Tungsten - Mining Journal

Tungsten - Mining Journal

Tungsten - Mining Journal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DEPOSITS<br />

All tungsten deposits are of magmatic<br />

or hydrothermal origin. Although<br />

more than 30 tungsten-bearing<br />

minerals are known, only two of<br />

them are important for extraction:<br />

wolframite (Fe, MnWO4) and<br />

scheelite (CaWO4). The concentration<br />

of these minerals in workable<br />

ores is usually 0.3-1% WO3.<br />

Wolframite is a general term<br />

for iron and manganese tungstates<br />

where the iron/manganese ratio can<br />

vary. A mineral with more than 80%<br />

FeWO4 is called Ferberite and a<br />

mineral with more than 80% MnWO MnWO4<br />

is called Hübnerite.<br />

During cooling of the magma,<br />

differential crystallisation occurs, and<br />

scheelite and wolframite are often<br />

found in veins where the magma<br />

has penetrated cracks in the earth’s<br />

crust. Most of the tungsten deposits<br />

are in younger mountain belts, for<br />

example the Alps, Himalayas and the<br />

Pacifi c rim.<br />

World tungsten resources have been estimated at<br />

7Mt W, including deposits that have so far not been<br />

proven to be economically workable. It is suggested<br />

that 30% of the resources are wolframite and 70%<br />

are scheelite ores. The former mineral contains<br />

76.5% WO3, while the latter contains 80.5% WO3.<br />

There are major deposits of these minerals in China<br />

(with about 57% of the world total), Russia, Austria<br />

and Portugal.<br />

4<br />

OVERVIEW<br />

WANTED<br />

<strong>Tungsten</strong> was an important metal<br />

during the Second World War<br />

(as a raw material for the<br />

weaponry industry) and, as the<br />

main European source of the<br />

element, Portugal was put under<br />

political pressure from both sides.<br />

PRODUCTION<br />

China is today by far the largest supplier of primary<br />

tungsten. The other principal producing countries are<br />

Austria, Bolivia, Canada, Portugal and Thailand. Mines<br />

have closed in recent decades in Australia, Brazil,<br />

France, Japan, South Korea, Sweden and the US.<br />

The extraction of tungsten has several stages,<br />

the ore being converted to tungsten oxide (WO2),<br />

which is heated with hydrogen or carbon, producing<br />

powdered tungsten. It can be used in that state or<br />

converted into solid bars.<br />

Ammonium Paratungstate (APT) is usually<br />

calcined to yellow (WO3) or blue oxide (WO3-X, a<br />

slightly substoichimetric trioxide with varying oxygen<br />

content). The yellow or blue oxide can be reduced to<br />

APT<br />

Ammonium Paratungstate is the main intermediate<br />

product and the main tungsten raw material traded<br />

in the market. (NH4)10(H2W12O42).4H2O<br />

June 2008 <strong>Mining</strong> <strong>Journal</strong> special publication <strong>Tungsten</strong><br />

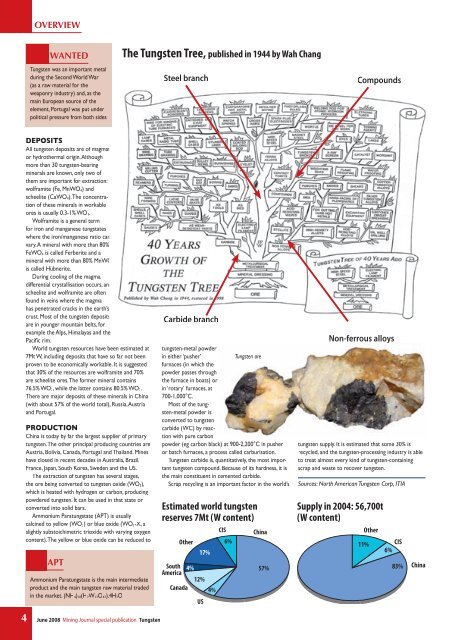

The <strong>Tungsten</strong> Tree, published in 1944 by Wah Chang<br />

Steel branch<br />

Carbide branch<br />

tungsten-metal powder<br />

in either ‘pusher’<br />

<strong>Tungsten</strong> ore<br />

furnaces (in which the<br />

powder passes through<br />

the furnace in boats) or<br />

in ‘rotary’ furnaces, at<br />

700-1,000°C.<br />

Most of the tungsten-metal<br />

powder is<br />

converted to tungsten<br />

carbide (WC) by reaction<br />

with pure carbon<br />

powder (eg carbon black) at 900-2,200°C in pusher<br />

or batch furnaces, a process called carburisation.<br />

<strong>Tungsten</strong> carbide is, quantitatively, the most important<br />

tungsten compound. Because of its hardness, it is<br />

the main constituent in cemented carbide.<br />

Scrap recycling is an important factor in the world’s<br />

Estimated world tungsten<br />

reserves 7Mt (W content)<br />

South<br />

America<br />

Other<br />

Canada<br />

4%<br />

12%<br />

17%<br />

US<br />

4%<br />

CIS<br />

6%<br />

China<br />

57%<br />

Compounds<br />

Non-ferrous alloys<br />

tungsten supply. It is estimated that some 30% is<br />

recycled, and the tungsten-processing industry is able<br />

to treat almost every kind of tungsten-containing<br />

scrap and waste to recover tungsten.<br />

Sources: North American <strong>Tungsten</strong> Corp, ITIA<br />

Supply in 2004: 56,700t<br />

(W content)<br />

11%<br />

Other<br />

CIS<br />

6%<br />

83%<br />

China