Hazardous Waste Disposal with Thermal Oxidation - John Zink ...

Hazardous Waste Disposal with Thermal Oxidation - John Zink ...

Hazardous Waste Disposal with Thermal Oxidation - John Zink ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

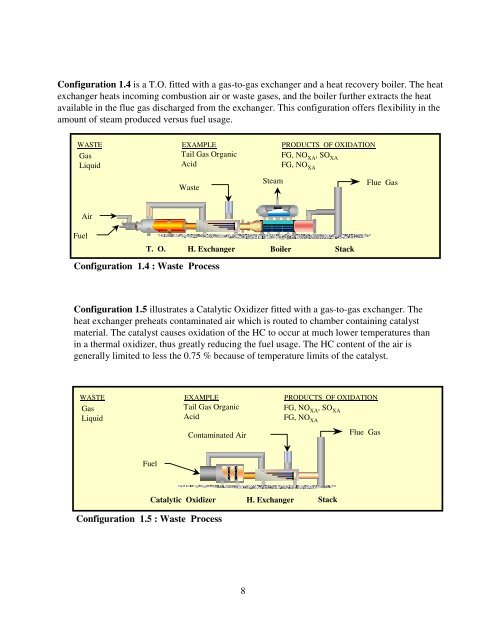

Configuration 1.4 is a T.O. fitted <strong>with</strong> a gas-to-gas exchanger and a heat recovery boiler. The heat<br />

exchanger heats incoming combustion air or waste gases, and the boiler further extracts the heat<br />

available in the flue gas discharged from the exchanger. This configuration offers flexibility in the<br />

amount of steam produced versus fuel usage.<br />

WASTE EXAMPLE PRODUCTS OF OXIDATION<br />

Gas<br />

Liquid<br />

Air<br />

Fuel<br />

T. O.<br />

Tail Gas Organic<br />

Acid<br />

<strong>Waste</strong><br />

H. Exchanger<br />

Configuration 1.4 : <strong>Waste</strong> Process<br />

Steam<br />

FG, NO XA ,SO XA<br />

FG, NO XA<br />

Boiler<br />

Stack<br />

Flue Gas<br />

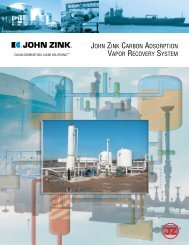

Configuration 1.5 illustrates a Catalytic Oxidizer fitted <strong>with</strong> a gas-to-gas exchanger. The<br />

heat exchanger preheats contaminated air which is routed to chamber containing catalyst<br />

material. The catalyst causes oxidation of the HC to occur at much lower temperatures than<br />

in a thermal oxidizer, thus greatly reducing the fuel usage. The HC content of the air is<br />

generally limited to less the 0.75 % because of temperature limits of the catalyst.<br />

WASTE EXAMPLE PRODUCTS OF OXIDATION<br />

Gas<br />

Liquid<br />

Fuel<br />

Tail Gas Organic<br />

Acid<br />

Contaminated Air<br />

Catalytic Oxidizer<br />

Configuration 1.5 : <strong>Waste</strong> Process<br />

8<br />

H. Exchanger<br />

FG, NO XA ,SO XA<br />

FG, NO XA<br />

Stack<br />

Flue Gas