Newsletter_ENG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

September 2015<br />

news<br />

www.tecnocom.com<br />

A WINNING GROUP ON<br />

THE INTERNATIONAL<br />

MARKETS<br />

For tecnocom, 2014 was a record<br />

year: a record turnover and a record<br />

number of countries reached in terms<br />

of sales and distribution.<br />

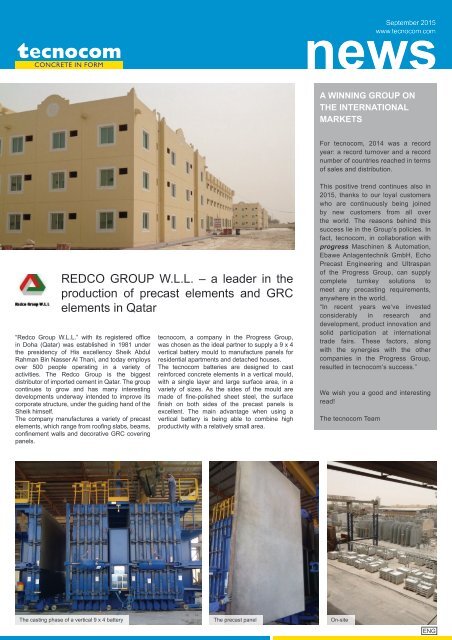

REDCO GROUP W.L.L. – a leader in the<br />

production of precast elements and GRC<br />

elements in Qatar<br />

“Redco Group W.L.L.” with its registered office<br />

in Doha (Qatar) was established in 1981 under<br />

the presidency of His excellency Sheik Abdul<br />

Rahman Bin Nasser Al Thani, and today employs<br />

over 500 people operating in a variety of<br />

activities. The Redco Group is the biggest<br />

distributor of imported cement in Qatar. The group<br />

continues to grow and has many interesting<br />

developments underway intended to improve its<br />

corporate structure, under the guiding hand of the<br />

Sheik himself.<br />

The company manufactures a variety of precast<br />

elements, which range from roofing slabs, beams,<br />

confinement walls and decorative GRC covering<br />

panels.<br />

tecnocom, a company in the Progress Group,<br />

was chosen as the ideal partner to supply a 9 x 4<br />

vertical battery mould to manufacture panels for<br />

residential apartments and detached houses.<br />

The tecnocom batteries are designed to cast<br />

reinforced concrete elements in a vertical mould,<br />

with a single layer and large surface area, in a<br />

variety of sizes. As the sides of the mould are<br />

made of fine-polished sheet steel, the surface<br />

finish on both sides of the precast panels is<br />

excellent. The main advantage when using a<br />

vertical battery is being able to combine high<br />

productivity with a relatively small area.<br />

This positive trend continues also in<br />

2015, thanks to our loyal customers<br />

who are continuously being joined<br />

by new customers from all over<br />

the world. The reasons behind this<br />

success lie in the Group‘s policies. In<br />

fact, tecnocom, in collaboration with<br />

progress Maschinen & Automation,<br />

Ebawe Anlagentechnik GmbH, Echo<br />

Precast Engineering and Ultraspan<br />

of the Progress Group, can supply<br />

complete turnkey solutions to<br />

meet any precasting requirements,<br />

anywhere in the world.<br />

“In recent years we‘ve invested<br />

considerably in research and<br />

development, product innovation and<br />

solid participation at international<br />

trade fairs. These factors, along<br />

with the synergies with the other<br />

companies in the Progress Group,<br />

resulted in tecnocom‘s success.”<br />

We wish you a good and interesting<br />

read!<br />

The tecnocom Team<br />

The casting phase of a vertical 9 x 4 battery<br />

The precast panel<br />

On-site<br />

<strong>ENG</strong><br />

<strong>Newsletter</strong>_<strong>ENG</strong>.indd 1 07.09.2015 14:15:21

September 2015<br />

www.tecnocom.com<br />

EPCE – Empresa Publica Cementera del<br />

Ecuador<br />

TECNOCOM SUPPLIES TILTING TABLES TO Riobamba in Ecuador<br />

EPCE - Empresa Publica Cementera del Ecuador opened a new industrial plant equipped with tecnocom tilting tables and Echo Precast equipment<br />

for manufacturing prestressed hollow core slabs. These tables are used to manufacture sandwich wall panels, solid panels for interiors<br />

used in the construction of apartments and residential estates.<br />

EPCE workers<br />

Ecuador works<br />

tecnocom supplied the latest generation<br />

TTE tilting tables (TTE – Tilting Table<br />

Export) characterised by an innovative<br />

structure made of polished sheet steel<br />

with an automated machine for the perfect<br />

product. With the TTE, tecnocom designers<br />

paid particular attention to finding a way<br />

to make transportation easier and reduce<br />

transportation costs.<br />

In fact, the table is divided into two parts<br />

so it can easily be transported in standard<br />

containers.<br />

The special design lets the Customer<br />

combine the two parts of the table easily<br />

on-site, guaranteeing a perfect casting<br />

surface.<br />

EPCE chose tecnocom technology so they<br />

could install a production line for producing<br />

solid exterior and interior sandwich panels at<br />

exceptionally low costs, with a perfect product.<br />

TTE – Tilting Table Export<br />

The latest generation tilting tables being assembled on-site in Riobamba<br />

<strong>Newsletter</strong>_<strong>ENG</strong>.indd 2 07.09.2015 14:15:25

September 2015<br />

www.tecnocom.com<br />

news<br />

BOLEYN MAGIC WALL PANEL LTD – the leading<br />

producer of prefabricated building solutions in Kenya<br />

In May 2015 “Boleyn”, a Chinese company based in Nairobi started introducing precast concrete building solutions to the Kenyan market to<br />

construct residential apartments in multi-storey blocks, independent homes and community living units as well as accommodation for the police<br />

and armed forces.<br />

The high-capacity production<br />

plant in Kitengela<br />

has just been finished<br />

and can produce precast<br />

elements for factories,<br />

roads, bridges and motorways<br />

after purchasing all<br />

the moulds and equipment<br />

required from tecnocom.<br />

tecnocom, part of the<br />

Progress Group, was<br />

chosen as the partner to<br />

supply the equipment for<br />

the production of all types<br />

of prestressed concrete<br />

beams, pillars, roof beams,<br />

slabs, “new jersey” type<br />

road barriers, precast<br />

stairways and “sandwich”<br />

type panels offering high<br />

thermal insulation.<br />

This equipment gives the<br />

factory access to the latest<br />

technologies to manufacture<br />

all kinds of structures<br />

for commercial, civil and<br />

industrial construction work.<br />

Self-reacting line Staircase shutters “New Jersey” mould “New Jersey” element<br />

QANBAR DYWIDAG PRECAST CONCRETE COMPANY<br />

LIMITED – a very competitive company throughout Saudi<br />

Arabia and the Persian Gulf (GCC) countries<br />

“Qanbar Dywidag Precast Concrete Company<br />

Limited” (QDC) was established in 1981<br />

as a partnership between one of the biggest<br />

businessmen in the eastern province, Sheik<br />

Abdul Razzak Mohammad Al-Ansari Qanbar<br />

and one of the biggest General Contractors<br />

and manufacturers of prefabricated concrete<br />

elements, Dyckerhoff & Widmann AG<br />

(DYWIDAG).<br />

In January 2002, Sheik Abdul took over<br />

DYWIDAG and became the sole owner of<br />

QDC, which today employs over 500 people.<br />

The company has many prestigious contracts<br />

under its belt including projects for the Royal<br />

Commission of Jubail, the Saudi Arabian<br />

Oil Company and many more. tecnocom<br />

was chosen as the partner to supply a selfreacting<br />

line with a capacity of 1,100 tonnes<br />

complete with a series of sides for<br />

manufacturing beams.<br />

The company is very competitive in terms of<br />

quality-related costs and record construction<br />

times with projects throughout Saudi Arabia<br />

and the Persian Gulf (GCC) countries.<br />

Mould for various beams<br />

and precast elements<br />

Self-reacting line on-site<br />

<strong>Newsletter</strong>_<strong>ENG</strong>.indd 3 07.09.2015 14:15:29

September 2015<br />

www.tecnocom.com<br />

TOO “KOSTANAY MBI” – the biggest construction<br />

firm in Kazakhstan<br />

TOO “KOSTANAY MBI” chose the companies of the Progress Group for its new precast<br />

works in Kostanay. This plant manufactures sandwich wall panels, solid panels for<br />

interior walls, slab elements and prestressed hollow core slabs, precast staircases<br />

and precast slabs with ventilation ducts. The plant is equipped with machines of the<br />

very latest generation of mesh welding plants, a stirrup bender, and a staircase mesh<br />

welder manufactured by progress Maschinen & Automation.<br />

The site includes an Echo Precast Engineering plant for hollow core slabs and an<br />

Ebawe Anlagentechnik 56-pallet carousel plant.<br />

tecnocom was chosen for the production of interior wall panels, precast staircases and<br />

precast slabs with ventilation ducts, a product tecnocom is specialized in, being one<br />

of the leading manufacturers of battery moulds for these precast slabs with ventilation<br />

ducts.<br />

The company in Kazakhstan<br />

The tecnocom battery<br />

mould produces elements<br />

with three ventilation<br />

ducts each, and can produce<br />

up to 4,800 articles/<br />

year when used in a double<br />

day shift.<br />

This battery of the latest<br />

generation can be used to<br />

manufacture this special<br />

element with high-productivity,<br />

guaranteeing reduced<br />

cleaning, oiling and<br />

reinforcement times, of the<br />

cones used to produce the<br />

slabs with ventilation ducts.<br />

The battery and precast element The battery and precast element The Kostanay Kazakhstan works<br />

In the next few months we will be present at the following exhibitions:<br />

Bauma Conexpo Africa<br />

15.09.-18.09.2015<br />

Johannesburg (ZA)<br />

www.bcafrica.com<br />

BIG 5 Dubai<br />

23.11.-26.11.2015<br />

Dubai (UAE)<br />

www.thebig5.ae<br />

Excon<br />

25.11.-29.11.2015<br />

Bengaluru, Karnataka (IN)<br />

www.excon.in<br />

We look forward to your visit!<br />

ICCX St. Petersburg<br />

09.12. - 11.12.2015<br />

St. Petersburg (RU)<br />

www.iccx.org/russia<br />

tecnocom S.p.A.<br />

Via Antonio Zanussi, 305 • 33100 Udine - Italy • Tel. +39 0432 621 222 • Fax +39 0432 621 200<br />

info@tecnocom.com • www.tecnocom.com<br />

<strong>Newsletter</strong>_<strong>ENG</strong>.indd 4 07.09.2015 14:15:35