HEMPEL HEMPEL'S EPOXY KNIFING FILLER 355SA

HEMPEL HEMPEL'S EPOXY KNIFING FILLER 355SA

HEMPEL HEMPEL'S EPOXY KNIFING FILLER 355SA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Product Data<br />

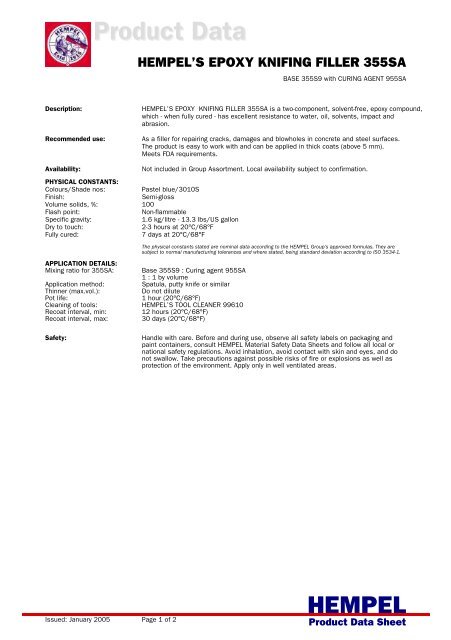

<strong>HEMPEL</strong>’S <strong>EPOXY</strong> <strong>KNIFING</strong> <strong>FILLER</strong> <strong>355SA</strong><br />

BASE 355S9 with CURING AGENT 955SA<br />

Description: <strong>HEMPEL</strong>’S <strong>EPOXY</strong> <strong>KNIFING</strong> <strong>FILLER</strong> <strong>355SA</strong> is a two-component, solvent-free, epoxy compound,<br />

which - when fully cured - has excellent resistance to water, oil, solvents, impact and<br />

abrasion.<br />

Recommended use: As a filler for repairing cracks, damages and blowholes in concrete and steel surfaces.<br />

The product is easy to work with and can be applied in thick coats (above 5 mm).<br />

Meets FDA requirements.<br />

Availability: Not included in Group Assortment. Local availability subject to confirmation.<br />

PHYSICAL CONSTANTS:<br />

Colours/Shade nos: Pastel blue/3010S<br />

Finish: Semi-gloss<br />

Volume solids, %: 100<br />

Flash point: Non-flammable<br />

Specific gravity: 1.6 kg/litre - 13.3 lbs/US gallon<br />

Dry to touch: 2-3 hours at 20°C/68°F<br />

Fully cured: 7 days at 20°C/68°F<br />

The physical constants stated are nominal data according to the <strong>HEMPEL</strong> Group's approved formulas. They are<br />

subject to normal manufacturing tolerances and where stated, being standard deviation according to ISO 3534-1.<br />

APPLICATION DETAILS:<br />

Mixing ratio for <strong>355SA</strong>: Base 355S9 : Curing agent 955SA<br />

1 : 1 by volume<br />

Application method: Spatula, putty knife or similar<br />

Thinner (max.vol.): Do not dilute<br />

Pot life: 1 hour (20°C/68°F)<br />

Cleaning of tools: <strong>HEMPEL</strong>’S TOOL CLEANER 99610<br />

Recoat interval, min: 12 hours (20°C/68°F)<br />

Recoat interval, max: 30 days (20°C/68°F)<br />

Safety: Handle with care. Before and during use, observe all safety labels on packaging and<br />

paint containers, consult <strong>HEMPEL</strong> Material Safety Data Sheets and follow all local or<br />

national safety regulations. Avoid inhalation, avoid contact with skin and eyes, and do<br />

not swallow. Take precautions against possible risks of fire or explosions as well as<br />

protection of the environment. Apply only in well ventilated areas.<br />

Issued: January 2005 Page 1 of 2<br />

1/2<br />

<strong>HEMPEL</strong><br />

Product Data Sheet

<strong>HEMPEL</strong>'S <strong>EPOXY</strong> <strong>KNIFING</strong> <strong>FILLER</strong> <strong>355SA</strong><br />

SURFACE The surface must be sound and free from dust, loose paint, oil/grease and other contaminants.<br />

PREPARATION: Metal: Remove oil and grease, etc. with suitable detergent. Remove salt and other contaminants<br />

by (high pressure) fresh water cleaning. Abrasive blasting, power tool cleaning or sanding,<br />

depending on material and condition of the surface. Finally clean the area with <strong>HEMPEL</strong>’S THINNER<br />

08450. Priming after abrasive blast cleaning, but prior to filling, can be done with a thin layer of<br />

e.g. HEMPADUR 15590.<br />

Concrete: Remove slip agent and other possible contaminants by emulsion washing followed by<br />

high pressure hosing with fresh water. Remove scum layer and loose matter to a hard, rough and<br />

uniform surface, preferably by abrasive blasting, possibly by other mechanical treatment or acid<br />

etching. Seal surface with suitable sealer, e.g. HEMPADUR SEALER 05990, prior to filling.<br />

APPLICATION Use only where application and curing can proceed at temperatures above 5°C/41°F.<br />

CONDITIONS: The temperature of the substrate should also be above this limit.<br />

Apply only on a dry and clean surface with a temperature above the dew point to avoid<br />

condensation.<br />

PRECEDING None, or according to specification.<br />

COAT:<br />

SUBSEQUENT According to specification.<br />

COAT:<br />

REMARKS: Mix and stir the two components thoroughly until an even colour is achieved, whereafter the filler is<br />

ready for use. Do not mix more than is necessary for use within the pot life.<br />

If the maximum recoating interval is exceeded, roughening of the surface is necessary to ensure<br />

intercoat adhesion.<br />

May be sanded after 20 hours (20°C/68°F).<br />

Note: <strong>HEMPEL</strong>’S <strong>EPOXY</strong> <strong>KNIFING</strong> <strong>FILLER</strong> <strong>355SA</strong> is for professional use only.<br />

ISSUED BY: <strong>HEMPEL</strong> PAINTS (SAUDI ARABIA) W.L.L. - <strong>355SA</strong>3010SSA004<br />

This Product Data Sheet supersedes those previously issued.<br />

For explanations, definitions and scope, see “Explanatory Notes” in the <strong>HEMPEL</strong> Book.<br />

Data, specifications, directions and recommendations given in this data sheet represent only test results or<br />

experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness<br />

under the actual conditions of any intended use of the Products herein must be determined exclusively<br />

by the Buyer and/or User.<br />

The Products are supplied and all technical assistance is given subject to <strong>HEMPEL</strong>'s GENERAL CONDITIONS OF<br />

SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed in writing. The Manufacturer and Seller<br />

disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence,<br />

except as expressed in said GENERAL CONDITIONS for all results, injury or direct or consequential losses or<br />

damages arising from the use of the Products as recommended above, on the overleaf or otherwise.<br />

Product data are subject to change without notice and become void five years from the date of issue.<br />

Issued: January 2005 Page 2 of 2<br />

2/2<br />

Product Data Sheet