Operator'sIVianual - Ppe-pressure-washer-parts.com

Operator'sIVianual - Ppe-pressure-washer-parts.com

Operator'sIVianual - Ppe-pressure-washer-parts.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CheckSpray Gunand Spray Tip Extension<br />

Examinehoseconnectionto spraygun and makesure it is<br />

secure.Testtrigger by pressingit and makingsure it springs<br />

backinto placewhenyou releaseit. Do not depressredbutton<br />

andtest trigger.Youshould not beableto presstrigger. Replace<br />

spraygun immediatelyif it fails anyof thesetests.<br />

SprayTip Maintenance<br />

A pulsing sensation felt while squeezingthe spray gun trigger<br />

may be causedby excessive pump <strong>pressure</strong>. The principal<br />

causeof excessive pump <strong>pressure</strong> is a spray tip clogged or<br />

restricted with foreign materials, such as dirt, etc. To correct<br />

the problem, immediately clean the spray tip following these<br />

instructions:<br />

1. Shut off engine and turn off water supply.<br />

2. ALWAYSpoint spray gun in a safe direction, press red<br />

button and and squeezespray gun trigger to release<br />

retained high water <strong>pressure</strong>.<br />

O-Ring Maintenance<br />

Purchasean O-Ring RepairKit, item 7175116, at your local<br />

Searsor by calling 1-888-4-1VlY-NOME(469-4663) or onlineat<br />

www.sears.<strong>com</strong>,it is not includedwith the <strong>pressure</strong><strong>washer</strong>.<br />

This kit includesreplacemento-rings anda waterinlet filter.<br />

Referto the instructionsheetprovidedin the kit to serviceyour<br />

unit's o-rings.<br />

A. WARNING The high <strong>pressure</strong> stream of water that<br />

this and equipment its underlying produces tissues, can leading cut through to serious skin<br />

injury and possible amputation.<br />

* NEVERrepairleakingconnectionswithsealantof any kind.<br />

Replaceo-ringor seal.<br />

ENGINEMAINTENANCE<br />

_lL WARNING Unintentional sparking can result in fire or<br />

A. WARNING The high <strong>pressure</strong> stream of water that<br />

_¢<br />

electric shock.<br />

this and equipment its underlying produces tissues, can leadingto cut through serious skin<br />

injury and possible amputation.<br />

Spray gun traps high water <strong>pressure</strong>, even when engine is<br />

stopped and water is disconnected, which can cause<br />

injury.<br />

* Keephigh<strong>pressure</strong>hoseconnectedto pumpandspraygun<br />

whilesystemis pressurized.<br />

* ALWAYSpointspraygunin safedirection,pressredbutton<br />

andsqueezesprayguntriggerto releasehigh<strong>pressure</strong>,every<br />

timeyou stopengine.<br />

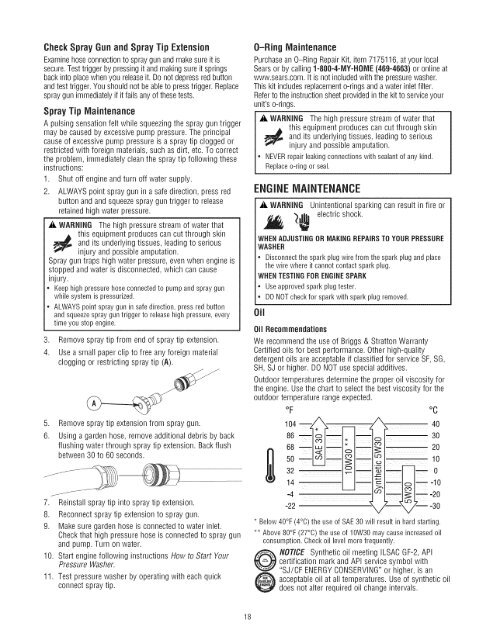

3. Remove spray tip from end of spray tip extension.<br />

4. Use a small paper clip to free any foreign material<br />

clogging or restricting spray tip (A).<br />

5. Remove spray tip extension from spray gun.<br />

6. Usinga garden hose, remove additionaldebris by back<br />

flushingwater through spray tip extension. Backflush<br />

between 30 to 60 seconds.<br />

7. Reinstall spray tip into spray tip extension.<br />

8. Reconnectspray tip extension to spray gun.<br />

9. Make sure garden hose is connected to water inlet.<br />

Checkthat high <strong>pressure</strong> hose is connected to spray gun<br />

and pump. Turn on water.<br />

10. Start enginefollowing instructions How to Start Your<br />

Pressure Washer.<br />

11. Test <strong>pressure</strong><strong>washer</strong> by operating with each quick<br />

connect spray tip.<br />

WHENADJUSTINGOR MAKING REPAIRSTOYOUR PRESSURE<br />

WASHER<br />

* Disconnect the spark plug wire from the spark plug and place<br />

the wire where it cannot contact spark plug.<br />

WHENTESTINGFOR ENGINESPARK<br />

* Useapproved spark plug tester.<br />

* DONOT check for spark with spark plug removed.<br />

Oil<br />

Oil Re<strong>com</strong>mendations<br />

We re<strong>com</strong>mend the use of Briggs & Stratton Warranty<br />

Certified oils for best performance. Other high-quality<br />

detergent oils are acceptable if classified for service SF,SG,<br />

SH,SJ or higher. DO NOTuse special additives.<br />

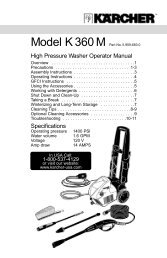

Outdoor temperatures determine the proper oil viscosity for<br />

the engine. Usethe chart to select the best viscosity for the<br />

outdoor temperature range expected.<br />

oF<br />

104___ 506886 _o__<br />

32 .o<br />

14<br />

-4<br />

-22<br />

oc<br />

\ 40<br />

;_30<br />

_°_20<br />

10<br />

_m m 0<br />

-20<br />

--_C °<br />

-30<br />

* Below40°F(4°C)the useof SAE30will resultin hardstarting.<br />

** Above80°F(27°C)the useof 10W30maycauseincreasedoil<br />

consumption.Checkoil levelmorefrequently.<br />

O<br />

certification OTICE Synthetic mark and oil API meeting service ILSACGF-2,API<br />

symbol with<br />

"SJ/0F ENERGYCONSERVING"or higher, is an<br />

acceptable oil at all temperatures. Useof synthetic oil<br />

does not alter required oil change intervals.<br />

18