FOCOLARE 80 Idro Crystal - DSA - HJS-Internethandel

FOCOLARE 80 Idro Crystal - DSA - HJS-Internethandel

FOCOLARE 80 Idro Crystal - DSA - HJS-Internethandel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Focolare <strong>80</strong> <strong>Idro</strong> <strong>Crystal</strong> - <strong>DSA</strong><br />

The exhaust venting pipe must be hermetically fixed to the chimney and can have a maximum inclination of 45°; this<br />

is to prevent excessive condensate deposits produced in the initial lighting phase and/or excessive settling of soot,<br />

and also prevents the slowing of the vented fumes.<br />

A connection that is not hermetically sealed can cause the appliance to malfunction.<br />

The internal diameter of the connection pipe must correspond to the external diameter of the exhaust pipe on the<br />

appliance. This is guaranteed by pipes to DIN 1298 standard.<br />

The depression to the chimney must be 17 – 20 Pa (1.7 – 2 mm of column of water).<br />

The measurement must always be made with the appliance warm (nominal heat yield). When depression exceeds 20<br />

Pa (2 mm of column of water), it is necessary to reduce it by installing a supplementary draught regulator (butterfly<br />

valve) into the discharge pipe or into the chimney.<br />

IMPORTANT: With the use of metal pipes, it is indispensable that they be insulated with a suitable material<br />

(coverings in insulating fibre resistant up to 600°C) to prevent deterioration of the masonry or of the<br />

counterplate.<br />

It is indispensable that the space between the upper part, the sides of the appliance, and the incombustible material<br />

deflector on the hood be constantly ventilated.<br />

For this reason, there must be an air intake from below (cool air inlet) and an outlet above (warm air outlet).<br />

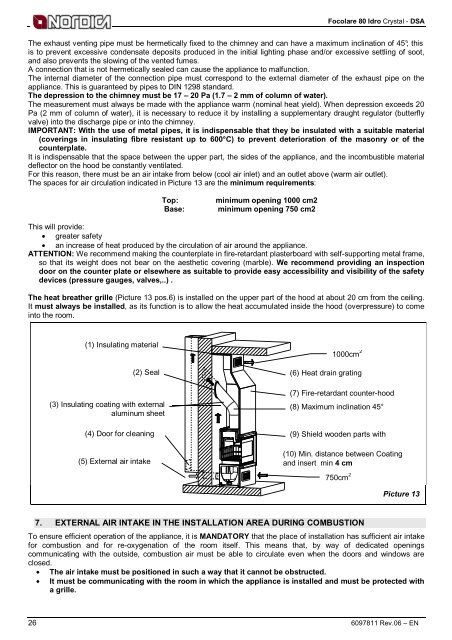

The spaces for air circulation indicated in Picture 13 are the minimum requirements:<br />

Top: minimum opening 1000 cm2<br />

Base: minimum opening 750 cm2<br />

This will provide:<br />

• greater safety<br />

• an increase of heat produced by the circulation of air around the appliance.<br />

ATTENTION: We recommend making the counterplate in fire-retardant plasterboard with self-supporting metal frame,<br />

so that its weight does not bear on the aesthetic covering (marble). We recommend providing an inspection<br />

door on the counter plate or elsewhere as suitable to provide easy accessibility and visibility of the safety<br />

devices (pressure gauges, valves,..) .<br />

The heat breather grille (Picture 13 pos.6) is installed on the upper part of the hood at about 20 cm from the ceiling.<br />

It must always be installed, as its function is to allow the heat accumulated inside the hood (overpressure) to come<br />

into the room.<br />

(1) Insulating material<br />

(2) Seal<br />

(3) Insulating coating with external<br />

aluminum sheet<br />

(4) Door for cleaning<br />

(5) External air intake<br />

1000cm 2<br />

(6) Heat drain grating<br />

(7) Fire-retardant counter-hood<br />

(8) Maximum inclination 45°<br />

(9) Shield wooden parts with<br />

(10) Min. distance between Coating<br />

and insert min 4 cm<br />

750cm 2<br />

7. EXTERNAL AIR INTAKE IN THE INSTALLATION AREA DURING COMBUSTION<br />

Picture 13<br />

To ensure efficient operation of the appliance, it is MANDATORY that the place of installation has sufficient air intake<br />

for combustion and for re-oxygenation of the room itself. This means that, by way of dedicated openings<br />

communicating with the outside, combustion air must be able to circulate even when the doors and windows are<br />

closed.<br />

• The air intake must be positioned in such a way that it cannot be obstructed.<br />

• It must be communicating with the room in which the appliance is installed and must be protected with<br />

a grille.<br />

26 6097811 Rev.06 – EN