catalog 98-1210 - Automatic Distillation - ADU4

catalog 98-1210 - Automatic Distillation - ADU4

catalog 98-1210 - Automatic Distillation - ADU4

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

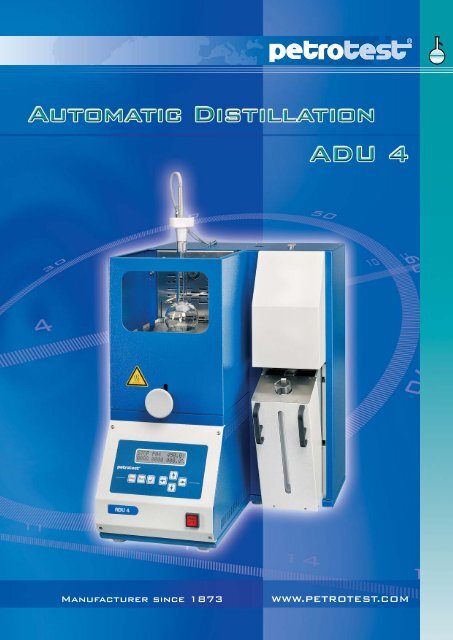

Manufacturer since 1873<br />

WWW.PETROTEST.COM

2<br />

front view<br />

Dry-Point set-up<br />

receiver tempering chamber<br />

control panel<br />

� Cover: 11-1542<br />

<strong>Distillation</strong> at Atmospheric Pressure<br />

<strong>Automatic</strong> <strong>Distillation</strong> Unit - ADU 4<br />

ASTM D 86 - IP 123 - ISO 3405 (DIN 51 751 - NF M 07-002) - JIS K2254<br />

Solvents: ASTM D 850 - ASTM D 1078 - IP 195<br />

For the examination of motor<br />

gasolines, aviation gasolines,<br />

aviation turbine fuels, special<br />

boiling point spirits, naphthas,<br />

white spirits, kerosines, gas oils,<br />

distillate fuel oils, solvents and<br />

similar petroleum products.<br />

- low price - high value<br />

- software included<br />

- ultra-high heating<br />

power<br />

- safety-heater-rods<br />

reduce burn-risk<br />

Advantages<br />

The price is lower than the price of the<br />

competitors.<br />

The ADU 4-System is a modular system.<br />

The PC and the tempering unit are not built-in<br />

to reduce the probability of a malfunction of the<br />

complete system.<br />

This makes repairs easier to handle and to<br />

bridge since the user may connect another<br />

matching PC or cooler.<br />

Unique: Volume-Detection totally without<br />

mechanically moving parts.<br />

The probability of a malfunction is reduced to a<br />

minimum.<br />

Built-in fi re-extinguisher<br />

11-0542<br />

The highest achievable temperature is defi nitely<br />

above the requested standard-range. A high<br />

fi nal boiling point of 425 °C (stem corrected)<br />

can be reached in the samples.<br />

A 125 ml Quartz-fl ask should be used for such<br />

applications.<br />

Basic software ADUcon and the software<br />

upgrade ADUpro are included in each ADU 4.<br />

Small bench space:<br />

400 x 550 x 450 mm only.<br />

Low weight: 20 kg only<br />

Minimum confi guration:<br />

ADU 4, Thermostat and Printer

Details<br />

The idea for this apparatus is to<br />

create a modular system, which<br />

can be up-graded on demand with<br />

a Tempering Unit, PC or Printer.<br />

Its characteristics are:<br />

- Volume detection by solid<br />

light barrier system<br />

- Fire-Extinguisher<br />

(Attention: requires connection<br />

to 6-12 bar pre-pressured<br />

external CO2 or N2.)<br />

- Demands only an external<br />

cooling system of small<br />

capacity<br />

- Small, swing-out receiver<br />

tempering chamber!<br />

- General supply of PCsoftware<br />

ADUpro for<br />

graphic evaluation<br />

- LIMS connection is possible<br />

ADU - Software<br />

Extensions recommended:<br />

- Computer (MS Windows®<br />

compatible) for the ADU is<br />

highly recommended.<br />

Programs will be automatically<br />

stored, temperature/volume<br />

spread sheets and graphics<br />

are available.<br />

- Printer (incl. data-cable) for<br />

a numerical printout of results<br />

(if no PC is used).<br />

The temperatures of 5 vol%<br />

and the important values will<br />

be printed without graphics<br />

- <strong>Automatic</strong> Dry Point Detection<br />

requires sensor according to<br />

fl a s k s i ze<br />

- Spare Part Set<br />

for approx. 12 months operation<br />

ADUcon Basic-Software to allow a computer-supported operation.<br />

Accessories required:<br />

- Glassware for others than<br />

ASTM D 86 (Group 1-4)<br />

- Dry-Point Sensor<br />

- External Tempering System<br />

to assure an ADU working range<br />

of 0 to +80 °C:<br />

- automatic & ADU controlled:<br />

distillation group 0-4 & 1-4<br />

and solvents<br />

- manual, low cost version:<br />

distillation group 1-4 and<br />

solvents<br />

In connection with a controlled<br />

tempering system, the ADU 4 is<br />

able to change the group from<br />

0 to 4 during the process.<br />

NOTE: A customer owned<br />

tempering system could be<br />

used, if it is able to provide a<br />

0°C-cooling capacity of:<br />

...approx. 200 W for group 0,<br />

...approx. 70 W for group 1-4<br />

For automatic data transfer a<br />

serial RS232-interface with<br />

HAAKE confi guration is required.<br />

ADUpro-Screen: Temperature Graph<br />

ADUpro PC-Software as an extension module for ADUcon with additional functions:<br />

Heat-Parameter Optimizer: If necessary, this software recommends more adequate heat-parameters for<br />

the next test run, automatically.<br />

Pre-selected Temperature-Spread-Sheet: In addition to the Volume-Spread-Sheet it allows to select<br />

nearly all required temperature-values (corrected temperature like barometric pressure corrected and<br />

evaporated values) and the corresponding volume recovered.<br />

Supports the distillation of solvents acc. ASTM D 850 & D 1078 with a preset parameter library for<br />

different solvents.<br />

Connection and simultaneous run of up to six ADU-units with one PC<br />

(If the PC does not have that many RS232-ports, we recommend the use of a USB-Hub.)<br />

Note: Each ADU-unit requires a separate ADUpro-Software installation.<br />

ADUpro-Screen: <strong>Distillation</strong> Rate<br />

ADUpro-Screen: Fix Point Report<br />

ADUpro-Screen: Sample Info<br />

3

4<br />

with Fire-Extinguisher<br />

with Fire-Extinguisher<br />

& Dry-Point<br />

Connection Set<br />

Main Unit<br />

11-0542<br />

11-0543<br />

11-1542<br />

11-1543<br />

ADU 4 - <strong>Automatic</strong> <strong>Distillation</strong> Unit<br />

Petroleum Products : ASTM D 86 - ISO 3405 - IP 123 - JIS K2254<br />

(Solvents : ASTM D 850 - ASTM D 1078 - IP 195 with additional equipment)<br />

Consisting of:<br />

Heating cabinet with built-in fi re-extinguisher, microprocessor controlled electric heater<br />

(1200 W), temperature probe and jack for height adjustment of fl ask.<br />

Condenser tube with water jacket for tempering by external thermostatic circulator.<br />

Recovery cabinet with light barrier detection.<br />

High-grade stainless steel housing with two-color powder coating, digital display, keys,<br />

and RS232 interface.<br />

Dimensions (WxHxD): 400 x 550 x 450 mm, weight: approx. 20 kg<br />

Supplied with:<br />

1 ADUcon-software to allow a computer-supported operation.<br />

1 ADUpro-software as PC extension module with additional functions:<br />

- Heat-Parameter Optimizer (If necessary, this software recommends more adequate heatparameters<br />

for the next test run automatically.<br />

- Pre-selected Temperature-Spread-Sheet: In addition to the Volume-Spread-Sheet it allows<br />

to select nearly all required temperature-alues (corrected temp.) and the corresponding<br />

volume recovered.)<br />

- Support of solvent distillation acc. ASTM D 850 & D 1078<br />

(with a preset parameter library for different solvents)<br />

- Connection and simultaneous run of up to 6 ADU-units with 1 PC<br />

(if the PC does not have that many RS232-ports, we recommend the use of a USB-Hub)<br />

Note: Each ADU-unit requires a separate ADUpro-Software installation.<br />

1 glassware according ASTM D 86 (Group 1-4)<br />

(1 fl ask 125 ml, 2 glass-ceramic plates with hole 1x Ø 38 mm & 1x Ø 50 mm)<br />

1 PTFE-stopper 19/26 to hold the temperature probe<br />

1 stopper to connect fl ask & condenser tube<br />

1 graduated cylinder 100 ml with metal base<br />

1 drip tongue<br />

1 cleaning coil for the condenser tube<br />

1 test sample (300 ml bottle)<br />

1 insulating hose set for cooler connection<br />

1 connection set (data cable for cooler, 0-modem cable, RS232-adapter, USB-converter)<br />

To be ordered separately:<br />

- Cooler (boiling group related)<br />

- Glassware according ASTM D 86 (Group 0)<br />

- Glassware according ASTM D 850 - ASTM D 1078 - IP 195 (Solvents)<br />

- Dry-Point Sensor (depending on the fl ask size)<br />

- Data Evaluation (computer-set or serial printer!)<br />

Available with the following extensions:<br />

ADU 4 - with built-in Fire-Extinguisher<br />

(requires external CO 2 or N 2 supply with a pre-pressure between 6 and 12 bar).<br />

Power supply: 230 V, 50 Hz<br />

Power supply: 115 V, 60 Hz<br />

ADU 4 - with built-in Fire-Extinguisher & Dry-Point Detection<br />

(requires external CO 2 or N 2 supply with a pre-pressure between 6 and 12 bar,<br />

dry-point sensor to be ordered separately acc. fl ask size).<br />

Power supply: 230 V, 50 Hz<br />

Power supply: 115 V, 60 Hz

Calibration Equipment<br />

11-0571 Volume-Detection Calibration Set, comprising:<br />

Burette (50:0.1 ml) and Burette Holder Set<br />

11-0582 Temperature Calibration Set, comprising:<br />

Calibration-Resistor-Set and Thermometer IP 39C (offi cially certifi ed)<br />

Reference Liquid for <strong>Distillation</strong><br />

11-0590 .. of Mineral Oil Products (Boiling Characteristics) ASTM D 86 - ISO 3405<br />

Initial Boiling Point: approx. 160°C / Final Boiling Point: approx. 360°C, 255 ml<br />

11-0591 .. of Gasoline (Unleaded) ASTM D 86<br />

Certifi ed Value: approx. 34 °C - 180 °C, 250 ml<br />

11-0593 .. of Diesel ASTM D 86<br />

Certifi ed Value: approx 165 °C - 362 °C, 250 ml<br />

Glassware<br />

11-0546 Glassware Set (Group 0-4)<br />

ASTM D 86 - ISO 3405 - IP 123 - JIS K2254<br />

comprising:<br />

1 fl ask 100 ml, neck 19/26 (group 0)<br />

1 glass-ceramic plate with hole Ø 32 mm (group 0)<br />

1 fl ask 125 ml, neck 19/26 (group 1-4)<br />

1 glass-ceramic plate with hole Ø 38 mm (group 1-4)<br />

1 glass-ceramic plate with hole Ø 50 mm (group 1-4)<br />

11-0524 <strong>Distillation</strong> flask, 125 ml, quartz glass, ground socket (NS 19/26)<br />

with thermometer immersion-mark, side pipe Ø 7 mm (for temperatures above 370 °C)<br />

11-0547 Glassware Set (Solvents)<br />

ASTM D 850 - ASTM D 1078 - IP 195<br />

comprising:<br />

1 fl ask 200 ml, neck 19/26<br />

1 glass-ceramic plate with hole Ø 25 mm<br />

1 glass-ceramic plate with hole Ø 32 mm<br />

1 glass-ceramic plate with hole Ø 38 mm<br />

1 glass-ceramic plate with hole Ø 50 mm<br />

11-0596 Measuring Cylinder "HR", 100 ml, borosilicate glass, graduated<br />

(complete tube, metal base with KALREZ O-ring high resistant against solvents<br />

like Acetone, 1-Butanol, Ethylacetat etc.)<br />

11-0575 Anti-Dazzle Screen (for dazzling-free dry-point observations)<br />

Dry-Point<br />

11-0587 Dry-Point Sensor, fits 200 ml flask<br />

11-0588 Dry-Point Sensor, fits 100/125 ml flask<br />

Tempering Devices<br />

(for an ADU-working range of 0 to +80 °C)<br />

suitable for boiling group 0 - 4 and solvents<br />

25-0393<br />

25-0394<br />

Circulator, operating span -28 to +150 °C<br />

with RS232-interface (automatically regulated by ADU-Unit)<br />

Power supply: 230 V, 50/60 Hz<br />

Power supply: 115 V, 60 Hz<br />

suitable for boiling group 1 - 4 and solvents (only if boiling point >50°C)<br />

25-0397<br />

25-03<strong>98</strong><br />

25-0395<br />

25-0396<br />

Circulator, operating span -10 to +100 °C<br />

with RS232-interface (automatically regulated by ADU-Unit)<br />

Power supply: 230 V, 50/60 Hz<br />

Power supply: 115 V, 60 Hz<br />

Circulator, operating span -10 to +100 °C<br />

manually regulated<br />

Power supply: 230 V, 50/60 Hz<br />

Power supply: 115 V, 60 Hz<br />

Volume-Detection Calibration<br />

Set<br />

Anti-Dazzle Screen<br />

Dry-Point Sensor<br />

inside the Flask<br />

Thermostatic Circulator<br />

5

6<br />

Software Set<br />

11-0567<br />

11-0554 & 11-0596<br />

11-0556 & 11-0595<br />

11-0572<br />

Boiling<br />

11-0545 Boiling Stones against the boiling retardation (pack of 20 g)<br />

Note! Do not use with dry-point detection.<br />

Condenser<br />

11-0597 O-Ring Set for condenser tube stopper and fl ask-neck (Chemraz)<br />

Data Evaluation<br />

25-0282<br />

25-0283<br />

25-0803<br />

11-05<strong>98</strong><br />

11-0594<br />

Serial Impact Printer for single sheet & continuous paper (instead of a PC)<br />

Supplied with: 1 data transmission cable, 1 ink ribbon (black)<br />

Technical Data:<br />

Ports : serial, USB (1.1) & parallel<br />

Dimensions : 37 x 28 x 16 cm (WxDxH), weight 5 kg<br />

Power supply : 220/240 V, 50/60 Hz<br />

Power supply : 100/130 V, 50/60 Hz<br />

PC with Monitor and Graphic-Printer<br />

to connect up to 6 ADU-Units<br />

(detailed specifi cations upon request)<br />

Power supply: 230 V, 50 Hz<br />

USB Hub 4-port 2.0<br />

If a PC does not have enough ports to connect up to 4 ADU´s,<br />

we surgest to order a 4-port USB-hub (verifi ed for petrotest® instruments)<br />

Power supply with EU-plug<br />

Power supply and US-plug-adapter<br />

Spares for Measuring Cylinder<br />

11-0567 Drip Tongue<br />

11-0554 Cylinder, 100 ml, borosilicate glass, graduated<br />

(complete with tube, metal base and O-rings)<br />

11-0596 Cylinder "HR", 100 ml, borosilicate glass, graduated<br />

(complete with tube, metal base and O-rings)<br />

11-0555 Cylinder Tube, made of borosilicate glass<br />

11-0556 Cylinder Metal Base with 3 O-rings (fi ts 11-0555)<br />

11-0595 Cylinder Metal Base "HR" with 3 O-rings (top one high resistant) (fi ts 11-0555)<br />

11-0557 O-Rings fi t metal base 11-0556 inside, pack of 10<br />

11-0573 O-Rings fi t metal base 11-0556 outside, pack of 10<br />

Tool for Measuring Cylinder<br />

11-0572 Dismantling Device for measuring cylinder base

Spares for Calibration<br />

11-0564 Burette, 50:0.1 ml, to calibrate volume detector<br />

11-0565 Burette-Holder<br />

23-0010 O-Rings, Viton, 34 x 3 mm, pack of 10 (as spare part for Burette-Holder)<br />

26-0037 Thermometer IP39C (officially certified)<br />

Spares for Heating<br />

11-0135<br />

11-0136<br />

11-0137<br />

11-0138<br />

Heater Support Board, 150 x 150 x 4 mm, glass ceramics,<br />

Ø 25 mm, center hole (1‘‘) (ASTM D 850)<br />

Ø 32 mm, center hole (1¼‘‘) (Group 0 & ASTM D 1078, IP 195)<br />

Ø 38 mm, center hole (1½‘‘) (Group 1-2 & ASTM D 850 + D 1078, IP 195)<br />

Ø 50 mm, center hole (2‘‘) (Group 3-4 & ASTM D 850)<br />

11-0561 Electric Heater Assembly, 1200 W (incl. 1 rod with & w/o sensor each)<br />

11-0039 Heating Rod without temperature sensor, 600 W, 115/230 V<br />

11-0579 Heating Rod with integrated temperature sensor, 600 W, 115/230 V<br />

11-0578 Heating-Temperature Sensor (NiCr-Ni))<br />

11-0559 Pt-100 Sample-Temperature Probe<br />

11-0521 Stopper, PTFE, for the temperature probe, complete with 2 O-rings<br />

25-0225 Hose-Set, insulated (Ø 10 mm, 2x 2 m, incl. fi ttings)<br />

Spares for Glassware<br />

11-0574 Spare Parts Set ASTM D 86 (Group 1-4)<br />

for approx. 1 year:<br />

10x 11-0515 (125 ml fl ask),<br />

2x 11-0554 (100 ml cylinder),<br />

1x 11-0558 (5 stoppers),<br />

1x 11-0559 (temperature probe),<br />

1x 11-0567 (drip tongue)<br />

11-0514<br />

11-0515<br />

11-0524<br />

11-0517<br />

<strong>Distillation</strong> Flask, ground socket (NS 19/26)<br />

with thermometer immersion-mark, side pipe Ø 7 mm<br />

100 ml, ASTM E133/A, Engler-shape (Group 0)<br />

125 ml, ASTM E133/B, Engler-shape (Group 1-4)<br />

125 ml, made of quartz glass (for temperatures above 370°C) (Group 1-4)<br />

200 ml, ASTM E133/C, Barret-shape (Solvents)<br />

Spares for Condenser<br />

11-0549 Cleaning Coil for condenser tube<br />

11-0558 Stopper for the condenser tube, pack of 5<br />

11-0584 O-Ring Set for condenser tube stopper (1 outer- & 2 inner- O-rings)<br />

(recommended for ASTM D 850 + D 1078)<br />

11-0135 - 11-0138<br />

11-0559<br />

11-0521<br />

11-0514 - 11-0524<br />

11-0549<br />

11-0558<br />

7

Manufacturer of<br />

Petroleum Test Equipment<br />

since 1873<br />

Development<br />

Quality Control<br />

Presented by:<br />

Petrotest Building<br />

ISO 9001<br />

certifi ed<br />

processes...<br />

...all under<br />

one roof!<br />

training<br />

Ludwig-Erhard-Ring 13 · 15827 Dahlewitz - Germany · Tel.: +49 (0) 33708 / 56-300 · Fax: +49 (0) 33708 / 56-556<br />

e-mail: info@petrotest.com · website: www.petrotest.com<br />

Production<br />

Storage<br />

We reserve the right of changes without prior notice.<br />

<strong>98</strong>-<strong>1210</strong> 09/06