global<br />

petrochemical production, she said.<br />

“The 10 years <strong>to</strong> 2020 will be the decisive<br />

decade of opportunity, a golden age for our<br />

region in terms of economic conditions and<br />

commercial opportunities,” said Al Falih.

Majid Al Futtaim Ventures and Dalkia<br />

recently announced an extension <strong>to</strong><br />

their joint venture, initially agreed in 2002,<br />

which enables the companies <strong>to</strong> expand the<br />

MAF Dalkia brand of facilities and energy<br />

management services in<strong>to</strong> the Gulf, Levant<br />

and Egypt markets.<br />

As part of the expansion, MAF Dalkia<br />

will extend its focus <strong>to</strong> specific facilities<br />

and energy management opportunities in<br />

Saudi Arabia, Qatar, Egypt and other key<br />

geographies, while leveraging regional<br />

and international expertise in healthcare,<br />

telecommunications, and other key industry<br />

verticals across the region.<br />

By 2011, MAF Dalkia will be providing<br />

facilities and energy management services<br />

for an estimated 3.3 million square meters<br />

of commercial and residential space in the<br />

Middle East, in addition <strong>to</strong> managing at<br />

least 125,000TR cooling capacity and 2,550<br />

Embraer has appointed ExecuJet<br />

Aviation Group, in Dubai (UAE), as a<br />

new Embraer Authorized Service Center<br />

(EASC) for the Legacy 600 and Legacy<br />

650 executive jets. ExecuJet Dubai will<br />

provide scheduled and unscheduled<br />

maintenance services at Dubai<br />

International Airport.<br />

“We are delighted <strong>to</strong> provide Legacy 600<br />

and Legacy 650 executive jet cus<strong>to</strong>mers<br />

in the Middle East with a new alternative<br />

MAF Ventures and Dalkia<br />

extend joint venture<br />

Mwh power managed through various client<br />

initiatives.<br />

“As an increasing number of commercial<br />

projects and <strong>to</strong>wers in the region are<br />

completed, owners are looking for facilities<br />

management partners that have proven<br />

leadership in energy efficiency, operational<br />

cost reduction, and maximization of resources<br />

- MAF Dalkia has this firsthand experience,<br />

and the expansion of our joint venture is in<br />

large part a response <strong>to</strong> cus<strong>to</strong>mer demand<br />

around the region,” said Ahmed Galal Ismail,<br />

CEO of Majid Al Futtaim Ventures and<br />

Chairman of MAF Dalkia.<br />

To expedite the regional roll-out of the<br />

expanded joint venture, MAF Dalkia and<br />

Dalkia International will merge their current<br />

Embraer names new<br />

executive jets service center<br />

in Middle East<br />

for their maintenance needs,” said An<strong>to</strong>nio<br />

Martini Ne<strong>to</strong>, Embraer Vice President<br />

- Cus<strong>to</strong>mer Support and Services, Europe,<br />

Africa and the Middle East.<br />

“As the fleet of Embraer super midsize and<br />

large executive jets grows in the region, with<br />

nearly 25 aircraft in operation, the naming<br />

of one more authorized service center in<br />

the UAE marks the Company’s commitment<br />

<strong>to</strong> offer a comprehensive and high-level<br />

support structure <strong>to</strong> our cus<strong>to</strong>mers,” he<br />

added.<br />

This appointment coincides with last week’s<br />

delivery of the first Legacy 650 large<br />

executive jet in the region. It also reinforces<br />

News<br />

GCC<br />

facilities management operations in Bahrain,<br />

where the companies count banks, shopping<br />

malls and mixed use destinations among<br />

their current clients. With its focus on energy<br />

optimization, MAF Dalkia has reduced CO2<br />

emissions by more than 36,000 <strong>to</strong>ns in 2009<br />

by introducing more sustainable facilities and<br />

energy management solutions for its clients.<br />

MAF Dalkia commits <strong>to</strong> optimizing energy<br />

usage, with a corresponding energy savings<br />

of between 10-15%. In addition <strong>to</strong> energy,<br />

telecom and healthcare, MAF Dalkia has<br />

highlighted sec<strong>to</strong>rs such as hospitality,<br />

education, commercial real estate, industry,<br />

public sec<strong>to</strong>r and cooling plants as the<br />

major drivers for growth in the Middle East’s<br />

facilities management landscape in 2011.<br />

the Embraer Cus<strong>to</strong>mer Support and<br />

Services network in the Middle East, which<br />

now has authorized service centers in Abu<br />

Dhabi and Dubai, and a dedicated spare<br />

parts distribution center in Dubai.<br />

“ExecuJet welcomes the opportunity <strong>to</strong><br />

extend its support <strong>to</strong> the Embraer Legacy<br />

600/650 aircraft, which will be served out<br />

of our newly acquired 5000 m2 hangar<br />

situated next <strong>to</strong> our existing facility at Dubai<br />

International Airport. ExecuJet currently<br />

holds Legacy 600/650 line and base<br />

maintenance authorizations with National<br />

Airworthiness Authority approvals,”<br />

stated Nick Weber, Maintenance Direc<strong>to</strong>r,<br />

ExecuJet Middle East.<br />

January 2011 Link<br />

11

IRELAND SPECIAL Business<br />

Critical Success Fac<strong>to</strong>rs in<br />

the Re-engineering of 21st<br />

Century Supply Chains<br />

The changing business environment has sharpened<br />

the focus on the need for robust approaches <strong>to</strong> supply<br />

chain improvement.<br />

This article sets out the key elements<br />

of traditional re-engineering<br />

processes. It goes on <strong>to</strong> outline some<br />

of the key characteristics of SCM excellence,<br />

based on the author’s experience and on<br />

documented evidence in the literature.<br />

Based on the performance of firms in<br />

relation <strong>to</strong> these key characteristics, a<br />

number of critical success fac<strong>to</strong>rs (CSFs)<br />

for effective supply chain re-engineering<br />

are identified and the key elements of a<br />

roadmap are proposed.<br />

Organisational Re-engineering<br />

Companies have long realised the need for<br />

company-wide approaches <strong>to</strong> organisation<br />

design and redesign. The development<br />

of systems engineering approaches <strong>to</strong><br />

manufacturing system redesign in the 1970s<br />

and 1980s was followed by the focus on<br />

organisational re-engineering, often based<br />

on business processes, in the 1980s and<br />

1990s. A common feature of all of these<br />

approaches is a recognition that “the<br />

whole is greater than the sum of the parts”.<br />

In other words, optimising subsystems<br />

(whether those subsystems are functional<br />

departments, production sites or individual<br />

processes in the manufacturing cycle) can<br />

result in a sub-optimised <strong>to</strong>tal system. Lack<br />

The increasingly<br />

international nature of<br />

markets and companies<br />

has resulted in many<br />

companies becoming<br />

part of large and complex<br />

global supply chains<br />

12 Link January 2011<br />

of efficiency and/or effectiveness is often<br />

a result of the poorly designed interfaces<br />

between subsystems rather than any<br />

inherent subsystem weaknesses. There<br />

are numerous examples of companies who<br />

have generated significant improvements<br />

in competitive advantage as a result of the<br />

application of this “<strong>to</strong>tal systems” thinking.<br />

A product is delivered <strong>to</strong> the ultimate<br />

cus<strong>to</strong>mer through a complex interaction<br />

of several companies on the way. The<br />

supplier’s ability <strong>to</strong> give the cus<strong>to</strong>mer<br />

what they want, when they want it, at<br />

the price and quality that they want, is<br />

not just determined by the efficiency<br />

and effectiveness of the supplier’s own<br />

operation. Inefficiencies anywhere in the<br />

supply chain will reduce the chances of the<br />

supplier competing successfully. Without a<br />

proper focus on “<strong>to</strong>tal” (i.e. integrated) SCM,<br />

therefore, a company will never achieve its<br />

true competitive potential. The increasingly<br />

international nature of markets and<br />

companies has resulted in many companies<br />

becoming part of large and complex global<br />

supply chains. In addition, the potential<br />

benefits associated with emerging ICT<br />

solutions provide the opportunity <strong>to</strong><br />

simultaneously improve cus<strong>to</strong>mer service<br />

levels and <strong>to</strong> reduce supply chain costs.<br />

These fac<strong>to</strong>rs have sharpened the focus on<br />

the need for improvements in all aspects of<br />

supply chain performance.<br />

Characteristics of SCM<br />

Excellence<br />

So what are the characteristics in evidence<br />

in companies that might be regarded<br />

as world class. “World Class” in this<br />

context means companies that have been<br />

successful in <strong>to</strong>ugh, competitive international<br />

Edward Sweeney<br />

markets over a sustained period of time. It<br />

is impossible <strong>to</strong> develop an exhaustive list<br />

of the characteristics of SCM excellence but<br />

the following four elements appear <strong>to</strong> be of<br />

critical importance for most companies in<br />

most sec<strong>to</strong>rs:<br />

uIdentification and measurement of<br />

cus<strong>to</strong>mer service because cus<strong>to</strong>mer service<br />

‘sets the spec’ for supply chain design<br />

uIntegration of supply chain activities and<br />

information because many supply chain<br />

NVAs are caused by fragmented supply<br />

chain configurations<br />

uSCM a senior management function<br />

because SCM is a strategic activity<br />

uEstablishment and measurement of<br />

supply chain key performance indica<strong>to</strong>rs<br />

(KPI’s) because what gets measured gets<br />

done!<br />

This is based on documented evidence<br />

of SCM “best practice” and allies with the<br />

author’s experience. These characteristics<br />

form the basis of a roadmap for effective<br />

supply chain re-engineering.<br />

Supply Chain Re-engineering<br />

Improving supply chain performance through<br />

re-engineering involves: analysis of internal<br />

and external parameters using relevant data<br />

which has been collected; the identification<br />

and evaluation of possible alternative

improvements and their detailed planning;<br />

and, the implementation of planned<br />

improvements including the associated<br />

change management. In short,<br />

Re-engineering = Analysis + Planning +<br />

Implementation<br />

It is important <strong>to</strong> bear in mind that, in<br />

supply chain re-engineering, no panacea<br />

or “magic solution” exists. Furthermore, as<br />

every company and every supply chain is<br />

unique in some respect it is inappropriate<br />

<strong>to</strong> attempt <strong>to</strong> copy or imitate companies<br />

regarded as being exponents of good<br />

practice. The uniqueness could be with<br />

respect <strong>to</strong> products or services supplied,<br />

processes, cus<strong>to</strong>mer expectations,<br />

people and cultural issues, systems or<br />

any one of a number of other fac<strong>to</strong>rs. The<br />

following section identifies some of the<br />

key elements of such an approach, based<br />

on the characteristics of supply chain reengineering<br />

discussed earlier.<br />

Elements of a Systematic<br />

Approach <strong>to</strong> Supply Chain<br />

Re-engineering<br />

Understanding Cus<strong>to</strong>mer Service. As pointed<br />

out earlier, cus<strong>to</strong>mer service ‘sets the spec’<br />

for supply chain design. In other words, as<br />

shown in Figure 1, a market driven cus<strong>to</strong>mer<br />

service strategy provides the performance<br />

specification for integrated SCM.<br />

In short, understanding cus<strong>to</strong>mer service<br />

requirements in targeted market segments<br />

forms the basis of any effective supply chain<br />

re-engineering and change process.<br />

Supply Chain Organisation. In many<br />

traditionally managed supply chains,<br />

individual supply chain functions (e.g.<br />

purchasing, production, transport<br />

and warehousing) are measured and<br />

management in isolation from each other.<br />

The net result is that the overall supply chain<br />

fails <strong>to</strong> achieve its true competitive potential<br />

as the constituent elements operate at cross<br />

purposes. A key SCM objective relates <strong>to</strong><br />

the replacement this traditional, often highly<br />

fragmented, supply chain organisation<br />

with structures which are characterised by<br />

higher levels of integration. This has serious<br />

implications for approaches used <strong>to</strong> more<br />

effectively structure organisations. For<br />

example, it is the author’s contention that<br />

future organisational structures are more<br />

likely <strong>to</strong> be described in terms of processes<br />

and networks (both internal and external)<br />

rather than functions and hierarchy.<br />

Technology – The Great Enabler? There<br />

can be little doubt that ICT has the potential<br />

<strong>to</strong> have a serious positive impact on supply<br />

chain performance. This is largely due <strong>to</strong><br />

its potential <strong>to</strong> facilitate higher levels of<br />

integration of supply chain activities and<br />

supply chain data. However, this potential has<br />

often been unfulfilled for a variety of reasons.<br />

These include a piecemeal approach <strong>to</strong> ICT<br />

planning and implementation, and tactical (as<br />

opposed <strong>to</strong> strategic) approaches <strong>to</strong> supply<br />

chain integration. These problems have<br />

often been exacerbated by legacy systems<br />

with multiple platforms and standards both<br />

internally and across the wider supply chain.<br />

Supply Chain KPIs in World Class<br />

Companies. In designing robust and<br />

integrated supply chain performance<br />

measurement systems it is important <strong>to</strong><br />

study and learn from organisations which<br />

are regarded as exemplars of best practice.<br />

Table 1 shows some of the features which<br />

tend <strong>to</strong> be incorporated in<strong>to</strong> the performance<br />

measurement systems of successful<br />

companies.<br />

Figure 1: Cus<strong>to</strong>mer service ‘sets the spec’ for integrated SCM<br />

Business<br />

TABLE 1: CHARACTERISTICS OF ROBUST<br />

PERFORMANCE MEASUREMENT SYSTEMS<br />

IRELAND SPECIAL<br />

The net result is that<br />

the overall supply chain<br />

fails <strong>to</strong> achieve its true<br />

competitive potential<br />

as the constituent<br />

elements operate at cross<br />

purposes<br />

The importance of performance<br />

measurement and KPIs in the re-engineering<br />

process can not be overstated. It provides<br />

companies with a rational basis for<br />

continuous improvement. It is important that<br />

an integrated system of KPIs is designed as<br />

part of the process and that the measures<br />

become an integral part of the supply chain.<br />

uMeasures should relate directly <strong>to</strong> company and business unit strategy<br />

uAn integrated approach should be adopted across the company and the supply chain<br />

uMeasures should change over time <strong>to</strong> reflect changing imperatives and priorities<br />

uMeasures should be as simple and easy <strong>to</strong> use as possible and should give fast<br />

feedback <strong>to</strong> staff<br />

uExcessive numbers of measures should be avoided (if you try <strong>to</strong> measure <strong>to</strong>o many<br />

things you may end up effectively measuring nothing!)<br />

uMeasures should aim <strong>to</strong> “teach” staff about their sphere of operation and as a basis for<br />

continuous improvement, rather than being purely for moni<strong>to</strong>ring and control purposes<br />

January 2011 Link<br />

13

IRELAND SPECIAL Business<br />

14 Link January 2011<br />

December 2010<br />

Dear Colleagues,<br />

I am delighted <strong>to</strong> have the opportunity <strong>to</strong><br />

greet my fellow <strong>SCLG</strong> Colleagues around<br />

the globe, the <strong>SCLG</strong> Management team<br />

in Dubai and most importantly our broad<br />

spectrum of members.<br />

In this special edition of Link, the<br />

focus will take on a very Irish aspect with<br />

contribu<strong>to</strong>rs from Ireland sharing their<br />

thoughts, viewpoints and experience on<br />

supply chain and logistics matters as<br />

they pertain <strong>to</strong> the market in Europe. The<br />

articles will provide an overview of the<br />

political, geographic social and economic<br />

demographics, which will influence the<br />

impacts on supply chain and logistics<br />

operations during 2011.<br />

Regular readers will be familiar with a<br />

number of our contribu<strong>to</strong>rs and we have<br />

added some new names and faces whom<br />

I trust will provide you with a broader<br />

range of views and opinions on SCM in<br />

Ireland.<br />

I would like <strong>to</strong> thank Patrick Francis<br />

and his team at Link for their help in<br />

producing this issue. Thank you <strong>to</strong> all our<br />

contribu<strong>to</strong>rs for their time and for sharing<br />

their expertise with us. A special note of<br />

thanks <strong>to</strong> our members for their continued<br />

support of <strong>SCLG</strong>.<br />

As an industry we are facing in<strong>to</strong><br />

some very challenging times where<br />

creativity and innovation will be the<br />

differential between merely surviving<br />

or achieving sustainable growth. Within<br />

the <strong>SCLG</strong> we have the thought leaders,<br />

practical implementers and energy<br />

drivers <strong>to</strong> keep us at the forefront of the<br />

new economy in the new year.<br />

With this mind may I wish you a very<br />

healthy and plenteous 2011.<br />

Kind regards,<br />

John Halpin<br />

President<br />

<strong>SCLG</strong> - Ireland<br />

Towards a Supply Chain<br />

Re-engineering Roadmap<br />

A comprehensive supply chain re-engineering<br />

roadmap must incorporate the four key<br />

issues discussed in the previous section. It<br />

starts with a market driven cus<strong>to</strong>mer service<br />

strategy which provides the performance<br />

specification for integrated SCM. In relation<br />

<strong>to</strong> supply chain organisation it requires a<br />

focus on processes and effectiveness, with<br />

a strong emphasis on network arrangements<br />

and shared services. ICT has the potential<br />

<strong>to</strong> facilitate integration between supply chain<br />

processes. However, for this potential <strong>to</strong><br />

be realised creative ICT strategies need<br />

<strong>to</strong> be developed and implemented. Again<br />

the focus needs <strong>to</strong> be on (value-adding)<br />

processes and on the people dimension.<br />

Finally, the integrated supply chain process<br />

KPIs provide organisations with a rational<br />

basis for continuous improvement. These<br />

measures feed back in<strong>to</strong> the development of<br />

the cus<strong>to</strong>mer service strategy thus closing<br />

the loop. This roadmap provides the basis for<br />

logical and systematic approaches <strong>to</strong> supply<br />

chain re-engineering. The Systems Approach<br />

is one such approach.<br />

Elements of The Systems<br />

Approach<br />

The systems approach <strong>to</strong> analysing supply<br />

chains and improving their performance<br />

recognises that the process of reengineering<br />

supply chains needs <strong>to</strong> be<br />

carried out in a logical and systematic<br />

manner. The approach has been developed<br />

based on the experiences of a range of<br />

companies in a range of different business<br />

sec<strong>to</strong>rs. There are at least four distinct<br />

constituent elements of this systems<br />

approach.<br />

The principles summarise the underlying<br />

thinking and concepts. If the supply<br />

chain under consideration is regarded as<br />

the system then the environment is the<br />

business environment in which that supply<br />

chain operates. The methodology is the<br />

series of steps <strong>to</strong> be followed in analysing<br />

and improving a typical supply chain. The<br />

methodology helps <strong>to</strong> identify the most<br />

suitable solution for a particular supply<br />

chain but there are approaches which<br />

appear <strong>to</strong> exist in the majority of worldclass<br />

companies. The guidelines on good<br />

practice summarise the main relevant<br />

elements of world class operating practice.<br />

Finally, the <strong>to</strong>ols and techniques support the<br />

implementation of the methodology.<br />

Concluding Comments<br />

Re-engineering is, first and foremost, about<br />

change. The development of a supply<br />

chain change management capability is of<br />

paramount importance if the re-engineering<br />

process is <strong>to</strong> result in real change and<br />

sustainable performance improvement. The<br />

reality in <strong>to</strong>day’s competitive world is that<br />

standing still effectively means falling behind.<br />

Innovation in all aspects of SCM is the key <strong>to</strong><br />

survival and success. It is also worth noting<br />

that in reality most innovation is a series<br />

of small incremental steps in line with the<br />

Japanese Kaizen principle. The approach<br />

<strong>to</strong> re-engineering outlined in this article<br />

focuses on the four key aspects of service<br />

delivery based on clearly unders<strong>to</strong>od market<br />

requirements, integration of supply chain<br />

activities and data, supply chain organisation<br />

and the measurement of performance.<br />

The systems approach (<strong>to</strong> analysing<br />

supply chains and improving their<br />

performance) provides a basis for achieving<br />

world class standards for supply chains<br />

operating in all types of industry. The<br />

approach involves considering the whole<br />

supply chain and avoiding a situation where<br />

subsystems are optimised but the whole<br />

supply chain is sub-optimal.

Public Procurement and<br />

Value for Money – The Road<br />

<strong>to</strong> Success<br />

Our success in achieving Value for Money (VFM) will<br />

only be fully achieved when we have the processes<br />

in place <strong>to</strong> consistently measure savings across<br />

multiple agencies on the cost elements of the<br />

procurement cycle.<br />

Government Buildings Dublin Ireland<br />

Public Procurement carries the<br />

bureaucracy of cumbersome<br />

regulations, directives and pro<strong>to</strong>cols.<br />

They are there <strong>to</strong> provide mechanisms <strong>to</strong><br />

protect the integrity of how public money<br />

is spent. Today with economic pressures<br />

<strong>to</strong> save money a € saved is a € that we do<br />

not have <strong>to</strong> borrow at expensive interest<br />

rates. This is an important point, for<br />

example in the private sec<strong>to</strong>r that same €<br />

saved goes straight <strong>to</strong> the bot<strong>to</strong>m line. It<br />

can be a measure of our failure or success.<br />

Our success in achieving Value for Money<br />

(VFM) will only be fully achieved when we<br />

have the processes in place <strong>to</strong> consistently<br />

measure savings across multiple agencies<br />

on the cost elements of the procurement<br />

cycle. It is therefore in our interests <strong>to</strong><br />

avoid expenditure whenever and wherever<br />

possible. This point alone raises some<br />

important questions, for example: Does<br />

how we spend Public Money achieve VFM?<br />

Is there anything different we can do <strong>to</strong><br />

improve VFM? Do we collaborate with other<br />

Departments sufficiently? Do we measure<br />

our VFM achievements <strong>to</strong> a standard and<br />

with challenging targets? The financial<br />

challenges facing us for the foreseeable<br />

future means we can no longer rely on the<br />

old ways of doing things. Every element<br />

where a cost arises in the Procurement<br />

Cycle must be challenged and managed<br />

Dr. Dermot Carey<br />

Economics<br />

IRELAND SPECIAL<br />

for VFM. The private sec<strong>to</strong>r has faced<br />

these challenges for the last few years and<br />

have implemented cost controls for their<br />

survival in many cases. There are many<br />

similarities between the private and public<br />

sec<strong>to</strong>r procurement and we should learn<br />

what best and successful practices can be<br />

adapted and adopted. It means for some<br />

a radical shift in thinking, approach and<br />

culture. We do not have the luxury <strong>to</strong> be<br />

complacent when €Billions are at stake.<br />

We must think commercially and embrace<br />

the experiences of the private sec<strong>to</strong>r and<br />

the advice from advocates of best practice<br />

Procurement & Supply Chain. I mention<br />

supply chain here because the public sec<strong>to</strong>r<br />

procurement cycle demands a robust and<br />

sustainable supply chain for our public<br />

services. How this supply chain is selected<br />

managed and measured determines the<br />

quality of service delivered but also VFM. In<br />

this context it makes common sense that we<br />

manage our supply chains as an integrated<br />

body. If we fail <strong>to</strong> address this fundamental<br />

approach we are exposing ourselves <strong>to</strong><br />

unnecessary costs and multiple fragmented<br />

activities with no value add. This is only<br />

the tip of the iceberg, if we continue <strong>to</strong> buy<br />

as separate entities we are sending mixed<br />

messages in<strong>to</strong> the market place. This not<br />

only compromises our buying power but<br />

adds unnecessary supply costs. If we are<br />

January 2011 Link 15

IRELAND SPECIAL Economics<br />

serious about Value for Money this cannot<br />

be allowed <strong>to</strong> continue. The integrated<br />

approach <strong>to</strong> procurement and supply chain<br />

has been advocated for over a decade now<br />

and many organisations are striving <strong>to</strong> adopt<br />

the concept. This time presents us not only<br />

with challenges but also with the opportunity<br />

<strong>to</strong> make those radical changes for effective<br />

procurement in<strong>to</strong> the future.<br />

We will explore some aspects of<br />

the integrated approach and how it can<br />

influence VFM. Organizations that effectively<br />

collaborate with their procurement and<br />

supply chain partners position themselves<br />

for success in 21st-century markets. When<br />

focused methods, and tried and tested<br />

techniques are adopted or transferred <strong>to</strong><br />

specifically address the objectives of the<br />

Procurement and Supply Chain arena, the<br />

results are always positive, by contributing<br />

substantial savings, efficiencies and<br />

benefits.<br />

When these methods and techniques<br />

are followed it means that you are working<br />

<strong>to</strong> a set of practices and principles that<br />

deliver benefits in a consistent manner.<br />

There is a growing awareness that<br />

Integrated Procurement and Supply Chain<br />

management provides the extra edge for<br />

greater efficiency and differentiate itself<br />

from the competition. One way <strong>to</strong> achieve<br />

this is for Procurement managers <strong>to</strong> look at<br />

their operation from a holistic perspective<br />

by adopting effective, proven methods<br />

<strong>to</strong> increase the chances of success.<br />

Conversely if you don’t manage your<br />

purchases and supply activities in a planned<br />

and structured way, and you continue <strong>to</strong><br />

do what you have always done, you will<br />

continue <strong>to</strong> get what you have always got.<br />

Even with decades of hands on<br />

experience in the procurement and supply<br />

chain arena, we at MRM-Global never cease<br />

<strong>to</strong> be amazed at the number of different<br />

ways roles have adapted. There is no single<br />

method of execution, and that can lead <strong>to</strong><br />

The importance of<br />

effective procurement<br />

and supply is summarised<br />

as “Provide continuity<br />

of supply of goods and<br />

services ’’<br />

16 Link January 2011<br />

difficulties when being held accountable<br />

for efficiency improvements and/or cost<br />

reductions against a common background of<br />

expectations.<br />

Without doubt effective procurement<br />

can provide a vital contribution through<br />

VFM and yet, <strong>to</strong>o often, no clear vision or<br />

integrated action plan <strong>to</strong>wards achieving this<br />

objective is present. Why is this? There<br />

appears <strong>to</strong> be no clear answer. Excuses are<br />

abundant as <strong>to</strong> why certain things cannot<br />

be done. The sheer volume and complexity<br />

of purchasing and supply activities for the<br />

majority of public organisations creates a<br />

scenario where there is usually little time and<br />

fragmented or no data/information available.<br />

This lack of consolidated data creates a<br />

problem because of the many variables<br />

associated with procurement and SCM. This<br />

often results in ‘fire-fighting’ becoming the<br />

order of the day. Planned areas of activity<br />

are often focused only on a part of the<br />

whole, for example inven<strong>to</strong>ry turns, leaving<br />

other areas of opportunity untapped and<br />

inadequately managed.<br />

The importance of effective procurement<br />

and supply might be summarised as follows:<br />

‘’Provide continuity of supply of goods<br />

and services at lowest cost and minimum<br />

contractual risk’’. From a performance<br />

perspective, in private sec<strong>to</strong>r procurement, a<br />

1% saving is equivalent, from a profitability<br />

perspective, <strong>to</strong> a minimum of a 10% increase<br />

in sales. A similar analogy needs <strong>to</strong> be<br />

developed for VFM in the public sec<strong>to</strong>r. This<br />

puts procurement in<strong>to</strong> a position of being<br />

an important contribu<strong>to</strong>r and a strategic<br />

necessity and not an order department. If<br />

we take one element of supply costs for<br />

example, inven<strong>to</strong>ry, a primary focus will be <strong>to</strong><br />

achieve optimum s<strong>to</strong>ck turn rates. Not only<br />

will this support providing high service levels<br />

when properly managed, but also frees up<br />

valuable working capital. With coordinated<br />

actions good inven<strong>to</strong>ry management will<br />

influence how well warehousing operates<br />

and, in turn, logistics.<br />

By integrating these efforts on a cross<br />

functional level VFM will be optimised<br />

through integrated procurement. So how<br />

do you achieve Integrated Procurement<br />

and Supply Chain Management (IPSCM)?<br />

We at MRM-Global believe the answer lies<br />

in the design of the process itself. Some<br />

processes work better than others and the<br />

better ones tend <strong>to</strong> have a more holistic<br />

approach. The processes that are not as<br />

The Four Courts Dublin<br />

good are more fragmented in their design.<br />

From our research we have found that the<br />

integrated approach delivers better results.<br />

This is evidenced by results from a number<br />

of organisations, providing substantial<br />

improvements in efficiencies and cost<br />

reductions. The process supporting IPSCM,<br />

when it incorporates project and portfolio<br />

based models, improves performances<br />

even further. Project and portfolio elements<br />

have been proven <strong>to</strong> provide substantial<br />

benefits. Unless the process reflects<br />

and complements cross functional interrelationships<br />

from demand planning <strong>to</strong><br />

fulfilment, and the associated operating<br />

procedures, the danger of a fragmented<br />

process remains. We have studied these<br />

areas and have integrated our findings in<strong>to</strong><br />

the creation of a new process model. We<br />

have developed a process that supports end<br />

<strong>to</strong> end procurement and supply.<br />

Whilst most practitioners will readily<br />

acknowledge the logic <strong>to</strong> the process, <strong>to</strong>o<br />

often they are constrained in implementing<br />

such a model due <strong>to</strong> work pressures. This<br />

is one of the main reasons that integration

1<br />

percent saving is equivalent,<br />

from a profitability perspective,<br />

<strong>to</strong> a minimum of a 10%<br />

increase in sales<br />

is either not fully functional and/or not widely<br />

practiced. It is logical, therefore, <strong>to</strong> state that<br />

there are areas of lost opportunity or VFM<br />

not being optimized by not capitalising on the<br />

potential benefits derived from the integrated<br />

approach. The question we must ask is, can<br />

we continue <strong>to</strong> allow this <strong>to</strong> continue? Key<br />

drivers and motiva<strong>to</strong>rs at MRM-Global are<br />

<strong>to</strong> create and provide solutions that both<br />

support the concept for sustainability and<br />

offer consistency in their application. To this<br />

end we have developed the MRM-Global<br />

Value Delivery Methodology. This process<br />

in itself is the culmination of many years of<br />

effort and commitment and represents a<br />

significant contribution <strong>to</strong> the profession.<br />

However, used in isolation, it still leaves<br />

the responsibility <strong>to</strong> leaders and practitioners<br />

<strong>to</strong> interpret and undertake an implementation<br />

program. It is at this point that things tend<br />

<strong>to</strong> go awry. It is not the lack of ability or<br />

commitment from people <strong>to</strong> implement the<br />

integrated processes and culture, it typically<br />

comes down <strong>to</strong> the lack of time and support<br />

<strong>to</strong>ols <strong>to</strong> enable the transformation. To assist<br />

in the achievement and enjoy the rewards<br />

of world-class practices, we have developed<br />

a product <strong>to</strong> support the procurement and<br />

supply process. This product is called<br />

PRESIS. It is compatible with existing legacy<br />

as well as modern ERP systems and is<br />

complementary <strong>to</strong> planning, purchasing,<br />

inven<strong>to</strong>ry, warehousing and distribution<br />

packages. We designed the product <strong>to</strong><br />

bridge the gap in existing processes <strong>to</strong> act<br />

as a practical aid for practitioners <strong>to</strong> succeed<br />

in the implementation of the integrated<br />

concept.<br />

Furthermore, it provides the necessary<br />

<strong>to</strong>ols and scenario based intelligence for<br />

visibility across multiple agencies in the<br />

procurement and supply functions. This<br />

in turn provides a reliable method for<br />

consistency in process, decision-making<br />

ability, cost competitiveness and resilience<br />

Economics<br />

IRELAND SPECIAL<br />

<strong>to</strong> cope with the challenges of the economy<br />

and market changes. Legacy or bespoke<br />

corporate systems tend not <strong>to</strong> have data<br />

in a format that matches procurement and<br />

supply decision-making needs. The data<br />

is frequently of a transactional nature with<br />

a financial reporting emphasis. PRESIS is<br />

designed <strong>to</strong> provide the decision makers<br />

across procurement with scenario-based<br />

intelligence. This eliminates the need for<br />

tedious analysis and more importantly allows<br />

for cross-functional planning, accountability,<br />

consolidation, collaboration and standard<br />

measures for performance. This design<br />

differentiates itself from other applications in<br />

the market.<br />

There is no one prescriptive method as<br />

<strong>to</strong> how procurement is best managed and<br />

many of the recommendations regarding<br />

procurement will be applicable <strong>to</strong> any SCM<br />

portfolio and will apply <strong>to</strong> both private and<br />

public sec<strong>to</strong>r organisations. Any differences<br />

in methods will be specific <strong>to</strong> the nature of<br />

the organisation, however, the procurement<br />

and supply cycle will have a common<br />

approach. MRM Global’s recommended<br />

methods follow a structured approach <strong>to</strong><br />

procurement in an integrated and project<br />

based manner.<br />

This approach requires that data is<br />

converted in<strong>to</strong> information at key points in<br />

the decision making process throughout<br />

the procurement and supply cycle. For<br />

those organisations that have a fragmented<br />

approach it will require time and resources<br />

dedicated <strong>to</strong> capturing and converting data.<br />

The upside is that, once completed, it is<br />

easy <strong>to</strong> maintain and more importantly, you<br />

can now develop procurement and supply<br />

plans in a consistent manner.<br />

Current literature, recommends the<br />

integrated approach, typically without giving<br />

a proven method as <strong>to</strong> how <strong>to</strong> achieve<br />

that approach. Our experience shows the<br />

integrated concept demands a structured<br />

approach supported by detailed information<br />

in a procurement and supply format. Our<br />

offering and approach is one that has been<br />

developed from decades of experience<br />

and has proven successful for many<br />

organisations. MRM Global offers tried and<br />

tested methods, supported by unsurpassed<br />

procurement and supply industry knowledge<br />

underpinned with confidence in the<br />

knowledge that ‘’it works’’.<br />

Dr. Dermot Carey at www.mrm-global.com.<br />

January 2011 Link 17

IRELAND SPECIAL Trade<br />

Evolution of the Irish Supply<br />

Chain – Irelands Engagement?<br />

Notwithstanding the excellent lineage of industry trade<br />

and support bodies, albeit superintended by-in-large,<br />

with Supply Chain practitioners from the state and<br />

semi state companies.<br />

Ireland is often described as a small<br />

highly fragmented trading nation.<br />

Notwithstanding the excellent lineage<br />

of industry trade and support bodies, albeit<br />

superintended by-in-large, with Supply Chain<br />

practitioners from the state and semi state<br />

Companies. The Irish Supply Chain market in<br />

the main, remains locked in a uncoordinated<br />

sec<strong>to</strong>r of suppliers competing for diminishing<br />

volume; in loads, consignments, shipments,<br />

cargo, warehousing, cus<strong>to</strong>ms clearance<br />

etc. The exception <strong>to</strong> this is the MNC’s<br />

specifically, the manufactures who excel<br />

under their own six sigma programmes. The<br />

government over the past 10-15 years has<br />

18 Link January 2011<br />

not helped its own significant trade sec<strong>to</strong>r and<br />

by default itself, with an absence of a National<br />

Supply Chain Policy. Ireland is an island and<br />

wholly dependent on its import and exports.<br />

Ironically Irish Exports are currently equal<br />

<strong>to</strong> or better than the Euro average, which<br />

highlights two key points: (1) Ireland’s private<br />

sec<strong>to</strong>r manufacturing and exporting services,<br />

even against the current economic back drop<br />

is doing very well (2) the need <strong>to</strong> understand<br />

how an Integrated Supply Chain can act as<br />

a catalyst for effectiveness and efficiency at<br />

a time when it is most needed for the public<br />

purse.<br />

Fig 1. 1975 – 2010 Key Supply Chain Logistics Evolution - Note: Time line is best estimate only<br />

Nigel Devenish<br />

Continuity & Change has witnessed continued improved SCM value-added solutions

Fig 2<br />

The predominant command-andcontrol<br />

structure of regula<strong>to</strong>ry policy can<br />

be, is and continues <strong>to</strong> be, restrictive and<br />

inefficient in developing a strong Irish Supply<br />

Chain position. Integrated Supply Chain<br />

management solutions, for example through<br />

the collaboration between government<br />

agencies and regulated entities has not been<br />

pursued, with continued reluctance <strong>to</strong> accept<br />

and acknowledge private sec<strong>to</strong>r solution<br />

design models, these programs have not<br />

gained widespread public body acceptance.<br />

The cognitive and institutional barriers <strong>to</strong><br />

this acceptance continue <strong>to</strong> burden the Irish<br />

taxpayer. These barriers act out of force of<br />

habit, creating a resistance <strong>to</strong> change and a<br />

rejection of new forms of working for example,<br />

‘smarter not harder’. The policy change<br />

requires a shift in how individuals think and<br />

how institutions guide that thinking. Apply this<br />

<strong>to</strong> the Irish Health System, and through an<br />

integrated supply chain the savings <strong>to</strong> the tax<br />

payer would be measured in multi millions<br />

whilst simultaneously improving service<br />

levels.<br />

But how far advanced are the Irish Logistic<br />

and Supply Chain operations /opera<strong>to</strong>rs<br />

compared <strong>to</strong> their European / Global Rivals?<br />

(Where are Ireland’s core areas of activities in<br />

the SCM Execution of <strong>to</strong>day?)<br />

Transport<br />

With weighted preponderance <strong>to</strong> owner<br />

drivers, in-cab technology is not universal;<br />

the high capital cost for implementation<br />

and poor ROI put’s off many. This is further<br />

exacerbated when small hauliers only<br />

have the security of one main contract and<br />

aggravated further by limited commercial<br />

supply chain experience by those opera<strong>to</strong>rs.<br />

The ability <strong>to</strong> coordinate loads and volume<br />

<strong>to</strong> ease the empty running through<br />

collaboration / partnership is not in evidence.<br />

This is exacerbated by the refusal <strong>to</strong> adopt<br />

post codes throughout ROI. Over 200 Million<br />

people throughout Europe have them, but<br />

the authorities in ROI have consistently<br />

blocked and or delayed entry of post codes.<br />

There is evidence this may occur in 2011 but<br />

30 plus years after the rest of Europe! The<br />

absence of this simple universal accepted<br />

practise, further illustrate how the Irish<br />

Government even the Green Party has failed<br />

<strong>to</strong> grasp the environmental and commercial<br />

benefits by having post codes and the direct<br />

benefit this has for the whole supply chain<br />

management and by default, Irish SME’s<br />

cost effective operations.<br />

3PL & 4PL Opera<strong>to</strong>rs<br />

The key 3PL / 4PL Opera<strong>to</strong>rs further combat<br />

the perennial ‘one way traffic’ with their<br />

clients where investment is held back with<br />

‘open book’ contracts. Managing the weekly<br />

angst of manufactured fac<strong>to</strong>ry approach <strong>to</strong><br />

RFQ’s is giving way <strong>to</strong> the extraordinary high<br />

contract churn rate with ever decreasing<br />

margins, we are seeing logistics being taken<br />

back in house. In part, in Ireland (excluding<br />

the MNC’s in the main) why is it so many<br />

Irish based SME enterprises have their<br />

Supply Chain Cost as a percentage of their<br />

overall operating cost, well in <strong>to</strong> double digits<br />

when it should be between 8-10%? Ireland<br />

in Supply Chain terms within the 3PL /4PL<br />

organisations have become no more than a<br />

Trade<br />

IRELAND SPECIAL<br />

cheap labour market. It has been a race <strong>to</strong><br />

the bot<strong>to</strong>m, as this critical business is seen<br />

increasingly as a commodity! Interestingly<br />

by in large and one can argue specifically<br />

within Ireland; so many SME’s still do not<br />

see Supply Chain Management as an<br />

Executive function, thus we see it as a<br />

function for Financial Direc<strong>to</strong>rs and not by<br />

Supply Chain Direc<strong>to</strong>rs. Surprising when you<br />

look at the overall cost of the Supply Chain<br />

<strong>to</strong> their own businesses (see above)? One<br />

criterion remains fundamental; the market<br />

has not changed: as the following illustration<br />

demonstrates, the commercial Needs and<br />

Wants of all cus<strong>to</strong>mers and end users is<br />

universal they all want:<br />

Conclusion<br />

As Fig 1 shows the market is moving<br />

<strong>to</strong>wards greater complexity. It can be argued<br />

SCM Consultants including 3 & 4 PL’s have<br />

focused on the ‘Supply’ side without much<br />

consideration for the Demand side. The time<br />

– line in Fig 1 does reflect the acceleration<br />

of change and adoption of new methodology<br />

within the industry. As part of this change<br />

the industry can expect a move <strong>to</strong>wards<br />

the true value proposition being developed<br />

under ‘knowledge Capital’ <strong>to</strong> generate the<br />

optimum solution – Demand & Supply. Why?<br />

Because the current manufactured RFQ’s,<br />

commoditisation and contract churn within<br />

the industry is unsustainable. Future solution<br />

design will come from credible knowledge<br />

Capital solution design engineers. In effect<br />

they will look <strong>to</strong> integrate the supply chain.<br />

This will require getting on board early<br />

on with cus<strong>to</strong>mers in the sales cycle and<br />

or building the bridges in confidence with<br />

cus<strong>to</strong>mers <strong>to</strong> design the optimum solution.<br />

This will not involve high capital cost<br />

programmes, future solution design will be<br />

underpinned by Saas on a pay as go basis.<br />

This will integrate even the smallest of<br />

opera<strong>to</strong>rs <strong>to</strong> provide the last mile optimum<br />

solution......<br />

The benefits of <strong>SCLG</strong> are <strong>to</strong> offer<br />

practical industry advice, solutions,<br />

guidance, and training <strong>to</strong> support<br />

practitioners throughout the Middle East,<br />

Ireland, and in due course the UK. I look<br />

forward <strong>to</strong> working with the Irish members<br />

in 2011.<br />

Nigel Devenish BSc,Executive Direc<strong>to</strong>r Jarlis Ltd,<br />

http://ie.linkedin.com/in/nigeldevenish<br />

January 2011 Link 19

IRELAND SPECIAL Information Technology<br />

The Utilization of Information<br />

Technology for Supply Chain<br />

Management in Ireland<br />

The traditional concern of supply chain management<br />

has been the movement of materials from original<br />

source <strong>to</strong> the point of final consumption.<br />

The traditional concern of supply chain<br />

management has been the movement<br />

of materials from original source <strong>to</strong><br />

the point of final consumption. In addition <strong>to</strong><br />

the downstream flow of materials, modern<br />

supply chain management is also concerned<br />

with other flows such as the upstream flow<br />