SERVICE MANUAL AIR PURIFIER KC-C100E-W ... - Y. Servis Girişi

SERVICE MANUAL AIR PURIFIER KC-C100E-W ... - Y. Servis Girişi

SERVICE MANUAL AIR PURIFIER KC-C100E-W ... - Y. Servis Girişi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TopPage<br />

<strong>KC</strong><strong>C100E</strong>W<br />

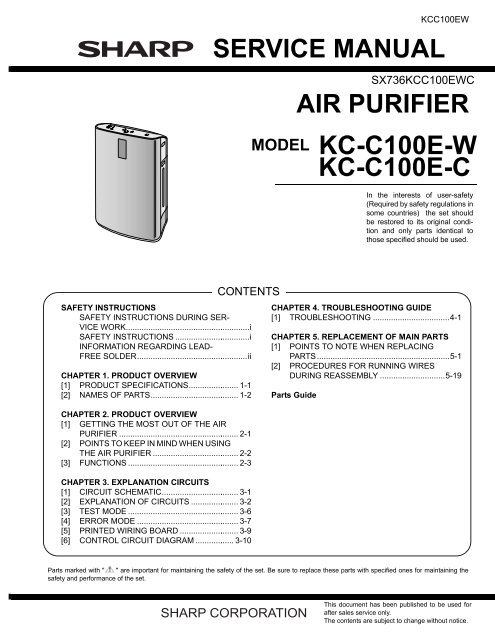

<strong>SERVICE</strong> <strong>MANUAL</strong><br />

CONTENTS<br />

SAFETY INSTRUCTIONS<br />

SAFETY INSTRUCTIONS DURING SER-<br />

VICE WORK.......................................................i<br />

SAFETY INSTRUCTIONS .................................i<br />

INFORMATION REGARDING LEAD-<br />

FREE SOLDER.................................................ii<br />

CHAPTER 1. PRODUCT OVERVIEW<br />

[1] PRODUCT SPECIFICATIONS...................... 1-1<br />

[2] NAMES OF PARTS....................................... 1-2<br />

CHAPTER 2. PRODUCT OVERVIEW<br />

[1] GETTING THE MOST OUT OF THE <strong>AIR</strong><br />

<strong>PURIFIER</strong> ..................................................... 2-1<br />

[2] POINTS TO KEEP IN MIND WHEN USING<br />

THE <strong>AIR</strong> <strong>PURIFIER</strong> ...................................... 2-2<br />

[3] FUNCTIONS ................................................. 2-3<br />

CHAPTER 3. EXPLANATION CIRCUITS<br />

[1] CIRCUIT SCHEMATIC.................................. 3-1<br />

[2] EXPLANATION OF CIRCUITS ..................... 3-2<br />

[3] TEST MODE ................................................. 3-6<br />

[4] ERROR MODE ............................................. 3-7<br />

[5] PRINTED WIRING BOARD .......................... 3-9<br />

[6] CONTROL CIRCUIT DIAGRAM ................. 3-10<br />

MODEL<br />

SX736<strong>KC</strong><strong>C100E</strong>WC<br />

CHAPTER 4. TROUBLESHOOTING GUIDE<br />

[1] TROUBLESHOOTING ..................................4-1<br />

CHAPTER 5. REPLACEMENT OF MAIN PARTS<br />

[1] POINTS TO NOTE WHEN REPLACING<br />

PARTS ...........................................................5-1<br />

[2] PROCEDURES FOR RUNNING WIRES<br />

DURING REASSEMBLY .............................5-19<br />

Parts Guide<br />

<strong>AIR</strong> <strong>PURIFIER</strong><br />

<strong>KC</strong>-<strong>C100E</strong>-W<br />

<strong>KC</strong>-<strong>C100E</strong>-C<br />

In the interests of user-safety<br />

(Required by safety regulations in<br />

some countries) the set should<br />

be restored to its original condition<br />

and only parts identical to<br />

those specified should be used.<br />

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the<br />

safety and performance of the set.<br />

This document has been published to be used for<br />

after sales service only.<br />

The contents are subject to change without notice.

<strong>KC</strong><strong>C100E</strong>W<br />

<strong>KC</strong><strong>C100E</strong>W<br />

SAFETY INSTRUCTIONS<br />

Service Manual<br />

SAFETY INSTRUCTIONS DURING <strong>SERVICE</strong> WORK<br />

Before disassembling a product, verify that the plug has been removed from the power outlet. Exercise caution while working.<br />

�SAFETY INSTRUCTIONS PRIOR TO WORK<br />

DANGER<br />

Be sure to remove the plug from the power outlet before beginning<br />

work (danger of electrical shock).<br />

�SAFETY INSTRUCTIONS DURING WORK<br />

WARNING<br />

Parts in the parts guide indicated by are important for safety.<br />

When replacing one of these parts, be sure to use only the specified<br />

part to ensure safety (danger of smoke, fire, and/or electrical<br />

shock).<br />

CAUTIONS<br />

Run lead wires so that they do not touch edges of parts (danger of<br />

electrical shock due to wire breakage).<br />

Exercise caution when working near and handling the edges of<br />

metal parts (danger of cutting your hand).<br />

Run lead wires in their original positions using ties to prevent them<br />

from touching movable parts (danger of electrical shock and fire due<br />

to wire breakage).<br />

After replacing a part, verify that the wiring has been performed correctly<br />

and securely in accordance with the schematic (danger of<br />

smoke and fire).<br />

�SAFETY INSTRUCTIONS FOLLOWING WORK<br />

WARNING<br />

Following repair or replacement, be sure to use an insulation resistance<br />

tester to test the insulation resistance. If the insulation resistance<br />

is 10 MΩ or less, inspect each part and replace failed parts<br />

(danger of electrical shock).<br />

Before plugging in the plug, wipe between the prongs with a dry<br />

cloth. Insert the plug firmly into the outlet. If there is dust or moisture<br />

on the plug, admonish the customer (danger of fire).<br />

CAUTIONS<br />

Following service, verify that no screws, tools, or debris have fallen<br />

into the unit before turning on the power (danger of electrical<br />

shock).<br />

Remove dust from the filter. If a large amount of dust has accumulated,<br />

instruct the customer that it is necessary to remove the dust<br />

(danger of abnormal overheating).<br />

SAFETY INSTRUCTIONS<br />

WARNING<br />

Use only a 220-240 VAC power source.<br />

Danger of fire and electrical shock.<br />

Do not use the product if the power cord or plug is damaged or the<br />

connection to the wall outlet is loose.<br />

Danger of fire, electrical shock, and short-circuiting.<br />

Do not damage, modify, excessively bend, pull, twist, or bind the<br />

power cord. Do not place heavy objects on the cord or jam the cord<br />

between objects.<br />

The cord may break and cause fire or electrical shock.<br />

Do not modify the product.<br />

The product should only be disassembled and repaired by a qualified<br />

service technician.<br />

Danger of fire, electrical shock, and injury. Consult the store where<br />

the product was purchased or your nearest service center.<br />

i<br />

WARNING<br />

Do not insert or remove the plug when your hand is wet.<br />

Danger of electrical shock.<br />

Periodically remove dust from the plug.<br />

Moisture in accumulated dust may cause an insulation failure that<br />

results in fire or electrical shock.<br />

Before cleaning, inspecting, or moving the unit, be sure to power off<br />

the unit and remove the plug from the power outlet.<br />

Danger of electrical shock or injury.<br />

When abnormality is felt, it turns off power and the power plug is<br />

pulled out.<br />

CAUTIONS<br />

Do not climb onto or lean on the unit.<br />

The unit may topple, resulting in human injury or product failure.<br />

Do not insert fingers, metal rods, or other foreign objects in the vents<br />

and air intakes.<br />

Danger of electrical shock; product failure may occur.<br />

Do not allow lit cigarettes, burning incense, or other lit or flammable<br />

materials near the unit.<br />

Danger of fire.<br />

Do not use the unit in a bathroom or other location where there is<br />

steam or moisture, or in a location where water may splash on the<br />

unit.<br />

Danger of fire and electrical shock; product failure may occur.<br />

Do not wipe the unit with benzene or thinner, or spray insecticide on<br />

it.<br />

Danger of electrical shock and fire; cracks may form in the product<br />

case.<br />

Do not use in a location where particles of oil such as vegetable oil<br />

are suspended in the air.<br />

Danger of injury due to falling: cracks may form in the product case.<br />

Do not run the unit in a location where an aerosol insecticide foggier<br />

is used.<br />

Insecticide will accumulate inside the machine and then be discharged<br />

from the vents, adversely affecting health.<br />

After using an insecticide, ventilate the location thoroughly before<br />

running the unit.<br />

Do not drink the water in the Mist tray or tank.<br />

This may cause illness.<br />

Replace the water in the tank and Mist tray with fresh tap water<br />

every day.<br />

Clean the inside of the unit regularly to keep it sanitary.<br />

If not cleaned, mildew and bacteria may grow in the dirt and deposits<br />

and cause unpleasant odors. In rare cases, this may cause an allergic<br />

reaction and adversely affect health.<br />

If used together with a burner apparatus, ventilate the room.<br />

Failure to ventilate may result in carbon monoxide poisoning.<br />

This product does not remove carbon monoxide or other harmful<br />

substances.<br />

When removing the plug, always grasp the plug and never pull the<br />

cord.<br />

Danger of fire, electrical shock, and short-circuiting.<br />

When not using the unit for an extended period of time, be sure to<br />

remove the plug from the power outlet.<br />

Deterioration of the insulation may cause electrical shock, current<br />

leakage, and/or fire.<br />

When moving the unit, be sure to remove the tank and Mist tray<br />

from the unit and grasp the hand grips on the left and right side of the<br />

unit.<br />

If the tank and mist tray are not removed before moving the unit,<br />

water may spill onto the floor.

CAUTIONS<br />

When the unit is not in use, discard the water.<br />

When not using the unit, discard the water in the tank and Mist tray.<br />

Water left in the tank and Mist tray may cause mildew and bacteria<br />

to grow.<br />

Use only tap water.<br />

(Tap water is normally disinfected with chlorine, making it difficult for<br />

bacteria to grow.)<br />

Do not use water that is 40°C or higher, or a chemical, aromatic, or<br />

dirty water. This may cause deformation and product failure. Use of<br />

mineral water, alkali-ion water, well water, or water from a water purifier<br />

may result in increased deposits that make it easy for mildew<br />

and bacteria to grow.<br />

Do not block the air intake and vents.<br />

This may cause product failure.<br />

Do expose the unit to direct sunlight or place it near a heater.<br />

This may result in deformation and discoloration, and/or cause the<br />

temperature and humidity sensors and safety devices to malfunction.<br />

Air inside the tank may expand and cause the water to overflow.<br />

Do not use in a location where steam from a humidifier will blow onto<br />

the unit.<br />

This may shorten the filter life and lead to product failure.<br />

Do not run the unit with the filter,Mist unit, or tank removed.<br />

Air purification will not take place.<br />

In addition, water leakage and/or product failure may occur.<br />

Do not use in a location where the unit is not stable.<br />

Do not use the unit if it is tilted or on its side.<br />

The unit may fall and cause injury; product failure and/or water leakage<br />

may occur.<br />

Do not place the unit or heavy objects on the power cord, or jam the<br />

cord between other objects.<br />

This may damage the cord and cause fire or electrical shock.<br />

Do not wash the dust filter.<br />

The dust collecting ability of the filter will be lost.<br />

Before installling the Washable Active Carbon Filter, allow it to dry<br />

thoroughly.<br />

Installing the filter while it is damp may damage the dust filter and<br />

cause blown air to have an unpleasant odor.<br />

Do not use a detergent to clean the unit.<br />

This may damage the unit and cause cracks to form. This may also<br />

cause a sensor failure.<br />

Neither tea nor water are spilt.<br />

It doesn‘t apply to water , and water is put in directly the main body<br />

Cause of electric shock, short, and ignition<br />

INFORMATION REGARDING LEAD-FREE SOLDER<br />

�ADOPTION OF LEAD-FREE SOLDER<br />

This model uses lead-free solder. The LF mark indicates lead-free solder<br />

and appears on circuit boards and in the service manual. The letter<br />

following the LF mark indicates the type of lead-free solder.<br />

(Example)<br />

Indicates tin-silver-copper lead-free solder.<br />

�USING LEAD-FREE SOLDER<br />

When soldering to repair a lead-free solder board, use a lead-free solder.<br />

Do not use conventional lead solder, as this may cause accidents<br />

and failures due to cracking.<br />

ii<br />

<strong>KC</strong><strong>C100E</strong>W<br />

CAUTIONS<br />

It doesn‘t use it in the reached range of a small child.<br />

Cause of electric shock, short,and ignition.<br />

It doesn‘t use it for a special usage of the prerervation of the work of<br />

art etc.<br />

It casuses the quality decrease of the preservation goods.<br />

Mist filter is never used excluding this air purifier.<br />

Freezing is noted.<br />

Please throw away the water of the tank and the Mist tray when<br />

there<br />

is fear of freezing.<br />

Damage of tank or Mist tray and cause of water leak and breakdown.<br />

Use it within the range fron 5 to 35°C in room temperature.<br />

It doesn‘t use it in the be dewy place.<br />

The longevity of the filter decreases, and it causes the breakdown.<br />

CAUTIONS<br />

It doesn`t set it up in the following<br />

places.<br />

Place where direct sunshine → Cause of transformation and<br />

strikes.<br />

discoloration.<br />

Near thing hot such as heat- → Cause of transformation and<br />

ing apparatus.<br />

discoloration.<br />

Place where air inlet is closed<br />

with curtain etc..<br />

→ Cause of breakdown.<br />

Near equipment using electric<br />

waves such as television<br />

radios and radio clock.(within<br />

2m)<br />

On thick-piled carpet and<br />

mattress, etc.<br />

→ Cause of electric wave trouble.<br />

→ Malfunction of sensor and<br />

cause of fall<br />

NOTE:- Radio or TV Intreference<br />

• If this air purifier should does cause interference to radio or<br />

television reception, try to correct the interference by one or<br />

more of the following measures:<br />

• Reorient or relocate the receiving antenna.<br />

• Increase the separation between the air purifier and radio/TV<br />

receiver.<br />

• Connect the equipment into an outlet on a circuit different from<br />

that to which the receiver is connected.<br />

• Consult the dealer or an experienced radio/TV technician for<br />

help.<br />

The melting point of lead-free solder (Sn - Ag - Cu) is 40°C higher than<br />

lead solder, and thus it is recommended that you use a special soldering<br />

iron. If you do not know where to obtain lead-free solder and a suitable<br />

soldering iron, please contact your nearest SHARP service center<br />

or service branch.

<strong>KC</strong><strong>C100E</strong>W<br />

�SOLDERING WORK<br />

The melting point of lead-free solder (Sn-Ag-Cu) is approximately<br />

220°C, 40°C higher than conventional solder, and wettability is not as<br />

good. For this reason there is a tendency to keep the soldering iron in<br />

contact with the board for a long time. However, this may cause lifted<br />

lands and heating in excess of the heat tolerance of components, and<br />

thus the soldering iron should be removed from the board as soon as<br />

you have verified that a bond has formed.<br />

Lead-free solder has a higher proportion of tin, which causes<br />

increased corrosion of the tip of the soldering iron, and thus care<br />

should be taken to turn off the soldering iron whenever it is not in use.<br />

Any different type of solder remaining on the tip of the soldering iron<br />

will form an alloy with lead-free solder, thus the tip should be cleaned<br />

after you have finished soldering.<br />

If the tip of the soldering iron turns a dark color while you are soldering,<br />

clean the tip with steel wool or fine-grained sandpaper.<br />

APPLICABLE CIRCUIT BOARDS<br />

PART CODE PART NAME<br />

CPWB-A175KKKZ <strong>C100E</strong> PWB UNIT<br />

iii

<strong>KC</strong><strong>C100E</strong>W CHAPTER 1. PRODUCT OVERVIEW Service Manual<br />

[1] PRODUCT SPECIFICATIONS<br />

* 1:Room temperature—20°C, Humidity—30%<br />

* 2:Based on the standard of the JEMA (Japan Electrical Manufactures Association),JEM1467<br />

* 3:Based on JEM1467 of the Japan Electrical Manufacturers' Association.<br />

– When 10 cigarettes per day are smoked in the location where the air purifier is installed.<br />

1 – 1<br />

<strong>KC</strong><strong>C100E</strong>W<br />

Power supply 220-240V (50/60Hz)<br />

Operation mode Clean air operation (Humidification:OFF) Clean air & Humidify operation<br />

Fan Speed Operation Fan Speed Adjustment MAX MED LOW MAX MED LOW<br />

Rated Power 41W 11.6W 3.8W 40W 13.5W 6.8W<br />

Humidification (ml/hour) *1 — — — 600 400 230<br />

Fan speed (m3/hour) 306 168 60 288 168 84<br />

Fan rpm (rpm) 1220 780 380 1200 780 480<br />

Noise (dBA)*2 47 35 15 47 35 22<br />

Recommended room size ( ㎡) *2<br />

~38<br />

Dust collection method Mechanical purification<br />

Protective devices Current fuse OFF when current is abnormal (2.5A)<br />

Control panel (button) Clean Air Button,Clean Air & Humidify Button, Clean Ion Shower Button, Power Off Button,<br />

Clean Air Mode<br />

Clean Air & Humidify-<br />

Mode<br />

Fan Speed Button, Plasmacluster ON/OFF Button, Filter Reset Button, Light ON/OFF Button<br />

Clean Air Indicator Light … Lighting, Fan Speed Indicator Light … Lighting<br />

Clean Air & Humidify Indicator Light … Lighting,Fan Speed Indicator Light … Lighting,<br />

Humidity Indicator Light (30,40,50,60,70) … Lighting,<br />

Water supply Indicator Light … Flashing: the light will illuminate when the water tank reeds to<br />

be refilled<br />

Display Lamp<br />

Clean ion shower Mode Clean ion shower Indicator Light…Lighting<br />

Plasmacluster [ON] Plasmacluster ON/OFF Indicator Light … Lighting,<br />

Plasmacluster Indicator Light … Lighting<br />

Indicated by 4 Light<br />

Dust Monitor<br />

Clean (All Green) ⇔ Pollution level low (All Yellow ) ⇔ Pollution level high (All<br />

Red)<br />

Dimensions 378mm (W) x 265mm (D) x 586mm (H)<br />

Weight 9.0kg<br />

Cord length 2.0m<br />

Installations the stand Free standing type<br />

Accessories<br />

Operation manual , HEPA filter, washable deodorizing filter,Mist filter.<br />

Filter replacement times<br />

Options<br />

HEPA filter..........................................Approx.5 years after opening package*3<br />

Washable deodorizing filter ......... Approx.5 years after opening package*3<br />

Mist filter........................................... Approx.2 years after opening package<br />

Replacement filters<br />

•HEPA filter .................................... Parts Code:PFIL-A155KKEZ<br />

•Washable deodorizing filter.... Parts Code:PFIL-A157KKEZ<br />

•Mist fillter...................................... . Parts Code:PFIL-A156KKEZ<br />

REDUCING STANDBY POWER CONSUMPTION<br />

When the plug is inserted in the power outlet, this product consumes approximately 0.7W of power to operate<br />

the electronic circuits. To conserve energy, remove the plug from the power outlet when the product is not in<br />

use.

<strong>KC</strong><strong>C100E</strong>W<br />

[2] NAMES OF PARTS<br />

1. MAIN UNIT DISPLAY<br />

Filter Reset Button/<br />

Indicator Light (red)<br />

Light ON/OFF Button Fan Speed Button/<br />

Indicator Light (green)<br />

2. FRONT MONITOR<br />

Indicates condition and humidity of room air.<br />

Plasmacluster Indicator<br />

Light(blue)<br />

Blue : Plasmacluster ON<br />

Light off : Plasmacluster OFF<br />

Humidity Indicator Light<br />

(green)<br />

Displays the approximate humidity<br />

level in the room. Only<br />

displays when the Clean Air<br />

& Humidify Mode is selected.<br />

Humidity setting cannot be<br />

adjusted.<br />

(Ex.) At 60% humidity<br />

Plasmacluster ON/OFF Button/<br />

Indicator Light (green)<br />

Power ON Button<br />

Clean Air & Humidify MODE Button/<br />

Indicator Light (green)<br />

Clean Air MODE Button/<br />

Indicator Light (green)<br />

1 – 2<br />

DUST MONITOR<br />

Power OFF Button<br />

Press any of the buttons to<br />

select mode and start the unit<br />

CLEAN ION SHOWER MODE Button/<br />

Indicator Light (blue)<br />

The dust sensor continuously monitors<br />

the air and changes colour depending<br />

on air purity.<br />

Sensor Reading<br />

Clean Very Impure<br />

all green yellow<br />

ODOUR MONITOR<br />

all red<br />

The odour sensor continuously monitors<br />

the air and changes colour depending on<br />

odour intensity.<br />

faint<br />

Odour in the room<br />

storong<br />

green yellow red<br />

Water Supply Indicator Light(red)<br />

This light will illuminate when the water<br />

tank needs to be refilled

3. ILLUSTRATIVE DIAGRAM - FRONT<br />

4. BACK<br />

Handle<br />

(2 locations left and right)<br />

Sensors<br />

• Dust Sensor<br />

• Temperature / Humidity Sensor<br />

Tank Handle<br />

Water Tank<br />

(For humidifying)<br />

Humidifying Filter<br />

Filter Frame<br />

Tank Cap<br />

Float<br />

Humidifying Tray<br />

Power Cord<br />

Plug<br />

Air Outlet<br />

Main Unit Display<br />

Front Monitor<br />

Odour Sensor<br />

Main Unit<br />

1 – 3<br />

Air Inlet<br />

Date Label<br />

(Rating Label)<br />

Air Outlet<br />

HEPA Filter (white)<br />

<strong>KC</strong><strong>C100E</strong>W<br />

Washable Deodorizing<br />

Filter (black)<br />

Tabs<br />

Back Panel (Pre-Filter)

<strong>KC</strong><strong>C100E</strong>W<br />

<strong>KC</strong><strong>C100E</strong>W CHAPTER 2. PRODUCT OVERVIEW Service Manual<br />

[1] GETTING THE MOST OUT OF THE <strong>AIR</strong> <strong>PURIFIER</strong><br />

1. HOW THE <strong>AIR</strong> <strong>PURIFIER</strong> WORKS<br />

The fan inside the air purifier draws air from the room into the unit through the air intake. The air passes through the filters inside the unit (washable<br />

deodorizing filter and HEPA filter ) and then is blown back out into the room through the air outlet. This cycle repeats continuously.<br />

One passage of air through the HEPA filter removes 99.97% of dust and other particles of size 0.3mm (standalone dust removal efficiency of dust<br />

(HEPA) filter).<br />

As air repeatedly passes through the washable deodorizing filter, odour components are gradually adsorbed by the filter and removed from the air.<br />

(Odour components are also adsorbed by the HEPA filter.)<br />

2. UNDERSTANDING THE PRODUCT<br />

2.1. ODOUR<br />

Some odour components that adhere to the filters will leave the filters and pass out through the air outlet as an odour. Depending on the environment<br />

of use, the performance of the filters may deteriorate after several months. Early replacement of filters is recommended once you begin to notice an<br />

unpleasant odour.<br />

When an odour becomes noticeable, wash the washable deodorizing filter. If the odour still remains after washing the deodorizing filter, odour components<br />

that adhere to the HEPA filter are leaving the HEPA filter. Replace the HEPA filter.<br />

2.2. About humidifying<br />

The humidifying method is "Evaporation type. "<br />

The inhaled air is passed through the Mist filter as it is and it humidifies it.<br />

Therefore, the humidifying ability changes by the inhaled temperature of air and the influence of humidity.<br />

The humidifying ability might decrease when the room temperature is low and when humidity is high.<br />

The humidifying ability is an amount of humidifying when driving by 20°C in room temperature and 30% in relative humidity.<br />

Because water has evaporated to the humidifying driving at the normal temperature, steam is not seen.<br />

When it uses for the first time, and water doesn't soak into the Mist filter, it takes time to obtain an enough humidification ability.<br />

(If the Mist filter is wet before it uses it, it becomes early.)<br />

3. USEFUL INFORMATION<br />

3.1. ODOUR SENSOR<br />

When the plug is inserted into a power outlet , the odor sensor reads the current condition of the room air as ”clean air” , stores this condition in memory,<br />

and detects dirty air accordingly.<br />

If the plug is inserted into a power outlet when the air is dirty and the air purifier is set to auto mode, the air purifier may operate in silent mode for a<br />

certain interval.<br />

DETECTS SOMETIMES DETECTS DOES NOT DETECT<br />

• Tabacco and incense odours<br />

• Cosmetics, alcohol, etc.<br />

• Sprays<br />

3.2. DUST SENSOR<br />

The dust sensor can detect dust and particles several mm in size.<br />

• Air currents due to opening and closing a<br />

door, sudden changes temperature<br />

DETECTS DOES NOT DETECT<br />

• House dust<br />

(dust, dead mites/ticks, mold spores, pollen)<br />

• Tobacco smoke (particles)<br />

• Alcohol<br />

• Gases<br />

• Bacteria, viruses<br />

3.3. Mist Filter<br />

The life of the Mist filter changes depending on the driving time and the water quality used.<br />

In maintenance, the standard once a month.Please maintain it as shown in the manual when the balloon air smells, the humidifying ability decreases<br />

or how of the water of the tank for the decrease has decreased.<br />

Please exchange the Mist filters even if it is within in two years when becoming it to be the following even if you maintain it as shown in the manual.<br />

• The fur and the smell cannot be taken.<br />

• Discoloration like the black and yellow, etc. is awful.<br />

• Red brown and a white hardening adhered to all aspects of the Mist filter.<br />

• The damage and the transformation are awful.<br />

In addition, in order to extend the life of the Mist filter, humidification is not necessary, throw away the water of the Mist tray and the tank.<br />

2 – 1<br />

• House dust<br />

(dust, dead mites/ticks, mold spores, pollen)

3.4. Humidification FUNCTION<br />

2 – 2<br />

<strong>KC</strong><strong>C100E</strong>W<br />

1. The air purifier works even if there is no water in the tank<br />

• The air purifier functions fully even if water is not added to the tank, however, adding water so that Humidification mode operates enables an<br />

even more effective purification through the synergy with bacteriaremoving ions.<br />

2. The Mist filter sometimes becomes discolored after Humidification mode begins operating<br />

• The discoloration is due to impurities in tap water such as calcium and iron, and is normal.<br />

3. Steam/mist is not visible<br />

• Humidifies air (the water is vaporized) by directing the air flow against the Mist filter, and for this reason steam is not visible.<br />

like it is with a steam an method or an ultrasonic method.<br />

4. The air that blows out is not warm<br />

• Heat is removed when the water is vaporized, and thus the air that blows out is not warm. Depending on the size of the room, the air may feel<br />

cold.<br />

5. The amount of vaporized mist that blows out varies depending on humidity and temperature conditions<br />

• It is more difficult to vaporize water on rainy days when the humidity is high or when the temperature in the room is low, and thus less vaporized<br />

mist blows out. (Less water is used in the tank.)<br />

[2] POINTS TO KEEP IN MIND WHEN USING THE <strong>AIR</strong> <strong>PURIFIER</strong><br />

1. INSTALLATION<br />

Keep the area around the unit clear.<br />

• Do not place any objects within 60 cm of the area above the air outlet.<br />

• Place the air purifier on a stable, level surface.<br />

– (The unit may vibrate if placed on a carpet or rug.)<br />

– (If placed on a surface that is not level, water may leak.)<br />

2. IMPORTANT SAFETY INSTRUCTIONS<br />

To prevent machine failure and accidents (fire, electrical shock, and<br />

injury), follow these safety instructions:<br />

• Do not use in place of a ventilation fan or range hood.<br />

• Do not insert objects or your fingers into the air intake, air outlet, or<br />

filter case.<br />

This is extremely dangerous as there are high-voltage components<br />

and a rotating fan inside the unit.<br />

• Do not use in a location with excessive moisture.<br />

• Do not use over or near heaters.<br />

• Do not allow flammable substances to enter the air intake.<br />

• Do not block the air intake or air outlet.<br />

• Do not knock the unit over or allow it to fall.<br />

• If used in a closed room, ventilate the room.<br />

The air purifier does not include a ventilation function or carbon<br />

monoxide removal function.<br />

3. REPLACING THE FILTERS<br />

3.1. USEABLE LIFE OF THE FILTERS<br />

When used in a normal household, the life of the filters is:<br />

• HEPA filter...................Approx. 5 years after the package is opened<br />

• Washable deodorizing filter......Approx. 5 years after the package is<br />

opened<br />

– This is the amount of time until the dust collection and deodorizing<br />

capabilities of the filters decrease to one-half of their initial<br />

capability when the air purifier draws in the smoke of ten cigarettes<br />

a day (based on JEMA 1467 of the Japan Electrical Manufacturers'<br />

Association).<br />

The indicated life is a general guideline.<br />

In some environments performance may deteriorate after several<br />

months of use.<br />

Early replacement is recommended when an unpleasant odour<br />

is noticed.<br />

• Mist filter......................Approx. 2 years after the package is opened<br />

– The indicated life is a general guideline.<br />

In some environments performance may deteriorate after several<br />

months of use.<br />

Early replacement is recommended if cleaning fails to remove<br />

water deposits (white, black, or yellow deposits) or if the filter or<br />

sheet is damaged or is losing its shape.<br />

3.2. GUIDELINES FOR REPLACEMENT<br />

The replacement time varies depending on the location where the air<br />

purifier is used.<br />

Write down the date on which you began using the filters on the Date<br />

label on the machine and use this as a guideline for filter replacement.<br />

3.3. IN THE FOLLOWING CIRCUMSTANCES, REPLACE-<br />

MENT WILL BE NECESSARY MUCH SOONER THAN<br />

USUAL:<br />

• If the unit draws in soot or carbon substances.<br />

• If the unit is installed in a coffee shop, mah-jongg parlor, barber<br />

shop, beauty salon, or other store or office.<br />

3.4. OPTIONAL REPLACEMENT FILTERS<br />

Date Lavel<br />

・HEPA filter..................................Parts Coad: PFIL-A155KKEZ<br />

・ Washable deodorizing filter ........Parts Coad: PFIL-A157KKEZ<br />

・ Mist filter.....................................Parts Coad: PFIL-A156KKEZ

<strong>KC</strong><strong>C100E</strong>W<br />

[3] FUNCTIONS<br />

1. CLEAN <strong>AIR</strong> & HUMIDIFY MODE<br />

CLEAN <strong>AIR</strong> & HUMIDIFY MODE<br />

Use the Clean Air & Humidify Mode to quickly clean the air, reduce odours and to humidify.<br />

1<br />

2<br />

3<br />

Fill Water Tank.<br />

Press the CLEAN <strong>AIR</strong> & HUMIDIFY MODE Button.<br />

• If the power cord was not unplugged between uses, the<br />

unit will automatically re-start at the previously selected<br />

settings.<br />

Press the FAN SPEED Button to select the desired<br />

fan speed.<br />

• Indicator lights will show the fan speed<br />

currently selected.<br />

Press the Power OFF Button to turn the unit off.<br />

About Automatic Humidify Mode<br />

About the Temperature/Humidity Sensors. The Temperature/<br />

Humidity sensors automatically detect and adjust humidity<br />

according to changes in room temperature. Depending on<br />

the size and humidity of the room, humidity may not reach<br />

55~65%. In such cases, it is recommended that CLEAN <strong>AIR</strong><br />

& HUMIDIFY/MAX MODE be used.<br />

2 – 3<br />

Temperature<br />

~18ºC<br />

18ºC~24ºC<br />

24ºC~<br />

Humidity<br />

65%<br />

60%<br />

55%

2. CLEAN <strong>AIR</strong> MODE<br />

Use the Clean Air Mode when additional humidity is not required.<br />

1<br />

2<br />

CLEAN <strong>AIR</strong> MODE<br />

Press the CLEAN <strong>AIR</strong> MODE Button on the display.<br />

• If the power cord was not unplugged between uses, the unit<br />

will automatically re-start at the previously selected settings.<br />

Press the FAN SPEED BUTTON to select the<br />

desired fan speed.<br />

• Indicator lights will show the fan speed<br />

currently selected.<br />

Press the Power OFF Button to turn the unit off.<br />

3. CLEAN ION SHOWER MODE<br />

1<br />

CLEAN ION SHOWER MODE<br />

Press the CLEAN ION SHOWER MODE Button<br />

on the display to select this mode.<br />

operation.<br />

2 – 4<br />

<strong>KC</strong><strong>C100E</strong>W<br />

CLEAN<br />

ION<br />

SHOWER<br />

Mode<br />

with<br />

humidi<br />

cation<br />

releases<br />

concentrated<br />

Plasmacluster<br />

ions.<br />

-<br />

-<br />

ter Tank when this mode is selected.<br />

when there’s no water in it.<br />

Press the Power OFF Button to turn the unit off.

<strong>KC</strong><strong>C100E</strong>W<br />

4. PLASUMACLUSTER ON / OFF BUTTON<br />

Plasmacluster ON/OFF Button<br />

Press the Plasmacluster ON/OFF Button to turn Plasmacluster<br />

Ion Mode ON and OFF. A green light will indicate that the<br />

Plasmacluster Ion Mode in ON.<br />

5. LIGHTS ON / OFF BUTTON<br />

LIGHTS ON/OFF Button<br />

Press this button to turn Front Panel monitor lights ON and<br />

OFF.<br />

6. WATER SUPPLY INDICATOR LIGHT<br />

WATER SUPPLY INDICATOR LIGHT<br />

When the Water Tank is empty, the Water Supply Indicator<br />

Please note the light will not flash even when the Water<br />

Tank is empty during the Clean Air Mode and the Clean ION<br />

SHOWER Mode.<br />

Sound indicator setting for water supply.<br />

In addition to the Indicator Light, the unit can be set to signal<br />

with an audible beep when the Water Tank is empty. With the<br />

unit OFF, press the Lights ON/OFF button for 3 seconds to turn<br />

the audible signal ON.<br />

Cancellation<br />

To cancel the audible signal, with the unit OFF, press the Lights<br />

ON/OFF button again more than 3 seconds.<br />

2 – 5

7. ADJUSTMENT OF SENSOR DETECTION SENSITIVITY<br />

ADJUSTMENT OF SENSOR DETECTION SENSITIVITY<br />

2 – 6<br />

<strong>KC</strong><strong>C100E</strong>W<br />

Set to ‘low” if the DUST MONITOR and ODOUR MONITOR is constantly red to reduce<br />

sensitivity, and set to ‘high’ if the DUST MONITOR and ODOUR MONITOR is constantly<br />

green to increase sensitivity.<br />

1<br />

2<br />

3<br />

With the unit OFF, press the Fan Speed Button for 3 seconds.<br />

The Fan Speed Indicator Lights will display the currently set sensor sensitivity level. The<br />

factory setting is Standard, indicated by the MED light.<br />

Press the Fan Speed Button to set<br />

the desired sensor sensitivity.<br />

Refer to the diagram on the right to select the<br />

desired sensor sensitivity level.<br />

Press the Power OFF Button.<br />

Note that if the Power OFF Button is not pushed<br />

within 8 seconds of adjusting sensor sensitivity,<br />

the setting will be saved automatically. The<br />

sensor sensitivity setting will be saved even if<br />

the unit is unplugged.<br />

Fan Speed<br />

Indicator Light<br />

Sensor Detection<br />

sensitivity<br />

High<br />

Standard<br />

Low

<strong>KC</strong><strong>C100E</strong>W<br />

<strong>KC</strong><strong>C100E</strong>W CHAPTER 3. EXPLANATION CIRCUITS Service Manual<br />

[1] CIRCUIT SCHEMATIC<br />

��������������<br />

�����������������������<br />

����<br />

�����������<br />

����������<br />

����<br />

����<br />

��� ��� �� ��� ���<br />

����<br />

��<br />

��������������������<br />

������������������<br />

��<br />

���<br />

�����<br />

���<br />

��<br />

3 – 1<br />

����<br />

�����������<br />

����<br />

����������������<br />

��������<br />

����<br />

��������������������<br />

������<br />

�������������������

[2] EXPLANATION OF CIRCUITS<br />

1. BLOCK DIAGRAM<br />

2. EXPLANATION OF CIRCUITS<br />

2.1. NOISE PREVENTION CIRCUIT<br />

3 – 2<br />

<strong>KC</strong><strong>C100E</strong>W<br />

This protects the circuits from external noise and power surges entering through the AC plug, and also absorbs noise exiting outward from the AC<br />

plug. The circuit consists of film capacitors C1 and C4, varistor VRS1, current fuse FUSE1, and line filter L1.<br />

2.2. POWER SUPPLY CIRCUIT<br />

2.2.1 Vm<br />

The commercial power supply (220-240 V AC) passes through current fuse FUSE1, is rectified by diode bridge DB1, smoothed by electrolytic<br />

capacitor C2, and supplied as the fan motor power source and the power source for power supply circuit. (Vm= Approx. 310-340 V DC)<br />

2.2.2 VL<br />

Output no. 1 is rectified by diode D3, smoothed by electrolytic capacitor C12 and used as power supply VL for the buzzer drive circuit, fan motor drive<br />

circuit, rotor motor drive circuit, and cluster unit drive circuit. (VL= Approx. 15 V DC)<br />

2.2.3 VDD<br />

�<br />

�<br />

�<br />

� �<br />

�<br />

�����<br />

����������<br />

�������<br />

���������<br />

�������������<br />

������<br />

�������������<br />

�������<br />

��������������<br />

���������<br />

�������<br />

�����������<br />

�������������<br />

���������������������������������������<br />

Output no. 2 is rectified by diode D4, smoothed by electrolytic capacitor C11 and used as a power supply for microprocessor LSI1,<br />

dust sensor circuit, odor sensor circuit, the other sensors circuit, and LED drive circuit.<br />

(Vdd= Approx. 5 V DC)<br />

2.3. POWER SUPPLY CLOCK GENERATION CIRCUIT<br />

�<br />

�<br />

������������<br />

�������<br />

�<br />

����������������������<br />

�����������<br />

���������<br />

�������<br />

������������<br />

�������������<br />

� �<br />

�������������<br />

�����������<br />

�������<br />

�����������<br />

�������<br />

���������<br />

�������<br />

���������<br />

�������<br />

������<br />

�������<br />

������������<br />

�������<br />

The voltage between the input terminal of DB1 and the output terminal of DB1 (GND) is divided by resistors R21, R22, and R23 and fed into digital.transistor<br />

Q21 to convert it into a square wave signal of the same frequency as the commercial power supply. The signal passes through resistor<br />

R25 and ceramic capacitor C22 and is fed into pin 1 of microprocessor LSI1.<br />

Microprocessor LSI1 uses this signal as a reference signal for the time count, and thereby identifies the power supply frequency and performs time<br />

control of various types of output.<br />

�<br />

�<br />

�<br />

�<br />

�

<strong>KC</strong><strong>C100E</strong>W<br />

If the state of this input signal remains "H" or "L" longer than a certain time, microprocessor LSI1 determines that a power failure has occurred and<br />

stops the output of the fan motor, plasma cluster unit, rotor motor, dust sensor, odor sensor, buzzer, and LEDs.<br />

2.4. CLOCK CIRCUIT<br />

This circuit generates the clock signal that is required for the operation of microprocessor LSI1.<br />

The oscillation frequency is 8 MHz and is supplied by ceramic oscillator CF1.<br />

2.5. KEY INPUT CIRCUIT<br />

When a key is pressed, a strobe signal corresponding to that key is fed into pin 19 or pin 20 of microprocessor LSI1. The strobe signal is detected and<br />

the pressed key identified.<br />

・Key ON : "H"<br />

・Key OFF : "L"<br />

2.6. LED DRIVE CIRCUIT<br />

・Static drive circuit<br />

ION SIGN LED, QUICK CLEAN LED, DUST MONITOR LED, ODOR MONITOR LED are controlled by static drive.<br />

When "H" is output from pins 21,22 of the microprocessor LSI-1, driverIC IC-110 is turned on and ION SIGN LED, QUICK CLEAN LED is lighted.<br />

Dust monitor LED1 ~ 4 are 2-color LED of green and red, and they will become yellow if green lights up simultaneously with red.<br />

According to the detection value of dust sensor or gas sensor, these LED are lighted as three colors of green, yellow and red.<br />

When "L" is output from pins 30 ~ 33,38,39,44,45 of the microprocessor LSI-1 according to the detection value of dust sensor, transistor Q130 ~<br />

Q137turned on and dust monitor LED 1 ~ 4 light to green, yellow or red.<br />

・Dynamic drive circuit<br />

LED other than LED which are controlled above-mentioned static drive are controlled by dynamic drive.<br />

Repeated "H" and "L" signals are output from pins 34 to 37 of microprocessor LSI1 to make the bases of the corresponding transistors Q110 to Q113<br />

successively go "L" for a set period of time and turn on each transistor. When "H" is output from one of pins 23 to 27 of microprocessor LSI1 at this<br />

timing and turn on each port of driver IC IC-110, the LED connected to that pin illuminates.<br />

2.7. EEPROM CIRCUIT<br />

The cumulative fan motor operating time (judgement time for turning on FILTER LED) and other data is written to or read from the EEPROM (IC90)by<br />

means of a repeated "H"/"L" signal from/to pins 17 and 18 of microprocessor LSI1.<br />

EEPROM(IC90) has memorized a part of deta peculiar to a model. (fan motor number of rotations, sensor detection level etc.)<br />

2.8. BUZZER CIRCUIT<br />

DriverIC IC-150 is driven by an "H"/"L" signal from pin 63 of microprocessor LSI1 to sound buzzer BZ1. The sounding frequency of the buzzer is<br />

approximately 4 kHz.<br />

2.9. ODOR SENSOR CIRCUIT (Not deployment in <strong>KC</strong>-C70E)<br />

A pulse signal is output from pin 58 of microprocessor LSI1 as the odor sensor drive signal, and this pulse-drives the odor sensor by means of the circuit<br />

consisting of R77,Q71, Q72, R73, R74, R76 and C73.<br />

The sensor output signal passes through R71 and C71 and is fed into pin 50 (the A/D conversion terminal) of microprocessor LSI1.<br />

2.9.1 PRINCIPLE OF THE ODOR SENSOR<br />

When an odor component such as ammonia, hydrogen or alchol comes in contact with the surface of the sensor element, which is a Metallic Oxide<br />

semiconductor, the resistsnce changes, and this is used to detect odors such as cigarette smoke and other common odors.<br />

・Weak odor : high resistance → high output voltage<br />

・Strong odor : low resistance → low output voltage<br />

2.9.2 CONTROL<br />

The detection value 5 seconds after the unit is powered on is taken as the reference value, and after that the value is detected at 1-second intervals<br />

and compared to the reference value to identify the dirtiness of the air, gas monitor display and fan motor control are performed based on the dirtiness<br />

of the air.<br />

However, from the last operation stop, when a new start is carried out within 1 minute, the reference value of the last operation is inherited.<br />

While the unit is running and for 1 minute after an operation the odor sensor continuously operates, however, when the unit stops the circuit is<br />

stopped to reduce standby power consumption.<br />

3 – 3

The degree of dirtiness detected with the odor sensor is judged in four steps, and turns on a gas monitor as follows.<br />

3 – 4<br />

<strong>KC</strong><strong>C100E</strong>W<br />

Reference value : Current level cleaner than reference value → The reference value is immediately changed to the current<br />

value.<br />

Current level dirtier than reference value and the level → The reference value is not changed.<br />

is changing<br />

When the level becomes cleaner than the reference level later,<br />

(odor suddenly increases due to cigarette smoke etc.) the reference value is updated.<br />

Current level dirtier than reference value<br />

but level does not change (natural change)<br />

→<br />

The reference value is not changed.<br />

The reference value is updateed to the cleanest state at 8minute<br />

intervals.<br />

When the saturation of the output in the direction of dirt is detected, the degree of dirtiness is revised as saturation processing every scheduled time<br />

by one step to the direction of clean.<br />

2.10. DUST SENSOR CIRCUIT<br />

A pulse signal is output through driver IC IC-150 from pin 61 of microprocessor LSI1as the dust sensor drive signal (the signal is fed into pin 3 of sensor<br />

connector DUST), and the sensor output (pin 5 of sensor connector DUST) signal passes through R62 and C63 and is fed into pin 49 (the A/D<br />

conversion terminal) of microprocessor LSI1.<br />

2.10.1 PRINCIPLE OF DUST SENSOR<br />

The infrared LED emits light based on the pulse signal input from the microprocessor, and the light reflects off from dust passing through the sensor.<br />

The internal light reception element detects this light, amplifies it, and outputs a signal from the output terminal.<br />

・Minimal dust : minimal received light → small output (low voltage)<br />

・Much dust : much received light → large output (high voltage)<br />

2.10.2 CONTROL<br />

The first time the unit is operated, the value approximately 2 seconds after the unit is powered on is compared to the initial reference value setting in<br />

the microprocessor. If clean, the reference value is updated to the new value.If dirtier than a specified value, the reference value is not changed.<br />

When operation is begun at later times, after 2 seconds the value is compared to the reference value of the previous time and control is performed<br />

accordingly.<br />

The dust sensor operates continuously while the unit runs and identifies the level of dirtiness by comparing the detection value with the reference<br />

value. every about 1 second. Dust monitor display, fan motor control are performed 9steps by <strong>KC</strong>-<strong>C100E</strong> and <strong>KC</strong>-C150E, 5steps by <strong>KC</strong>-C70E based<br />

on the level of dirtiness.<br />

Reference value : Current level cleaner than reference value → The reference value is immediately changed to the<br />

current value.<br />

: Current level dirtier than reference value → The reference value is not changed.<br />

→ When the level becomes cleaner than the reference<br />

level later, the reference value is updated.<br />

The dust sensor only operates while the unit is running. When the unit is stopped, the sensor is stopped to reduce standby power consumption.<br />

(DUST MONITOR DISPLAY) [ G : green Y:yellow R:red ]<br />

・<strong>KC</strong>-<strong>C100E</strong>, <strong>KC</strong>-C150E (Display by 4LED)<br />

�������������������<br />

�������<br />

・ <strong>KC</strong>-C70E (Display by 2LED)<br />

�������������������<br />

�������<br />

������������������� �������� ������ ��������� �������<br />

������� ����� ������ ���<br />

������������������� ������������������<br />

�����������������<br />

�������� �������� �������� �������� �������� �������� �������� �������� ��������<br />

������������ ������� ������� ������� ������������ ������� ������� ������� ������������<br />

�������� �������� �������� �������� ��������<br />

������������ ��� ������������ ��� ������������

<strong>KC</strong><strong>C100E</strong>W<br />

2.11. TEMPERATURE AND HUMIDITY SENSOR CIRCUIT<br />

The temperature and humidity in the room are minitored by the temperature and humidity sensors.<br />

The temperature sensor detects the temperature by feeding the signal of HUMI connector's pin4 into pin51 of microprocessor LSI1.<br />

The humidity sensor detects the humidity by feeding the signal of HUMI connector's pin2 into pin52 of microprocessor LSI1.<br />

2.12. FAN MOTOR DRIVE CIRCUIT<br />

The fan motor has 4 input terminals and 1 output terminal.<br />

Vm<br />

(Pin 7-FM)<br />

GND<br />

(Pin 5-FM)<br />

Vcc<br />

(Pin 3-FM)<br />

Vs<br />

(Pin 2-FM)<br />

PG<br />

(Pin CN-C1)<br />

: DC voltage input that supplies the power for motor revolution (Vm= approx. 311 V DC).<br />

Vm is created by the power circuit and input directly. Supplied continuously.<br />

: Ground.<br />

Vm, Vcc, Vs, PG and all other voltages are differences in electric potential relative to this value.<br />

: DC voltage input terminal that forms the power supply for the circuit inside the fan motor.<br />

When the unit is running, an "H" signal from pin62 of microprocessor LSI-1 causes IC-150 and Q44 to turn ON and supply a<br />

voltage approximately equal to VL to Vcc (Vcc = approx. 15 V DC).<br />

: Input terminal that controls the rpm of the fan motor (speed command signal).<br />

Following supply to Vcc when the unit is running, a PWM (x/256ms) pulse is output from pin 41 of microprocessor LSI1. This<br />

is smoothed by the circuit consisting of C41, R41 to R43, Q41, and Q42, and after passing through R46 and C43, supplies a<br />

DC voltage to Vs (Vs = approx. 0 to 6 V DC).<br />

: Fan motor rpm output terminal (feedback signal).<br />

Outputs a pulse signal according to the rpm, which passes through the circuit consisting of R44, R45, R47, and C42 is fed<br />

into pin 40 of microprocessor LSI-1.<br />

The microprocessor obtains the current rpm based on this PG signal and controls the above Vs signal to attain the specified<br />

rpm. This control takes place continuously.<br />

2.13. PLASMACLUSTER DRIVE CIRCUIT<br />

The plasma cluster unit is a power supply unit that supplies high voltage for the emission of ions from the cluster electrode. 12V DC is supplied to the<br />

plasma cluster unit to operate it.<br />

When "H" is output from pin 64 of microprocessor LSI1 to turn on driver IC IC-150, the unit is running.<br />

2.14. WATER LEVEL DETECTION CIRCUIT<br />

This detects whether or not there is water in the humidification tray.<br />

When water is contained in the humidification tray, Hall IC outputs the "L" level, and when water is not contained in the humidification tray,<br />

Hall IC turns off and serves as the "H" level by pull-up resistance R121.<br />

The sensor output signal passes through R123 and C121 and is fed into pin8 of microprocessor LSI1.<br />

2.15. ROTOR MOTOR DRIVE CIRCUIT<br />

Supply of 220V AC takes place when solid state relay SSR1 turns on.<br />

When the humidification filter frame rotates, "H" is output from pin 59 of microprocessor LSI1 to turn on driverIC IC-150 and thereby drive SSR1.<br />

However, when it is judged that water is not in the humidification tray by a water level detection circuit, solid state relay SSR1 does not turn on.<br />

2.16. ROTOR POSITION DETECTION CIRCUIT<br />

This is a circuit for detecting the position where the humidification filter is not soaked in the water in the humidification tray.<br />

When the humidification filter frame rotates and reaches to the position where the humidification filter is not soaked in the water in the humidification<br />

tray, Hall IC outputs the "L" level.<br />

When there is no humidification filter in the position which is not soaked in the water of the humidification tray, Hall IC turns off and serves as the "H"<br />

level. by pull-up resistance R120.<br />

The sensor output signal passes through R122 and C120 and is fed into pin2 of microprocessor LSI1, and the position of a humidification filter is<br />

judged.<br />

3 – 5

[3] TEST MODE<br />

1. Overview Test mode is used to check the operation of the circuit boards, sensors, and load outputs.<br />

2. Entering test mode Turn on the power while pressing the "PLASMACLUSTER ON/OFF BUTTON" and "FAN SPEED BUTTON".<br />

3. Exiting test mode Pushing the "POWER OFF BUTTON"or wait for tens of seconds to 1 minute after turning off the power.<br />

4. Description Follow the procedures below to check the operation of the circuit boards, sensors, and load outputs.<br />

��� �� �����<br />

��<br />

�����������<br />

�����<br />

�������������������<br />

������������������� �����������������<br />

���������������<br />

�������������������� ����������������� �������� � ������������������������������<br />

� � � � ������ � ���� �<br />

��� �<br />

�����������<br />

����������<br />

� �������� � �<br />

�<br />

�<br />

�<br />

�<br />

�����������������������������<br />

��������������������<br />

����������������������������<br />

� ��� � �<br />

�� �� �� �� �� ���������� ��������������������������������������������<br />

��� � � � � � � �<br />

����������������������������� ����������������� �������� � � ������������������������������������<br />

� �<br />

�����<br />

� � ������ �<br />

�<br />

���� �<br />

��� �<br />

��� �<br />

���������<br />

����������<br />

�<br />

�������� �<br />

�<br />

�<br />

�<br />

�<br />

� �<br />

�� �� �� �� �� ����������<br />

���� ��<br />

���������������<br />

��� � � � � � � �<br />

����������������������������� ����������������� �������� � �����������������������������<br />

� �<br />

�����<br />

� � ������ �<br />

�<br />

���� �<br />

��� �<br />

��� �<br />

���������<br />

����������<br />

� �������� �<br />

�<br />

�<br />

�<br />

�<br />

� �<br />

�� �� �� �� �� ����������<br />

���� �<br />

���������������<br />

��� � � � � � � �<br />

����������������������������� ����������������� �������� � �������������������������������<br />

� �<br />

�����<br />

� � ������ � ���� �<br />

��� �<br />

���������<br />

����������<br />

� �������� � �<br />

�<br />

�<br />

� ����������<br />

������������<br />

�<br />

�������������������������<br />

������������������������������������������������<br />

��������������������������������������������������������<br />

� ��� � � �� �� �� �� �� ���������� ����������������������������<br />

��� � � � � � � � ����������������������������������������<br />

�������������������������<br />

���������������������������� �������� �������� � �������������������<br />

� �<br />

�����<br />

� � ������ � ���� �<br />

��� �<br />

���������<br />

����������<br />

� �������� � �<br />

�<br />

�<br />

�<br />

�<br />

�������������������������������������������<br />

��������������������������<br />

����������������������������<br />

� ��� � � �� �� �� �� �� ���������� �������������������������������������������<br />

��� � ����������������������� � � � � � � ������������������������<br />

�����������������������������������������<br />

�����������������������<br />

������������������������������������������<br />

�������� �������� � ����������������������<br />

� �<br />

�����<br />

� � ������ � ���� �<br />

��� �<br />

���������<br />

����������<br />

� �������� � �<br />

�<br />

�<br />

�<br />

�<br />

������������������������������������������<br />

� ��� � � �� �� �� �� �� ����������<br />

��� � ����������������������� � � � � � �<br />

���������������������������������� �������� �������� � ����������������������<br />

� �<br />

�����<br />

� � ������ � ���� �<br />

��� �<br />

���������<br />

����������<br />

� �������� � �<br />

�<br />

�<br />

�<br />

�<br />

������������������������������������������<br />

� ��� � � �� �� �� �� �� ����������<br />

��� � ����������������������� � � � � � �<br />

��������������������������<br />

� � � � ������ �<br />

�����<br />

���� �<br />

��� �<br />

����������������� �������� �<br />

���������<br />

����������<br />

�<br />

� �������� � �<br />

�<br />

� ����������<br />

������������<br />

�<br />

���������������������������<br />

� ��� � � �� �� �� �� �� ���������� � �������������������������������<br />

��� � ����������������������� � � � � � �<br />

���������������������������������������������� ����������������� �������� � � �������������������������������<br />

� �<br />

�����<br />

�<br />

�<br />

�<br />

������ � ���� �<br />

��� �<br />

���������<br />

����������<br />

� �������� � �<br />

�<br />

�<br />

� ����������<br />

������������<br />

�<br />

���������������������������������������<br />

������������������������������������������<br />

������������������������������<br />

���� � ��� � � �� �� �� �� �� ���������� �������������������������������������������<br />

��� � ����������������������� � � � � � � �������������������������������<br />

��������������������������<br />

�����������������������������������������������������<br />

�������� �����������������������������������������<br />

�������������������<br />

3 – 6<br />

<strong>KC</strong><strong>C100E</strong>W

<strong>KC</strong><strong>C100E</strong>W<br />

��������������������������������������������<br />

���������������������������������������������������������������������������������������������������������<br />

[4] ERROR MODE<br />

1) Overview<br />

Error mode is a self-diagnostic function that uses sensors to detect abnormal conditions and failures in the unit and circuits, and executes load<br />

operation and error displays based on what is detected. The unit has 6 error modes.<br />

2) Ceramic oscillator error<br />

(1) Overview<br />

Error mode that activates when detecting oscillation abnormality of the ceramic oscillator.<br />

(2) Detection time<br />

During electricity always<br />

(3) Error display<br />

ION SHOWER LED flashes in a 1-second cycle. All other LEDs are off.<br />

(4) Load operation<br />

All loads are turned off. The buzzer does not sound.<br />

(5) Switch operation<br />

All switch operations are disabled.<br />

(6) Solution<br />

Replace the circuit board.<br />

3) EEPROM error<br />

�������������������<br />

(1) Overview<br />

Error mode that activates if a communication error or data error is detected while reading the EEPROM after the unit is powered on.<br />

(2) Detection time<br />

Immediately following unit power-on.<br />

(3) Error display<br />

The AUTO LED flashes in a 1-second cycle. All other LED are off.<br />

(4) Load operation<br />

All loads are turned off. The buzzer does not sound.<br />

(5) Switch operation<br />

All switch operations are disabled.<br />

(6) Solution<br />

Replace the circuit board.<br />

4) Fan motor rpm error<br />

�������������������� �������������������������<br />

����������������<br />

���������������<br />

���������������<br />

������������������������<br />

�����<br />

����������������������������<br />

����� ��������<br />

�������������<br />

�������������������������������������<br />

�������������������<br />

�����������������<br />

��������������������������������������<br />

��������������������������������������<br />

����������������<br />

3 – 7<br />

�������������������������<br />

�������������������������<br />

���������������������������������������������������������������<br />

����������������������������������������<br />

�����������������������������������������������<br />

�������������������<br />

������������������������������������������������������<br />

���������������������<br />

�������������������������<br />

(1) Overview<br />

Error mode that activates when locking of the fan motor or an open connector is detected.<br />

This error mode activates when the rpm of the fan motor is detected to be 0rpm consecutively for 15 seconds.<br />

(2) Detection time<br />

During all modes when unit is running.<br />

(3) Error display<br />

The LOW LED flashes in a 1-second cycle. All other LED are off.<br />

(4) Load operation<br />

All loads are immediately turned off and operation is stopped. The buzzer does not sound.

(5) Switch operation<br />

All switches are effective as usual.<br />

(6) Solution<br />

Verify that the connector of the fan motor is inserted, otherwise, replace the fan motor or the circuit board.<br />

5) Humidification rotor position detection error<br />

6) Room temperature sensor error<br />

7) Humidity sensor error<br />

3 – 8<br />

<strong>KC</strong><strong>C100E</strong>W<br />

(1) Overview<br />

Error mode that activates when locking of the humidification Humid motor or an open connector is detected..<br />

This error mode activates when there is not the state change of the position detection SW during Humid motor operating for 4minutes.<br />

( In normalcy, the position detection SW is ON for about 1 second once in about 90 seconds.)<br />

When it ran without setting the humidification filter frames at a unit, this error mode activates equally.<br />

(2) Detection time<br />

During “CLEAN <strong>AIR</strong> & HUMIDIFY” running. (Except for a setting Fan speed “MAX”.)<br />

(3) Error display<br />

The CLEAN <strong>AIR</strong> & HUMIDIFY LED flashes in a 1-second cycle.<br />

(4) Load operation<br />

Humidification Humid motor is turned off and another loads are continues operation..<br />

(5) Switch operation<br />

All switches are effective as usual.<br />

(6) Solution<br />

① Install the humidification filter, filter frame, tray, and float precisely.<br />

It is removed by the change of the driving mode. (Not removed by the change of the fan speed mode.)<br />

At the time of water feed detection change ( no water → enough water ), it is removed.<br />

② Verify that the connector of the Humid motor and Humid position pwb unit is inserted definitely.<br />

③ Replace the Humid motor , circuit board.<br />

(1) Overview<br />

Error mode that activates when a short-circuit or broken wire is detected in the room temperature sensor. Operation of all modes .<br />

Operation of all modes continues and the unit can be operated normally.<br />

(2) Detection time<br />

After 2 seconds progress from a startup the unit.. (Remove 5 seconds after the power supply outlet insertion.)<br />

(3) Error display<br />

The humidity indicator lamp (30) flashes in a 1-second cycle. All other LED continue normal operation. [<strong>KC</strong><strong>C100E</strong> . <strong>KC</strong>C150E]<br />

The humidity indicator lamp (LOW) flashes in a 1-second cycle. All other LED continue normal operation. [<strong>KC</strong>C70E]<br />

However, when the water supply lamp is on, it does not display.<br />

(4) Load operation<br />

All load outputs continue normal operation. (Control for room temperature 20 ℃ ).<br />

(6) Solution<br />

Verify that the connector of the temperature and humidity sensor is inserted. Otherwise, replace the temperature and humidity sensor<br />

or the circuit board.<br />

(1) Overview<br />

Error mode that activates when a short-circuit or broken wire is detected in the circuit to detect humidity.<br />

Operation of all modes continues and the unit can be operated normally.<br />

(2) Detection time<br />

After 2 seconds progress from a startup the unit.. (Remove 5 seconds after the power supply outlet insertion.)<br />

(3) Error display<br />

The humidity indicator lamp (70) flashes in a 1-second cycle. All other LED continue normal operation. [<strong>KC</strong><strong>C100E</strong> . <strong>KC</strong>C150E]<br />

The humidity indicator lamp (HIGH) flashes in a 1-second cycle. All other LED continue normal operation. [<strong>KC</strong>C70E]<br />

However, when the water supply lamp is on, it does not display.<br />

(4) Load operation<br />

All load outputs continue normal operation. (Control for humidity 30%)<br />

(6) Solution<br />

Verify that the connector of the temperature and humidity sensor is inserted. Otherwise, replace the temperature and humidity sensor<br />

or the circuit board.

<strong>KC</strong><strong>C100E</strong>W<br />

[5] PRINTED WIRING BOARD<br />

3 – 9

[6] CONTROL CIRCUIT DIAGRAM<br />

AC220~240V 50/60Hz<br />

3 – 10<br />

<strong>KC</strong><strong>C100E</strong>W<br />

E

<strong>KC</strong><strong>C100E</strong>W<br />

<strong>KC</strong><strong>C100E</strong>W CHAPTER 4. TROUBLESHOOTING GUIDEService<br />

Manual<br />

• When replacing parts, use only the specified parts.<br />

• Service of the PWB ass'y:<br />

* The PWB ass'y set consists of the control board K, the power supply board K, the gas sensor board K, and the IC switch board K. All are X.<br />

[1] TROUBLESHOOTING<br />

No. Trouble Possible cause and symptom Remedy<br />

1 The unit does not run Wiring failure Check connector insertion; repair or replace<br />

When rotated by hand, the fan is very heavy<br />

(motor failure + blown board current fuse)<br />

Replace motor and PWB ass'y<br />

Blown current fuse [FUSE1] on power supply Inspect motor and then replace board (rotate<br />

board K.<br />

fan by hand and if very heavy, replace motor<br />

and board)<br />

Blown current fuse [FUSE1] on power supply Replace PWB ass'y<br />

board K and damaged varistor [VRS1] (Possibility that 470 V was applied)<br />

PWB ass'y failure Replace<br />

Broken wire in power cord Replace<br />

2 Clean ion shower Indicator Light flashes<br />

and unit does not run<br />

PWB ass'y failure Replace<br />

3 Fan speed indicator light "LOW " flash or Motor harness not correctly inserted in board Insert connector<br />

blinks and unit does not run<br />

Motor failure Replace<br />

PWB ass'y failure Replace<br />

4 Fan speed indicator light "AUTO "flash or<br />

blinks and unit does not run<br />

PWB ass'y failure Replace<br />

5 Clean Air & Humidify Indicator Light Humidification motor harness not correctly insert connector<br />

flashes and Clean Air & Humidify Mode inserted in board<br />

does not run<br />

Humidification motor failure Replace<br />

Humidification motor ass'y failure Repar or Replace<br />

Humidification filter ass'y failure Repar or Replace<br />

PWB ass'y failure Replace<br />

6 Humidity indicator light "30" flash or The Temperature/Humidity Sensor harness Connector insertion.<br />

blinks.<br />

has not been correctly inserted.<br />

The Temperature/Humidity Sensor is defective.<br />

Temperature/Humidity Sensor exchange.<br />

The PWB unit is defective. PWB unit exchange.<br />

7 Humidity Indicator light "70" flash or blinks The Temperature/Humidity Sensor harness<br />

has not been correctly inserted.<br />

Connector insertion<br />

The Temperature/Humidity Sensor is defective.<br />

Temperature/Humidity Sensor exchange.<br />

The PWB unit is defective. PWB unit exchange.<br />

8 Unit immediately resets (operation stops) PWB ass'y failure Replace<br />

9 No response when button pressed Button stays down when pressed Repair<br />

Defective assembly. Repair or replace<br />

PWB ass'y failure Replace<br />

10 Abnormal noise is heard Defective motor installation Repair<br />

Defective fan installation Repair or replace<br />

Motor failure Replace<br />

Defective fan shape Replace<br />

Defective Humidification motor ass'y installation<br />

Repair<br />

Humidification motor ass'y failure Replace<br />

Humidification motor failure Replace<br />

Defective Humidification filter ass'y installation<br />

Repair<br />

Humidification filter ass'y failure Replace<br />

11 Front monitor does not display normally Dust has accumulated on sensor filter of dust<br />

sensor<br />

Clean sensor filter<br />

Unit used in a location such as a kitchen<br />

where there is oily smoke or soot<br />

Clean sensor and/or replace part/board<br />

Defective wiring Repair or replace<br />

Dust sensor failure Replace dust sensor<br />

PWB ass'y failure Replace PWB ass'y<br />

4 – 1

No. Trouble Possible cause and symptom Remedy<br />

Does not humidify. Life of Mist filter. Mist filter exchange.<br />

12<br />

Tank cap defective.<br />

Humidication motor failure<br />

Tank cap exchange.<br />

Humidication motor exchange<br />

The PWB unit is defective. PWB unit exchange.<br />

13<br />

The water of the tank does not decrease. Life of Mist filter.<br />

Tank cap defective.<br />

Mist filter exchange.<br />

Tank cap exchange.<br />

14<br />

15<br />

16<br />

The water supply indicator light doesn't<br />

flash even if water is lost.<br />

The water supply lamp doesn't go off<br />

even<br />

Hole IC PWB defective. PWB unit exchange.<br />

The PWB unit is defective. PWB unit exchange.<br />

Float defective. Float exchange.<br />

Hole IC PWB defective. PWB unit exchange.<br />

The PWB unit is defective. PWB unit exchange.<br />

Float defective. Float exchange.<br />

The wind of the air outlet smells. There is a smell even if the Washable Active<br />

Carbon filter is washed as shown in the manual.<br />

The odor which is stained in the HEPA filter is<br />

discharged.<br />

There is a smell even if the Mist filter is<br />

washed as shown in the manual.<br />

4 – 2<br />

<strong>KC</strong><strong>C100E</strong>W<br />

Washable Active Carbon filter exchange.<br />

HEPA filter exchange.<br />

Mist filter exchange.<br />

Problem Not a failure<br />

Cause and symptom Remedy<br />

Poor dust collection ability. The prefilter is clogged Clean<br />

An object is obstructing the air intake or air outlet Move unit to a different place<br />

Past the filter replacement time Replace filter<br />

Air blown out has unpleasant odour. Washable active carbon filter not dried sufficiently Dry washable active carbon filter sufficiently after<br />

after being washed<br />

washing<br />

Unpleasant odour emitted from HEPA filter Replace HEPA filter (charge required)<br />

Unpleasant odour emitted from Humidification filter Replace Humidification filter (charge required)<br />

Unit makes a repeated clicking sound. This sound is made when plasmacluster ions are generated. Advise people who are bothered by this<br />

sound to place the unit farther away.<br />

Unit sometimes makes a clicking sound, The intensity of the sound varies (sometimes it is almost imperceptible) depending on the humidity in<br />

sometimes not<br />

the room, however, the plasmacluster ion effect is the same.<br />

Unit makes a bubbling sound. This is the sound of air entering the tank when it is supplying the mist tray with water.<br />

Filter indicatar light dose not turn off. Insert the plug into the power outlet and press the filter reset button on the unit. Advise customer to be<br />

sure to press the button for 3 seconds after washing the filter.<br />

The water supply indicator light doesn't flash<br />

even if water is lost.<br />

Does dirt and the foreign body adhere to the float<br />

and<br />

Maintain the Mist tray.<br />

the tray and does not the movement of the float<br />

worsen?<br />

when cannot be repaired, exchange.<br />

The water supply indicator light doesn't go off<br />

even if water is put in.<br />

Does dirt and the foreign body adhere to the float<br />

and<br />

Maintain the Mist tray.<br />

the tray and does not the movement of the float When cannot be repaired, exchange.<br />

worsen? The tray is not correctly installed.<br />

Tray insertion.<br />

The water of the tank does not decrease. The Mist filter is not maintained. Maintain the Mist filter.<br />

When cannot be repaired, exchange.<br />

The HEPA filter and Washable Deodrizing filter is Maintain the HEPA filter and Washable Deodriz-<br />

not<br />

ing filter.<br />

maintained. When cannot be repaired, exchange.<br />

Does not humidify. The Mist filter is not maintained. Maintain the Mist filter.<br />

When cannot be repaired, exchange.<br />

The HEPA filter and Washable Deodrizing filter is Maintain the HEPA filter and Washable Deodriz-<br />

not<br />

ing filter.<br />

maintained. When cannot be repaired, exchange.<br />

It is humidifying "Automatic operation" and the<br />

humidity of<br />

the room is more than target value (55 to 65%).<br />

Changes into manual operation.

<strong>KC</strong><strong>C100E</strong>W<br />

<strong>KC</strong><strong>C100E</strong>W CHAPTER 5. REPLACEMENT OF MAIN PARTS Service Manual<br />

• During assemply of the unit following service, make sure that all screws are replaced in their original positions.<br />