Frettage - Schrumpfen - Shrinking - Schaublin SA

Frettage - Schrumpfen - Shrinking - Schaublin SA

Frettage - Schrumpfen - Shrinking - Schaublin SA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

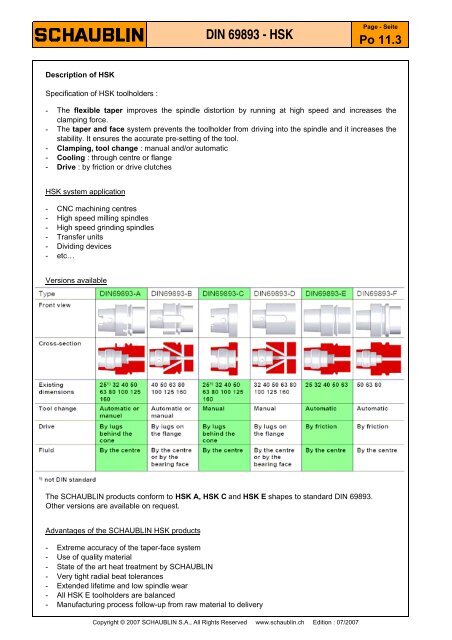

Description of HSK<br />

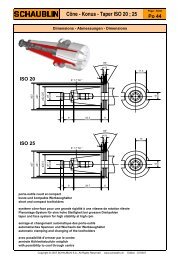

Specification of HSK toolholders :<br />

- The flexible taper improves the spindle distortion by running at high speed and increases the<br />

clamping force.<br />

- The taper and face system prevents the toolholder from driving into the spindle and it increases the<br />

stability. It ensures the accurate pre-setting of the tool.<br />

- Clamping, tool change : manual and/or automatic<br />

- Cooling : through centre or flange<br />

- Drive : by friction or drive clutches<br />

HSK system application<br />

- CNC machining centres<br />

- High speed milling spindles<br />

- High speed grinding spindles<br />

- Transfer units<br />

- Dividing devices<br />

- etc…<br />

Versions available<br />

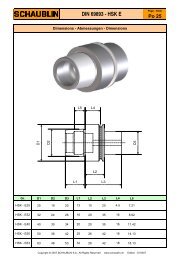

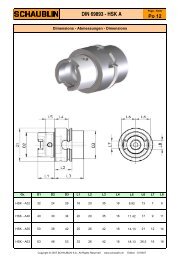

The SCHAUBLIN products conform to HSK A, HSK C and HSK E shapes to standard DIN 69893.<br />

Other versions are available on request.<br />

Advantages of the SCHAUBLIN HSK products<br />

DIN 69893 - HSK<br />

- Extreme accuracy of the taper-face system<br />

- Use of quality material<br />

- State of the art heat treatment by SCHAUBLIN<br />

- Very tight radial beat tolerances<br />

- Extended lifetime and low spindle wear<br />

- All HSK E toolholders are balanced<br />

- Manufacturing process follow-up from raw material to delivery<br />

Copyright © 2007 SCHAUBLIN S.A., All Rights Reserved www.schaublin.ch Edition : 07/2007<br />

Page - Seite<br />

Po 11.3