TS 100 R Manuel d'utilisation et d'entretien Operator's ... - Husqvarna

TS 100 R Manuel d'utilisation et d'entretien Operator's ... - Husqvarna

TS 100 R Manuel d'utilisation et d'entretien Operator's ... - Husqvarna

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

English<br />

24<br />

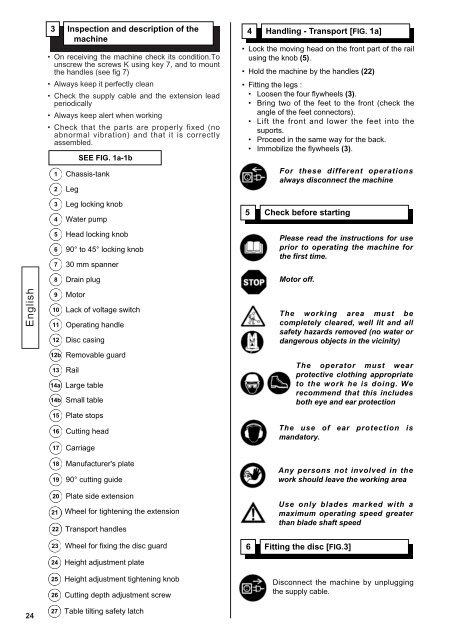

3 Inspection and description of the<br />

machine<br />

• On receiving the machine check its condition.To<br />

unscrew the screws K using key 7, and to mount<br />

the handles (see fig 7)<br />

• Always keep it perfectly clean<br />

• Check the supply cable and the extension lead<br />

periodically<br />

• Always keep alert when working<br />

• Check that the parts are properly fixed (no<br />

abnormal vibration) and that it is correctly<br />

assembled.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

12b<br />

13<br />

14a<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

Chassis-tank<br />

Leg<br />

Leg locking knob<br />

Water pump<br />

Head locking knob<br />

90° to 45° locking knob<br />

30 mm spanner<br />

Drain plug<br />

Motor<br />

Lack of voltage switch<br />

Operating handle<br />

Disc casing<br />

Removable guard<br />

Rail<br />

SEE FIG. 1a-1b<br />

Large table<br />

14b<br />

Small table<br />

Plate stops<br />

Cutting head<br />

Carriage<br />

Manufacturer's plate<br />

90° cutting guide<br />

Plate side extension<br />

Wheel for tightening the extension<br />

Transport handles<br />

Wheel for fixing the disc guard<br />

Height adjustment plate<br />

Height adjustment tightening knob<br />

Cutting depth adjustment screw<br />

Table tilting saf<strong>et</strong>y latch<br />

4 Handling - Transport [FIG. 1a]<br />

• Lock the moving head on the front part of the rail<br />

using the knob (5).<br />

• Hold the machine by the handles (22)<br />

• Fitting the legs :<br />

• Loosen the four flywheels (3).<br />

• Bring two of the fe<strong>et</strong> to the front (check the<br />

angle of the fe<strong>et</strong> connectors).<br />

• Lift the front and lower the fe<strong>et</strong> into the<br />

suports.<br />

• Proceed in the same way for the back.<br />

• Immobilize the flywheels (3).<br />

For these different operations<br />

always disconnect the machine<br />

5 Check before starting<br />

Please read the instructions for use<br />

prior to operating the machine for<br />

the first time.<br />

Motor off.<br />

The working area must be<br />

compl<strong>et</strong>ely cleared, well lit and all<br />

saf<strong>et</strong>y hazards removed (no water or<br />

dangerous objects in the vicinity)<br />

The operator must wear<br />

protective clothing appropriate<br />

to the work he is doing. We<br />

recommend that this includes<br />

both eye and ear protection<br />

The use of ear protection is<br />

mandatory.<br />

Any persons not involved in the<br />

work should leave the working area<br />

Use only blades marked with a<br />

maximum operating speed greater<br />

than blade shaft speed<br />

6 Fitting the disc [FIG.3]<br />

Disconnect the machine by unplugging<br />

the supply cable.