Tungsten - Mining Journal

Tungsten - Mining Journal

Tungsten - Mining Journal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2<br />

OVERVIEW<br />

CONTENTS<br />

Overview 2-4<br />

Exploration 5-6<br />

Map 8-9<br />

Profi les:<br />

Amanta Resources 7<br />

Geodex Minerals 10<br />

Malaga 11<br />

North American <strong>Tungsten</strong> 12<br />

Oriental Resources 13<br />

Ormonde <strong>Mining</strong> 14<br />

Queensland Ores 15<br />

Cover: montage of scheelite and tungsten images,<br />

with ‘w’ the chemical symbol for wolfram<br />

Photo: North American <strong>Tungsten</strong><br />

Published in June 2008 by:<br />

<strong>Mining</strong> Communications Ltd<br />

Albert House, 1 Singer Street<br />

London EC2A 4BQ<br />

Tel: +44 (0)20 7216 6060 Fax: +44 (0)20 7216 6050<br />

E-mail: editorial@mining-journal.com<br />

Website: www.mining-journal.com<br />

Supplement editor: Chris Hinde<br />

Design and production: Tim Peters,<br />

Karen Leverington, Vickie Johnstone<br />

Printed by Latimer Trend, Plymouth, UK<br />

© <strong>Mining</strong> Communications Ltd 2008<br />

An Aspermont company<br />

ITIA<br />

The International <strong>Tungsten</strong> Industry Association<br />

was inaugurated in Brussels in February 1988, and<br />

is registered as an association with scientifi c<br />

purposes under Belgian law. The members of ITIA,<br />

from 17 countries, include mining companies,<br />

processors/consumers, trading companies and<br />

assayers. Website: www.itia.org.uk<br />

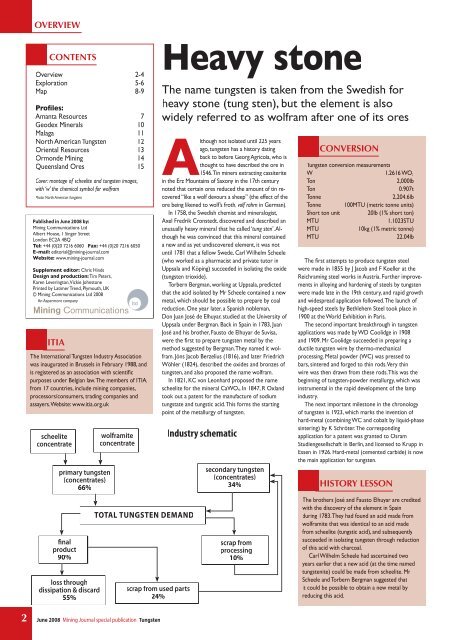

scheelite<br />

concentrate<br />

primary tungsten<br />

(concentrates)<br />

66%<br />

� nal<br />

product<br />

90%<br />

loss through<br />

dissipation & discard<br />

55%<br />

wolframite<br />

concentrate<br />

TOTAL TUNGSTEN DEMAND<br />

scrap from used parts<br />

24%<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong><br />

Heavy stone<br />

The name tungsten is taken from the Swedish for<br />

heavy stone (tung sten), but the element is also<br />

widely referred to as wolfram after one of its ores<br />

Although not isolated until 225 years<br />

ago, tungsten has a history dating<br />

back to before Georg Agricola, who is<br />

thought to have described the ore in<br />

1546. Tin miners extracting cassiterite<br />

in the Erz Mountains of Saxony in the 17th century<br />

noted that certain ores reduced the amount of tin recovered<br />

“like a wolf devours a sheep” (the effect of the<br />

ore being likened to wolf’s froth, volf rahm in German).<br />

In 1758, the Swedish chemist and mineralogist,<br />

Axel Fredrik Cronstedt, discovered and described an<br />

unusually heavy mineral that he called ‘tung sten’. Although<br />

he was convinced that this mineral contained<br />

a new and as yet undiscovered element, it was not<br />

until 1781 that a fellow Swede, Carl Wilhelm Scheele<br />

(who worked as a pharmacist and private tutor in<br />

Uppsala and Köping) succeeded in isolating the oxide<br />

(tungsten trioxide).<br />

Torbern Bergman, working at Uppsala, predicted<br />

that the acid isolated by Mr Scheele contained a new<br />

metal, which should be possible to prepare by coal<br />

reduction. One year later, a Spanish nobleman,<br />

Don Juan José de Elhuyar, studied at the University of<br />

Uppsala under Bergman. Back in Spain in 1783, Juan<br />

José and his brother, Fausto de Elhuyar de Suvisa,<br />

were the fi rst to prepare tungsten metal by the<br />

method suggested by Bergman. They named it wolfram.<br />

Jöns Jacob Berzelius (1816), and later Friedrich<br />

Wöhler (1824), described the oxides and bronzes of<br />

tungsten, and also proposed the name wolfram.<br />

In 1821, KC von Leonhard proposed the name<br />

scheelite for the mineral CaWO4. In 1847, R Oxland<br />

took out a patent for the manufacture of sodium<br />

tungstate and tungstic acid. This forms the starting<br />

point of the metallurgy of tungsten.<br />

Industry schematic<br />

secondary tungsten<br />

(concentrates)<br />

34%<br />

scrap from<br />

processing<br />

10%<br />

CONVERSION<br />

<strong>Tungsten</strong> conversion measurements<br />

W 1.2616 WO3<br />

Ton 2,000lb<br />

Ton 0.907t<br />

Tonne 2,204.6lb<br />

Tonne 100MTU (metric tonne units)<br />

Short ton unit 20lb (1% short ton)<br />

MTU 1.1023STU<br />

MTU 10kg (1% metric tonne)<br />

MTU 22.04lb<br />

The fi rst attempts to produce tungsten steel<br />

were made in 1855 by J Jacob and F Koeller at the<br />

Reichraming steel works in Austria. Further improvements<br />

in alloying and hardening of steels by tungsten<br />

were made late in the 19th century, and rapid growth<br />

and widespread application followed. The launch of<br />

high-speed steels by Bethlehem Steel took place in<br />

1900 at the World Exhibition in Paris.<br />

The second important breakthrough in tungsten<br />

applications was made by WD Coolidge in 1908<br />

and 1909. Mr Coolidge succeeded in preparing a<br />

ductile tungsten wire by thermo-mechanical<br />

processing. Metal powder (WC) was pressed to<br />

bars, sintered and forged to thin rods. Very thin<br />

wire was then drawn from these rods. This was the<br />

beginning of tungsten-powder metallurgy, which was<br />

instrumental in the rapid development of the lamp<br />

industry.<br />

The next important milestone in the chronology<br />

of tungsten is 1923, which marks the invention of<br />

hard-metal (combining WC and cobalt by liquid-phase<br />

sintering) by K Schröter. The corresponding<br />

application for a patent was granted to Osram<br />

Studiengesellschaft in Berlin, and licensed to Krupp in<br />

Essen in 1926. Hard-metal (cemented carbide) is now<br />

the main application for tungsten.<br />

HISTORY LESSON<br />

The brothers José and Fausto Elhuyar are credited<br />

with the discovery of the element in Spain<br />

during 1783. They had found an acid made from<br />

wolframite that was identical to an acid made<br />

from scheelite (tungstic acid), and subsequently<br />

succeeded in isolating tungsten through reduction<br />

of this acid with charcoal.<br />

Carl Wilhelm Scheele had ascertained two<br />

years earlier that a new acid (at the time named<br />

tungstenite) could be made from scheelite. Mr<br />

Scheele and Torbern Bergman suggested that<br />

it could be possible to obtain a new metal by<br />

reducing this acid.