Mud Conditioning System - PRAKLA Bohrtechnik GmbH

Mud Conditioning System - PRAKLA Bohrtechnik GmbH

Mud Conditioning System - PRAKLA Bohrtechnik GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

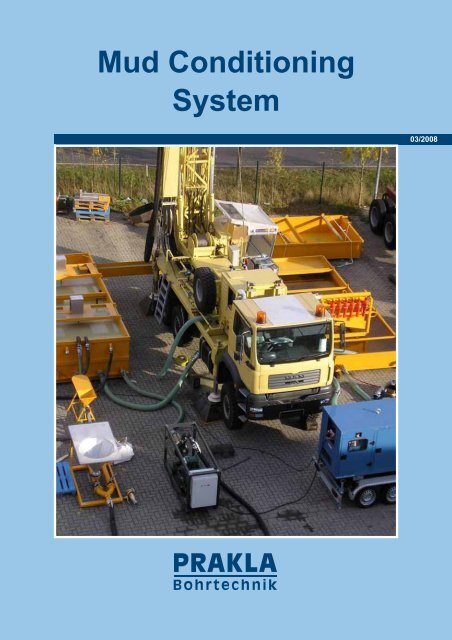

<strong>Mud</strong> <strong>Conditioning</strong><br />

<strong>System</strong><br />

03/2008

Table of Contents<br />

Table of Contents<br />

1 About this description........................................................................................................................ 3<br />

1.1 Related documents............................................................................................................................... 3<br />

2 Technical description......................................................................................................................... 4<br />

2.1 Setting up the auxiliary units................................................................................................................. 5<br />

2.2 Auxiliary pump ...................................................................................................................................... 6<br />

2.3 Hopper .................................................................................................................................................. 7<br />

2.4 <strong>Mud</strong> tanks ............................................................................................................................................. 8<br />

2.5 <strong>Mud</strong> ditch ............................................................................................................................................ 10<br />

2.6 Desander ............................................................................................................................................ 11<br />

2.7 Hose and hose couplings ................................................................................................................... 12<br />

3 Other accessories............................................................................................................................. 13<br />

4 Technical data................................................................................................................................... 14<br />

List of Figures<br />

Fig. 1 Auxiliary units arranged around the rotary drilling rig ................................................................... 5<br />

Fig. 2 Auxiliary pump............................................................................................................................... 6<br />

Fig. 3 Hopper, big.................................................................................................................................... 7<br />

Fig. 4 Hopper, small ................................................................................................................................ 7<br />

Fig. 5 <strong>Mud</strong> tank with mixer ...................................................................................................................... 8<br />

Fig. 6 Other mud tanks............................................................................................................................ 9<br />

Fig. 7 <strong>Mud</strong> ditch..................................................................................................................................... 10<br />

Fig. 8 Desander..................................................................................................................................... 11<br />

Fig. 9 Hose and strainer........................................................................................................................ 12<br />

Fig. 10 Coupling and adapter.................................................................................................................. 12<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 2

About this description<br />

1 About this description<br />

This technical document provides important information about the auxiliary units for the rotary drilling<br />

rig. Besides an overview, you can find instructions for safe and correct installation of the auxiliary<br />

units at the usage site.<br />

Read this document carefully and in full before starting to set up and work with the auxiliary units of<br />

the rotary drilling rig.<br />

Observe all universally valid legal and other binding European and national regulations and the<br />

national regulations related to the prevention of accidents, public road traffic and environmental protection.<br />

1.1 Related documents<br />

Also read and observe the suppliers' documentation for the auxiliary units. These documents are<br />

part and parcel of the present technical description.<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 3

Technical description<br />

2 Technical description<br />

The auxiliary units described in this document must be ordered separately. They are no components<br />

of the rotary drilling rig and, thus, are not included in its scope of delivery.<br />

Note that this technical description does not provide any instructions on how to use and<br />

control the auxiliary units.<br />

Follow the instructions for proper connection, control and operation of the auxiliary units<br />

provided in the suppliers' documentation.<br />

Auxiliary units include several components that are detailed on the following pages:<br />

� Auxiliary pump (see page 6)<br />

� Hopper (see page 7)<br />

� <strong>Mud</strong> tank (see page 8)<br />

� <strong>Mud</strong> ditch (see page 10)<br />

� Desander (see page 11)<br />

� Hoses and hose couplings (see page 12)<br />

In order to obtain the auxiliary units in the wanted configuration, please contact our customer service.<br />

You can find the address in chapter “Other accessories” on page 13.<br />

Other accessories and auxiliary parts are also available from our customer service. Please refer to<br />

chapter “Other accessories” for a list of the available accessories.<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 4

Technical description<br />

2.1 Setting up the auxiliary units<br />

The following overview shows the possible setup and basic arrangement of a fully equipped rotary<br />

drilling rig system with the corresponding auxiliary units as an example.<br />

In individual cases the arrangement may be different, depending on the local usage site and conditions.<br />

Fig. 1 Auxiliary units arranged around the rotary drilling rig<br />

1 <strong>Mud</strong> tank with mixer 6 Generator (optional)<br />

2 <strong>Mud</strong> ditch 7 Auxiliary pump<br />

3 Hoses and hose couplings 8 Hopper, big<br />

4 <strong>Mud</strong> tank with sieve 9 Hopper, small<br />

5 Desander<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 5

Technical description<br />

2.2 Auxiliary pump<br />

Fig. 2 Auxiliary pump<br />

1 Hopper<br />

connector<br />

2 <strong>Mud</strong> tank<br />

connector<br />

The electrical auxiliary pump pumps water from the mud tank to the hopper, where the drilling mud is<br />

produced.<br />

On one side of the auxiliary pump, the hose of the mud tank is connected. On the other side, the<br />

hose of the big hopper is connected. A bypass on the big hopper also allows you to connect the<br />

pump directly to the small hopper.<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 6

Technical description<br />

2.3 Hopper<br />

Fig. 3 Hopper, big<br />

The two hoppers allow you to produce the drilling mud. You can use either the big and/or the small<br />

hopper, depending on the required mud volume.<br />

The hose from the auxiliary pump (1) is connected to the bypass (2). The drilling mud either passes<br />

the big hopper or directly flows through the small hopper unit before reaching the mud tank, depending<br />

on the position of the lever on the bypass.<br />

When setting up the system, place the small hopper between the big hopper and the drilling tank.<br />

The small hopper is equipped with Storz couplings for connecting the hoses.<br />

Fig. 4 Hopper, small<br />

1 Auxiliary pump<br />

connector<br />

2 Bypass<br />

3 <strong>Mud</strong> tank<br />

connector<br />

4 Small hopper<br />

connector<br />

1 Big hopper<br />

connection<br />

2 <strong>Mud</strong> tank<br />

connector<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 7

Technical description<br />

2.4 <strong>Mud</strong> tanks<br />

<strong>Mud</strong> tanks in various sizes and of different types are available for configuring a mud system according<br />

to your needs. Besides the mud tank with mixer shown in this description, smaller mud tanks or<br />

mud tanks with bleeder are available.<br />

Fig. 5 <strong>Mud</strong> tank with mixer<br />

1 Mixer<br />

2 Separator<br />

3 Mixer II<br />

The big mud tank has two chambers separated by a separator. A mixer can be installed above each<br />

chamber. The first mixer (1) is powered externally via a generator. The second mixer (3) is powered<br />

via a cable connected to the first mixer.<br />

The separator (2) has openings in the bottom part, allowing you to either separate or link the two<br />

chambers.<br />

The big mud tank has various inlet and outlet connectors for the drilling mud. An external auxiliary<br />

pump (see chapter Auxiliary pump on page 6) can be connected to one of the two lower connectors,<br />

Another connector is assigned to the centrifugal pump on the rotary drilling rig.<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 8

Technical description<br />

The picture below shows you some examples of the available mud tank types.<br />

Fig. 6 Other mud tanks<br />

1 <strong>Mud</strong> tank with<br />

bleeder<br />

2 <strong>Mud</strong> tank, flat<br />

3 <strong>Mud</strong> tank, small<br />

For details of the available mud tank variants please contact our customer service. You can find the<br />

address in chapter “Other accessories” on page 13.<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 9

Technical description<br />

2.5 <strong>Mud</strong> ditch<br />

Fig. 7 <strong>Mud</strong> ditch<br />

A mud ditch is available for setting up the mud system for your rotary drilling rig. The mud returning<br />

from the borehole passes the mud ditch to reach the big mud tank.<br />

For details of the mud ditch please contact our customer service. You can find the address in chapter<br />

“Other accessories” on page 13.<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 10

Technical description<br />

2.6 Desander<br />

Fig. 8 Desander<br />

The desander separates solids from the drilling mud, but without affecting or modifying the drilling<br />

mud itself. Its charging volume is indicated in m³/h and depends on several parameters. In order to<br />

ensure optimal operating conditions, the desander must be placed on the collecting pan (see Fig. 8)<br />

The desander's main components are:<br />

� A coarse sieve (5) for filtering out stones of more than 5 mm<br />

� A cyclone washer for separating fine particles from the drilling mud<br />

� A collecting pan under the coarse sieve<br />

1 Duct<br />

2 Cyclone washer<br />

3 Collecting pan<br />

4 Hose<br />

5 Coarse sieve<br />

The drilling mud flows through a hose (4) into the cyclone washer. In the cyclone washer (2), the solids<br />

are separated from the drilling mud by centrifugal forces. The desander is available with four or<br />

six cyclone washers. A pressure gauge indicates the drilling mud input pressure.<br />

The solids are evacuated via a duct (1). The remaining drilling mud flows through a hose to the collecting<br />

pan (3).<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 11

Technical description<br />

2.7 Hose and hose couplings<br />

Fig. 9 Hose and strainer<br />

The basic set of hoses with different hose couplings required for connecting the auxiliary units to<br />

each other or to the drilling rig is included in the scope of delivery. Additionally, a strainer (1) for<br />

sucking in the drilling mud from the drilling hole is available.<br />

Fig. 10 Coupling and adapter<br />

1 Strainer<br />

1 Perrot coupling<br />

2 Adapter<br />

Standardly, hoses of 5 m and 10 m length are included in the delivery scope. Storz couplings or Perrot<br />

couplings (1) are used for connecting the hoses. The appropriate adapters (2) for interconnecting<br />

several hoses are also available. For details of the available hoses, hose couplings and adapters<br />

please contact our customer service.<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 12

Other accessories<br />

3 Other accessories<br />

Various additional accessories can be ordered for the rotary drilling rig.<br />

The following accessories are available:<br />

� Drill string components like drill pipes, cross-overs, bits, stabilizers and collars<br />

� Additional vehicles like tank trucks, trailers, workshop containers and crane trucks<br />

� Auxiliary compressors<br />

� Work platforms<br />

The customer service will help you to select and order the required accessories. You can reach the<br />

service center of <strong>PRAKLA</strong> <strong>Bohrtechnik</strong> <strong>GmbH</strong> under:<br />

<strong>PRAKLA</strong> <strong>Bohrtechnik</strong> <strong>GmbH</strong><br />

Moorbeerenweg 3<br />

D-31228 Peine<br />

Phone: +49 (0)5171 9055-0<br />

Fax: +49 (0)5171 9055-100<br />

e-mail: info@prakla-bohrtechnik.de<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 13

Technical data<br />

4 Technical data<br />

Hopper, big<br />

Item No. 16000325<br />

Dimensions<br />

Length / Width / Height 1,930 / 1,000 / 1,086 mm<br />

Weight 244 kg<br />

Connection 5''<br />

Flowrate 1,500 l/min at 8 bar<br />

Hopper, smal<br />

Item No. 16000326<br />

Dimensions<br />

Length / Width / Height 1,240 / 704 / 1,008 mm<br />

Weight 40 kg<br />

Connection 2,5''<br />

Flowrate 750 l/min at 8 bar<br />

Auxiliary pump<br />

Item No. 16000327<br />

Dimensions<br />

Length / Width / Height 2,103 / 793 / 1,263 mm<br />

Weight 884 kg<br />

Flowrate max. 2,000 l/min at max. 8 bar<br />

Power 400 V; 50 Hz; 55 kW<br />

Desander<br />

Item No. 16000328<br />

Dimensions<br />

Cyclone washer 6 pieces<br />

Length / Width / Height 2,005 / 590 / 1,314 mm<br />

Weight 206 kg<br />

Flowrate 1.080 l at 2,5 bar<br />

Tank, big<br />

Item No. 11520240<br />

Dimensions<br />

Length / Width / Height 5,500 / 2,300 / 1,210 mm<br />

Weight 2,450 kg<br />

Tank, medium size<br />

Item No. 11520245<br />

Dimensions<br />

Length / Width / Height 3,245 / 2,300 / 600 mm<br />

Weight 975 kg<br />

Tank, small<br />

Item No. 11520243<br />

Dimensions<br />

Length / Width / Height 3,245 / 2,300 / 500 mm<br />

Weight 920 kg<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 14

Technical data<br />

<strong>Mud</strong> ditch<br />

Item No. 16059262<br />

Dimensions<br />

Length / Width / Height 3,000 / 300 / 350 mm<br />

Weight 96 kg<br />

Mixer I<br />

Item No. 16000320<br />

Dimensions<br />

Length / Width / Height 2,360 / 860 / 2,050 mm<br />

Weight 158 kg<br />

Power 0.75 kW; 82 rpm<br />

Mixer 4 propellers of 650 mm of diameter<br />

Mixer II<br />

Item No. 16000334<br />

Dimensions<br />

Length / Width / Height 2,360 / 860 / 2,050 mm<br />

Weight 158 kg<br />

Power 0.75 kW; 82 rpm<br />

Mixer 4 propellers of 650 mm of diameter<br />

Strainer<br />

Item No. 11002056<br />

Dimensions<br />

Length / Width / Height 280 / 280 / 680 mm<br />

Connection 5'' Perrot<br />

<strong>Mud</strong> <strong>Conditioning</strong> <strong>System</strong> 03/2008 15

<strong>PRAKLA</strong> <strong>Bohrtechnik</strong> <strong>GmbH</strong><br />

Moorbeerenweg 3<br />

D-31228 Peine<br />

Phone: +49 (0)5171 9055-0<br />

Fax: +49 (0)5171 9055-100<br />

info@prakla-bohrtechnik.de<br />

www.prakla-bohrtechnik.de<br />

A BAUER Group company