Monteringsanvisning Ronda 160 - Nordpeis

Monteringsanvisning Ronda 160 - Nordpeis

Monteringsanvisning Ronda 160 - Nordpeis

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

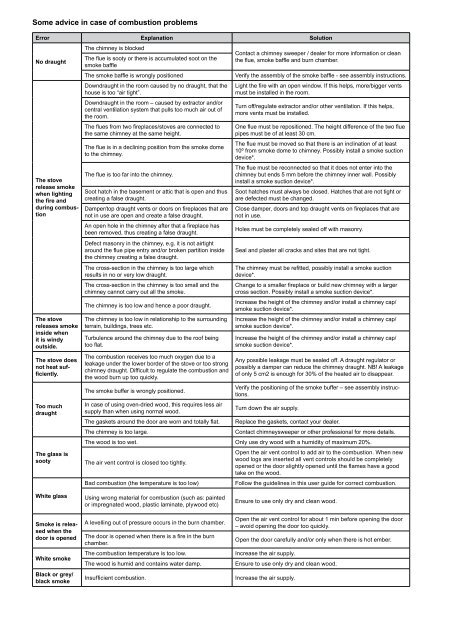

Some advice in case of combustion problemsError Explanation SolutionNo draughtThe stoverelease smokewhen lightingthe fire andduring combustionThe stovereleases smokeinside whenit is windyoutside.The stove doesnot heat sufficiently.Too muchdraughtThe glass issootyThe chimney is blockedThe flue is sooty or there is accumulated soot on thesmoke baffleThe smoke baffle is wrongly positionedDowndraught in the room caused by no draught, that thehouse is too “air tight”.Downdraught in the room – caused by extractor and/orcentral ventilation system that pulls too much air out ofthe room.The flues from two fireplaces/stoves are connected tothe same chimney at the same height.The flue is in a declining position from the smoke dometo the chimney.The flue is too far into the chimney.Soot hatch in the basement or attic that is open and thuscreating a false draught.Damper/top draught vents or doors on fireplaces that arenot in use are open and create a false draught.An open hole in the chimney after that a fireplace hasbeen removed, thus creating a false draught.Defect masonry in the chimney, e.g. it is not airtightaround the flue pipe entry and/or broken partition insidethe chimney creating a false draught.The cross-section in the chimney is too large whichresults in no or very low draught.The cross-section in the chimney is too small and thechimney cannot carry out all the smoke.The chimney is too low and hence a poor draught.The chimney is too low in relationship to the surroundingterrain, buildings, trees etc.Turbulence around the chimney due to the roof beingtoo flat.The combustion receives too much oxygen due to aleakage under the lower border of the stove or too strongchimney draught. Difficult to regulate the combustion andthe wood burn up too quickly.The smoke buffer is wrongly positioned.In case of using oven-dried wood, this requires less airsupply than when using normal wood.The gaskets around the door are worn and totally flat.The chimney is too large.Contact a chimney sweeper / dealer for more information or cleanthe flue, smoke baffle and burn chamber.Verify the assembly of the smoke baffle - see assembly instructions.Light the fire with an open window. If this helps, more/bigger ventsmust be installed in the room.Turn off/regulate extractor and/or other ventilation. If this helps,more vents must be installed.One flue must be repositioned. The height difference of the two fluepipes must be of at least 30 cm.The flue must be moved so that there is an inclination of at least10º from smoke dome to chimney. Possibly install a smoke suctiondevice*.The flue must be reconnected so that it does not enter into thechimney but ends 5 mm before the chimney inner wall. Possiblyinstall a smoke suction device*.Soot hatches must always be closed. Hatches that are not tight orare defected must be changed.Close damper, doors and top draught vents on fireplaces that arenot in use.Holes must be completely sealed off with masonry.Seal and plaster all cracks and sites that are not tight.The chimney must be refitted, possibly install a smoke suctiondevice*.Change to a smaller fireplace or build new chimney with a largercross section. Possibly install a smoke suction device*.Increase the height of the chimney and/or install a chimney cap/smoke suction device*.Increase the height of the chimney and/or install a chimney cap/smoke suction device*.Increase the height of the chimney and/or install a chimney cap/smoke suction device*.Any possible leakage must be sealed off. A draught regulator orpossibly a damper can reduce the chimney draught. NB! A leakageof only 5 cm2 is enough for 30% of the heated air to disappear.Verify the positioning of the smoke buffer – see assembly instructions.Turn down the air supply.Replace the gaskets, contact your dealer.Contact chimneysweeper or other professional for more details.The wood is too wet. Only use dry wood with a humidity of maximum 20%.The air vent control is closed too tightly.Bad combustion (the temperature is too low)Open the air vent control to add air to the combustion. When newwood logs are inserted all vent controls should be completelyopened or the door slightly opened until the flames have a goodtake on the wood.Follow the guidelines in this user guide for correct combustion.White glassSmoke is releasedwhen thedoor is openedWhite smokeBlack or grey/black smokeUsing wrong material for combustion (such as: paintedor impregnated wood, plastic laminate, plywood etc)A levelling out of pressure occurs in the burn chamber.The door is opened when there is a fire in the burnchamber.The combustion temperature is too low.The wood is humid and contains water damp.Insufficient combustion.Ensure to use only dry and clean wood.Open the air vent control for about 1 min before opening the door– avoid opening the door too quickly.Open the door carefully and/or only when there is hot ember.Increase the air supply.Ensure to use only dry and clean wood.Increase the air supply.