Tungsten - Mining Journal

Tungsten - Mining Journal

Tungsten - Mining Journal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

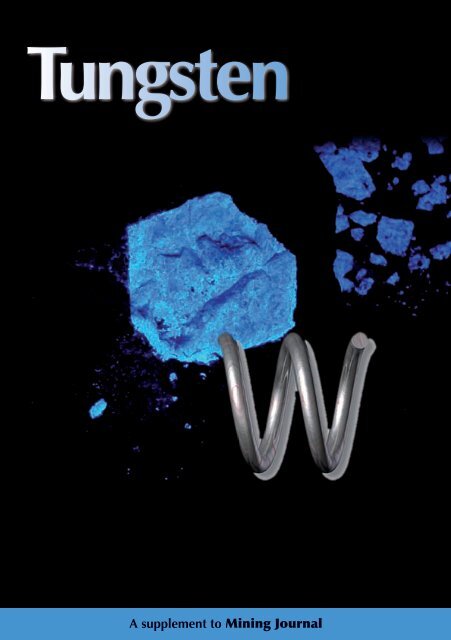

<strong>Tungsten</strong><br />

A supplement to <strong>Mining</strong> <strong>Journal</strong>

2<br />

OVERVIEW<br />

CONTENTS<br />

Overview 2-4<br />

Exploration 5-6<br />

Map 8-9<br />

Profi les:<br />

Amanta Resources 7<br />

Geodex Minerals 10<br />

Malaga 11<br />

North American <strong>Tungsten</strong> 12<br />

Oriental Resources 13<br />

Ormonde <strong>Mining</strong> 14<br />

Queensland Ores 15<br />

Cover: montage of scheelite and tungsten images,<br />

with ‘w’ the chemical symbol for wolfram<br />

Photo: North American <strong>Tungsten</strong><br />

Published in June 2008 by:<br />

<strong>Mining</strong> Communications Ltd<br />

Albert House, 1 Singer Street<br />

London EC2A 4BQ<br />

Tel: +44 (0)20 7216 6060 Fax: +44 (0)20 7216 6050<br />

E-mail: editorial@mining-journal.com<br />

Website: www.mining-journal.com<br />

Supplement editor: Chris Hinde<br />

Design and production: Tim Peters,<br />

Karen Leverington, Vickie Johnstone<br />

Printed by Latimer Trend, Plymouth, UK<br />

© <strong>Mining</strong> Communications Ltd 2008<br />

An Aspermont company<br />

ITIA<br />

The International <strong>Tungsten</strong> Industry Association<br />

was inaugurated in Brussels in February 1988, and<br />

is registered as an association with scientifi c<br />

purposes under Belgian law. The members of ITIA,<br />

from 17 countries, include mining companies,<br />

processors/consumers, trading companies and<br />

assayers. Website: www.itia.org.uk<br />

scheelite<br />

concentrate<br />

primary tungsten<br />

(concentrates)<br />

66%<br />

� nal<br />

product<br />

90%<br />

loss through<br />

dissipation & discard<br />

55%<br />

wolframite<br />

concentrate<br />

TOTAL TUNGSTEN DEMAND<br />

scrap from used parts<br />

24%<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong><br />

Heavy stone<br />

The name tungsten is taken from the Swedish for<br />

heavy stone (tung sten), but the element is also<br />

widely referred to as wolfram after one of its ores<br />

Although not isolated until 225 years<br />

ago, tungsten has a history dating<br />

back to before Georg Agricola, who is<br />

thought to have described the ore in<br />

1546. Tin miners extracting cassiterite<br />

in the Erz Mountains of Saxony in the 17th century<br />

noted that certain ores reduced the amount of tin recovered<br />

“like a wolf devours a sheep” (the effect of the<br />

ore being likened to wolf’s froth, volf rahm in German).<br />

In 1758, the Swedish chemist and mineralogist,<br />

Axel Fredrik Cronstedt, discovered and described an<br />

unusually heavy mineral that he called ‘tung sten’. Although<br />

he was convinced that this mineral contained<br />

a new and as yet undiscovered element, it was not<br />

until 1781 that a fellow Swede, Carl Wilhelm Scheele<br />

(who worked as a pharmacist and private tutor in<br />

Uppsala and Köping) succeeded in isolating the oxide<br />

(tungsten trioxide).<br />

Torbern Bergman, working at Uppsala, predicted<br />

that the acid isolated by Mr Scheele contained a new<br />

metal, which should be possible to prepare by coal<br />

reduction. One year later, a Spanish nobleman,<br />

Don Juan José de Elhuyar, studied at the University of<br />

Uppsala under Bergman. Back in Spain in 1783, Juan<br />

José and his brother, Fausto de Elhuyar de Suvisa,<br />

were the fi rst to prepare tungsten metal by the<br />

method suggested by Bergman. They named it wolfram.<br />

Jöns Jacob Berzelius (1816), and later Friedrich<br />

Wöhler (1824), described the oxides and bronzes of<br />

tungsten, and also proposed the name wolfram.<br />

In 1821, KC von Leonhard proposed the name<br />

scheelite for the mineral CaWO4. In 1847, R Oxland<br />

took out a patent for the manufacture of sodium<br />

tungstate and tungstic acid. This forms the starting<br />

point of the metallurgy of tungsten.<br />

Industry schematic<br />

secondary tungsten<br />

(concentrates)<br />

34%<br />

scrap from<br />

processing<br />

10%<br />

CONVERSION<br />

<strong>Tungsten</strong> conversion measurements<br />

W 1.2616 WO3<br />

Ton 2,000lb<br />

Ton 0.907t<br />

Tonne 2,204.6lb<br />

Tonne 100MTU (metric tonne units)<br />

Short ton unit 20lb (1% short ton)<br />

MTU 1.1023STU<br />

MTU 10kg (1% metric tonne)<br />

MTU 22.04lb<br />

The fi rst attempts to produce tungsten steel<br />

were made in 1855 by J Jacob and F Koeller at the<br />

Reichraming steel works in Austria. Further improvements<br />

in alloying and hardening of steels by tungsten<br />

were made late in the 19th century, and rapid growth<br />

and widespread application followed. The launch of<br />

high-speed steels by Bethlehem Steel took place in<br />

1900 at the World Exhibition in Paris.<br />

The second important breakthrough in tungsten<br />

applications was made by WD Coolidge in 1908<br />

and 1909. Mr Coolidge succeeded in preparing a<br />

ductile tungsten wire by thermo-mechanical<br />

processing. Metal powder (WC) was pressed to<br />

bars, sintered and forged to thin rods. Very thin<br />

wire was then drawn from these rods. This was the<br />

beginning of tungsten-powder metallurgy, which was<br />

instrumental in the rapid development of the lamp<br />

industry.<br />

The next important milestone in the chronology<br />

of tungsten is 1923, which marks the invention of<br />

hard-metal (combining WC and cobalt by liquid-phase<br />

sintering) by K Schröter. The corresponding<br />

application for a patent was granted to Osram<br />

Studiengesellschaft in Berlin, and licensed to Krupp in<br />

Essen in 1926. Hard-metal (cemented carbide) is now<br />

the main application for tungsten.<br />

HISTORY LESSON<br />

The brothers José and Fausto Elhuyar are credited<br />

with the discovery of the element in Spain<br />

during 1783. They had found an acid made from<br />

wolframite that was identical to an acid made<br />

from scheelite (tungstic acid), and subsequently<br />

succeeded in isolating tungsten through reduction<br />

of this acid with charcoal.<br />

Carl Wilhelm Scheele had ascertained two<br />

years earlier that a new acid (at the time named<br />

tungstenite) could be made from scheelite. Mr<br />

Scheele and Torbern Bergman suggested that<br />

it could be possible to obtain a new metal by<br />

reducing this acid.

European free market prices (US dollars per MTU)<br />

US$<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

Jan 2004<br />

Jan 2005<br />

Source: Metal Bulletin<br />

Jan 2006<br />

Hardness: Second only to diamond, and<br />

tungsten carbide is used in a range of industrial<br />

applications, including high-speed cutting, heavy<br />

machinery and specialty alloys.<br />

Heat resistance: Highest melting point and<br />

lowest coeffi cient of expansion of all metals.<br />

Industrial applications include jet turbine engines<br />

and light-bulb fi laments.<br />

Density: Greater than lead and uranium, and<br />

industrial applications include ballast and sporting<br />

goods (golf clubs, tennis racquets and darts).<br />

Benign: <strong>Tungsten</strong> does not break down or<br />

decompose. Its industrial applications include<br />

fi shing weights and shotgun shot.<br />

Fluorescence: Pure scheelite is blue-white in<br />

ultraviolet light, a property that is utilised in<br />

prospecting.<br />

Jan 2007<br />

UNIQUE PROPERTIES<br />

<strong>Tungsten</strong> (given the chemical symbol W, from<br />

wolfram) has an atomic number of 74, and is an<br />

extremely hard, and very dense, grey to white metallic<br />

element. Of the metals, it has the highest melting<br />

point (3,422°C, which is second only to carbon<br />

among all elements), the lowest coeffi cient of<br />

expansion, the highest tensile strength (at temperatures<br />

above 1,650°C) and the lowest vapour pressure.<br />

It is also corrosion resistant and does not break down<br />

or decompose.<br />

Due to these unique attributes, tungsten has few<br />

replacements in a majority of its industrial applications.<br />

Although tungsten is often brittle and hard to<br />

work in its raw state, it can be cut with a hacksaw in<br />

its pure state.<br />

The pure form of tungsten is used mainly in<br />

electrical applications, but its many compounds and<br />

alloys are used in a wide range of applications. For<br />

example, because of its ability to produce hardness at<br />

high temperatures and its high melting point, tungsten<br />

is used in many high-temperature applications. These<br />

include light bulb, cathode-ray tube and vacuum tube<br />

fi laments, as well as heating elements and nozzles on<br />

rocket engines.<br />

PROPERTY SUMMARY<br />

The high melting point<br />

also makes tungsten suitable<br />

for aerospace and<br />

high temperature uses,<br />

including electrical, heating<br />

and welding applications,<br />

notably in the gas-tungsten<br />

arc-welding process (also<br />

called TIG welding). It is<br />

also used in electrodes, and<br />

in the emitter tips of fi eld<br />

emission electron-beam<br />

instruments, such as focused<br />

ion beam (FIB) and electron<br />

microscopes. The metal is<br />

also used in X-ray targets.<br />

<strong>Tungsten</strong> chemical<br />

compounds are used in<br />

catalysts, inorganic pigments<br />

and tungsten disulphide<br />

high-temperature lubricants<br />

which are stable to 500°C.<br />

<strong>Tungsten</strong> carbide (W2C or<br />

WC) is produced by heating powdered tungsten with<br />

carbon, and is one of the hardest carbides (with a melting<br />

point of 2,770°C for WC, and 2,780°C for W2C).<br />

WC is an effi cient electrical conductor (W2C less<br />

so) and tungsten carbide behaves in a manner very<br />

similar to that of unalloyed tungsten and is resistant<br />

to chemical attack, although it reacts strongly with<br />

chlorine to form tungsten hexachloride (WCl6).<br />

<strong>Tungsten</strong> carbide is used to make wear-resistant<br />

abrasives and cutters and knives for drills, circular<br />

saws, milling and turning tools. In these applications,<br />

tungsten carbide may be combined with cobalt, or<br />

coated with titanium nitride or titanium carbide.<br />

Because of the hardness and density of the element,<br />

tungsten fi nds use in heavy metal alloys that<br />

are used in armament, heat sinks and high-density<br />

applications, such as weights, counterweights, ballast<br />

keels for yachts, tail ballast for commercial aircraft<br />

and ballast in racing cars (including NASCAR and<br />

Formula 1). In armaments, tungsten (usually alloyed<br />

with nickel and iron or cobalt to form heavy alloys) is<br />

used in kinetic energy penetrators as an alternative to<br />

depleted uranium.<br />

<strong>Tungsten</strong> may be used in cannon shells, grenades<br />

and missiles to create supersonic shrapnel. Darts may<br />

Jan 2008<br />

OVERVIEW<br />

A 1mm tungsten bead helps this fi shing fl y sink more quickly<br />

contain a high proportion of tungsten, allowing their<br />

diameter to be smaller than those made of other<br />

metals, and permitting tighter groupings. Fishing lures<br />

and many fi shing fl ies use tungsten bead heads to<br />

sink the fl y rapidly. Some types of strings for musical<br />

instruments are wound with tungsten wire.<br />

<strong>Tungsten</strong>, which has a similar density to gold, is<br />

sometimes used in jewellery as an alternative to gold<br />

or platinum (its hardness makes it ideal for rings that<br />

will resist scratching, are hypoallergenic and will not<br />

need polishing). This property is especially useful in<br />

designs with a brushed fi nish.<br />

In metal alloys, high-speed steel contains tungsten<br />

(some tungsten steels contain as much as 18% W).<br />

Superalloys containing tungsten are used in turbine<br />

blades and wear-resistant parts and coatings.<br />

<strong>Tungsten</strong> powder is used as a fi ller material in<br />

plastic composites, which are used as a non-toxic<br />

substitute for lead in bullets, shot and radiation<br />

shields.<br />

Since the element’s thermal expansion is similar<br />

to borosilicate glass, it can also be used for making<br />

glass-to-metal seals. In electronics, tungsten is used as<br />

an interconnect material in integrated circuits.<br />

The oxides are used in ceramic glazes, and calcium/<br />

magnesium tungstates are used widely in fl uorescent<br />

lighting. Crystal tungstates are used as scintillation<br />

detectors in nuclear physics and nuclear medicine.<br />

Other salts that contain tungsten are used in the<br />

chemical and tanning industries. <strong>Tungsten</strong> ‘bronzes’<br />

(so-called due to the colour of the tungsten oxides)<br />

are used in paints.<br />

Presentation of WIDIA (hard-metal) at the 1927 Leipzig<br />

fair by Friedrich Krupp AG. A new material was born which<br />

revolutionised the tool industry. (This picture, published in<br />

1944 in Engineering & <strong>Mining</strong> <strong>Journal</strong>, illustrates the many<br />

applications of tungsten at that time.)<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong> 3

DEPOSITS<br />

All tungsten deposits are of magmatic<br />

or hydrothermal origin. Although<br />

more than 30 tungsten-bearing<br />

minerals are known, only two of<br />

them are important for extraction:<br />

wolframite (Fe, MnWO4) and<br />

scheelite (CaWO4). The concentration<br />

of these minerals in workable<br />

ores is usually 0.3-1% WO3.<br />

Wolframite is a general term<br />

for iron and manganese tungstates<br />

where the iron/manganese ratio can<br />

vary. A mineral with more than 80%<br />

FeWO4 is called Ferberite and a<br />

mineral with more than 80% MnWO MnWO4<br />

is called Hübnerite.<br />

During cooling of the magma,<br />

differential crystallisation occurs, and<br />

scheelite and wolframite are often<br />

found in veins where the magma<br />

has penetrated cracks in the earth’s<br />

crust. Most of the tungsten deposits<br />

are in younger mountain belts, for<br />

example the Alps, Himalayas and the<br />

Pacifi c rim.<br />

World tungsten resources have been estimated at<br />

7Mt W, including deposits that have so far not been<br />

proven to be economically workable. It is suggested<br />

that 30% of the resources are wolframite and 70%<br />

are scheelite ores. The former mineral contains<br />

76.5% WO3, while the latter contains 80.5% WO3.<br />

There are major deposits of these minerals in China<br />

(with about 57% of the world total), Russia, Austria<br />

and Portugal.<br />

4<br />

OVERVIEW<br />

WANTED<br />

<strong>Tungsten</strong> was an important metal<br />

during the Second World War<br />

(as a raw material for the<br />

weaponry industry) and, as the<br />

main European source of the<br />

element, Portugal was put under<br />

political pressure from both sides.<br />

PRODUCTION<br />

China is today by far the largest supplier of primary<br />

tungsten. The other principal producing countries are<br />

Austria, Bolivia, Canada, Portugal and Thailand. Mines<br />

have closed in recent decades in Australia, Brazil,<br />

France, Japan, South Korea, Sweden and the US.<br />

The extraction of tungsten has several stages,<br />

the ore being converted to tungsten oxide (WO2),<br />

which is heated with hydrogen or carbon, producing<br />

powdered tungsten. It can be used in that state or<br />

converted into solid bars.<br />

Ammonium Paratungstate (APT) is usually<br />

calcined to yellow (WO3) or blue oxide (WO3-X, a<br />

slightly substoichimetric trioxide with varying oxygen<br />

content). The yellow or blue oxide can be reduced to<br />

APT<br />

Ammonium Paratungstate is the main intermediate<br />

product and the main tungsten raw material traded<br />

in the market. (NH4)10(H2W12O42).4H2O<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong><br />

The <strong>Tungsten</strong> Tree, published in 1944 by Wah Chang<br />

Steel branch<br />

Carbide branch<br />

tungsten-metal powder<br />

in either ‘pusher’<br />

<strong>Tungsten</strong> ore<br />

furnaces (in which the<br />

powder passes through<br />

the furnace in boats) or<br />

in ‘rotary’ furnaces, at<br />

700-1,000°C.<br />

Most of the tungsten-metal<br />

powder is<br />

converted to tungsten<br />

carbide (WC) by reaction<br />

with pure carbon<br />

powder (eg carbon black) at 900-2,200°C in pusher<br />

or batch furnaces, a process called carburisation.<br />

<strong>Tungsten</strong> carbide is, quantitatively, the most important<br />

tungsten compound. Because of its hardness, it is<br />

the main constituent in cemented carbide.<br />

Scrap recycling is an important factor in the world’s<br />

Estimated world tungsten<br />

reserves 7Mt (W content)<br />

South<br />

America<br />

Other<br />

Canada<br />

4%<br />

12%<br />

17%<br />

US<br />

4%<br />

CIS<br />

6%<br />

China<br />

57%<br />

Compounds<br />

Non-ferrous alloys<br />

tungsten supply. It is estimated that some 30% is<br />

recycled, and the tungsten-processing industry is able<br />

to treat almost every kind of tungsten-containing<br />

scrap and waste to recover tungsten.<br />

Sources: North American <strong>Tungsten</strong> Corp, ITIA<br />

Supply in 2004: 56,700t<br />

(W content)<br />

11%<br />

Other<br />

CIS<br />

6%<br />

83%<br />

China

Activity report<br />

Exploration and development of tungsten projects is taking place around the world<br />

LAST month, Geodex Minerals Ltd<br />

upgraded the resource estimate at its<br />

Sisson Brook bulk-tonnage tungstenmolybdenum-copper<br />

deposit in western<br />

New Brunswick, Canada. The fi rm’s recent<br />

exploration efforts in the area have been divided<br />

between Sisson Brook and a more polymetallic group<br />

of targets surrounding the former Mount Pleasant<br />

mine. Measured and indicated resources at Sisson<br />

Brook now consist of 328Mlb tungsten and 108Mlb<br />

molybdenum at 0.025% W03 equivalent. Geodex is<br />

working towards the completion of a pre-feasibility study<br />

in September using these new resource numbers.<br />

In May, Ormonde <strong>Mining</strong> plc announced that it<br />

was focusing on bringing the Barruecopardo tungsten<br />

project in Spain into production as soon as possible,<br />

while it works on reducing costs at the Zarza<br />

polymetallic project, also in Spain.<br />

Initial studies at the Barruecopardo<br />

mine indicate the potential to revive<br />

operations with an underground project<br />

from the existing open pit. Inferred<br />

resources are estimated at 1.0Mt at an<br />

average grade of 0.7% WO3, and the study<br />

outlined a project producing 900t/y of<br />

tungsten at a capital cost of €10-15 million.<br />

The company hopes to complete evaluation<br />

of Barruecopardo by the end of this year and begin<br />

production in the second half of 2009.<br />

Also in May, AIM-listed Polo Resources Ltd<br />

announced that it was “chasing” GCM Resources plc<br />

with an offer valued at £60 million (US$118 million).<br />

Polo, which currently holds 29.7% of GCM, said the<br />

offer is “consistent with Polo’s strategy of building a<br />

signifi cant and diversifi ed portfolio”. The company’s<br />

main assets are coal, tungsten and uranium holdings<br />

in Mongolia.<br />

Queensland Ores Ltd (QOL) owns 85% of<br />

Wolfram Camp, Australia’s most historic producer of<br />

signifi cant quantities of tungsten, molybdenum and<br />

bismuth. The mine is due to commence concentrate<br />

shipments in July, marking Australia’s return as a<br />

producer of tungsten concentrate.<br />

QOL listed on the Australian Stock Exchange in<br />

2005, and redevelopment and construction work at<br />

Wolfram Camp began in November 2007. With an orefeed<br />

rate of 150,000t/y, QOL is expected to produce<br />

an annual average of 600t WO3 in a 65% wolframite<br />

concentrate, and 250,000lb Mo in a 50% molybdenum<br />

concentrate. In May, QOL announced a A$12 million<br />

capital raising that would leave the company debt free<br />

and with additional exploration funds to conduct<br />

near-mine defi nition drilling to increase the size of the<br />

current Wolfram Camp resource.<br />

In March, Oriental Minerals Inc upgraded its<br />

resource estimate for the Sangdong historical<br />

tungsten-molybdenum mine in South Korea. The fi rm<br />

had already released a resource estimate by consultant<br />

Wardrop Engineering, but the update includes further<br />

drilling results and a different cut-off grade.<br />

The previous cut-off grade was 0.15% WO3, but<br />

for the latest estimate it is 0.10% WO3-equivalent.<br />

Oriental Minerals said this cut-off grade represented a<br />

North American <strong>Tungsten</strong>’s Century mine in Canada<br />

recoverable grade, with recoveries of 70% for tungsten<br />

and 80% for molybdenum.<br />

Sangdong, about 170km southeast of Seoul, was<br />

mined by underground means from 1940-92 at annual<br />

rates of up to 600,000t of ore, and Oriental is<br />

investigating the potential for an open-pit operation<br />

to exploit the remaining resources.<br />

The estimate included drilling results from 42 holes<br />

completed by Oriental, plus 780 underground holes<br />

by previous operators. Wardrop is preparing a preliminary<br />

economic assessment of the development of an<br />

open-pit operation at Sangdong, which is due for<br />

completion in the September quarter.<br />

EXPLORATION<br />

Clockwise from top left: Vital Metals; Tyhee Development Corp’s Giant mine; Paradigm’s White Rock project; Amanta’s Doi Ngom mine<br />

At the time of the original resource estimate,<br />

chief executive Willie McLucas said: “This fi rst report<br />

illustrates the long-term potential of Sangdong as<br />

one of the largest known tungsten deposits in the<br />

world.” Oriental also noted that the drilling results<br />

contained “notable base-metal grades” in the<br />

limestone sequence overlying the west part of the<br />

Sangdong deposit.<br />

Wolf Minerals Ltd announced a maiden JORC<br />

resource estimate in March for its Hemerdon Ball<br />

tungsten-tin deposit in Devon, UK. The Perth-based fi rm<br />

reported that SRK Consulting had estimated inferred<br />

resources of 82Mt at 0.22% WO3 and 0.02% Sn (at a<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong><br />

5

6<br />

EXPLORATION<br />

0.12% W cut off). In 1981, Amax had<br />

outlined reserves of 0.183% WO3.<br />

The latest resource calculation was<br />

based on the relogging of core and<br />

re-assaying samples from 2,688m of<br />

drilling (303 holes were drilled, totalling<br />

21,846m). The mineralisation is hosted by<br />

sheeted greisen veins and stockworks in<br />

fresh and weathered granites, and<br />

surrounding killas (shale) units.<br />

At the end of last year, Wolf announced<br />

that it hoped to bring the historical mine<br />

back into production, saying the project<br />

would “form an excellent platform for the<br />

company to become a major tungsten and<br />

tin producer”. Wolf acquired the property<br />

at a cost of A$1 million and will pay an<br />

annual rent of A$145,000 as well as a net<br />

smelter royalty of 2%.<br />

Wolf expects mining to begin at the site in three<br />

years’ time, although the local authorities will<br />

undertake a full review of the project to reassess its<br />

environmental standards. The relevant planning<br />

permissions were passed in 1986 and are still valid,<br />

but will be revised “in line with modern mining<br />

practices”. The mine, once operational, is expected<br />

to produce 3,000t/y of tungsten over a mine life<br />

of 15-19 years.<br />

Thor <strong>Mining</strong> plc entered into an off-take<br />

agreement in March with CITIC Group for its Molyhil<br />

tungsten-molybdenum project in Australia’s Northern<br />

Territory. Under the terms of the deal, CITIC will take<br />

100% of the life-of-mine production from Molyhil.<br />

Thor said the agreement allowed the company to<br />

move forward with fi nalising funding for the project,<br />

for which fi nal development deals are expected in the<br />

current quarter.<br />

Galway Resources at work<br />

In November 2007, Thor confi rmed plans to<br />

increase the planned scope of Molyhil, but admitted<br />

that the new project would cost more. The review<br />

confi rmed a new reserve estimate (Thor had<br />

published the new JORC-compliant resource of 3.7Mt<br />

in September 2007) and increased the scale of the<br />

project from a throughput of 300,000t/y to 400,000t/y<br />

over a fi ve-year period. But, estimated capital costs<br />

were increased from the A$45.5 million outlined in a<br />

feasibility study at the end of 2006 to A$63.3 million.<br />

Thor noted that the higher capital costs include<br />

the outright purchase of mining equipment and<br />

power-generation plant, and the purchase of the<br />

processing plant and equipment, and village and<br />

infrastructure, rather than contracted services used<br />

for the previous estimate. As a result, cash operating<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong><br />

Operations of North American <strong>Tungsten</strong> Corporation (above)<br />

and Geodex (right)<br />

costs for the new project were estimated at A$78/t,<br />

compared with the previous A$94/t.<br />

Amanta Resources Ltd is focused on<br />

southeast Asia, and the Canadian company’s assets<br />

include three former tungsten mines near Chiang Mai<br />

in northern Thailand. It is now over a year since the<br />

military coup in Thailand, which was the world’s<br />

fourth-largest producer of tungsten prior to the<br />

collapse of the tungsten market in the early 1980s<br />

(with output peaking at 7,500t/y). Current production<br />

is barely 100t/y, but Amanta is convinced of the<br />

country’s potential. Drilling on the Mae Lama<br />

property has shown “signifi cant mineralisation” to a<br />

depth of over 200m, according to the company, with a<br />

strike length of over 700m at a typical width of 1.5m.<br />

Malaga Inc has discovered new mineralisation at<br />

its Pasto Bueno tungsten mine in northern Peru. The<br />

mine is the only operating tungsten mine in South<br />

America and the second largest in the Americas. Two<br />

mineralised vein structures have been identifi ed; one<br />

on either side of the Consuelo vein that is currently<br />

being mined. The new veins have been called Sauco<br />

(on the west side) and Paraiso (east side). Near-term<br />

exploration will focus on the Santa Marta vein, said<br />

the company earlier this year.<br />

In February, Largo Resources Ltd reported<br />

wide zones of tungsten and molybdenum mineralisation<br />

from ten drill holes, totalling 1,875 samples, at its<br />

Northern Dancer tungsten-molybdenum project in<br />

the Yukon. Drilling is focused on upgrading and<br />

expanding the resource of 242Mt grading 0.10% WO3,<br />

0.047% MoS2, including 36.8Mt grading 0.085% MoS2.<br />

In August 2007, Tyhee Development Corp<br />

announced additional gold and tungsten results from<br />

the Nicholas Lake main zone at its 100%-owned<br />

Yellowknife gold project in Canada. Tyhee had<br />

resampled all previously completed drill holes from<br />

the Nicholas project to assess the potential for a<br />

bulk-mineable resource.<br />

The fl agship project for Vital Metals Ltd is the<br />

Watershed scheelite deposit in north Queensland,<br />

150km northwest of Cairns. The project is at the<br />

pre-feasibility stage, with a programme of in-fi ll drilling,<br />

bulk sampling and metallurgical development in<br />

progress. A resource estimate by RSG Global Pty for<br />

Watershed indicated 21.8Mt at an average grade of<br />

0.26% WO3 (based on a cut-off grade of 0.1% WO3)<br />

for a contained WO3 content of 56,300t. The<br />

mineralisation at Watershed is open at depth and<br />

along strike in both directions.<br />

The company announced a year ago that it was<br />

also drilling a target to the south of the main<br />

deposit which identifi ed four potential new zones of<br />

scheelite mineralisation that could extend the limits<br />

of the resource by 200m. In addition to Watershed,<br />

Vital Metals has the rights to two other tungsten<br />

occurrences at advanced stages of exploration:<br />

Mt Alexander (100%-owned) and Mt Mulgine (where<br />

Vital Metals is earning a 70% stake).<br />

Also in Australia, Paradigm Gold Ltd owns the<br />

White Rock tungsten and tin project in Orange, New<br />

South Wales. The company announced assay results<br />

one year ago, confi rming a tin-rich halo surrounding<br />

tungsten mineralisation at the project. At that time<br />

Paradigm reported an estimated indicated and<br />

inferred resource of 150,000t at an average grade of<br />

0.9% WO3, based on historical drill results.<br />

The wholly-owned Mactung deposit of North<br />

American <strong>Tungsten</strong> Corporation was<br />

confi rmed in March 2007 as the largest, undeveloped,<br />

high-grade, tungsten skarn deposit in the world. The<br />

deposit lies on the border between the Yukon and<br />

Northwest Territories in Canada. A NI 43-101compliant<br />

evaluation by Scott Wilson Roscoe Postle<br />

Associates had given an indicated resource of 33.0Mt<br />

at an average grade of 0.88% WO3, and an inferred<br />

resource of 11.3Mt at 0.78% WO3.<br />

These fi gures included 22.2Mt and 4.6Mt, respectively,<br />

of ore with average grades of over 1% WO3.<br />

Based on these fi gures, which used data from 168 drill<br />

holes and a cut-off of 0.5% WO3, the deposit contained<br />

a combined 38.2Mmtu WO3.<br />

North American <strong>Tungsten</strong> Corporation is already in<br />

production at the Cantung mine in Canada’s<br />

Northwest Territories. The fi rm is expanding a newly<br />

discovered zone down-dip of the West Extension<br />

workings, where additional high-grade intersections<br />

were announced earlier this month.<br />

Galway Resources Ltd fi led a NI 43-101<br />

report by SRK Consulting one year ago for its<br />

Victorio molybdenum-tungsten project near Deming,<br />

New Mexico. Based on data from 71 holes (some<br />

50,000m of drilling), the deposit contains over 65Mlb<br />

of molybdenum and 57Mlb of WO3 in the indicated<br />

category, and 31Mlb molybdenum and 33Mlb WO3 in<br />

the inferred category. The cut-off grade was based on<br />

molybdenum valued at US$12/lb, combined with<br />

tungsten (WO3) valued at US$8/lb (yielding a rock<br />

value cut-off of US$40/t).

Amanta revives Thai tungsten<br />

AMANTA Resources, a publicly-traded<br />

Canadian company, focuses on the<br />

acquisition and development of strategic<br />

minerals in southeast Asia. Amanta<br />

selects known, high-quality mineral deposits<br />

with recognised potential as successful producers.<br />

Prior to the collapse of the tungsten market in the<br />

early 1980s, Thailand was the world’s fourth-largest<br />

producer of the metal with peak production of<br />

7,500t/y. Today, the country produces about 100t/y.<br />

Thailand’s rich potential is directly linked to the<br />

widespread occurrence of granitic intrusives of the<br />

southeast Asian tin-tungsten belt. In the 1970s and<br />

early 1980s tungsten concentrate was produced from<br />

a large number of small mines and a few larger ones.<br />

Recognising Thailand’s potential for tungsten<br />

production, Amanta acquired a 100% working interest<br />

in three former tungsten mines near Chiang Mai in<br />

northern Thailand. The company’s tungsten prospects<br />

at Mae Lama, Mae Chedi and Doi Ngom were among<br />

the larger producers of the 1980s, each outputting<br />

several hundred tonnes of concentrate per year, with<br />

peak production at Doi Ngom surpassing 1,000t/y.<br />

MAE LAMA TUNGSTEN PROJECT<br />

Of the three prospects, the Mae Lama property,<br />

southwest of Chiang Mai, offers the most immediate<br />

opportunity for fast-tracking into production.<br />

PEOPLE<br />

Massive wolframite crystals in<br />

Mae Lama production vein<br />

■Amanta Resources has a versatile, international<br />

team of engineers and geologists from Canada, the<br />

Netherlands, Thailand, Vietnam and the Philippines.<br />

■President and CEO Dr Gerald Wright<br />

is co-founder of the Crew group of companies.<br />

As former CEO of Asia Pacifi c Resources, he was<br />

responsible for developing that company’s major<br />

potash project in Thailand. Dr Wright holds a BSc<br />

and a PhD (engineering) from Queens University,<br />

Belfast, Northern Ireland, and he has been a PEng in<br />

British Columbia since 1980.<br />

■Executive vice-president and chief<br />

geologist Pieter Bakker holds an MSc in<br />

mining and geology from the University of Delft,<br />

Netherlands. He is a member of the Australian<br />

Institute of <strong>Mining</strong> and Metallurgy and is a<br />

chartered geologist in Thailand. He has also held<br />

the posts of chief, mineral resources section,<br />

United Nations ESCAP, ESCAP Bangkok, executive vicepresident,<br />

Indochina Goldfi elds, and senior vicepresident<br />

and director of Bong Mieu Holdings.<br />

Drilling at Mae Lama, December 2007 (above); massive wolframite crystals in Mae Lama drill core and grab sample (below)<br />

Mae Lama is a simple, wolframite-in-greisen-quartzvein<br />

deposit. The principal tungsten mineral is<br />

wolframite with associated minor scheelite. One main<br />

vein and dozens of minor ones are known in the<br />

licence area, many of which are mineralised, and the<br />

reported head grade for previous mining operations<br />

was 2% WO3.<br />

Drilling has demonstrated that the Mae Lama vein<br />

contains signifi cant tungsten mineralisation to a depth<br />

of over 200m, and traced it along the trend for 700m<br />

at a typical width of up to 1.5m. During<br />

the exploration programme, the<br />

company uncovered a number of old<br />

adits from the former mining<br />

operations at Mae Lama, which<br />

provide direct access to the two<br />

signifi cant, mineralised vein<br />

systems found on the property.<br />

Amanta geologists have<br />

observed high-grade<br />

mineralisation in situ. Based on<br />

these observations, photographic evidence and<br />

observed wolframite crystals in drill cores, the Mae<br />

Lama tungsten deposits are now considered to be<br />

classic, high-grade, narrow vein deposits.<br />

The fi rm is rehabilitating the former production<br />

openings to take channel and bulk samples from the<br />

production vein. Amanta plans an early resumption of<br />

tungsten production, with the objective of developing<br />

up to one million tonnes of ore and verifying the<br />

reported production grade of 2% WO3. Production at<br />

the mine could resume as early as mid-2009.<br />

Assuming grade and tonnage are verifi ed, Amanta<br />

anticipates a production level of up to 2,500t/y of<br />

high-grade tungsten concentrate, providing the<br />

company with a signifi cant revenue stream for up to<br />

ten years. Producing a concentrate rather than a<br />

fi nished product will ensure that both capital and<br />

ongoing production costs are minimised.<br />

OTHER TUNGSTEN PROJECTS<br />

The Mae Chedi property is located northeast of<br />

Chiang Mai. <strong>Tungsten</strong> ore (scheelite), associated with<br />

tin (cassiterite), occurs in quartz veins and stockworks<br />

in granitic rocks, and also in the contact zone<br />

between these and carboniferous mafi c intrusives.<br />

Disseminated mineralisation occurs as fi ne patches of<br />

scheelite-cassiterite in the granite, and as veins and<br />

veinlets up to 1m thick in the contact zone. A<br />

reconnaissance programme has yielded grab samples<br />

of up to 7% WO3.<br />

At Doi Ngom, southeast of Chiang Mai, tungsten<br />

ore is confi ned to silicifi ed breccia zones in Permian<br />

metasediment. The main tungsten mineral is ferberite,<br />

occurring as breccia fi ll and cement, and in fractures<br />

and veinlets. Ferberite is associated with fl uorite and<br />

stibnite. Shallow reconnaissance drilling has yielded<br />

tungsten grades of up to 1.8% WO WO3 over a 1m<br />

intercept in one drill hole plus a number of lower-<br />

grade intersections of up to 10m in other holes.<br />

OTHER PROJECTS<br />

Over the past four years, Amanta Resources has<br />

pursued an active exploration programme at<br />

its Langu gold project in southern Thailand,<br />

including 4,500m of reconnaissance drilling,<br />

with results of 1.4g/t Au to 3g/t Au. Amanta<br />

plans to drill an additional 25,000m and has<br />

commenced negotiations with a potential<br />

joint-venture partner.<br />

Amanta Resources recently received a 200km2 copper-exploration concession from the Lao People’s<br />

Democratic Republic. Amanta will hold a 100%<br />

working interest in the Luang Namtha copper project,<br />

located in Luang Namtha province.<br />

CONTACTS<br />

Amanta Resources Ltd<br />

1080-789 West Pender Street,<br />

Vancouver, BC, Canada V6C 1H2<br />

Tel: +1 604-730-9505<br />

Fax: +1 604-648-8096<br />

Email: info@amantaresources.com<br />

Web: www.amantaresources.com<br />

Exchange: TSXV<br />

Symbol: AMH<br />

PROFILE<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong> 7

GEOLOGICAL MAP<br />

<strong>Tungsten</strong> projects reported to global financial markets as of June 2008<br />

Number of Projects<br />

71 - 75 (1)<br />

21 - 70 (1)<br />

11 - 20 (2)<br />

2 - 10 (8)<br />

1 (12)<br />

Nil<br />

This map has been complied in good faith by intierra from internal and external published<br />

sources, but no representation is made nor warranty given (either express or implied) as to<br />

the completeness or accuracy of the materials that it contains.<br />

For continuously updated, more detailed information go to www.intierra.com.<br />

Intierra's copyright remains on all reproduction of materials from the map.<br />

Copyright Intierra Ltd 2008<br />

8 June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong><br />

Map depicts the number of tungsten projects<br />

reported to the North American, Australian,<br />

South African and London markets as of June 2008.<br />

Projects range from grass-roots exploration<br />

plays through to operating mines.

COUNTRY<br />

Canada<br />

Australia<br />

United States<br />

Mexico<br />

Thailand<br />

Portugal<br />

Spain<br />

Vietnam<br />

Brazil<br />

China<br />

Mongolia<br />

Peru<br />

TOTAL<br />

74<br />

63<br />

18<br />

15<br />

733<br />

3 2222<br />

Bolivia<br />

Indonesia<br />

Kyrgyzstan<br />

Namibia<br />

New Zealand<br />

Poland<br />

Russia<br />

Serbia<br />

Slovakia<br />

South Korea<br />

Tanzania<br />

United Kingdom<br />

1<br />

1 1111<br />

1 111<br />

1 1<br />

GEOLOGICAL MAP<br />

Note: China is the world’s largest<br />

producer of tungsten, followed by Russia.<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong> 9

10<br />

PROFILE<br />

Geodex Minerals aims to turn up<br />

tungsten at Sisson Brook project<br />

GEODEX Minerals Ltd has focused on<br />

the tungsten-molybdenum-zinc-indium<br />

suite of metals in western New<br />

Brunswick, Canada, for the past three<br />

years, almost alone in that regard.<br />

Work has been divided between Sisson Brook, a<br />

bulk-tonnage tungsten-molybdenum-copper deposit,<br />

and a more polymetallic group of targets surrounding<br />

the former Mount Pleasant mine. The company’s<br />

management consists of a knowledgeable team of<br />

geologists with extensive experience of mine development<br />

from working with such companies as Kennecott,<br />

Kamad Silver, Esso Minerals and Teck Corp.<br />

The company’s fl agship project, Sisson Brook, is a<br />

large, open-pittable deposit, located in the central part<br />

of the New Brunswick. The deposit was drilled by<br />

Kidd Creek from 1978-82, but the discovery was<br />

abandoned due to severe metal price setbacks in the<br />

mid-1980s. The deposit has been expanded by<br />

Geodex since 2005. The mineralised area extends for<br />

over 2km, encompassing at this point two northern<br />

zones with tungsten and copper, and a central, more<br />

signifi cant zone of tungsten and molybdenum of over<br />

300m wide. This Zone III has been the subject of<br />

three resource estimates and a preliminary, economic<br />

evaluation by Wardrop Engineering in November 2007.<br />

The most recent NI 43-101-compliant resource<br />

estimate (in June) upgraded Sisson Brook’s resources<br />

to measured and indicated status. The overall tonnage<br />

increase ranged from 37% at the lowest threshold<br />

level (0.025% WO3 equivalent) to 134% at the highest<br />

(0.225% WO3). The measured and indicated resources<br />

now consist of 328Mlb tungsten and 108Mlb molybdenum<br />

at 0.025% WO3 equivalent. The company is<br />

working towards completion of a pre-feasibility study<br />

in September using these new resource numbers.<br />

The project is currently on track to become the<br />

lowest-cost tungsten mine in North America. The<br />

deposit will have the benefi t of low-cost, open-pit<br />

mining in an easily accessible area and a willing labour<br />

force. Concentrate will be trucked to the port of<br />

Saint John, about two hours away on the Bay of Fundy<br />

coast. The largest mine in the nearby Bathurst mining<br />

district is due to close in mid-2010 after a 60-year life.<br />

This may have a positive impact on the supply of<br />

equipment and labour for the Sisson Brook, and<br />

encourage the New Brunswick government to<br />

fast-track its development.<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong><br />

Sisson Brook has the advantage of unsurpassed<br />

logistics: it lies on crown land, which is a major<br />

advantage for resource development; the area has<br />

been partially logged; there is ready access from a<br />

network of logging roads; a power line crosses the<br />

property, and it is located close to several small<br />

towns, which are serviced by a rail line and provincial<br />

highway 107.<br />

Construction and production would<br />

create many needed employment<br />

opportunities in New Brunswick. The<br />

company estimates about 750 jobs for local<br />

people during construction and 300 during<br />

full operation of the mine, ranging from<br />

trucking to offi ce administration. Three<br />

drills are presently on the property<br />

exploring extensions to various zones.<br />

Earlier this year, Geodex began<br />

metallurgical, geotechnical and environmental<br />

programmes to fast-track the<br />

deposit into production. Wardrop<br />

Engineering will be carrying out mine<br />

design and grade-optimisation studies over the course<br />

of the next few months on the project. In addition, the<br />

fi rm will also be aggressively exploring seven other<br />

properties in the area of the Sisson Brook mine site.<br />

Geodex’s second major project is Mount Pleasant<br />

West, a large property located adjacent to the Mount<br />

Pleasant mine, south of Fredericton in New Brunswick.<br />

This mine, presently owned by Adex <strong>Mining</strong> Inc, was<br />

operated briefl y by Billiton in the mid-1980s, and it<br />

contains deposits of molybdenum-tungsten and<br />

tin-indium. Geodex’s focus is on the indium potential<br />

in the Mount Pleasant West camp and the company’s<br />

land holdings cover what is probably the world’s<br />

largest area of premium indium-exploration targets.<br />

Geodex is about to conduct a major exploration drill<br />

programme at Mount Pleasant West.<br />

TUNGSTEN<br />

Approximately three-quarters of the in-ground<br />

resources at Sisson Brook are tungsten; a metal<br />

mainly used in light fi laments and metal-cutting tools.<br />

<strong>Tungsten</strong> has a density greater than that of lead and<br />

uranium, and its hardness is exceeded only by<br />

diamonds. It is very inert and replaces lead in<br />

uses where it is exposed to the environment<br />

(tungsten recently started replacing lead<br />

in bullets).<br />

Currently, tungsten output is all but<br />

monopolised by China, which produces about<br />

85% of the world’s supply (and further tariff and<br />

quota increases are anticipated to keep the<br />

scarce supply within China). Meanwhile, the<br />

country has increased its domestic demand for<br />

tungsten products, and it is now importing both<br />

scrap and concentrate.<br />

The price of tungsten is US$220-250/mtu for<br />

APT (ammonium paratungstate), a refi ned form in<br />

which the metal is usually bought and sold. Over<br />

the next fi ve years it is forecast that global prices<br />

for APT will increase by 25% from its current<br />

level. Current global consumption of tungsten is<br />

81,200t/y (including 59,800t of new primary<br />

production). Over the next fi ve years the consumption<br />

of tungsten is projected to rise to 109,328t,<br />

requiring almost 82,000t of primary output and an<br />

increase of 22,000t in new production.<br />

No new, major tungsten production has occurred<br />

outside China recently and is not expected until late<br />

2009. Barriers include the cost of mine development<br />

and the limited availability of high-grade deposits. With<br />

the high-grade tonnage at Sisson Brook recently<br />

increasing, there is further potential to increase output<br />

at Sisson Brook and decrease the payback period.<br />

Slated for construction in 2010 and production in<br />

2011, the Sisson Brook project will account for 5% of<br />

the world’s current consumption of tungsten.<br />

CONTACTS<br />

Geodex Minerals<br />

Suite 450-800 West Pender Street<br />

Vancouver, BC, Canada V6C 2V6<br />

Tel: +1 604 689 7771<br />

Fax: +1 604 689 5528<br />

E-mail: info@geodexminerals.com

Malaga rejuvenates Pasto Bueno<br />

PASTO Bueno is the only operating<br />

tungsten mine in South America and the<br />

second-largest in the Americas. Since<br />

the 1920s, more than 6Mt of tungsten<br />

ore has been extracted from the mine.<br />

In 2005, Malaga purchased 100% of Pasto Bueno from<br />

its former owners for US$3.25 million and reopened<br />

it the following year. Commercial production began in<br />

2007, and 57,336MTU of tungsten concentrate was<br />

produced at a cost of about US$120/MTU.<br />

Malaga’s management team has modernised the plant<br />

and mine, and are continuously seeking new ways to<br />

optimise its operation. The company has identifi ed three<br />

main areas where signifi cant progress could be<br />

made to dramatically lower production costs.<br />

ENERGY COSTS<br />

Energy requirements at the Pasto Bueno<br />

mine are met by diesel-powered<br />

generating units. Malaga has invested in<br />

a hydroelectric power-generation project<br />

at Pasto Bueno, which should be able to<br />

supply all the company’s energy needs by<br />

the end of 2008. The scheme includes a<br />

1.9MW hydroelectric power plant,<br />

equipped with two Pelton turbines and<br />

alternators, operating under a 170m waterhead and a<br />

22.9kV high-voltage transmission line.<br />

The company will be able to reduce its carbon<br />

emissions dramatically and save more than<br />

US$800,000 per year. The hydroelectric scheme<br />

is being built by Hidropesac SA, a subsidiary of<br />

Malaga Inc, in partnership with Electrokraft SA, a<br />

A NEW BEGINNING<br />

2007 HIGHLIGHTS<br />

■Commercial production began at Pasto Bueno<br />

in April<br />

■Sales of WO3 concentrate (MTUs):<br />

Q1 12,005 Q2 15,745<br />

Q3 14,704 Q4 14,882<br />

Total 57,336<br />

■Maximum milling capacity of 250tons/d<br />

reached in June<br />

■Average year-round ore-grade milled 1%;<br />

recovery rate 82%<br />

■Concentrate contains 75.46% WO3 and low<br />

impurities (Malaga-grade concentrate)<br />

Peruvian energy company, and<br />

Emerging Power Developers SA,<br />

a Swiss hydroelectric company.<br />

HIGHER ORE GRADES<br />

<strong>Tungsten</strong> mineralisation at the Pasto<br />

Bueno mine is present in veins,<br />

stockwerks, lenses, etc. It is highly<br />

variable – a recent series of 57 samples taken from<br />

three tungsten-bearing veins (Consuelo, Alonso and<br />

Maria Luisa) had grades ranging from 0.45% to 8.02%<br />

WO3. Over the past 18 months, Malaga has found<br />

more than 40 new veins, of which 25 are major<br />

structures. Based on the initial results of an ongoing,<br />

US$2 million drilling campaign that began in 2007,<br />

Malaga has initiated an underground resource<br />

2005 Price of WO3 concentrate reaches US$180-200/MTU<br />

Dynacor Mines (Malaga) buys 100% of the Pasto Bueno mine<br />

2006 Malaga invests US$7.5 million to restart the mine and plant<br />

Malaga signs three-year off-take agreement with Osram Sylvania<br />

2007 March Malaga announces US$2 million exploration and drilling campaign at Pasto Bueno<br />

November Malaga discovers new WO3 mineralised zones<br />

December Phase 1 of hydroelectric project completed<br />

2008 January Phase 2 of hydroelectric power-generation project initiated<br />

February Malaga announces discovery of new WO3 mineralised structures and veins<br />

Malaga starts underground resource-development programme<br />

HISTORY (1910-2002)<br />

1910s Surface outcropping WO3 discovered<br />

1920s-40s Informal small-scale mining<br />

1940 Industrial mining begins<br />

1980-83 Peak production years ≈70,000MTU/y<br />

1984-93 Production falls; no new investments<br />

1994 Avocet buys controlling interest from<br />

Santolalla family<br />

1995 Avocet invests US$1 million to<br />

increase production<br />

1998 WO3 concentrate production of<br />

25,100MTU<br />

1998 Avocet sells 80% interest back to<br />

Santolalla family<br />

1999-02 Production drops to 5,000MTU/y by 2002<br />

2002 Mine closes and declares bankruptcy;<br />

price of WO3 concentrate is US$45/MTU<br />

development programme, involving the excavation of<br />

new galleries and inclined shafts, to gain access to new,<br />

higher-grade zones for mining.<br />

INCREASED CAPACITY<br />

The company plans to increase its production capacity<br />

from the current maximum of 250t/d to 500t/d by<br />

mid-2009. Based on the current operating environment,<br />

increasing production capacity to 500t/d would<br />

lower the unit production cost signifi cantly. Finally, the<br />

results of the drilling campaign and undergrounddevelopment<br />

programme will enable Malaga to defi ne<br />

new tungsten reserves, based on which it intends to<br />

build a new plant with a much higher milling capacity.<br />

CONTACTS<br />

PROFILE<br />

Malaga Inc<br />

Canada:<br />

2000 McGill College, Suite 510, Montreal,<br />

Quebec H3A 3H3<br />

Tel: +1 514 288 3224 Fax: +1 514 288 8179<br />

Email: investors@malaga.ca<br />

Peru:<br />

Calle Luis Pasteur 1297, Lince, Lima<br />

Tel: +51 1 440 1728 Fax: +51 1 421 3643<br />

Website: www.malaga.ca<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong> 11

12<br />

PROFILE<br />

North American<br />

<strong>Tungsten</strong>’s three<br />

pillars of strength<br />

NORTH American <strong>Tungsten</strong> Corporation<br />

(NTC: TSX-V) is a publicly-listed<br />

Tier 1 junior resource company<br />

that is primarily engaged in the<br />

operation, development and<br />

acquisition of tungsten and other related mineral<br />

properties in Canada. The company’s 100%-owned<br />

Cantung mine and Mactung development project<br />

make it one of the few tungsten producers with a<br />

strategic development asset in the politically stable<br />

Western world.<br />

The basis of NTC’s operations are made up of<br />

three pillars of strength and achievement: the Cantung<br />

mine, the Mactung project and the Tundra pilot plant.<br />

FIRST PILLAR – CANTUNG<br />

The fi rst ‘pillar’ is the wholly-owned Cantung mine,<br />

located in Canada’s Northwest Territories. The<br />

underground mine, which is a primary producer of<br />

tungsten concentrate, opened in 1962. After a period<br />

of being on care and maintenance it is now back in<br />

operation and currently produces approximately<br />

300,000MTU of tungsten concentrate (WO3) per year<br />

(2007 production: 286,031MTU).<br />

Recent underground development and exploration<br />

drilling has intersected high-grade zones, some of<br />

which are proximal to existing mine workings.<br />

Selected high-grade results from recent drilling<br />

include: 16.5ft at 5.72% WO3; 16.9ft at 4.16% WO3;<br />

CONTACTS<br />

North American <strong>Tungsten</strong> Corporation<br />

1640-1188 West Georgia Street, Vancouver, BC<br />

V6E 4A2, Canada<br />

Tel: +1 604 684 5300 Fax: +1 604 684 2992<br />

Mobile: +1 604 512 1400<br />

Contact: Toni Williamson PhD,<br />

corporate geologist<br />

Email: Twilliamson@natungsten.com<br />

Web: www.natungsten.com<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong><br />

MACTUNG<br />

Key points to consider when considering the<br />

vast size and grade of Mactung are:<br />

■Mactung’s grade is signifi cantly higher than<br />

the average grade of currently operating<br />

Chinese tungsten mines<br />

■Mactung is located in a politically-stable<br />

country with transparent mining and<br />

ownership laws<br />

■At current tungsten prices, Mactung is worth<br />

approximately US$6.1billion. To put this into<br />

context of more familiar metals, this equates to<br />

a 12Moz gold deposit (at US$650/oz) or an<br />

80Mlb uranium deposit (at US$100/lb U3O8)<br />

■One MTU is equal to 10kg of WO3 per<br />

tonne, or 7.93kg of pure tungsten, and is the<br />

standard weight measure used in the industry.<br />

12ft at 3.24% WO3; 16.9ft at 4.16% WO3 (U-1233);<br />

33ft at 3.24% WO3, including 16.5ft at 5.72% WO3<br />

(U-1244); and 33.3ft at 1.81% WO3, including 12.8ft at<br />

3.14% WO3 (U-1245).<br />

An independent, updated resource estimate is<br />

expected to be complete in the latter half of 2008.<br />

The existing indicated resource (NI43-101-compliant<br />

from September 2006) comprises 3.0Mt grading<br />

1.21% WO3 (3.5 million STUs); 734,000t of inferred<br />

resources grading 0.74% WO3 (543,000STUs); and<br />

approximately 1Mt of probable reserves grading<br />

1.17% WO3 (1.2 million STUs).<br />

SECOND PILLAR – MACTUNG<br />

The Mactung project is by far the company’s largest<br />

asset and second pillar because of its size, grade and<br />

location. It is one of the largest known undeveloped,<br />

high-grade, tungsten-skarn deposits in the world. The<br />

project, located in the Yukon, is NI43-101 compliant,<br />

with indicated resources of 33Mt grading an average<br />

of 0.88% WO3, and an inferred mineral resource<br />

estimate of 11.3Mt grading 0.78% WO3.<br />

Wardrop Engineering Inc reviewed the historical<br />

feasibility studies to produce an undated economic<br />

assessment on Mactung in October 2007, after which<br />

a feasibility study commenced on the project. The<br />

bankable feasibility is on target to be complete by<br />

August 2008. At this time all permits will be fi led,<br />

including mining, environmental and water permits,<br />

followed by construction, with a target for Mactung to<br />

be operational by 2012.<br />

THIRD PILLAR – TUNDRA<br />

The third pillar of NTC is one that makes the<br />

company vertically integrated in the tungsten<br />

marketplace. The Tundra joint-venture pilot plant,<br />

located near Minnesota’s White Bear Lake, started<br />

test production in late 2006 and has yielded<br />

ammonium paratungstate (APT) of the highest grade<br />

and purity (wire grade 99.9%). The transaction to<br />

Buffalo <strong>Tungsten</strong>, a major supplier of tungsten and<br />

tungsten-related powders in the world marketplace in<br />

Buffalo, US, was at a premium to the average Metal<br />

Bulletin price for APT.<br />

The pilot plant has the ability to produce the<br />

highest-purity APT and composite material from<br />

incredibly low-grade concentrate. It has recently had<br />

an economic audit completed, which involved<br />

additional testing and evaluation at a continuous plant<br />

operational level, to aid in making a commercial and<br />

economically-viable decision. The APT produced has<br />

exceeded expectations for trace-level impurities, thus<br />

providing an enhanced fi nal APT product.<br />

The location of the Tundra JV makes it eligible for<br />

government incentives such as discounted electricity.<br />

This is a bonus in minimising capital expenditure and<br />

operating costs throughout the life of the plant.<br />

<strong>Tungsten</strong> APT has a two-year average price of<br />

about US$250/MTU, and prices have recently<br />

remained above US$253/MTU on the back of<br />

continued tight Chinese supply and robust demand.<br />

With more industrial applications appearing on the<br />

marketplace using tungsten, such as steel strengtheners<br />

and drill bits, one specialist niche is potentially<br />

able to use up to 10% of the global supply of tungsten<br />

in the near future. <strong>Tungsten</strong> is being used in leadreplacement<br />

applications due to its densifi cation and<br />

non-toxicity attributes, and it has already been<br />

successfully substituted for lead in fi shing sinkers and<br />

jigs, ballistics and x-ray machines.

Oriental Minerals is developing one of<br />

the world’s largest tungsten projects<br />

ORIENTAL Minerals is a<br />

Canada-based exploration and<br />

mine-development company<br />

with a diverse portfolio of<br />

precious and base-metal projects<br />

in South Korea. These include the Sangdong<br />

tungsten-molybdenum mine and the Ogcheon<br />

uranium project, as well as a number of other<br />

properties with signifi cant known mineralisation<br />

and excellent regional potential.<br />

The company has assembled a highly-skilled,<br />

locally-based, bilingual technical team and a board<br />

of directors with outstanding and relevant<br />

experience. Oriental Minerals is the only<br />

operating Western exploration company in South<br />

Korea and it has signifi cant early access to<br />

available opportunities countrywide.<br />

Oriental Minerals is focusing its primary efforts on<br />

the Sangdong tungsten-moly project; historically, one<br />

of the world’s largest producing tungsten mines. In<br />

mid-2006 the company acquired Sangdong, which was<br />

closed in 1992 due to low commodity prices, and<br />

restarted drilling in early 2007 to re-evaluate its<br />

bulk-mining potential (only high-grade veins were<br />

previously mined). Soon after, the company identifi ed<br />

a mineralised zone measuring 600m by 1,200m and<br />

150-200m thick.<br />

In March, Oriental Minerals released an NI43-101compliant<br />

resource estimate (based only on the fi rst<br />

42 holes drilled), which put the Sangdong resource at<br />

12.7Mt of 0.32% WO3 (tungsten), and 0.06% MoS2<br />

(molybdenum) indicated plus 67.7Mt of 0.29% WO3<br />

and 0.06% MoS2 inferred. This estimate made<br />

Sangdong one of the largest undeveloped tungsten<br />

deposits in the world.<br />

Since then, Oriental Minerals has drilled an<br />

additional 37 holes (for a total of 79 holes drilled) and<br />

completed a total of 20,000m of drilling. Four drill rigs<br />

continue to turn at Sangdong, both infi lling and<br />

stepping out, as the company moves towards<br />

completing its current 87-hole drill programme.<br />

Wardrop Engineering is working on a preliminary<br />

economic assessment (PEA), also known as a scoping<br />

study, which should be completed by the fourth<br />

Oriental Minerals<br />

24th Floor, 1111 West Georgia Street<br />

Vancouver BC V6E 4M3, Canada<br />

E-mail: skletas@orientalminerals.com<br />

Website: www.orientalminerals.com<br />

Contact: Spiro Kletas<br />

Tel: +1 604 681 5755<br />

Fax: +1 604 684 2990<br />

Ticker: TSX.V:OTL<br />

quarter of this year. Included in the PEA will be the<br />

results of Oriental Minerals’ last 45 holes of its<br />

current drill programme, which should result in a<br />

substantial increase in the resource. Furthermore,<br />

environmental and metallurgical studies are ongoing.<br />

The company recently sent a 600kg sample for<br />

metallurgical testing to SGS in Cornwall, UK.<br />

Oriental Minerals intends to fast-track Sangdong<br />

into production and is planning to commission a<br />

feasibility study soon after completion of the PEA.<br />

South Korea is an independent country with strong<br />

US ties, and it is a key trading partner with Canada<br />

and Australia. The world’s tenth-largest economy,<br />

South Korea welcomes overseas investment, having<br />

recently increased foreign-ownership allowance from<br />

49% to 100%. The country has well-established,<br />

workable mining laws, a locally-available trained mining<br />

workforce and excellent logistics infrastructure.<br />

South Korea is centrally located in Asia, where the<br />

high industrial growth rates are driving demand for<br />

tungsten and molybdenum.<br />

The world’s largest producer, China, recently<br />

restricted the export of these metals as they are<br />

needed for its own consumption. Many observers are<br />

forecasting increased consumption and global pricing<br />

for tungsten and molybdenum, driven mainly by<br />

growth in Asia. Both tungsten and molybdenum are<br />

used as alloys in steel-making.<br />

South Korea is home to some of the largest<br />

consumers of tungsten and molybdenum – such as<br />

steel-maker Posco, Hyundai Heavy Industries (the<br />

world’s largest ship-builder) and TaeguTec (part of<br />

Warren Buffet’s IMC Group) – and they currently<br />

import 100% of both metals for their use.<br />

Even though an updated NI43-101 is expected to<br />

increase the size of the deposit, Oriental Minerals<br />

already has a signifi cant amount of tungsten and<br />

molybdenum in situ. The current resource estimate<br />

equates to roughly 522Mlb of tungsten (currently<br />

priced at approximately US$13/lb) and 81Mlb of<br />

molybdenum (about US$32/lb).<br />

To add to the above, Sangdong has a historic<br />

‘deep molybdenum’ zone identifi ed and drilled out<br />

by the Koreans in the 1980s. It is estimated (non-<br />

NI43-101-compliant) to be 120Mt at 0.14% MoS2,<br />

including a high-grade section of 16Mt 0.40% MoS2.<br />

This ‘deep moly’ zone has been drilled by Oriental<br />

Minerals. However, the zone has not been included<br />

in its current resource estimate. Its drill result from<br />

this zone, though, returned 441m of 0.10% MoS2<br />

beneath 177m of 0.16% WO3 (hole SD-20).<br />

All drill results so far confi rm the company’s original<br />

theory of the bulk-mining potential at Sangdong. While<br />

there is a lot of work to do to prove up the resource,<br />

and numerous studies that will need to be completed,<br />

the future looks highly encouraging for Oriental<br />

Minerals and its tungsten-molybdenum project.<br />

CONTACTS Sangdong, looking west (below); drill hole (above)<br />

PROFILE<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong> 13

14<br />

PROFILE<br />

Fast-tracking an early production<br />

opportunity in Spain<br />

ORMONDE <strong>Mining</strong> plc has plans to<br />

become a signifi cant European<br />

tungsten producer by fast-tracking the<br />

development of its Barruecopardo<br />

project in Spain. Ormonde recently<br />

reported a threefold increase in the resource<br />

estimate for the project, which now stands at 3Mt at<br />

an average grade of 0.6% WO3, or 18,000t of contained<br />

WO3. Engineering studies are now in progress to<br />

facilitate an early production decision, with initial<br />

tungsten production targeted for the end of 2009.<br />

BACKGROUND<br />

Located in an historic tungsten-producing area in the<br />

Salamanca Province of western Spain, Barruecopardo<br />

operated as an open-pit tungsten mine until the early<br />

1980s. Like most Western tungsten mines, the operation<br />

was forced to close at that time due to the low<br />

prices forced upon the market by low-cost Chinese<br />

producers. With a production rate of up to 800,000t/y,<br />

it was one of Europe’s largest tungsten mines,<br />

producing a very high-quality scheelite concentrate.<br />

Ormonde acquired the rights to Barruecopardo in<br />

2005 as part of a joint venture with private Spanish<br />

companies over an extensive ground package in west<br />

Salamanca prospective for both tungsten and gold.<br />

Through funding the evaluation programmes on<br />

Barruecopardo and other prospects in the permit<br />

area, Ormonde currently has a 90% interest.<br />

Located on a brownfi eld site, the project is well<br />

served by existing road and power infrastructure and<br />

it enjoys strong community support.<br />

Detailed plan of the Barruecopardo project<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong><br />

GEOLOGY<br />

<strong>Tungsten</strong> mineralisation at Barruecopardo occurs<br />

as scheelite and wolframite in quartz veins that<br />

form part of a major granite-hosted vein swarm.<br />

Ormonde’s drilling has shown that the vein<br />

system has a total strike length of over 1,500m<br />

and extends deeper than 200m. The system is<br />

open both along-strike to the north and south,<br />

and at depth. Veins generally have a NNE strike<br />

and dip steeply to the east. Greisen alteration is<br />

commonly associated with the quartz veins.<br />

EXPLORATION<br />

Ormonde’s drilling programme in 2006-07 initially<br />

focused on high-grade tungsten veins occurring in the<br />

northern extension of the main open-pit mine (in the<br />

Filon Maestro mineralised zone). In late 2007 and<br />

early 2008, initial drilling of the southern area below<br />

the old open pit (targeted on the Filon Principal<br />

zone, which has a known strike length of 850m)<br />

demonstrated the potential for signifi cant widths of<br />

high-grade tungsten within a broader, low-grade zone.<br />

Drilling has now defi ned a tungsten deposit at<br />

Barruecopardo with multiple mineralised zones.<br />

The new resource estimate for the project, prepared<br />

by independent consultants CSA Global, is 3Mt grading<br />

0.60% WO3 in the JORC inferred category, up threefold<br />

on the company’s previous estimate. The scale of the<br />

increase in the resource refl ects the success of the<br />

company’s drilling programmes and the identifi cation of<br />

new resource zones along the known 1.5km strike<br />

length of the Barruecopardo deposit.<br />

There is extensive, additional resource potential as<br />

the resource zones remain completely open along<br />

strike and at depth. Additional resource targets<br />

include the adjacent Valdegallegos area, where a single<br />

Ormonde drill hole returned a high-grade tungsten<br />

interval, and several other prospect areas within the<br />

company’s extensive ground holding surrounding<br />

Barruecopardo. Further drilling success in these areas<br />

would add to the project’s long-term resource base.<br />

ORDER-OF-MAGNITUDE STUDY (JAN 08)<br />

The mining assumptions in the study are for an initial<br />

production rate of 200,000t/y, with underground<br />

access and ore transport via a decline from the<br />

surface. The steep dips, good ground conditions and<br />

visually distinctive mineralised zones should make for<br />

favourable mining conditions. The mining method<br />

envisaged by the study is predominantly mechanised,<br />

long-hole stoping with occasional use of shrinkage<br />

stoping. A minimum mining width of 2m was assumed<br />

for the mechanised mining method. The production<br />

rate may be increased post start-up when exploration<br />

of the other zones is advanced and multiple access<br />

points have been developed to all tungsten zones.<br />

Barruecopardo open-pit tungsten mine when operational<br />

MINERAL PROCESSING<br />

Scoping metallurgical testwork carried out last year<br />

showed that the tungsten minerals are coarse-grained<br />

and will be concentrated effectively by traditional,<br />

low-cost gravity equipment. The order-of-magnitude<br />

study therefore assumed that the tungsten ore would<br />

be processed via a three-stage crushing, a rod mill for<br />

coarse grinding, a gravity preconcentration circuit<br />

(using a combination of jigs and spirals) and a fi nal<br />

clean-up circuit to produce a saleable concentrate.<br />

The study assumed overall tungsten recoveries of<br />

70-80%, based on the results of the scoping testwork<br />

and documentation from the historic Barruecopardo<br />

open-pit operation. These grades and recoveries<br />

would result in production of around 90,000mtu of<br />

WO3 per year. Additional testwork is in progress to<br />

facilitate detailed process-plant design.<br />

FINANCIAL ANALYSIS<br />

The study’s preliminary capital-cost estimate is<br />

€10-15 million. This is for the development of an<br />

underground decline mine, construction of a 28t/hr<br />

processing plant and site infrastructure. Operating cost<br />