isa-drive-e - Igel Electric

isa-drive-e - Igel Electric

isa-drive-e - Igel Electric

- TAGS

- igel

- igelelectric.de

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

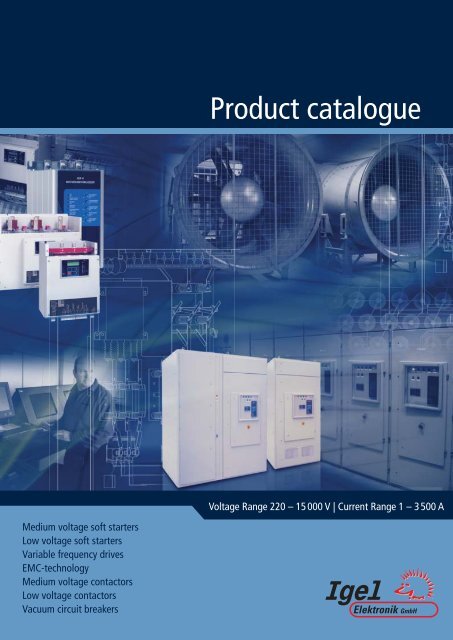

Medium voltage soft starters<br />

Low voltage soft starters<br />

Variable frequency <strong>drive</strong>s<br />

EMC-technology<br />

Medium voltage contactors<br />

Low voltage contactors<br />

Vacuum circuit breakers<br />

Product catalogue<br />

Voltage Range 220 – 15 000 V | Current Range 1 – 3 500 A

SELECTION<br />

Designated applications<br />

The following table assigns <strong>Igel</strong> Elektroniks‘ comprehensive product range<br />

to the appropriate application for each product line.<br />

applications<br />

pumps<br />

fans<br />

compressor<br />

submersible<br />

centrifugal<br />

axial<br />

radial<br />

piston<br />

screw<br />

ISA-B2P<br />

ISA-B<br />

ISA-A2P<br />

soft starters VFD<br />

ISA-A<br />

ISA-DS<br />

ISA-D<br />

ISA-HD<br />

ISA-OEM<br />

ISA-DRIVE-VT<br />

ISA-DRIVE-PLUS<br />

ISA-DRIVE-F<br />

o x x x x x<br />

o o o o x x x x x<br />

o o o x x x x<br />

o o o x x x x<br />

o<br />

o<br />

o o<br />

o o<br />

x<br />

x<br />

ISA-DRIVE-B<br />

x x x x x<br />

x x x x<br />

chiller<br />

x x x x x x x x x x<br />

shredder<br />

x x x x x<br />

mill<br />

o x x x x x<br />

crusher<br />

x x x x x<br />

conveyor belt<br />

o x x x x x<br />

milling mashine<br />

x x x x x x x x x x x x<br />

saw<br />

x x x x x x x x x x x x<br />

mixer<br />

o o o x x x x x<br />

blower<br />

o o o o x x x x x<br />

screw conveyor<br />

o x x x x x<br />

centrifuge o x x x x x<br />

cement pump o x x x x x<br />

X: well suited | O: partly suited<br />

ISA-DRIVE-E<br />

IMB<br />

DC<br />

injection<br />

brake

MEDIUM VOLTAGE SOFT STARTERS<br />

LOW VOLTAGE SOFT STARTERS<br />

VARIABLE FREQUENCY DRIVE<br />

DC INJECTION BRAKE<br />

THYRISTOR POWER SUPPLY<br />

EMC-TECHNOLOGY<br />

CONTACTORS<br />

SWITCHGEAR SOLUTIONS<br />

CONTENT<br />

About us 4 – 5<br />

Medium voltage technology<br />

ISA-HD<br />

Low voltage technology<br />

ISA-D and ISA-DS<br />

ISA-A and ISA-A2P<br />

ISA-B and ISA-B2P<br />

ISA-DRIVE-VT<br />

ISA-DRIVE-PLUS<br />

ISA-DRIVE-E<br />

ISA-DRIVE-B and ISA-DRIVE-F<br />

IMB<br />

TSE<br />

Line fi lters<br />

Line chokes<br />

Contactors and motor protection relays<br />

Vacuum contactors and circuit breaker<br />

Special solutions; medium voltage<br />

OEM serial production; low voltage<br />

6 – 7<br />

8 – 9<br />

10 – 11<br />

12 – 13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

3

4<br />

ABOUT US<br />

Sendenhorst<br />

Company history<br />

GERMANY<br />

Sendenhorst<br />

NORTH RHINE-WESTPHALIA<br />

Bonn<br />

Münster<br />

Düsseldorf<br />

Cologne<br />

Founded in 2001, by ex-Fanal Wuppertal employees,<br />

<strong>Igel</strong> dispose of a combined experience of<br />

over 25 years in <strong>drive</strong> technology. Our long term<br />

cooperation with leading international component<br />

manufacturers since the beginning of the<br />

80‘s, gives us a leading edge in the soft starters<br />

market, thus provides our customers with<br />

advanced technology and long term reliability.<br />

This technological edge placed <strong>Igel</strong> Elektronik<br />

in a leading position between the soft starters<br />

manufacturers.<br />

Today we offer worldwide largest product<br />

line of soft starters.<br />

Bielefeld<br />

Business activities<br />

As a specialist in <strong>drive</strong> technology we integrate<br />

systems and projects as well as supply single<br />

component for each project. We provide our<br />

customers with advanced design, unique in its<br />

cost effective performance and support our customers<br />

in throughout, from defi ning their needs<br />

to supplying a turn key solution. Some of our leading<br />

advantages are:<br />

| Application solution from concept to delivery<br />

| Design engineering to the highest<br />

specifi cations<br />

| Calculation of technical data<br />

| Solution Development and <strong>drive</strong> assembly<br />

| Components Installation<br />

| On site service<br />

Philosophy<br />

Together with our customers we have accepted<br />

the global market challenges and our increasing<br />

sales have proven our concept to be well<br />

perceived. During 2007 the increasing number<br />

of customers contributed to the increased<br />

sales fi gures placed us on the world map as a<br />

respected supplier. Our product range coveres<br />

all worldwide voltage levels and guarantees our<br />

customers the <strong>drive</strong> solution from one source<br />

and reduces developement- and adjustment<br />

costs. We provide supreme local service and<br />

support in every geographical zone where we<br />

focus our activities.

The world‘s largest low and medium voltage soft starter product range!<br />

Vision<br />

Our continuous growth in the last few years has<br />

our strategy confi rmed by our customers. We<br />

continuously improve our product and its performance,<br />

thus remain leaders in our fi eld. As<br />

a reliable supplier to the oil and gas industries<br />

demanding requirements, we will continue providing<br />

around the clock service and support to<br />

our global customers.<br />

Quality<br />

ABOUT US<br />

To the international customer a “Made in Germany“ product is perceived with utmost respect. It is<br />

therefore that we must preserve this perception for our products as well, by continuously monitoring<br />

the quality, reliability and ruggedness of every step in the manufacturing process. Our design<br />

engineering criterions enhance our processes, and the exceptional choice of components that we<br />

are making, from the purchasing stage through manufacturing and delivery, is assuring maximum<br />

performance when the product reaches the customers‘ site. From our marine products point of<br />

view, we have delivered Multi-Mega Watt soft starters which have completely changed the way the<br />

marine market is propelled today.<br />

The certifi cations we have obtained are from some of the more stringent bodies in the industrial<br />

and marine market segments, and are genuine to our quality management, standards of product<br />

manufacturing.<br />

5

MEDIUM<br />

VOLTAGE<br />

TECHN.<br />

6<br />

MEDIUM VOLTAGE SOFT STARTERS<br />

MEDIUM VOLTAGE<br />

INTERIOR VIEW ISA-HD<br />

This third generation, fi bre optic controlled, Medium<br />

Voltage Soft Starter is designed for use with<br />

standard asynchronous and synchronous motors.<br />

The ISA-HD is a highly sophisticated digital soft<br />

starter which ensures smooth, stepless acceleration<br />

and deceleration, eliminating current and<br />

mechanical shocks on motor and load. The ISA-HD<br />

may be supplied as a chassis or enclosed type with<br />

a multiple range of options.<br />

Options<br />

| Motor protection relay (MSR-HD)<br />

| High protection level (IP54)<br />

| RS 485 Modbus or Profi bus<br />

| Analogue output<br />

| Cabinet heater<br />

| Incoming cabinet with fuses<br />

or circuit breaker<br />

| Special parameters for synchronous<br />

motors<br />

| Multi motor start<br />

| Marine approvals<br />

NORMS AND APPROVALS<br />

Partial discharge design and test<br />

(Korona)<br />

The ISA-HD withstands EN 50178 part<br />

HD 625.1. Each starter ist fully tested for<br />

partial discharge (Korona) improving<br />

safety and long term reliability.<br />

DIGITAL<br />

Customer<br />

terminals<br />

Line Busbar<br />

Connections<br />

Soft Starter<br />

Power Section<br />

Soft Starter<br />

Control Module<br />

Line Contactor<br />

Bypass Contactor<br />

Wireless electronic potential<br />

transformer (EPT)<br />

Advanced Electronic Potential Transformer<br />

utilizing “wireless“ voltage measurement<br />

system.<br />

Production according to IEC 62271-200!<br />

| Illuminated LCD with 2 lines of<br />

16 characters each<br />

| Selectable languages: English, German,<br />

French or Spanish (aditional on request)<br />

| The LCD indicates the motor current, fault<br />

descriptions and statistical data.<br />

| The LEDs provide a quick status indication.<br />

(control voltage on, motor soft start, motor<br />

on, motor soft stop, motor stop, fault)<br />

Status Indications<br />

Operating Panel<br />

Motor Protection<br />

Relay<br />

Seperated<br />

Low Voltage<br />

Compartment<br />

Fiber-optic fi ring system<br />

Unique fi ber-optic fi ring system providing<br />

complete isolation between MV and LV<br />

compartments.<br />

Marine approvals on request<br />

| Easy settings by six clearly marked<br />

keys, user-friendly software with<br />

factory default parameters.

SPECIAL OPTIONS<br />

Direct power factor capacitor<br />

connection<br />

Power factor capacitors can be connected<br />

directly to the upstream contactor,<br />

omitting the need for additional contactors.<br />

ISA-HD<br />

M<br />

STARTING AND TESTING<br />

SPECIAL STARTING FEATURES<br />

LINE AND BYPASS CONTACTORS<br />

TECHNOLOGY<br />

Multi-voltage starters<br />

Unique dual-voltage connection allows for<br />

more than one voltage level to be used<br />

with the same soft starter.<br />

Saves space, weight, cabling, engineering<br />

and costs!<br />

Mains ”A“ Mains ”B“<br />

1,500-15,000V 1,500-15,000V<br />

MSR<br />

ISA-HD<br />

MSR MSR<br />

M<br />

M<br />

1,500-15,000V<br />

Motor “A“<br />

1,500-15,000V<br />

Motor “B“<br />

Low voltage test<br />

Innovative low voltage testing with a small 400V motor. This unique mode of operation allows for<br />

fully functional performance. Ensabling line and bypass contactors preperation as well as plant<br />

control system. (The procedure is fi eld initiated in minutes and includes active protection status<br />

with no need for any additional equipment.)<br />

“Dry“ No voltage testing<br />

“Dry“ testing allows thyristor fi ring and control test without mains voltage connection.<br />

Individual thyristor fault indication<br />

Unique fault indication to the individual thyristor level.<br />

Starting from Diesel Generator<br />

Wide 45–65Hz auto-tracking frequency range combining special software with unique hardware arrangement<br />

(designed for marine, offshore and generators operating under continuous frequency variation).<br />

Synchronous motor starting<br />

Highly sophisticated optional module allows for synchronous motor starting.<br />

| Line and bypass contactors are vacuum contactors or vacuum circuit breaker.<br />

| The contactors are fi xed mouted.<br />

| The contactors provide the DOL start option.<br />

COMMUNICATION RS 485<br />

RS 485 with MODBUS or PROFIBUS<br />

protocol enable:<br />

f<br />

| Remote (start, stop, etc.)<br />

| Monitoring (motor current, faults,<br />

statistical data)<br />

MEDIUM VOLTAGE SOFT STARTERS<br />

Multi-motor starting<br />

Unique Multi-motor program allows for<br />

more than one motor to be started with the<br />

same soft starter.<br />

MSR<br />

ISA-HD<br />

MSR<br />

M<br />

MSR<br />

| Remote parameter setting<br />

| Remote reset<br />

M<br />

MSR<br />

M<br />

MSR<br />

M<br />

MEDIUM<br />

VOLTAGE<br />

TECHN.<br />

7

ISA-HD<br />

8<br />

MEDIUM VOLTAGE SOFT STARTERS<br />

Range 60 – 2 000 A and 1500 – 15 000 V<br />

ISA-HD<br />

Digital medium voltage soft starters<br />

ADVANTAGES AT A GLANCE<br />

| Heavy duty design, 50°C ambient<br />

temperature<br />

| Comprehensive motor protection package<br />

| IP 32 standard, IP 54 optional<br />

| Synchronous motor starting, utilizing<br />

unique module<br />

| Innovative low voltage test mode – full<br />

testing with a small low voltage motor<br />

using standard built-in features<br />

| Advanced electronic potential transformer<br />

utilizing patent pending “wireless“ voltage<br />

measurement system<br />

| Unique, patent pending fi ber-optic fi ring<br />

system providing complete isolation<br />

between MV and LV compartments<br />

| Each starter is tested for partial discharge<br />

(Korona) improving safety and ensuring<br />

long term reliability<br />

| Wide 45 Hz – 65 Hz auto-tracking frequency<br />

range combining special software with<br />

unique hardware arrangement (design for<br />

marine, offshore and generators operating<br />

under continuous frequency variation)<br />

SWITCHGEAR OPTIONS<br />

| Line vacuum contactor<br />

| Bypass vacuum contactor<br />

| Control voltage: 110 V – 220 V AC, 110 V DC<br />

| Special thick paint<br />

| Multi cable transit (MCT)<br />

| Fan system – increased cooling<br />

| Tin plated busbars<br />

| Halogen free and fi re retardant materials<br />

| Main switch (on-load or off-load)<br />

| Main fuses (with striker-pin indication)<br />

Mulit-Motor-MCC formation with redundant supply<br />

Medium voltage MCC formation with load make fault break switches<br />

IEC 62271-200 type tested!<br />

| Motor Protection Relay (MSR-HD)<br />

| C/T‘s and P/T‘s<br />

| Digital Power Meter (DMA)<br />

| Low voltage control devices (selector<br />

switch, push button, indication lights etc.)<br />

| IP 32 to IP 65<br />

| Segregrated customer terminal section with<br />

cabinet light<br />

| IEC internal arc test up to 31,5 kA<br />

| IEC short circuit test up to 31,5 kA

APPLICATIONS<br />

Marine and Offshore<br />

| Water and ballast pumps<br />

| Refrigeration chillers and compressors<br />

| Hydraulic pumps and power packs<br />

| Thrusters<br />

| Main propulsion motors<br />

| Cargo pumps<br />

| Generator ready – auto frequency tracking<br />

System voltage<br />

V<br />

Current<br />

A<br />

Motor<br />

kW<br />

Dimensions (mm)<br />

W H D<br />

Weight<br />

(kg)<br />

2300<br />

60, 110, 200, 320, 400, 600, 700, 800, 1000, 1200 200 – 4030 270 – 5440 900 2300 1000 – 1100 500 – 1200<br />

3300 60, 110, 200, 320, 400, 600, 700, 800, 1000, 1200 280 – 5780 370 – 7800 900 2300 1000 – 1100 550 – 1250<br />

4160 60, 110, 200, 320, 400, 600, 700, 800, 1000, 1200 360 – 7290 480 – 9840 900 2300 1000 – 1200 550 – 1300<br />

6000 70, 140, 250, 300, 400, 500, 600, 700, 800, 1000, 1200 610 – 10520 820 – 14200 1100 – 1500 2300 1100 – 1500 850 – 1350<br />

6600 70, 140, 250, 300, 400, 500, 600, 700, 800, 1000, 1200 670 – 11570 900 – 15610 1100 – 1500 2300 1100 – 1500 850 – 1350<br />

10000 70, 140, 250, 300, 400, 500, 600, 700, 800, 1000, 1200 1020 – 17540 1370 – 23670 2400 – 3500 2300 1200 – 1400 2100 – 2800<br />

11000 70, 140, 250, 300, 400, 500, 600, 700, 800, 1000, 1200 1120 – 19290 1510 – 26040 2400 – 3500 2300 1200 – 1400 2100 – 2800<br />

13800 70, 140, 250, 300, 400, 500, 600, 700, 800, 1000, 1200 1410 – 24200 1900 – 32670 2800 – 4200 2300 1200 – 1400 2800 – 3100<br />

15000 70, 140, 250, 300, 400, 500, 600, 700, 800, 1000, 1200 1530 – 26310 2060 – 35510 2800 – 4200 2300 1200 – 1400 3150 – 4200<br />

MOTOR AND SOFT STARTER PROTECTION<br />

| Too many starts<br />

| Long start time<br />

| Elektronic shear-pin (start, run, jam)<br />

| Motor overload<br />

(adjustable tripping characteristic)<br />

| short circuit protection<br />

| Under current<br />

| Unbalanced current<br />

| Ground fault current<br />

| Phase sequence<br />

| Phase loss<br />

| Under/over frequency<br />

| Under/over voltage<br />

| External faults (two separate inputs)<br />

| Shorted SCR<br />

| Wrong Connection<br />

| Starter over temperature<br />

| Power on without start signal<br />

| Open bypass contactor<br />

1) case by case<br />

1)<br />

1)<br />

Industrial<br />

| Pumps<br />

| Compressors and chillers<br />

| Fans and blowers<br />

| Centrifuges<br />

| Hydraulic systems<br />

| Conveyors<br />

| Mills, crusher, shredder<br />

1)<br />

CONTROL<br />

1)<br />

HP<br />

| Multi-function programmable I/O‘s<br />

| Opto-isolated control inputs<br />

| Three change over output relays, 8A/250V AC:<br />

- “Immediate“ upon start,<br />

- “end of acceleration“,<br />

- “fault“ programmalbe as trip or trip-fail safe<br />

| Analogue output 0/4 – 20 mA, 0 – 10 V DC<br />

| RS 485 communication card with modbus/<br />

profi bus protocol<br />

| Touchscreen panel (optional)<br />

| Internal SPS for enhanced data recording<br />

1)<br />

MEDIUM VOLTAGE SOFT STARTERS<br />

1) 1)<br />

STARTING AND STOPPING<br />

| Soft start and soft stop<br />

| Current limit<br />

| Pump control characteristics<br />

| Torque and current control for optimized<br />

starting and stopping<br />

| Dual adjust<br />

| Pulse start (kick start)<br />

| Tacho feedback (option)<br />

Additional customised and special cabinet options<br />

are shown separately on pages 26–27 of this catalogue!<br />

9<br />

ISA-HD

LOW<br />

VOLTAGE<br />

TECHN.<br />

10<br />

LOW VOLTAGE<br />

LOW VOLTAGE<br />

LOW VOLTAGE TECHNOLOGY<br />

BYPASS<br />

The product lines ISA-B, -A, -A2P and -DS include an internal bypass.<br />

| This reliable components bypass the power electronics after the motor is at speed.<br />

| In addition the starters provide an auxiliary contact, allowing signaling of a successful motor start.<br />

(Many of our competitors call these auxiliary relays “a bypass contact“!)<br />

| The bypass function reduces the heat dissipation and eliminates the EMC load of the system.<br />

| As an option, ISA-DS series can be designed for DOL-start (available from ISA-DS 390).<br />

ANALOGUE<br />

The analogue product line provides simple potentiometer settings for all the parameters:<br />

| Familiar setting, similar to standard overload relays<br />

| Easy commissioning<br />

| Prior knowledge is not necessary<br />

| Status display via LEDs<br />

| ISA-A and ISA-A2P include motor protection functions<br />

CURRENT LIMIT<br />

The voltage increases linearly from the “Initial Voltage“ pre selected point. If the adjusted “Current Limit“ is reached, the voltage will<br />

stop ramping and remain at its level until the current is reduced below the adjusted “Current Limit“ level. In that case ramp up time<br />

is prolonged until the current has reduced below “Current Limit“ level.<br />

U<br />

U N<br />

U S<br />

t 1<br />

Soft starter output voltage<br />

t<br />

/ S<br />

/<br />

/ DOL<br />

/ N<br />

Current profile<br />

t<br />

When a motor starts with current limit, although<br />

the current is limited the motor provides<br />

suitable torque to accelerate the <strong>drive</strong>n<br />

load and reach “End of acceleration“. If<br />

the motor torque does not exceed the load<br />

torque the motor will not start. In these rare<br />

cases severe damages might occur to the<br />

motor and starter.<br />

The oscillogram shows, that the soft starter<br />

provides a smooth and stepless current and<br />

voltage ramp to the motor. Starting with the<br />

initial voltage which defi nes the starting<br />

current, the voltage ramps up until “Current<br />

Limit“ is reached. After the motor is at speed,<br />

the current will decrease, to the nominal motor<br />

current. The oscillogram shows a clear increasing<br />

voltage and current signal, thus, no<br />

spikes stressing the grid are present.<br />

Motor start measured with an oscilloscope<br />

(Ch1, voltage; Ch2-4 current L1 – L3)

PUMP CONTROL<br />

Our digital Soft Starters line of products ISA-D, ISA-DS and ISA-HD provide an advanced microprocessor based control algorithm, enabling<br />

the sophisticated pump control feature. The motor torque is continuously monitored to eliminate peak torque from stressing the motor,<br />

pump and pipe system. These soft starters provide 3 fi eld selectable pump control algorithms.<br />

Pump and special load control<br />

Two major problems are associated with starting and stopping of pumps.<br />

Voltage<br />

Area of<br />

Pump Control<br />

(Start Curve)<br />

Voltage<br />

Time<br />

Area of Pump<br />

Control (Start Curve)<br />

Standard ramp down<br />

Tu<br />

Ts<br />

Torque<br />

0<br />

1<br />

2<br />

3<br />

ISA-D OPTIONS<br />

Speed<br />

Curves<br />

Deceleration<br />

TECHNOLOGY<br />

Choice of three pump<br />

control and torque<br />

deceleration curves<br />

DOL Speed<br />

0<br />

1<br />

2<br />

3<br />

4, 5<br />

0 1 2 3 4 5<br />

4<br />

Extended Time<br />

Final<br />

Torque<br />

TECHNOLOGY VARIABLE FREQUENCY DRIVE (VFD)<br />

FREQUENCY CONVERTER<br />

LOW VOLTAGE<br />

Over-pressure during starting<br />

The sharp increase of torque towards the end of acceleration can cause high pressure and<br />

damage the pipe system. The pump control enables selection between three voltage ramp-up<br />

curves as well as torque curve to reduce peak torque. Current ramp is available for special loads.<br />

Water hammer during stopping<br />

During soft stop, when voltage is decreasing, motor torque may fall below load torque causing<br />

abrupt stalling instead of smoothly decreasing speed to zero. This creates the ”water hammer“<br />

phenomenon (resulting in a loud noise and damage to the pipe system). The pump control<br />

algorithm enables selection between three voltage ramp-down curves or torque curve preventing<br />

stall condition and eliminating water hammer.<br />

Analogue option card<br />

| Function 1: Thermistor-input, PTC or NTC<br />

| Function 2: Analogue-output, based on the motor current, programmable from 0 – 10 VDC, 4 – 20 mA, 0 – 20 mA or inverted<br />

Motor insulation option card<br />

This unique feature guarantees the availability of important plant components, such as fi re-extinguishing systems, redundant systems as well as submersible<br />

pumps. The system measures the motor insulation level while the motor is not in operation. Two programmable steps are available:<br />

| Alarm-Level, adjustable 0,2 – 5 MOhm<br />

| Start inhibit, adjustable 0,2 – 5 MOhm, avoids motor starting if the insulation is below the critical level.<br />

VFD‘s provide variable output frequencies, thus, allowing variable motor speeds independent of the input frequency, while saving energy<br />

with appropriate voltge and current levels to the motor.<br />

| Speed control is either local, via communication or through an external analog input<br />

| Programmable start/stop ramp functions<br />

| Unique and cost effective product selection quadratic torque (fan/pump) or constant torque (conveyor)<br />

EMC<br />

Electronic components cause electronic noise. To guarantee fl awless long term operation, line fi lters are implemented. These devices<br />

reduce interferences to a permitted level specifi ed by international standards.<br />

| According to European standard EN 13320<br />

| High level attenuation<br />

| Small foot space, for space-saving assembly<br />

| Chokes avoid voltage spikes caused by high frequency operation of modern semiconductor components.<br />

| Sinus fi lters enable long- or unshielded motor cables while running with a VFD.<br />

| Limitation of the du/dt values<br />

| Limitation of interferences to parallel cables<br />

| Extended lifetime and effi ciency of motors operated with VFD’s<br />

EMC<br />

LOW<br />

VOLTAGE<br />

TECHN.<br />

11

ISA-D<br />

12<br />

LOW VOLTAGE SOFT STARTERS<br />

Range 8 – 3 500 A and 200 – 1 000 V<br />

ISA-D<br />

Digital soft starters<br />

in heavy duty design<br />

ADVANTAGES AT A GLANCE<br />

| Superior starting and stopping characteristics<br />

| Comprehensive motor protection package<br />

| Easy commissioning<br />

| Complete line 8 – 3 500 A, 220 – 1 000 V<br />

| Heavy duty design<br />

| Robust construction<br />

| Standard ambient temperature: 50°C<br />

| Unique optional features including:<br />

- Motor insulation tester<br />

- RS 485 Modbus/Profi bus<br />

- Thermistor input /analogue output<br />

DISPLAYS (LED‘S)<br />

| LCD – 2 lines of 16 characters each<br />

| Selectable languages – english, german,<br />

french and spanish<br />

| 8 LEDs for quick indication status<br />

| Two display modes for basic and advanced<br />

applications<br />

| Friendly operation with default parameters<br />

| Statistic data including: total run time,<br />

total number of starts, total number of trips,<br />

last start-current, last start time, last trip,<br />

current at trip<br />

MOTOR AND STARTER PROTECTION<br />

| Compare to ISA-DS (p. 13)!<br />

STARTING AND STOPPING<br />

| Soft start and soft stop<br />

| Current limit<br />

| Pump control program<br />

| Torque and Current Control for optimized<br />

starting and stopping process<br />

| Dual adjustments – two starting and<br />

stopping characteristics<br />

| Pulse start<br />

| Slow speed with electronic reversing<br />

| Linear acceleration (tacho feedback)<br />

| Energy save for improved power factor<br />

OPTIONS<br />

| RS 485 Communication (details p. 7)<br />

| Analogue output (details p. 10)<br />

| Thermistor input<br />

| Motor insulation test<br />

| Preparation for bypass – to maintain<br />

protection when bypass is closed<br />

| Special anti-corrosive treatment – special<br />

coating for harsh enviroments<br />

| Illuminated LCD<br />

| Special tacho feedback<br />

| Remote display<br />

RELAY OUTPUT<br />

3 programmalbe change-overcontacts:<br />

| Operation with adjustable on- and<br />

off delay<br />

| End of acceleration– with adjustable<br />

time delay<br />

| Fault, programmable as fail save connection<br />

| Motor-isolation alarm<br />

APPLICATIONS ISA-D AND ISA-DS<br />

Industrial applications<br />

| Pumps<br />

| Hydraulic systems<br />

| Fans and blowers<br />

| Compressors<br />

| Conveyors<br />

1 000 V for mining applications<br />

| Pumps<br />

| Blowers<br />

| Conveyors<br />

KW<br />

at<br />

400V<br />

Starter<br />

Type<br />

(A)<br />

Dimensions<br />

(mm)<br />

W H D<br />

Weight<br />

(kg)<br />

4 ISA-D 8 153 310 170 4,5<br />

7,5 ISA-D 17 153 310 170 4,5<br />

15 ISA-D 31 153 310 217 6,8<br />

22 ISA-D 44 153 310 217 7,5<br />

30 ISA-D 58 153 310 217 7,5<br />

37 ISA-D 72 153 310 217 7,5<br />

45 ISA-D 85 274 385 279 15<br />

55 ISA-D 105 274 385 279 15<br />

75 ISA-D 145 274 385 279 15<br />

90 ISA-D 170 274 385 279 15<br />

110 ISA-D 210 590 500 292 31<br />

160 ISA-D 310 590 500 292 31<br />

200 ISA-D 390 590 500 292 31<br />

250 ISA-D 460 623 660 290 65<br />

315 ISA-D 580 623 660 290 65<br />

450 ISA-D 820 623 660 290 65<br />

525 ISA-D 950 623 660 290 65<br />

630 ISA-D 1100 723 1100 370 170<br />

800 ISA-D 1400 723 1100 370 170<br />

950 ISA-D 1800 723 1100 370 170<br />

1250 ISA-D 2150 750 1300 392 235<br />

1350 ISA-D 2400 900 1300 360 350<br />

1750 ISA-D 2700 900 1300 360 350<br />

1850 ISA-D 3000 900 1300 360 350<br />

2000 ISA-D 3500 900 1300 360 350<br />

1) case by case<br />

1)<br />

1) 1)

Marine and Offshore<br />

| Complete line 8 – 3 500 A, 220 – 1 000 V<br />

| Heavy duty, fully rated design<br />

| Robust construction<br />

| Generator ready – auto frequency<br />

tracking, enables motor starting<br />

at 45 – 65 Hz<br />

| User friendly operation<br />

| Unique protection for corrosive<br />

enviroments<br />

Range 8 – 1100 A and 200 – 690 V<br />

ISA-DS<br />

Digital soft starter with a built-in bypass<br />

ADVANTAGES AT A GLANCE<br />

| Superior starting and stopping characteristics<br />

| Comprehensive motor protection package<br />

| Easy commissioning<br />

| Fully equiped starters<br />

| Small foot print<br />

| Third generation microprocessor based<br />

design<br />

| Built-in bypass<br />

| RS 485 Communication<br />

| Frequency autotracking: 45 – 65 Hz<br />

| Unique optional features including:<br />

Analogue output and additional<br />

enhancements<br />

DISPLAYS (LED‘S)<br />

| LCD – 2 lines of 16 characters each<br />

| Selectable languages – english, german,<br />

french and spanish<br />

| 4 LEDs – On, Run, Ramp up/down and fault<br />

| Statistical data: start, stop and fault<br />

parameters<br />

| Full script parameter settings<br />

CONTROLS<br />

| Opto isolated inputs<br />

| Auxiliary relays: fault, end of acceleration<br />

or immediate (programmable)<br />

| Local and remote reset<br />

| RS 485 Modbus Communications for full<br />

control, display and programming<br />

| Future enhancements: analogue I/O card<br />

with thermistor input<br />

STARTING AND STOPPING<br />

| Soft start and soft stop<br />

| Current limit<br />

| Pump control program<br />

| Torque and Current Control for optimized<br />

starting and stopping process<br />

| Dual adjustments – two starting and<br />

stopping characteristics<br />

| Pulse start<br />

| Slow speed with electronic reversing<br />

OPTIONS<br />

| RS 485 Communication<br />

| Analogue output<br />

| Thermistor input<br />

| Special anti-corrosive treatment – special<br />

coating for harsh enviroments<br />

| Remote display<br />

| Ex-approvals and certifi cations<br />

MOTOR AND STARTER PROTECTION<br />

| Too many starts<br />

| Shear Pin (start, run, jam)<br />

| Electronic overload with selectable curves<br />

| Under current<br />

| Phase loss and phase sequence<br />

| Under, over and no voltage<br />

| Load loss (motor not connected)<br />

| Thyristor bypass<br />

| Starter over-temperature<br />

| External fault (input programmable)<br />

| Thyristor protection by varistors<br />

KW<br />

at<br />

400V<br />

LOW VOLTAGE SOFT STARTERS<br />

Starter<br />

Type<br />

(A)<br />

Dimensions<br />

(mm)<br />

W H D<br />

Weight<br />

(kg)<br />

4 ISA-DS 8 120 232 122 3,1<br />

7,5 ISA-DS 17 120 232 122 3,1<br />

15 ISA-DS 31 120 232 122 3,1<br />

22 ISA-DS 44 120 232 122 3,1<br />

30 ISA-DS 58 129 275 182 5,3<br />

37 ISA-DS 72 129 275 182 5,3<br />

45 ISA-DS 85 129 380 182 8,6<br />

55 ISA-DS 105 129 380 182 8,6<br />

75 ISA-DS 145 172 380 192 11,7<br />

90 ISA-DS 170 172 380 192 11,7<br />

110 ISA-DS 210 380 455 295 30,2<br />

160 ISA-DS 310 380 455 295 30,2<br />

200 ISA-DS 390 350 550 310 31<br />

250 ISA-DS 460 460 643 319 65<br />

315 ISA-DS 580 460 643 319 65<br />

450 ISA-DS 820 460 643 319 65<br />

525 ISA-DS 950 560 833 334 170<br />

630 ISA-DS 1100 560 833 334 170<br />

Special approved soft<br />

starters available for<br />

the Ex-area!<br />

13<br />

ISA-DS

ISA-A<br />

ISA-A2P<br />

14<br />

LOW VOLTAGE SOFT STARTERS<br />

Range 8 – 170 A and 230 – 600 V<br />

ISA-A and ISA-A2P<br />

Analogue soft starter with motor protection and built-in bypass<br />

ADVANTAGES AT A GLANCE<br />

| Soft start and soft stop<br />

| Current limit<br />

| Build-in motor protection<br />

| Build-in bypass<br />

| Start/stop by dry contact<br />

| Compact, small foot print<br />

| Aluminum housing<br />

| Integrated input voltage monitoring<br />

MOTOR AND STARTER PROTECTION<br />

| Electronic overload<br />

| Phase loss<br />

| Starter over-temperature<br />

| SCR protection by metal oxide varistors<br />

DISPLAYS (LED‘S)<br />

| On – mains voltage connected<br />

| Ramp up/down<br />

| Run<br />

| Overload<br />

| Phase loss<br />

| Over temperature<br />

AUXILIARY RELAYS<br />

| End of acceleration relay, N.O contact<br />

| Fault relay, N.O contact<br />

| Over temperature<br />

ISA-A<br />

KW<br />

at<br />

400V<br />

Starter<br />

Type<br />

(A)<br />

Dimensions<br />

(mm)<br />

W H D<br />

Weight<br />

(kg)<br />

4 ISA-A 8 120 232 105 2,6<br />

7,5 ISA-A 17 120 232 105 2,6<br />

15 ISA-A 31 120 232 105 2,6<br />

22 ISA-A 44 120 232 105 2,6<br />

30 ISA-A 58 129 275 185 5<br />

37 ISA-A 72 129 275 185 5<br />

45 ISA-A 85 129 380 185 8,4<br />

55 ISA-A 105 129 380 185 8,4<br />

75 ISA-A 145 172 380 195 11,8<br />

90 ISA-A 170 172 380 195 11,8<br />

ISA-A2P<br />

KW<br />

at<br />

400V<br />

Starter<br />

Type<br />

(A)<br />

Dimensions<br />

(mm)<br />

W H D<br />

Weight<br />

(kg)<br />

15 ISA-A2P 31 65 190 114 1,4<br />

22 ISA-A2P 44 65 190 114 1,4<br />

30 ISA-A2P 58 120 265 121 3,5<br />

37 ISA-A2P 72 120 265 121 3,5<br />

45 ISA-A2P 85 120 265 121 3,5<br />

55 ISA-A2P 105 120 265 121 3,5<br />

75 ISA-A2P 145 129 275 182 6,5<br />

90 ISA-A2P 170 129 275 182 6,5<br />

3-phase control (ISA-A und ISA-B)<br />

APPLICATIONS<br />

L 1 L2 L 3<br />

U V W<br />

| Pumps<br />

| Compressors<br />

| Fans<br />

| Blowers<br />

| Conveyors<br />

| Starting from weak power supplies<br />

(diesel generators etc.)

Range 8 – 58 A and 230 – 600 V<br />

ISA-B* und ISA-B2P<br />

Basic soft starter with built-in bypass<br />

2-phase (ISA-A2P and ISA-B2P) ADVANTAGES AT A GLANCE<br />

APPLICATIONS<br />

L L L<br />

1 2 3<br />

U V W<br />

| Pumps<br />

| Compressors<br />

| Fans<br />

| Conveyors<br />

| Light duty motors in industrial applications<br />

| Small conveyors (supermarkets etc.)<br />

| <strong>Electric</strong>ally <strong>drive</strong>n gates<br />

| Machine tools and appliances<br />

* high volume orders only<br />

| Soft start and soft stop<br />

| Build-in bypass<br />

| Start/stop by dry contact<br />

| End of acceleration relay, N.O contact<br />

| Compact, small foot print<br />

| DIN rail mounting<br />

(partly option)<br />

ISA-B2P<br />

KW<br />

at<br />

400V<br />

Starter<br />

Type<br />

(A)<br />

OUTPUT RELAYS<br />

| End of acceleration<br />

Dimensions<br />

(mm)<br />

W H D<br />

Weight<br />

(kg)<br />

4 ISA-B2P 8 45 75 105 0,5<br />

7,5 ISA-B2P 17 90 75 105 0,6<br />

11 ISA-B2P 22 90 75 105 0,6<br />

15 ISA-B2P 31 65 190 114 1,3<br />

22 ISA-B2P 44 65 190 114 1,3<br />

30 ISA-B2P 58 65 190 114 1,3<br />

37 ISA-B2P 72 120 265 121 3,0<br />

45 ISA-B2P 85 120 265 121 3,0<br />

55 ISA-B2P 105 120 265 121 3,0<br />

75 ISA-B2P 145 129 275 182 5,0<br />

90 ISA-B2P 170 129 275 182 5,0<br />

KW<br />

at<br />

400V<br />

LOW VOLTAGE SOFT STARTERS<br />

STARTER PROTECTION<br />

| SCR protection by metal oxide varistors<br />

DISPLAYS (LED‘S)<br />

| On – mains voltage connected<br />

| Ramp – voltage is ramping up/down<br />

(only ISA-B2P)<br />

| Run – motor is running (only ISA-B2P)<br />

ISA-B*<br />

Starter<br />

Type<br />

(A)<br />

Dimensions<br />

(mm)<br />

W H D<br />

Weight<br />

(kg)<br />

4 ISA-B 8 65 190 114 1,2<br />

7,5 ISA-B 17 65 190 114 1,2<br />

15 ISA-B 31 120 207 105 2,1<br />

22 ISA-B 44 120 207 105 2,1<br />

30 ISA-B 58 120 207 105 2,1<br />

OEM SOFTSTARTER<br />

Customised special solutions available<br />

on inquiry!<br />

ISA-B<br />

ISA-B2P<br />

15

ISA-<br />

DRIVE-VT<br />

16<br />

VARIABLE FREQUENCY DRIVE<br />

Range 7 – 300 A and 230 – 525 V<br />

ISA-DRIVE-VT<br />

Variable torque for fan and pump applications<br />

ADVANTAGES AT A GLANCE<br />

| 50°C ambient temperatur without<br />

de-rating<br />

| Fast setup with only 14 basis parameter<br />

| Internal PID-controller<br />

| Two interfaces:<br />

- Optical (IvDA) interface<br />

- RS 485/Modbus RTU<br />

| Programming by PDA or PC<br />

| Internal EMC-fi lter<br />

MOTOR- AND DRIVE PROTECTION<br />

| Overload protection 110 %/min<br />

| Over- and undervoltage<br />

| Catch option after voltage outage<br />

| Ixt protection above 100% rated current<br />

DISPLAYS (LED‘S)<br />

| 3 digits; 7-segment display<br />

I/O FEATURES<br />

| 3 digital inputs and outputs<br />

| 2 analogue inputs and 1 analogue output<br />

IP 55 high level protection<br />

inclusive reverse operation<br />

line switch and external<br />

speed control.<br />

ISA-DRIVE-<br />

VT-<br />

Motor rated<br />

power (kW)<br />

Mains Voltage/<br />

Phases (V+/10%)<br />

Line fuse<br />

(A)<br />

Output Voltage/<br />

Phases (V)<br />

Rated Current<br />

(A)<br />

Max. Motor<br />

Cable Length (m)<br />

Min. Braking<br />

Resistance (Ω)<br />

ISA-DRIVE-<br />

VT-<br />

Motor rated<br />

power (kW)<br />

Mains Voltage/<br />

Phases (V+/10%)<br />

Line fuse<br />

(A)<br />

Output Voltage/<br />

Phases (V)<br />

Rated Current<br />

(A)<br />

Max. Motor<br />

Cable Length (m)<br />

Min. Braking<br />

Resistance (Ω)<br />

15-230<br />

22-230<br />

30-230<br />

40-230<br />

55-230<br />

75-230<br />

110-230<br />

1,5 2,2 3,0 4,0 5,5 7,5 11 15 18,5 22 30 37 45<br />

220-240/1PH<br />

150-230<br />

185-230<br />

220-240/3PH or 1PH<br />

(with 50% power reduction)<br />

20 30 32 32 50 80 80-<br />

100<br />

100<br />

0-240/3PH<br />

15-400<br />

100-<br />

125<br />

220-230<br />

300-230<br />

370-230<br />

160 200 250-<br />

300<br />

450-230<br />

250-<br />

300<br />

7 10,5 14 18 25 39 46 61 72 90 110 150 180<br />

33 22 15 15 15 6 6 6 6 6 3 3 3<br />

22-400<br />

40-400<br />

55-400<br />

75-400<br />

110-400<br />

150-400<br />

185-400<br />

220-400<br />

100<br />

1,5 2,2 4 5,5 7,5 11 15 18,5 22 30 37 45 55 75 90 110 132 160<br />

300-400<br />

380–480/3PH<br />

10 10 20 32 32 50 50 80 80-<br />

100<br />

370-400<br />

100 100-<br />

125<br />

380–480/3PH<br />

450-400<br />

550-400<br />

750-400<br />

900-400<br />

1100-400<br />

1320-400<br />

1600-400<br />

160 200 250- 250- 315 350 400<br />

300 300<br />

4,1 5,8 9,5 14 18 25 30 39 46 61 72 90 110 150 180 202 240 300<br />

100<br />

47 47 33 22 22 22 22 12 12 12 12 12 6 6 6 6 6 6

Range 7 – 300 A and 230 – 525 V<br />

ISA-DRIVE-PLUS<br />

Latest sensorless vector control<br />

ADVANTAGES AT A GLANCE<br />

| 50°C ambient temperatur without<br />

de-rating<br />

| Fast setup with only 14 basis parameter<br />

| Internal PID-controller<br />

| 100 % torque at 0 Hz (without encoder)<br />

| Two interfaces:<br />

- Optical (IvDA) interface<br />

- RS 485/Modbus RTU<br />

| Programmable by PDA or PC<br />

| Torque control<br />

| Autotuning on motor data<br />

MOTOR- AND DRIVE PROTECTION<br />

| Overload protection 150 %/min<br />

| Over- and undervoltage<br />

| Catch option after voltage outage<br />

| Ixt protection above 100 % rated current<br />

DISPLAYS (LED‘S)<br />

| 3 digits; 7-segment display<br />

I/O FEATURES<br />

| Programmable I/O<br />

| 3 digital inputs<br />

| 2 analogue inputs<br />

| 3 digital output<br />

| 1 analogue output<br />

ISA-DRIVE-<br />

PLUS-<br />

4-230<br />

8-230<br />

15-230<br />

22-230<br />

30-230<br />

40-230<br />

55-230<br />

75-230<br />

VARIABLE FREQUENCY DRIVE<br />

Motor rated<br />

power (kW)<br />

0,37 0,75 1,5 2,2 3,0 4,0 5,5 7,5 11 15 18,5 22 30 37 45 55 75 90<br />

Mains Voltage/<br />

Phases (V+/10%)<br />

220-240/1PH<br />

220-240/3PH or 1PH<br />

(50% power reduction)<br />

Line fuse<br />

(A)<br />

6-10 10 20 30 32 32 50 50 80- 100<br />

100-<br />

160 200 250- 250- 315-<br />

100 125 300 300 350<br />

400 450-<br />

500<br />

Output Voltage/<br />

Phases (V)<br />

0-240/3PH<br />

Rated Current<br />

(A)<br />

2,3 4,3 7 10,5 14 18 25 30 46 61 72 89 110 150 180 202 240 300<br />

Max. Motor<br />

Cable Length (m)<br />

25 25<br />

100<br />

Min. Braking<br />

Resistance (Ω)<br />

33 22 15 15 15 15 6 6 6 3 3 3 3 3 3 3<br />

ISA-DRIVE-<br />

PLUS-<br />

8-400<br />

15-400<br />

22-400<br />

40-400<br />

55-400<br />

75-400<br />

110-400<br />

150-400<br />

Motor rated<br />

power (kW)<br />

0,75 1,5 2,2 4,0 5,5 7,5 11 15 18,5 22 30 37 45 55 75 90 110 132 160<br />

Mains Voltage/<br />

Phases (V+/10%)<br />

380-480/3PH<br />

Line fuse<br />

(A)<br />

6-10 10 10 20 32 32 50 50 80 80- 100<br />

100-<br />

160 200 250- 250- 315- 400 450-<br />

100 125 300 300 350 500<br />

Output Voltage/<br />

Phases (V)<br />

0-480/3PH<br />

Rated Current<br />

(A)<br />

2,2 4,1 5,8 9,5 14 18 25 30 39 46 61 72 90 110 150 180 202 240 300<br />

Max. Motor<br />

Cable Length (m)<br />

50<br />

100<br />

Min. Braking<br />

Resistance (Ω)<br />

47 47 47 33 22 22 22 22 12 12 12 12 6 6 6 6 6 6 6<br />

185-400<br />

110-230<br />

220-400<br />

150-230<br />

300-400<br />

185-230<br />

370-400<br />

220-230<br />

450-400<br />

300-230<br />

550-400<br />

370-230<br />

750-400<br />

450-230<br />

900-400<br />

550-230<br />

1100-400<br />

750-230<br />

1320-400<br />

900-230<br />

1600-400<br />

ISA-<br />

DRIVE-PLUS<br />

17

ISA-<br />

DRIVE-E<br />

18<br />

VARIABLE FREQUENCY DRIVE<br />

Range 1,5 – 33 A and 220 – 480 V<br />

ISA-DRIVE-E<br />

Robust VFD for industrial applications<br />

ADVANTAGES AT A GLANCE<br />

| 50°C ambient temperatur without<br />

de-rating<br />

| IP 20<br />

| Internal PID-controller<br />

| Programmable digital inputs<br />

| Vektor controlled<br />

| Programming by PDA or PC<br />

| Comprehensive accessories<br />

ISA-DRIVE-E-<br />

Motor Capacity<br />

(kW)<br />

Mains Voltage/<br />

Phases (V+/10%)<br />

Max. Input<br />

Current (A)<br />

Output Voltage/<br />

Phases (V)<br />

Rated Current<br />

Output (A)<br />

Frequency<br />

Domain (Hz)<br />

Switching<br />

Frequency (kHz)<br />

2-230<br />

4-230<br />

8-230<br />

15-230<br />

22-230<br />

MOTOR- AND DRIVE PROTECTION<br />

| Overload protection 150 %/min<br />

| Over- and undervoltage<br />

| Under current<br />

| PTC resistor<br />

| Output short-circuit safe<br />

| Jam-protection<br />

| Start options after voltage outage<br />

0,2 0,4 0,75 1,5 2,2 3,7 5,5 7,5 0,4 0,75 1,5 2,2 3,7 5,5 7,5 11<br />

1,9 2,7 5,1 9 15 20,6 26 34 1,9 3,2 4,3 7,1 11,2 14 19 26<br />

3PH 0 ˜ 230V<br />

1,6 2,5 4,2 7,5 11 17 25 33 1,5 2,5 4,2 5,5 8,2 13 18 24<br />

4-400<br />

8-400<br />

15-400<br />

22-400<br />

37-400<br />

230/3PH 400/3PH<br />

0,1–600<br />

1–15<br />

37-230<br />

55-230<br />

75-230<br />

3PH 0 ˜ 400V<br />

0,1–600<br />

1–15<br />

55-400<br />

75-400<br />

110-400<br />

I/O FEATURES<br />

| 6 programmable digital inputs<br />

| 1 programmable digital output<br />

| Analogue setpoint input<br />

| 2 multi function output relays<br />

DISPLAYS (LED‘S)<br />

| 4 digits; 7-segment display<br />

| 5 Status-LEDs<br />

APPLICATIONS

Range 3,7 – 400 A and 220 – 480 V<br />

ISA-DRIVE-B and ISA-DRIVE-F<br />

High-End VFD<br />

ADVANTAGES AT A GLANCE<br />

| 50°C ambient temperatur without<br />

de-rating<br />

| 150 % torque at 1Hz<br />

| 5 digital inputs with PLC-function<br />

| Internal PID-controller<br />

| Programming by PDA or PC<br />

| Internal EMC-fi lter<br />

| Autotuning on motor data<br />

| Sensorless vector control (ISA-DRIVE-B)<br />

| Comprehensive accessories<br />

ISA-DRIVE-B- and ISA-DRIVE-F-<br />

ISA-DRIVE-B<br />

ISA-DRIVE-F<br />

ISA-DRIVE-B<br />

ISA-DRIVE-F<br />

ISA-DRIVE-B<br />

ISA-DRIVE-F<br />

ISA-DRIVE-B<br />

ISA-DRIVE-F<br />

ISA-DRIVE-B<br />

ISA-DRIVE-F<br />

ISA-DRIVE-B<br />

ISA-DRIVE-F<br />

ISA-DRIVE-B<br />

ISA-DRIVE-F<br />

Motor Capacity<br />

(kW)<br />

Mains Voltage/<br />

Phases (V+/10%)<br />

Max. Input Current<br />

(A)<br />

Max. Input Current<br />

(A)<br />

Output Voltage/<br />

Phases (V)<br />

Rated Current<br />

Output (A)<br />

Rated Current<br />

Output (A)<br />

Frequency<br />

Domain (Hz)<br />

Frequency<br />

Domain (Hz)<br />

Switching<br />

Frequency (kHz)<br />

Switching<br />

Frequency (kHz)<br />

8-400<br />

15-400<br />

22-400<br />

MOTOR- AND DRIVE PROTECTION<br />

| Overload protection 150 %/min (ISA-DRIVE-B)<br />

| Overload protection 120 %/min (ISA-DRIVE-F)<br />

| Motor stops after blown fuse<br />

| Overvoltage and undervoltage<br />

| Output short-circuit safe<br />

| Jam-protection<br />

| Start options after voltage outage<br />

37-400<br />

55-400<br />

75-400<br />

110-400<br />

150-400<br />

185-400<br />

220-400<br />

300-400<br />

370-400<br />

VARIABLE FREQUENCY DRIVE<br />

I/O FEATURES<br />

| 6 digital inputs with PLC-function<br />

| 5 programmalbe digital outputs<br />

| Analogue setpoint input<br />

DISPLAYS (LED‘S)<br />

| 5 digits; 7-segment display<br />

| 5 status LEDs<br />

0,75 1,5 2,2 3,7 5,5 7,5 11 15 18,5 22 30 37 45 55 75 90 110 132 160 185 220<br />

380 ˜ 480/3PH<br />

3,2 4,3 5,9 11,2 14 19 25 32 39 49 60 63 90 130 160<br />

3,2 4,3 5,9 11,2 14 19<br />

450-400<br />

550-400<br />

25 33 46 56 70 75 95 110 150 180 200 240 300 380 400<br />

3PH 0 ˜ 480V<br />

2,7 4,2 5,5 8,5 13 18 24 32 38 45 60 73 91 110 150<br />

2,7 4,2 5,5 8,5 13 18 24 32 38 45 60 73 91 110 150<br />

0,1–400<br />

0,1–120<br />

1 – 15 1 – 9 1 – 6<br />

4 –10 3 – 9 2 – 6<br />

750-400<br />

900-400<br />

1100-400<br />

1320-400<br />

1600-400<br />

1850-400<br />

2200-400<br />

180 220 260 310 370 460<br />

ISA-DRIVE-B<br />

ISA-DRIVE-F<br />

19

IMB<br />

20<br />

DC INJECTION BRAKE<br />

Range 8 – 390 A and 230 – 600 V<br />

IMB<br />

DC injection brake<br />

ADVANTAGES AT A GLANCE<br />

The IMB electronic motor brake provides fast,<br />

smooth and frictionless stopping of a three<br />

phase induction motor, by injecting controlled<br />

DC current to the motor windings, after the<br />

mains contactor opened.<br />

| Preventing mechanical wear<br />

| Reducing stopping time of high inertia loads<br />

| Adjustable braking time<br />

| Auto stop – DC injection stops when<br />

motor stops<br />

| DIN rail mounting<br />

(Standard 10 A, option 17 – 58 A)<br />

| Easy installation and operation<br />

APPLICATIONS<br />

SETTINGS<br />

| Braking Torque – determines the DC current<br />

level injected to the motor windings<br />

| Two operation modes:<br />

1. Auto Mode:<br />

DC injection stops automatically when motor<br />

stops.<br />

2. Manual Mode:<br />

DC injection stops after the the pre-adjusted<br />

braking time. This mode can be used to<br />

“hold“ the load at stand still.<br />

DISPLAYS (LED‘S)<br />

| On – mains voltage connected<br />

| Braking contactor closed<br />

| DC injection on<br />

| Circular and band saws<br />

| Machine tools<br />

| Fast stopping of high inertia loads<br />

| Emergency stop (as long as mains supply<br />

remains on)<br />

KW<br />

at<br />

400V<br />

Brake<br />

Type<br />

(A)<br />

Dimensions<br />

(mm)<br />

W H D<br />

Weight<br />

(kg)<br />

5* IMB 10 90 75 105 0,5<br />

7,5 IMB 17 65 190 114 1,3<br />

15 IMB 31 65 190 114 1,3<br />

30 IMB 58 65 190 114 1,3<br />

55 IMB 105 154 280 160 5<br />

110 IMB 210 154 280 160 5,4<br />

160 IMB 310 224 384 222 12<br />

200 IMB 390 224 384 222 12<br />

* 5,5 kW at 415V<br />

TECHNOLOGY<br />

Cm<br />

M<br />

Cb<br />

IMB

Range 8 – 1 500 A and 220 – 1 000 V<br />

TSE<br />

Thyristor power supply<br />

ADVANTAGES AT A GLANCE<br />

The sophisticated digital thyristor power<br />

supply allows the stepless regulation of<br />

ohmic loads.<br />

| Analogue setpoint input<br />

| Complete programming and fault<br />

indication with LCD display<br />

| Integrated protection functions<br />

| Two control functions to minimise<br />

interferences<br />

| Steady power output also if one heating<br />

element is faulty.<br />

| Easy installation and easy operation<br />

APPLICATIONS<br />

| Extruder<br />

| Pipe heating<br />

| Lightings<br />

| All kinds of furnances<br />

| Oil heating devices<br />

| <strong>Electric</strong> heatinig elements<br />

FUNCTIONS<br />

| Digital parameter input<br />

| Master/Slave operation<br />

| Phase control or zero crossing (pulse)<br />

| Programmable output relay<br />

| Programmable set point input<br />

| Maintenance- free operation<br />

| Unlimited switching operations<br />

| RS 485-interface<br />

DISPLAYS (LED‘S)<br />

| LEDs for quick status overview<br />

| LCD – 2 lines, 16 characters<br />

| Paremeter input and fault output in full<br />

wording<br />

PROTECTION FUNCTIONS<br />

| Under current and over current<br />

| Phases unbalance<br />

| Under voltage and over voltage<br />

| Phase loss<br />

| Ground fault<br />

| Over power and under power limit exceeded<br />

| External failure<br />

| Connection control<br />

TSE Type FLC<br />

(A)<br />

Dimensions (mm)<br />

W H D<br />

Weight<br />

(kg)<br />

TSE 8 8 172 275 192 6,3<br />

TSE 17 17 172 275 192 6,3<br />

TSE 31 31 172 275 192 6,4<br />

TSE 44 44 172 275 192 6,5<br />

TSE 58 58 172 275 192 6,5<br />

TSE 72 72 172 275 192 6,5<br />

TSE 85 85 172 380 192 8,5<br />

TSE 105 105 172 380 192 8,5<br />

TSE 145 145 274 385 238 14,5<br />

TSE 170 170<br />

TSE 210 210<br />

TSE 310 310 380 455 295 31<br />

TSE 390 390<br />

THYRISTOR POWER SUPPLY<br />

274 385 238 14,5<br />

274 385 238 14,5<br />

380 455 295 31<br />

TSE 460 460 380 555 295 51<br />

TSE 580 580 470 655 302 53<br />

TSE 820 820 470 655 302 53<br />

TSE 950 950 on request<br />

TSE 1100 1100 on request<br />

TSE 1500 1500 on request<br />

21<br />

TSE

LINE<br />

FILTER<br />

22<br />

EMC-TECHNOLOGY<br />

Range 7 – 2 500 A and 230 – 690 V<br />

Line fi lter<br />

NF-K and NF-K-IT (Three-phase-fi lter)<br />

ADVANTAGES AT A GLANCE<br />

| Current ratings from 7 – 2500 A<br />

| High attenuation from 150 kHz to 30 Mhz<br />

| Small dimensions (bookstyle) and low weight<br />

| IP20 terminals<br />

| According European Standard EN 133200<br />

TECHNICAL DATA<br />

| Rated voltage: 480 VAC (NF-K), 690 VAC<br />

(NF-K-IT), 48 – 62 Hz<br />

| Rated current: 3-phase, 7 – 2500 A<br />

(see table)<br />

| Overload capability: 4-times rated current<br />

with the turning on, afterwards 1,5-times<br />

rated current for one minute, once per hour<br />

| Construction: according to EN 133200<br />

| Leakage current: see table<br />

| Construction: metal housing<br />

| Mounting: Fixing angles with holes<br />

| Ambient temperatur: 40°C<br />

(50°C without power reduction)<br />

| Terminals: Screw terminals, terminal<br />

cross-section (see table), PE (earthing of the<br />

housing) via screwed end<br />

| Protection class: IP 20<br />

| Dimensions: see table<br />

Typ Rated Rated voltage Leakage Dimensions<br />

Weight<br />

current at (VAC) current (mm)<br />

(kg)<br />

40 °C (A)<br />

(mA) H W D<br />

NF-K-7 7 480<br />

1,0 190 40 70 0,5<br />

NF-K-16 16 480<br />

1,4 250 45 70 0,8<br />

NF-K-30 30 480<br />

1,0 270 50 85 1,0<br />

NF-K-42 42 480<br />

1,2 310 50 85 1,0<br />

NF-K-55 55 480<br />

1,2 250 85 90 1,6<br />

NF-K-55/25 55 480<br />

1,2 250 85 90 1,8<br />

NF-K-75 75 480<br />

1,4 270 80 135 2,4<br />

NF-K-75/50 75 480<br />

1,4 270 80 150 3,4<br />

NF-K-100 100 480<br />

1,4 270 90 150 3,6<br />

NF-K-130 130 480<br />

1,0 270 90 150 3,6<br />

NF-K-180 180 480<br />

1,4 380 120 170 4,2<br />

Type Rated Rated voltage Leakage Dimensions<br />

Weight<br />

(for IT-mains) current at (VAC) current (mm)<br />

(kg)<br />

40 °C (A)<br />

(mA) H W D<br />

NF-K-IT-7 7 690<br />

0,01 190 40 70 0,6<br />

NF-K-IT-16 16 690<br />

0,01 250 45 70 0,9<br />

NF-K-IT-30 30 690<br />

0,01 270 50 85 1,1<br />

NF-K-IT-42 42 690<br />

0,01 310 50 85 1,1<br />

NF-K-IT-55 55 690<br />

0,02 250 85 90 1,8<br />

NF-K-IT-55/25 55 690<br />

0,02 250 85 90 1,9<br />

NF-K-IT-75 75 690<br />

0,02 270 80 135 3,5<br />

NF-K-IT-100 100 690<br />

0,02 270 90 150 3,8<br />

NF-K-IT-130 130 690<br />

0,02 270 90 150 4,0<br />

NF-K-IT-180 180 690<br />

0,02 380 120 170 4,4<br />

EMC

Range 2 – 400 A and 400 – 690 V<br />

Line choke<br />

(Three-phase-line choke)<br />

ADVANTAGES AT A GLANCE<br />

| Current ratings from 2 – 400 A<br />

| Limitation of harmonics<br />

| Safety part for PFC-installations<br />

| Protection of VFDs operating on weak<br />

power-supplies<br />

| Limitation of voltage-drops<br />

TECHNICAL DATA<br />

| Rated voltage: 400 VAC at 40 °C,<br />

50 – 60 Hz<br />

| Rated current: 3-phase, 2 – 400 A<br />

(see table)<br />

| Overload capability: 2-times rated current<br />

with the turning on, afterwards 1,5-times<br />

rated current for one minute, once per hour<br />

| Construction: according to EN 61558-2-20<br />

(VDE 0570)<br />

| Isolation class: up to 95 A: T40/B (130 °C),<br />

from 124 A: T40/F (155 °C)<br />

| Short-circuit voltage: 4%<br />

| Ambient temperature: -25 °C to +85 °C<br />

(above +40 °C with power reduction)<br />

| Terminals: screw terminals, terminal cross<br />

section (see table), PE (earthing) via screwed<br />

end<br />

| Protection class: IP 00 (VGB4 up to 150 A)<br />

| Dimensions: see table<br />

EMC-TECHNOLOGY<br />

Type Rated Rated voltage Inductivity Dimensions<br />

Weight<br />

current at (VAC) (mH) (mm)<br />

(kg)<br />

40 °C (A)<br />

W H D<br />

EPA3N-2 2 400<br />

14,0 80 120 64 1,1<br />

EPA3N-4 4 400<br />

7,30 80 120 70 1,9<br />

EPA3N-7 7 400<br />

4,20 100 125 75 2,1<br />

EPA3N-11 11 400<br />

2,60 125 130 75 2,9<br />

EPA3N-16 16 400<br />

1,80 125 130 75 3,3<br />

EPA3N-21 21 400<br />

1,40 155 150 80 4,2<br />

EPA3N-29 29 400<br />

1,00 155 150 95 6,0<br />

EPA3N-35 35 400<br />

0,84 155 175 110 6,8<br />

EPA3N-46 46 400<br />

0,64 190 200 110 9,3<br />

EPA3N-60 60 400<br />

0,49 190 200 120 11,0<br />

EPA3N-75 75 400<br />

0,39 190 235 130 12,4<br />

EPA3N-95 95 400<br />

0,30 210 255 170 16,0<br />

EPA3N-124 124 400<br />

0,23 210 255 180 17,4<br />

EPA3N-156 156 400<br />

0,19 230 285 220 23,5<br />

EPA3N-182 182 400<br />

0,16 240 305 230 28,0<br />

EPA3N-230 230 400<br />

0,13 240 305 240 32,5<br />

EPA3N-280 280 400<br />

0,10 300 385 240 35,0<br />

EPA3N-330 330 400<br />

0,09 300 390 260 41,0<br />

EPA3N-400 400 400<br />

0,07 300 390 275 51,0<br />

Special versions and other sizes on request!<br />

EMC<br />

LINE<br />

CHOKE<br />

23

CONTACT.,<br />

MOTOR<br />

PROTECTION<br />

24<br />

CONTACTORS<br />

Range 4 – 1200 A and 24 – 690 V<br />

Contactors and motor protection<br />

3-pole<br />

Type /<br />

3-pole<br />

kW<br />

at<br />

400V<br />

Current<br />

(A)<br />

Dimensions<br />

(mm)<br />

W H D<br />

Weight<br />

(kg)<br />

GH15BN 4 9 45 80 85 0,4<br />

GH15CN 5,5 12 45 80 85 0,4<br />

GH15DN 7,5 16 45 80 85 0,4<br />

GH15ET 11 25 45 80 91 0,4<br />

GH15FT 15 32 45 80 91 0,4<br />

GH15GT 18,5 40 60 114 109 1,2<br />

GH15HT 22 50 60 114 109 1,2<br />

GH15JT 30 63 60 114 109 1,2<br />

GH15KT 37 80 79 137 130 1,8<br />

GH15LT 45 95 79 137 130 1,8<br />

GH15MT 55 110 79 162 130 2<br />

GH15NT 75 150 110 170 162 4<br />

GH15PT 90 175 147 170 162 4,7<br />

GH44 110 210 177 209 190 7,3<br />

GH52 160 315 210 234 220 12,8<br />

GH55 250 450 220 250 225 13<br />

GH57 300 550 220 258 225 13,5<br />

GH62 400 700 280 307 291 26,4<br />

GH64 500 860 280 361 291 27,6<br />

GH76 580 1000 334 490 345 51<br />

GH78 680 1200 334 490 345 52<br />

1) on request<br />

MOTOR PROTECTION RELAY<br />

RTD32<br />

| Current range from 0,4 – 32 A<br />

RTD65<br />

| Current range from 10 – 65 A<br />

RTD74<br />

| Current range from 60 – 74 A<br />

RTD180<br />

| Current range from 60 – 180 A<br />

C316R<br />

| Current range from 63 – 310 A<br />

C316V<br />

| Current range from 260 – 800 A<br />

INFORMATION<br />

1)<br />

MOTOR CIRCUIT BREAKER<br />

GHA32<br />

| Current range from 0,1 – 32 A<br />

| Short circuit and overload protection<br />

| Phase loss protection<br />

| ON/OFF function<br />

| Status indication<br />

Our unique GH contactor line, RTD motor protection relays,GHA motor circuit breaker are produced<br />

in one of the last European production plants and widely used for marine applications. This guarantees<br />

the highest quality and immediate availability.

Range 200 – 1 600A and 2 300 – 24 000 V<br />

Vacuum contactors and circuit breakers<br />

3-pole<br />

VACUUM CONTACTORS<br />

Type/ 3-pole<br />

MVC77U032A25<br />

MVC77U034A25<br />

MVC77U036A25<br />

SVC77U038A25<br />

SVC77U031225<br />

MVC77U032A50<br />

MVC77U034A50<br />

MVC77U036A50<br />

SVC77U038A50<br />

SVC77U031250<br />

MVC77U032A72<br />

MVC77U034A72<br />

MVC77U036A72<br />

SVC77U038A72<br />

SVC77U031272<br />

INFORMATION<br />

Voltage<br />

(V)<br />

2500<br />

2500<br />

2500<br />

2500<br />

2500<br />

4160<br />

4160<br />

4160<br />

4160<br />

4160<br />

6600<br />

6600<br />

6600<br />

6600<br />

6600<br />

Current<br />

(A)<br />

200<br />

400<br />

600<br />

800<br />

1200<br />

200<br />

400<br />

600<br />

800<br />

1200<br />

200<br />

400<br />

600<br />

800<br />

1200<br />

Power<br />

(kW)<br />

662<br />

1287<br />

1654<br />

2022<br />

3013<br />

1103<br />

2206<br />

3309<br />

4044<br />

5100<br />

1838<br />

3676<br />

4963<br />

5882<br />

7350<br />

The contactors as well as the circuit breakers<br />

provide state of the art superior vacuum technology.<br />

This assures long term, highly reliable<br />

operation. The contactors guarantees 750.000<br />

operating cycles and the circuit breaker 150.000<br />

switching cycles without any maintenance over<br />

the expected 25 years lifespan<br />

VACUUM CIRCUIT BREAKER<br />

Rated voltage<br />

(kV)<br />

12<br />

24<br />

Lower terminal<br />

Movable contact<br />

with bellows<br />

Flexible junction shunt<br />

Drive insulator<br />

Opening spring<br />

Contact pressure<br />

spring<br />

Actuator coil<br />

Armature<br />

Rated short-circuit<br />

breaking current (kA)<br />

12,5/16/20/32,5<br />

12,5/16<br />

Upper terminal<br />

Stub shaft<br />

Dimensions (mm)<br />

Pole center distance<br />

150/210<br />

210/275<br />

Vacuum tube<br />

Interlocking pins<br />

Synchronize shaft<br />

Magnetic actuator<br />

(complete module)<br />

Width Height<br />

440/560 474/474<br />

560/690 509/509<br />

CONTACTORS<br />

Depth<br />

265<br />

265<br />

Frame<br />

Auxiliary contacts<br />

Weight<br />

(kg)<br />

34/36<br />

36/38<br />

Support<br />

insulator<br />

VAC.-CON.,<br />

CIRCUIT<br />

BREAKER<br />

25

SPECIAL<br />

SOLUTIONS<br />

MV<br />

26<br />

SWITCHGEAR SOLUTIONS<br />

Range 60 – 2 000 A and 2 300 – 15 000 V<br />

Special solutions medium voltage<br />

Customised special solutions for the electrical <strong>drive</strong> business<br />

INFORMATION<br />

From the beginning, <strong>Igel</strong> Elektronik provides<br />

turn key solutions for the electrical <strong>drive</strong> business.<br />

Beginning with standard IP32 soft starter<br />

cabinets, the product range is continuously expanded<br />

with many types of features and a vari-<br />

ADVANTAGES AT A GLANCE<br />

| Many years of experience in the medium<br />

voltage <strong>drive</strong> and distribution cabinet<br />

production<br />

| Brand independent production<br />

| Service and Engineering team for world<br />

wide operation<br />

| Project engineering and consultation by<br />

experienced employees out of the medium<br />

voltage area<br />

| Customised solutions<br />

| Implementation of Control-, Protection- and<br />

Scada systems.<br />

APPLICATIONS<br />

| Starter for asynchronous motors<br />

| Starter for synchronous motors<br />

| Starter for slip ring motors<br />

| Power factor connection<br />

| Energy distribution<br />

ety of products for a variety of applications. The<br />

professional engineering team and quality of<br />

the products generated an increasing demand<br />

for control and energy distribution cabinets. An<br />

optimized purchasing, production and logistic<br />

WE OFFER<br />

| Factory acceptance test<br />

| Marine or special approvals<br />

| Load test<br />

| Preliminary engineering<br />

| Projecting<br />

| Calculations<br />

| Drawings<br />

| Approval/modifi cation drawings<br />

| Highly qualifi ed personal<br />

| Commissioning<br />

| Assembly and connection<br />

| Full service package<br />

| Trial operations<br />

| Turn-Key-Solutions<br />

| International Service<br />

| Selectable production locations<br />

| Certifi cation/Approval<br />

| Engineering service<br />

| Equipment integration<br />

system enables cost and time effi cient industrial<br />

production; Please ask your local <strong>Igel</strong> Elektronik<br />

representative for detailed technical information<br />

concerning our medium voltage switchgear<br />

solutions.

Range 1 – 3 500 A and 24 – 1 000 V<br />

OEM serial production<br />

Serial production and OEM production of switchgears for the mechanical engineering<br />

ADVANTAGES AT A GLANCE<br />

| Competitive prices due to OEM production<br />

| Combined test run of the switchboard,<br />

including <strong>drive</strong> unit<br />

| Direct service and guarantee of the <strong>drive</strong><br />

manufacturer<br />

| Project engineering and consulation by<br />

experienced team from the <strong>drive</strong> engineering<br />

| OEM production including stockkeeping for<br />

the customer<br />

| Turn key solutions for many applications<br />

| Customized solutions<br />

| Variable combinations of different functions:<br />

- energy distribution<br />

- control<br />

- terminal sections<br />

- power factor connection<br />

- motor starter<br />

| Variable in the adaptation of the space<br />

conditions<br />

| Inplementation of control-, protection- and<br />

scada systems<br />

APPLICATIONS<br />

| Pump control<br />

| Crane control<br />

| Wood working machines<br />

| Construction equipment<br />

| Compressors<br />

| Cooling compressors (chiller)<br />

WE OFFER<br />

| Marine or special approvals<br />

| Quality assurance according to customers<br />

requirements<br />

| Prototyping for approval<br />

| Projecting<br />

| Preperation of drawings according to<br />

customers requirements<br />

| Quality trained specialised staff<br />

| Commissioning<br />

SWITCHGEAR SOLUTIONS<br />

| Type-test on request<br />

| Installation<br />

| Turn-Key-Solutions<br />

| International Service<br />

| Production “Made in Germany“<br />

| Engineering Services<br />

| Equipment integration<br />

| Approval certifi cation service<br />

OEM<br />

SERIAL<br />

PRODUCTION<br />

27

<strong>Igel</strong> Elektronik GmbH<br />

Industrieweg 13 –15<br />

48324 Sendenhorst<br />

Germany<br />

Fon: +49 (0) 25 26 93 89 - 0<br />

Fax: +49 (0) 25 26 93 89 - 22<br />

E-Mail: info@igelelektronik.de<br />

www.igelelektronik.de<br />

www.softstarter.eu