- Page 2 and 3:

Abdul Latief Sulam TEKNIK PEMBUATAN

- Page 4 and 5:

KATA SAMBUTAN Puji syukur kami panj

- Page 6 and 7:

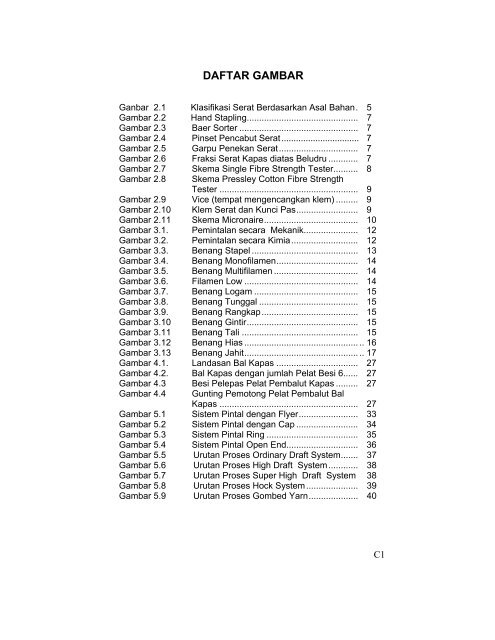

DAFTAR ISI iii Halaman KATA SAMBUTA

- Page 8 and 9:

5.8.1 Bahan Baku...................

- Page 10 and 11:

5.13.7.2 Putaran Rol Penggilas pada

- Page 12 and 13:

5.18.2.2 Penampung (Colektor) .....

- Page 14 and 15:

6.9. Anyaman Kain Khusus ..........

- Page 16 and 17:

8.6.2.1 Penguluran Lusi dengan kend

- Page 18 and 19:

DAFTAR ISTILAH / GLOSARI 1. Serat :

- Page 20 and 21:

DESKRIPSI KONSEP PENULISAN − Buku

- Page 22 and 23:

Level Kualifikasi Kompetensi Sub Ko

- Page 24 and 25:

Level Kualifikasi Kompetensi Sub Ko

- Page 26 and 27:

Level Kualifikasi Kompetensi Sub Ko

- Page 28 and 29:

Level Kualifikasi Kompetensi Sub Ko

- Page 30 and 31:

Level Kualifikasi Kompetensi Sub Ko

- Page 32:

Level Kualifikasi Kompetensi Sub Ko

- Page 35 and 36:

2 - Teknologi Pembuatan Serat - Tek

- Page 38 and 39:

4 BAB II BAHAN BAKU 2.1 Pengertian

- Page 40 and 41:

6 2.3 Jenis Kapas Dilihat dari panj

- Page 42 and 43:

8 Fraksi Serat Kapas di atas Beludr

- Page 44 and 45:

10 penampang yang tertentu, jumlah

- Page 46 and 47:

12 BAB III BENANG Benang adalah sus

- Page 48 and 49:

14 tetapi ada juga yang berasal dar

- Page 50 and 51:

16 Benang lusi ialah benang untuk l

- Page 52 and 53:

18 kekuatan benang, baik untuk bena

- Page 54 and 55:

20 makin tinggi nomornya. Penomeran

- Page 56 and 57:

22 pound. Berapa Ne 2 nya ? Jawab :

- Page 58 and 59:

24 benangnya makin rendah nomornya,

- Page 60:

26 memperoleh efek-efek lainnya. Ko

- Page 63 and 64:

28 Besi pelepas atau gunting pemoto

- Page 65 and 66:

30 Dalam pelaksanaannya blending da

- Page 67 and 68:

produksi dan mengurangi putus benan

- Page 69 and 70:

34 Sistem ini digunakan untuk memin

- Page 71 and 72:

36 pemintalan ini akan diuraikan pa

- Page 73 and 74:

38 Indonesia. Urutan proses dapat d

- Page 75 and 76:

40 untuk keperluan kain rajut, bena

- Page 77 and 78:

42 Keterangan : A. Benang gintir da

- Page 79 and 80:

44 - Garnett Machine Proses ini ber

- Page 81 and 82:

46 Bertujuan agar serat-serat yang

- Page 83 and 84:

48 roving yang diolah. Jenis mesin

- Page 85 and 86:

50 - Persentase mulur rami hampir s

- Page 87 and 88:

52 Spreading Peminyakan Carding Set

- Page 89 and 90:

54 pada bagian penyortiran yang mel

- Page 91 and 92:

56 5. Larutan kimiawai sebagai pelu

- Page 93 and 94:

58 Saling berkaitan dengan antihan

- Page 95 and 96:

60 Sistem konventional, umumnya di

- Page 97 and 98:

62 5.12 Proses di Mesin Blowing Gam

- Page 99 and 100:

64 serat kapas (1), yang akan diter

- Page 101 and 102:

66 Pada dasarnya harus dijaga supay

- Page 103 and 104:

68 mengakibatkan kerusakan pada ser

- Page 105 and 106:

70 Keterangan : 1. Batang saringan

- Page 107 and 108:

72 Keterangan : 1. Batang saringan

- Page 109 and 110:

74 5.12.7.1 Proses di Mesin Scutche

- Page 111 and 112:

76 berputar lebih lambat. Perputara

- Page 113 and 114:

78 Tabel 5.2 Hubungan Antara Tebal

- Page 115 and 116:

80 Gambar 5.37 Bagian Penyuapan Mes

- Page 117 and 118:

82 kecil dari gaya centrifugal koto

- Page 119 and 120:

84 Maka jumlah tekanan yang diberik

- Page 121 and 122:

86 penggulung per cm kapas = 1062 ,

- Page 123 and 124:

88 5.12.9.4 Pengujian Persen Limbah

- Page 125 and 126:

90 Keterangan : puli A = Ø 5 inch

- Page 127 and 128:

92 5.12.10.3 Perhitungan Regangan R

- Page 129 and 130:

94 RM = 1 . . diameter rol penggul

- Page 131 and 132:

96 5.12.11 Perhitungan Produksi Pro

- Page 133 and 134:

98 6. Pembersihan dan pelumasan bea

- Page 135 and 136:

100 Keterangan : 1. Gulungan lap 2.

- Page 137 and 138:

102 Gambar 5.47 Lap Cadangan 5.13.1

- Page 139 and 140:

104 melengkung untuk menahan kemung

- Page 141 and 142:

106 Gambar 5.51 Rol Pengambil, Pisa

- Page 143 and 144:

108 Terjadinya pemisahan kotoran da

- Page 145 and 146:

110 Kerangka dimana poros tersebut

- Page 147 and 148:

112 silinder. Letak flat-flat pada

- Page 149 and 150:

114 Proses ini terjadi pada saat la

- Page 151 and 152:

116 lebih halus daripada yang dipak

- Page 153 and 154:

118 poros sisir doffer (diameter ±

- Page 155 and 156:

120 pasangan rol penggilas. Tekanan

- Page 157 and 158:

122 Dari terompet, sliver tersebut

- Page 159 and 160:

124 - recorder, alat untuk mencatat

- Page 161 and 162:

126 Untuk keperluan penyetelan, bia

- Page 163 and 164:

128 Rpm = 220 Gambar 5.68 Susunan R

- Page 165 and 166:

130 R 20 yang berhubungan dengan ro

- Page 167 and 168:

132 Regangan Nyata (RN) Nomor kelua

- Page 169 and 170:

134 5.13.9 Pergantian Roda Gigi Pad

- Page 171 and 172:

136 sumbu sliver, sebagai persiapan

- Page 173 and 174:

138 berukuran lebih kurang sama den

- Page 175 and 176:

140 terdepan harus diambil sebesarb

- Page 177 and 178:

142 5.14.2.4.2 Pembebanan Mati / Ba

- Page 179 and 180:

144 5.14.2.6 Proses Peregangan Sebe

- Page 181 and 182:

146 yang sama atas bahan yang menga

- Page 183 and 184:

148 Berikut ini diberikan pedoman p

- Page 185 and 186:

150 bergerak dengan kecepatan Vb -

- Page 187 and 188:

152 Diameter terompet (inch) = k x

- Page 189 and 190:

154 - spectograph dan recordernya,

- Page 191 and 192:

156 Keterangan : A = puli Ø 112 mm

- Page 193 and 194:

158 merupakan regangan jumlah dari

- Page 195 and 196:

160 Produksi/Jam/5 delivery 0, 9 ·

- Page 197 and 198:

162 tidak dapat memuat banyak, maka

- Page 199 and 200:

164 serta meluruskan tekukan, kare

- Page 201 and 202:

166 Keterangan : 1. Pengatur sliver

- Page 203 and 204:

168 - Mengadakan peregangan lebih l

- Page 205 and 206:

170 2. Pelumasan gear box setiap 1

- Page 207 and 208:

172 yang berhubungan dengan R 2 / S

- Page 209 and 210:

174 Menurut perhitungan di atas, di

- Page 211 and 212:

176 Gambar 5.105 Skema Bagian Penyu

- Page 213 and 214:

178 Gambar 5.113 Penjepitan Lap Kar

- Page 215 and 216:

180 Gambar 5.119 Penyuapan Lap Gamb

- Page 217 and 218:

182 Gambar 5.123 Skema Bagian Penam

- Page 219 and 220:

184 Gambar 5.127 Skema Bagian Penam

- Page 221 and 222:

186 5.17.4 Bagian Perangkapan, Pere

- Page 223 and 224:

188 Gambar 5.137 Coiler Coiler (20

- Page 225 and 226:

190 Bagian yang disetel 3. Kesejaja

- Page 227 and 228:

192 Bagian yang disetel 7. Jarak an

- Page 229 and 230:

194 Tapi cara yang baik, dilakukan

- Page 231 and 232:

196 Kalau satu mesin Combing mempun

- Page 233 and 234:

198 dari atas secara axial dan sete

- Page 235 and 236:

200 tidak saling bergesekan yang da

- Page 237 and 238:

202 pengantar ini sepanjang mesin d

- Page 239 and 240:

204 5.18.2.5 Penyetelan Jarak antar

- Page 241 and 242:

206 5.18.3.1 Flyer Gambar 5.158 Fly

- Page 243 and 244:

208 Gambar 5.160 Susunan Roda Gigi

- Page 245 and 246:

210 Karena gerakan dari baut (5a) d

- Page 247 and 248:

212 telah menahan roda gigi Rachet

- Page 249 and 250:

214 dilakukan dengan cermat, agar t

- Page 251 and 252:

216 Keterangan : Puli A = 5 inci P

- Page 253 and 254:

218 Keterangan : KPR = Kecepatan pe

- Page 255 and 256:

220 RM R Q = KPR kedua( Q) KPR ket

- Page 257 and 258:

222 Regangan Nyata nomor Keluar = n

- Page 259 and 260:

224 Dari uraian diatas dapat dipero

- Page 261 and 262:

226 5.18.7 Perhitungan Produksi Bia

- Page 263 and 264:

228 tertentu, misalnya satu minggu.

- Page 265 and 266:

230 Prinsip bekerjanya mesin Ring S

- Page 267 and 268:

232 untuk digulung pada bobin. Kare

- Page 269 and 270:

234 Nama-nama peralatan penting dar

- Page 271 and 272:

236 secara pasip karena adanya gese

- Page 273 and 274:

238 5.19.2.5 Pembebanan pada Rol At

- Page 275 and 276: 240 Gambar 5.182 Skema Bagian Pengg

- Page 277 and 278: 242 5.19.3.7 Tin Roll Gambar 5.189

- Page 279 and 280: 244 Gambar 5.190 Hubungan antara TP

- Page 281 and 282: 246 Keterangan : 1. Eksentrik 2. ba

- Page 283 and 284: 248 (2), maka rantai B akan menjadi

- Page 285 and 286: 250 5.19.3.10 Bentuk Gulungan Benan

- Page 287 and 288: 252 b. Kekuatan benang per helai, a

- Page 289 and 290: 254 Keterangan : Puli A = 20 cm Pu

- Page 291 and 292: 256 (RPR) dimisalkan 1 (satu). Rega

- Page 293 and 294: 258 Karena bahan yang diolah adalah

- Page 295 and 296: 260 2. RPA TA TPI 3. RPA x TPI TA

- Page 297 and 298: 262 Nsp . inch Ne1 Keterangan : K

- Page 299 and 300: 264 Produksi Nyata Untuk menghitun

- Page 301 and 302: 266 Gambar 5.198 Skema dan Cara Pen

- Page 303 and 304: 268 (3). Karena perputaran rol pena

- Page 305 and 306: 270 kecepatan penggulungan bobin (7

- Page 307 and 308: 272 5.20.2 Bagian Penggulungan Nama

- Page 309 and 310: 274 Tin rol (14) suatu silinder bes

- Page 311 and 312: 276 Hubungan antara TPI dan Kekuata

- Page 313 and 314: 278 Keterangan : 6. Eksentrik 7. ba

- Page 315 and 316: 280 terputar ke kiri oleh rantai (B

- Page 317 and 318: 282 meter) sudah mencapai angka yan

- Page 319 and 320: 284 h. Bentuk gulungan benang tidak

- Page 321 and 322: Lihat gambar 5.220 Susunan roda gig

- Page 323 and 324: PENUTUP Buku ini diharapkan dapat m

- Page 325: 14. Soji Muramatsu. Jacquard Weavin

- Page 329 and 330: Gambar 5.83 Pasangan-pasangan Rol p

- Page 331 and 332: Gambar 5.161 Batang Penggeser......

- Page 333 and 334: Gambar 6.14 Anyaman Polos .........

- Page 335 and 336: Gambar 7.40 A, B, C, D, E Peralatan

- Page 337 and 338: Gambar 8.2 Bagian-bagian Utama Mesi

- Page 339: l DAFTAR TABEL Tabel 2.1 Penilaian