INSERTO Crystal 50 - 50v - 50v p30 - 70 - 80 - 100 - ofenseite.com

INSERTO Crystal 50 - 50v - 50v p30 - 70 - 80 - 100 - ofenseite.com

INSERTO Crystal 50 - 50v - 50v p30 - 70 - 80 - 100 - ofenseite.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

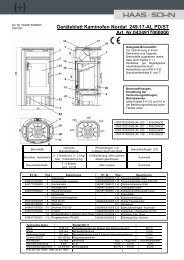

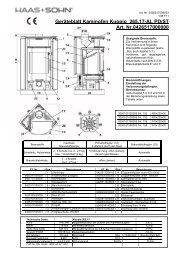

<strong>INSERTO</strong> <strong>Crystal</strong> <strong>50</strong> – <strong>50</strong>v – <strong>50</strong>v <strong>p30</strong> – <strong>70</strong> – <strong>80</strong> – <strong>100</strong><br />

12. NORMAL OPERATION<br />

The nominal power of the appliance is of: see Chap.18. This power will be reached with a minimum depression in the<br />

chimney of see Chap.18. With the registers located on the front of the appliance, it is possible to adjust the heat<br />

emission of the same. They have to be opened according to the calorific need. The best <strong>com</strong>bustion (with minimum<br />

emissions) is reached when, by loading the wood, most part of the air for <strong>com</strong>bustion flows through the secondary air<br />

register.<br />

Never overload the appliance (see the hourly wood load in the table here below). Too much fuel and too much<br />

air for the <strong>com</strong>bustion may cause overheating and then damage the stove.<br />

You should always use the <strong>INSERTO</strong> with the door closed in order to avoid damages due to overheating (forge<br />

effect). The inobservance of this rule makes the warranty expire.<br />

The <strong>INSERTO</strong> is an appliance with intermittent operation.<br />

Besides the adjustment of air for <strong>com</strong>bustion, the intensity of the <strong>com</strong>bustion and consequently the thermal<br />

performance of your appliance is influenced by the stack. A good draught of the stack requires a stricter adjustment of<br />

air for <strong>com</strong>bustion, while a poor draught requires a more precise adjustment of air for <strong>com</strong>bustion.<br />

To verify the good <strong>com</strong>bustion, check whether the smoke <strong>com</strong>ing out from the stack is transparent.<br />

If it is white, it means that the appliance is not properly adjusted or the wood is too wet; if instead the smoke is gray or<br />

black, it signals that the <strong>com</strong>bustion is not <strong>com</strong>plete (it is necessary a greater quantity of secondary air).<br />

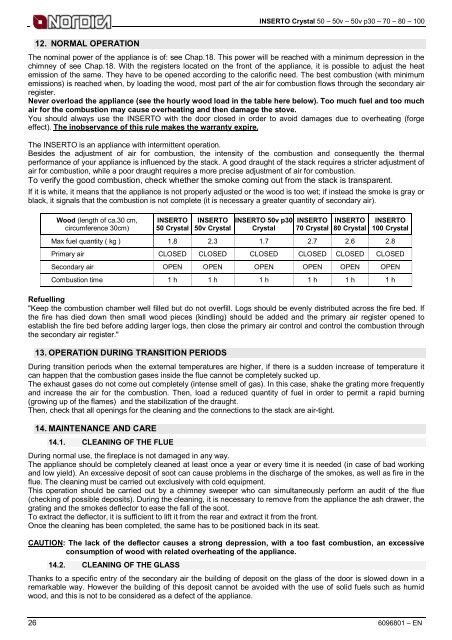

Wood (length of ca.30 cm,<br />

circumference 30cm)<br />

<strong>INSERTO</strong><br />

<strong>50</strong> <strong>Crystal</strong><br />

<strong>INSERTO</strong><br />

<strong>50</strong>v <strong>Crystal</strong><br />

<strong>INSERTO</strong> <strong>50</strong>v <strong>p30</strong><br />

<strong>Crystal</strong><br />

<strong>INSERTO</strong><br />

<strong>70</strong> <strong>Crystal</strong><br />

<strong>INSERTO</strong><br />

<strong>80</strong> <strong>Crystal</strong><br />

<strong>INSERTO</strong><br />

<strong>100</strong> <strong>Crystal</strong><br />

Max fuel quantity ( kg ) 1.8 2.3 1.7 2.7 2.6 2.8<br />

Primary air CLOSED CLOSED CLOSED CLOSED CLOSED CLOSED<br />

Secondary air OPEN OPEN OPEN OPEN OPEN OPEN<br />

Combustion time 1 h 1 h 1 h 1 h 1 h 1 h<br />

Refuelling<br />

"Keep the <strong>com</strong>bustion chamber well filled but do not overfill. Logs should be evenly distributed across the fire bed. If<br />

the fire has died down then small wood pieces (kindling) should be added and the primary air register opened to<br />

establish the fire bed before adding larger logs, then close the primary air control and control the <strong>com</strong>bustion through<br />

the secondary air register."<br />

13. OPERATION DURING TRANSITION PERIODS<br />

During transition periods when the external temperatures are higher, if there is a sudden increase of temperature it<br />

can happen that the <strong>com</strong>bustion gases inside the flue cannot be <strong>com</strong>pletely sucked up.<br />

The exhaust gases do not <strong>com</strong>e out <strong>com</strong>pletely (intense smell of gas). In this case, shake the grating more frequently<br />

and increase the air for the <strong>com</strong>bustion. Then, load a reduced quantity of fuel in order to permit a rapid burning<br />

(growing up of the flames) and the stabilization of the draught.<br />

Then, check that all openings for the cleaning and the connections to the stack are air-tight.<br />

14. MAINTENANCE AND CARE<br />

14.1. CLEANING OF THE FLUE<br />

During normal use, the fireplace is not damaged in any way.<br />

The appliance should be <strong>com</strong>pletely cleaned at least once a year or every time it is needed (in case of bad working<br />

and low yield). An excessive deposit of soot can cause problems in the discharge of the smokes, as well as fire in the<br />

flue. The cleaning must be carried out exclusively with cold equipment.<br />

This operation should be carried out by a chimney sweeper who can simultaneously perform an audit of the flue<br />

(checking of possible deposits). During the cleaning, it is necessary to remove from the appliance the ash drawer, the<br />

grating and the smokes deflector to ease the fall of the soot.<br />

To extract the deflector, it is sufficient to lift it from the rear and extract it from the front.<br />

Once the cleaning has been <strong>com</strong>pleted, the same has to be positioned back in its seat.<br />

CAUTION: The lack of the deflector causes a strong depression, with a too fast <strong>com</strong>bustion, an excessive<br />

consumption of wood with related overheating of the appliance.<br />

14.2. CLEANING OF THE GLASS<br />

Thanks to a specific entry of the secondary air the building of deposit on the glass of the door is slowed down in a<br />

remarkable way. However the building of this deposit cannot be avoided with the use of solid fuels such as humid<br />

wood, and this is not to be considered as a defect of the appliance.<br />

26 6096<strong>80</strong>1 – EN