Manual - Jma.es

Manual - Jma.es

Manual - Jma.es

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

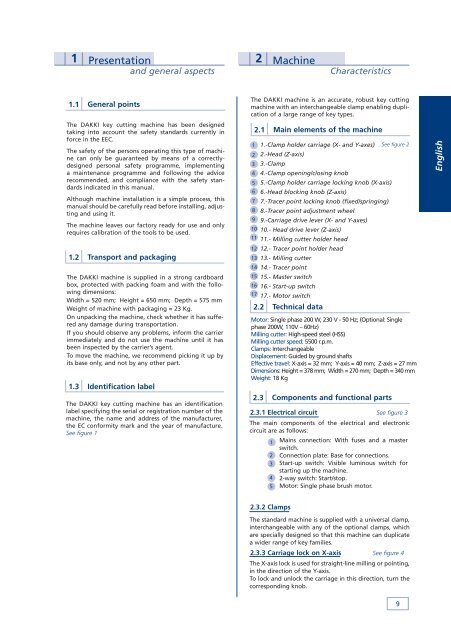

1 Pr<strong>es</strong>entation2 Machineand general aspectsCharacteristics1.1General pointsThe DAKKI key cutting machine has been d<strong>es</strong>ignedtaking into account the safety standards currently inforce in the EEC.The safety of the persons operating this type of machinecan only be guaranteed by means of a correctlyd<strong>es</strong>ignedpersonal safety programme, implementinga maintenance programme and following the advicerecommended, and compliance with the safety standardsindicated in this manual.Although machine installation is a simple proc<strong>es</strong>s, thismanual should be carefully read before installing, adjustingand using it.The machine leav<strong>es</strong> our factory ready for use and onlyrequir<strong>es</strong> calibration of the tools to be used.1.2The DAKKI machine is supplied in a strong cardboardbox, protected with packing foam and with the followingdimensions:Width = 520 mm; Height = 650 mm; Depth = 575 mmWeight of machine with packaging = 23 Kg.On unpacking the machine, check whether it has sufferedany damage during transportation.If you should observe any problems, inform the carrierimmediately and do not use the machine until it hasbeen inspected by the carrier’s agent.To move the machine, we recommend picking it up byits base only, and not by any other part.1.3Transport and packagingIdentification labelThe DAKKI key cutting machine has an identificationlabel specifying the serial or registration number of themachine, the name and addr<strong>es</strong>s of the manufacturer,the EC conformity mark and the year of manufacture.See figure 1The DAKKI machine is an accurate, robust key cuttingmachine with an interchangeable clamp enabling duplicationof a large range of key typ<strong>es</strong>.2.1Main elements of the machine12341.-Clamp holder carriage (X- and Y-ax<strong>es</strong>)2.-Head (Z-axis)3.-Clamp4.-Clamp opening/closing knobSee figure 25678910111213141516175.-Clamp holder carriage locking knob (X-axis)6.-Head blocking knob (Z-axis)7.-Tracer point locking knob (fixed/springing)8.-Tracer point adjustment wheel9.-Carriage drive lever (X- and Y-ax<strong>es</strong>)10.- Head drive lever (Z-axis)11.- Milling cutter holder head12.- Tracer point holder head13.- Milling cutter14.- Tracer point15.- Master switch16.- Start-up switch17.- Motor switch2.2 Technical dataMotor: Single phase 200 W, 230 V - 50 Hz; (Optional: Singlephase 200W, 110V – 60Hz)Milling cutter: High-speed steel (HSS)Milling cutter speed: 5500 r.p.m.Clamps: InterchangeableDisplacement: Guided by ground shaftsEffective travel: X-axis = 32 mm; Y-axis = 40 mm; Z-axis = 27 mmDimensions: Height = 378 mm; Width = 270 mm; Depth = 340 mmWeight: 18 Kg2.3Components and functional parts2.3.1 Electrical circuit See figure 3The main components of the electrical and electroniccircuit are as follows:1 Mains connection: With fus<strong>es</strong> and a masterswitch.2 Connection plate: Base for connections.3 Start-up switch: Visible luminous switch forstarting up the machine.4 2-way switch: Start/stop.5 Motor: Single phase brush motor.English2.3.2 ClampsThe standard machine is supplied with a universal clamp,interchangeable with any of the optional clamps, whichare specially d<strong>es</strong>igned so that this machine can duplicatea wider range of key famili<strong>es</strong>.2.3.3 Carriage lock on X-axis See figure 4The X-axis lock is used for straight-line milling or pointing,in the direction of the Y-axis.To lock and unlock the carriage in this direction, turn thecorr<strong>es</strong>ponding knob.9