Capture Jet™ Hood with Side-Jet Technology - Halton

Capture Jet™ Hood with Side-Jet Technology - Halton

Capture Jet™ Hood with Side-Jet Technology - Halton

- TAGS

- capture

- halton

- www.halton.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

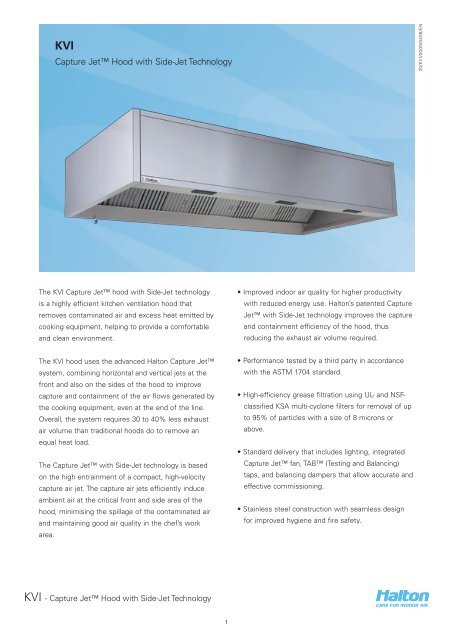

KVI<br />

<strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

The KVI <strong>Capture</strong> <strong>Jet</strong> hood <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> technology<br />

is a highly efficient kitchen ventilation hood that<br />

removes contaminated air and excess heat emitted by<br />

cooking equipment, helping to provide a comfortable<br />

and clean environment.<br />

The KVI hood uses the advanced <strong>Halton</strong> <strong>Capture</strong> <strong>Jet</strong><br />

system, combining horizontal and vertical jets at the<br />

front and also on the sides of the hood to improve<br />

capture and containment of the air flows generated by<br />

the cooking equipment, even at the end of the line.<br />

Overall, the system requires 30 to 40% less exhaust<br />

air volume than traditional hoods do to remove an<br />

equal heat load.<br />

The <strong>Capture</strong> <strong>Jet</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> technology is based<br />

on the high entrainment of a compact, high-velocity<br />

capture air jet. The capture air jets efficiently induce<br />

ambient air at the critical front and side area of the<br />

hood, minimising the spillage of the contaminated air<br />

and maintaining good air quality in the chef’s work<br />

area.<br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

1<br />

• Improved indoor air quality for higher productivity<br />

<strong>with</strong> reduced energy use. <strong>Halton</strong>’s patented <strong>Capture</strong><br />

<strong>Jet</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> technology improves the capture<br />

and containment efficiency of the hood, thus<br />

reducing the exhaust air volume required.<br />

• Performance tested by a third party in accordance<br />

<strong>with</strong> the ASTM 1704 standard.<br />

• High-efficiency grease filtration using UL- and NSFclassified<br />

KSA multi-cyclone filters for removal of up<br />

to 95% of particles <strong>with</strong> a size of 8 microns or<br />

above.<br />

• Standard delivery that includes lighting, integrated<br />

<strong>Capture</strong> <strong>Jet</strong> fan, TAB (Testing and Balancing)<br />

taps, and balancing dampers that allow accurate and<br />

effective commissioning.<br />

• Stainless steel construction <strong>with</strong> seamless design<br />

for improved hygiene and fire safety.<br />

20/KVI/0000/0408/EN

9<br />

1<br />

10<br />

Construction<br />

3 4 5<br />

6 7 8<br />

The KVI kitchen canopy comprises a <strong>Capture</strong> <strong>Jet</strong> unit<br />

<strong>with</strong> side jets, a <strong>Capture</strong> <strong>Jet</strong> centrifugal fan<br />

(optional), an IP65 light fitting, adjustment dampers,<br />

airflow measurement taps and a KSA grease<br />

separator.<br />

All visible parts of the canopy are manufactured from<br />

polished stainless steel AISI 304 and the unexposed<br />

parts from galvanised steel. Joints on the lower edge<br />

are fully welded.<br />

A collection tray or a drain tap is fitted into the grease<br />

drain channel in order to enable the removal of the<br />

grease and dirt extracted by the KSA multi-cyclone<br />

separator.<br />

The <strong>Capture</strong> <strong>Jet</strong> air plenum is thermally insulated<br />

using non-fibre-releasing material to prevent vapours<br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

2<br />

2<br />

CODE DESCRIPTION<br />

1 Outer casing – visible parts in stainless steel AISI 304<br />

2 Exhaust air connection and adjustment damper<br />

3 <strong>Capture</strong> <strong>Jet</strong> fan and grille<br />

4 Access hatch<br />

5 Light fitting <strong>with</strong> electrical junction box<br />

6 <strong>Capture</strong> <strong>Jet</strong> nozzles<br />

7 KSA grease filter<br />

8 Grease collection tray or drain tap<br />

9 Thermal insulation<br />

10 Access hatch<br />

from condensing on the inner face of the canopy<br />

above the cooking equipment.<br />

Testing and balancing taps (TAB) for flow<br />

measurement are fitted to the exhaust plenum and<br />

the <strong>Capture</strong> <strong>Jet</strong> air plenum.<br />

The new <strong>Capture</strong> <strong>Jet</strong> family is manufactured in the<br />

form of modular sections. Large canopies are<br />

assembled using a combination of separate modules<br />

<strong>with</strong>out any beams between the modules, meaning<br />

that one long section is created, which is aesthetically<br />

preferable.<br />

The modular sections make transportation and site<br />

handling easier.<br />

20/KVI/0000/0408/EN

Modular Sections<br />

KVI - (1 closed end)<br />

QUICK DATA<br />

KVI - (2 opened ends)<br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

3<br />

KVI - (1 closed end)<br />

Recommended Exhaust air volume Recommended <strong>Capture</strong> <strong>Jet</strong> air volume<br />

(<strong>with</strong> width = 1300)<br />

L1 (section length) L l/s m3 /h l/s m3 /h<br />

1500 1600 389 … 602 1400 … 2169 27 97<br />

2000 2100 519 … 803 1867 … 2892 31 112<br />

2500 2600 648 … 1004 2333 … 3615 35 127<br />

5000 5100 1296 … 2008 4667 … 7230 56 202<br />

7500 7600 1945 … 3012 7000 … 10845 77 277<br />

10000 10100 2593 … 4017 9334 … 14460 98 352<br />

20/KVI/0000/0408/EN

Function<br />

The kitchen canopy above cooking appliances contains<br />

the rising warm air and contaminants (A).<br />

The <strong>Capture</strong> <strong>Jet</strong> (B) increases the efficiency of<br />

capture of the smoke and contaminated air at both the<br />

face and sides for enhanced performance at the end<br />

of the cooking line and directs the contaminated air<br />

Accessories<br />

• Cover Boards – where canopies are below ceiling<br />

level<br />

• Infill Panels<br />

• KSA grease filters<br />

• Blind filter in stainless steel<br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

4<br />

Heat spilling <strong>Capture</strong> &<br />

containment<br />

towards the KSA grease separator (C), where the<br />

grease particles and other impurities are separated<br />

from the exhaust air using the cyclone separation<br />

principle. Grease and contaminants that have been<br />

removed flow into a drain channel and towards the<br />

collection tap/tray (D).<br />

• Non-standard spigots sizes and position<br />

• Canopy cut outs to fit around columns<br />

• Exhaust/supply roof in stainless steel<br />

• U profile for hanging<br />

20/KVI/0000/0408/EN

DIMENSIONS (mm)<br />

KVI - (2 closed ends)<br />

L 1100 … 3100<br />

B 1200 … 1700<br />

H 555<br />

D2 315<br />

G 250<br />

J 170<br />

Note: The dimensions above are for modular sections only;<br />

larger canopies are assembled using a combination of separate<br />

modules, which makes transportation and site handling easier.<br />

Light<br />

A 25<br />

F 175<br />

E 450<br />

I 720 (L1 1500 2x36W)<br />

LOCATION OF CONNECTIONS (mm)<br />

For typical sizes<br />

Exhaust <strong>Capture</strong> <strong>Jet</strong><br />

1 Ø315 2 Ø315 1 Ø160<br />

L N N1 M M1 N<br />

1600 L/2 L1/2 375 325 L/2<br />

2100 L/2 L1/2 500 450 L/2<br />

2600 L/2 L1/2 500 450 L/2<br />

3100 L/2 L1/2 500 450 L/2<br />

WEIGHT (KG)<br />

L/B 1300 1500 1700<br />

1600 103 109 115<br />

2100 120 126 132<br />

2600 138 144 150<br />

3100 156 162 168<br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

5<br />

N<br />

Optional spigot<br />

Ø160<br />

KVI - (2 closed ends)<br />

M<br />

J<br />

E<br />

F<br />

A<br />

B<br />

I<br />

Wall<br />

ØD2<br />

G<br />

Wall<br />

M1<br />

M1<br />

50<br />

H<br />

50<br />

N1<br />

L1<br />

L<br />

20/KVI/0000/0408/EN

DIMENSIONS (mm)<br />

KVI - (1 closed end)<br />

L2 1050 … 3050<br />

B 1200 … 1700<br />

H 555<br />

D2 315<br />

G 250<br />

J 170<br />

Note: The dimensions above are for modular sections only;<br />

larger canopies are assembled using a combination of separate<br />

modules, which makes transportation and site handling easier.<br />

Light<br />

A 25<br />

F 175<br />

E 450<br />

I 720 (L1 1500 2x36W)<br />

LOCATION OF CONNECTIONS (mm)<br />

For typical sizes<br />

WEIGHT (KG)<br />

Exhaust <strong>Capture</strong> <strong>Jet</strong><br />

1 Ø315 2 Ø315 1 Ø160<br />

L2 N1 M1 N1<br />

1550 (L2-50)/2 325 (L2-50)/2<br />

2050 (L2-50)/2 450 (L2-50)/2<br />

2550 (L2-50)/2 450 (L2-50)/2<br />

3050 (L2-50)/2 450 (L2-50)/2<br />

L2/B 1300 1500 1700<br />

1550 98 104 110<br />

2050 115 121 127<br />

2550 133 139 145<br />

3050 151 157 163<br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

6<br />

Optional spigot<br />

Ø160<br />

KVI - (1 closed end)<br />

N1<br />

M<br />

J<br />

E<br />

F<br />

A<br />

B<br />

I<br />

Wall<br />

ØD2<br />

G<br />

M1<br />

M1<br />

H<br />

50<br />

N1<br />

L1<br />

L2<br />

20/KVI/0000/0408/EN

DIMENSIONS (mm)<br />

KVI - (2 open ends)<br />

L1 1000 … 3000<br />

B 1200 … 1700<br />

H 555<br />

D2 315<br />

G 250<br />

J 170<br />

Note: The dimensions above are for modular sections only;<br />

larger canopies are assembled using a combination of separate<br />

modules, which makes transportation and site handling easier.<br />

Light<br />

A 25<br />

F 175<br />

E 450<br />

I 720 (L1 1500 2x36W)<br />

LOCATION OF CONNECTIONS (mm)<br />

For typical sizes<br />

Exhaust <strong>Capture</strong> <strong>Jet</strong><br />

1 Ø315 2 Ø315 1 Ø160<br />

L1 N1 M1 N1<br />

1500 L1 /2 325 L1 /2<br />

2000 L1 /2 450 L1 /2<br />

2500 L1 /2 450 L1 /2<br />

3000 L1 /2 450 L1 /2<br />

WEIGHT (KG)<br />

L1/B 1300 1500 1700<br />

1500 93 99 105<br />

2000 110 116 122<br />

2500 128 134 140<br />

3000 146 152 158<br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

7<br />

KVI - (2 opened ends)<br />

N1<br />

Optional spigot<br />

Ø160<br />

J<br />

E<br />

F<br />

A<br />

B<br />

I<br />

ØD2<br />

G<br />

M1<br />

M1<br />

H<br />

N1<br />

L1<br />

20/KVI/0000/0408/EN

Pressure drop and sound data, exhaust<br />

H= 555<br />

∆Ptab = Pressure loss of filters measured<br />

from Measuring tap<br />

∆Pst = Total exhaust static pressure loss<br />

30,70,100 = Damper opening in %<br />

Section-1000<br />

pst<br />

[Pa]<br />

pst<br />

[Pa]<br />

300<br />

200<br />

100<br />

50<br />

30<br />

20<br />

300<br />

200<br />

100<br />

50<br />

30<br />

20<br />

30<br />

35<br />

300 400 500<br />

40<br />

45<br />

50<br />

55<br />

30<br />

70<br />

100<br />

qv [l/s]<br />

1000 2000 3000 qv [m3/h]<br />

L r = 8 dB<br />

30<br />

35<br />

LpA dB(A)<br />

40<br />

200 300 400 500<br />

800<br />

qv [l/s]<br />

500 720<br />

1000 1440 1800 qv [m3/h]<br />

L r = 8 dB<br />

LpA dB(A)<br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

45<br />

50<br />

30<br />

55<br />

70<br />

100<br />

8<br />

Section-1500<br />

pst<br />

[Pa]<br />

pst<br />

[Pa]<br />

300<br />

200<br />

100<br />

50<br />

30<br />

20<br />

300<br />

200<br />

100<br />

50<br />

30<br />

20<br />

L r = 8 dB<br />

Section-2000 Section-2500<br />

400<br />

L r = 8 dB<br />

30<br />

�P st<br />

�P tab<br />

35<br />

LpA dB(A)<br />

40<br />

45<br />

300 500<br />

50<br />

30<br />

55<br />

70<br />

100<br />

qv [l/s]<br />

1000 2000 qv [m3/h]<br />

30<br />

1800<br />

500<br />

35<br />

LpA dB(A)<br />

40<br />

45<br />

50<br />

600<br />

1000<br />

30<br />

55<br />

70<br />

100<br />

qv [l/s]<br />

2000 3000 qv [m3/h]<br />

20/KVI/0000/0408/EN

Section-3000<br />

pst<br />

[Pa]<br />

300<br />

200<br />

100<br />

50<br />

30<br />

20<br />

L r = 8dB<br />

30<br />

LpA dB(A)<br />

35<br />

40<br />

45<br />

500 600<br />

1000<br />

50<br />

1200<br />

30<br />

55<br />

70<br />

100<br />

qv [l/s]<br />

2000 3000 5000 qv [m3/h]<br />

T.A.B. / Exhaust air-flow rate adjustment<br />

Recommended pressure TAB 50-120 Pa<br />

�p<br />

TAB<br />

" w.g.<br />

0.8<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.12<br />

Pa<br />

200<br />

120<br />

100<br />

50<br />

30<br />

70<br />

80<br />

90<br />

100<br />

120<br />

140 160 180 200<br />

9<br />

300<br />

400<br />

500 600 700 800 900 1000<br />

20<br />

150 200 250 300 400 500 600 700<br />

1000<br />

1500 2000 2500 2900<br />

250<br />

300<br />

400<br />

KSA active section 500 mm<br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

500<br />

600<br />

1000<br />

KVI K-FACTOR CHART, EXHAUST<br />

KSA (Number of filters) K factor (m 3 /h) K factor (l/s)<br />

1 68,7 19,1<br />

2 137,5 38,2<br />

3 204,7 56,9<br />

4 270,9 75,2<br />

5 339,5 94,3<br />

6 408,4 113,4<br />

1500<br />

1000<br />

2000<br />

1500<br />

2000<br />

3000<br />

2500<br />

4000<br />

1200<br />

3000<br />

5000<br />

l/s<br />

cfm<br />

m³/h<br />

20/KVI/0000/0408/EN

Suggested specifications<br />

The kitchen hood shall be constructed from 1.0-mm<br />

AISI 304 stainless steel.<br />

The kitchen hood shall be supplied complete <strong>with</strong><br />

<strong>Capture</strong> <strong>Jet</strong> technology, high-efficiency multi-cyclone<br />

grease filters, pressure measurement taps, exhaust air<br />

spigots <strong>with</strong> adjustment dampers, and a fluorescent<br />

light fitting <strong>with</strong> installation hatch.<br />

The size shall be as indicated in the drawings.<br />

Outer casing<br />

• Outer casing panels are constructed from AISI 304<br />

stainless steel in a brushed satin finish in a modular<br />

construction. The joints of the lower edge shall be<br />

fully welded to be liquid-tight, avoiding harmful<br />

dripping of condensation. All exposed welds are<br />

ground and polished to the original finish of the<br />

metal.<br />

• The bottom edge of the exhaust plenum should be<br />

aerodynamically designed (no flat surface or<br />

bounce).<br />

• Canopy ends shall be of double-sidewall construction<br />

(no single wall permitted).<br />

Exhaust<br />

• The exhaust air flow will be based on the convective<br />

heat generated by the appliances underneath each<br />

canopy. Submittal shall include convective heat<br />

calculations based on the input power of the<br />

appliance served.<br />

• The hood’s mounting height shall be in accordance<br />

<strong>with</strong> the drawings supplied, as a moderate increase<br />

in exhaust rate is required if the hood is installed<br />

higher than designed.<br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

10<br />

<strong>Capture</strong> <strong>Jet</strong> <strong>with</strong> side-jet technology<br />

• The hood shall be designed <strong>with</strong> <strong>Capture</strong> <strong>Jet</strong><br />

technology and <strong>Side</strong>-<strong>Jet</strong> technology to reduce the<br />

exhaust air flow rate required and to improve the<br />

capture and containment efficiency of the hood not<br />

only at the front but also on the sides of the canopy,<br />

while reducing energy consumption. The <strong>Capture</strong><br />

<strong>Jet</strong> air shall be introduced through a special<br />

discharge panel and shall not exceed 10% of the<br />

calculated exhaust air flow. The <strong>Capture</strong> <strong>Jet</strong><br />

discharge velocity shall be, at minimum, 8 m/s. Slotor<br />

grille-type discharge shall not be used. The<br />

<strong>Capture</strong> <strong>Jet</strong> chamber is to be insulated.<br />

• The hood shall be supplied <strong>with</strong> a <strong>Capture</strong> <strong>Jet</strong> fan<br />

to provide the required air flow at the indicated<br />

static pressure. The fan is to be provided by the<br />

hood manufacturer, so an additional supply air<br />

system is not required for the <strong>Capture</strong> <strong>Jet</strong> system.<br />

Grease filters<br />

• The hood shall be equipped <strong>with</strong> a KSA-model multicyclone<br />

stainless steel grease extractor. The grease<br />

extraction efficiency is 93% for particles <strong>with</strong> a<br />

diameter of 5 microns and 98% for those <strong>with</strong> a<br />

diameter of 15 microns or larger, as tested by an<br />

independent testing laboratory. The pressure loss<br />

over the extractor shall not exceed 120 Pa at the<br />

flow rates calculated. Sound levels shall not exceed<br />

an LpA rating of 50 dB(A). The filter shall be NSFand<br />

UL-classified. Baffle- or slot-type grease<br />

extractors shall not be used.<br />

TAB ports and air flow balancing<br />

• The air flows through the KSA separator and the<br />

<strong>Capture</strong> <strong>Jet</strong> air chamber are to be determined via<br />

the integral TAB ports mounted in the hood. The air<br />

flows are to be determined by the pressure vs. air<br />

flow curves supplied by <strong>Halton</strong>.<br />

• The replacement air shall be delivered <strong>with</strong> a supply<br />

control damper of type MSM.<br />

• The spigot connections for supply and extracted air<br />

shall be supplied <strong>with</strong> a sealing gasket and air-flowbalancing<br />

damper plate.<br />

20/KVI/0000/0408/EN

Light fixtures<br />

• Each canopy shall be provided <strong>with</strong> a fluorescent<br />

light fixture to provide approx. 500 lux at the cooking<br />

appliances work surface. The light is protected <strong>with</strong><br />

a stainless steel hatch <strong>with</strong> plain milled finish,<br />

surrounded by a tempered-glass light diffuser (the<br />

heat tolerance of the glass shall be -40 to 300 ˚C).<br />

The hatch shall be hinged and held in position <strong>with</strong><br />

screws.<br />

Fire suppression system<br />

• The kitchen hood fire extinguishing system shall<br />

protect the kitchen hood against grease fires<br />

through a completely automatic fire control system<br />

of the wet chemical type. The fire detection system<br />

shall be capable of detecting fire in the hood, duct,<br />

or surface equipment and shall automatically<br />

discharge liquid extinguishing agent into the plenum<br />

chamber, exhaust duct collar, and cooking appliance<br />

areas to eliminate the possibility of re-ignition or<br />

re-flash. System components shall include a springloaded<br />

release mechanism, agent tank brass nozzles<br />

<strong>with</strong> blow-off caps and stainless steel appliance<br />

drops, a fusible link detector, wall-mounted<br />

emergency pull stations, a wall-mounted automan<br />

and cabinet, and a mechanical gas valve installed in<br />

the gas line serving the cooking equipment (valve<br />

provided by the fire protections system<br />

manufacturer and installed in the gas line by a<br />

plumber). The system’s installation shall be<br />

performed by an authorised representative of the<br />

system manufacturer and conform to UL 300<br />

requirements and local codes.<br />

Type: KVI Manufacturer: <strong>Halton</strong><br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

11<br />

20/KVI/0000/0408/EN

Product code<br />

SAP product code KVI_3<br />

WE = Closed end(s)<br />

2 = 2 walls<br />

R = Right side wall<br />

L = Left side wall<br />

N = No wall<br />

H = Height<br />

555-555<br />

555-400<br />

L = Lenght<br />

If WE = N L = 1000, 1050,……3000<br />

If WE = R or L L = 1050, 1100,……3050<br />

If WE = 2 L = 1100, 1150,..….3100<br />

LF = Light fitting<br />

T5 T5<br />

T8 T8<br />

N No<br />

LC = Light color<br />

830 830<br />

840 840<br />

930 930<br />

940 940<br />

B = Width<br />

If LF = T5 or T8 B = 1200,1250,……..1700<br />

If LF = N B = 1000,1050,……..1700<br />

NB = Number of blind filters<br />

NB = 0,1,2,3,4,5,6<br />

EC = Number of exhaust connections<br />

1 = 1 spigot<br />

2 = 2 spigots<br />

3 = 3 spigots<br />

N = no spigot<br />

ED = Exhaust damper<br />

1 = Yes<br />

N = No<br />

KVI - <strong>Capture</strong> <strong>Jet</strong> <strong>Hood</strong> <strong>with</strong> <strong>Side</strong>-<strong>Jet</strong> <strong>Technology</strong><br />

12<br />

CJ = <strong>Capture</strong> jet fan<br />

5 = Nothing (no CJ fan, no connection<br />

plenum...)<br />

6 = CJ fan + grille<br />

7 = CJ fan + spigot Ø160<br />

8 = Spigot Ø160 + damper type MSM<br />

(No CJ fan)<br />

CD = Canopy drain<br />

D = Drain tap<br />

C = Collection tray<br />

HS = Hanging system<br />

S = Standard<br />

U = U profile<br />

M=Material<br />

AS = Full stainless steel<br />

AT = Full stainless steel 1,2 mm<br />

CS = Standard<br />

CT = Standard 1,2 mm<br />

Sub product<br />

KB (cover board)<br />

KI (Infill panel)<br />

Code example<br />

KVI/N-1000-1000-555, LF=T5, LC=830, NB=0, EC=N,<br />

ED=N, CJ=6, CD=D, HS=S, MA=CS, ZT=N<br />

20/KVI/0000/0408/EN