savremeni razvoj konstrukcije i proizvodnje vij^anih kompresora ...

savremeni razvoj konstrukcije i proizvodnje vij^anih kompresora ...

savremeni razvoj konstrukcije i proizvodnje vij^anih kompresora ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Ma{instvo 2(3), 63 - 78, (1999)<br />

N.Sto{i},...: SAVREMENI RAZVOJ KONSTRUKCIJE...<br />

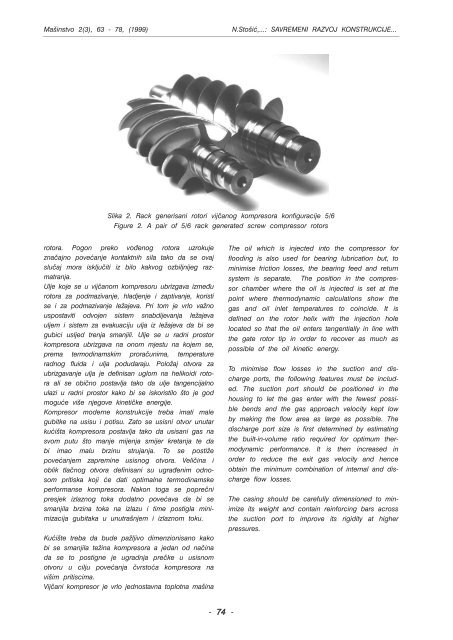

Slika 2. Rack generisani rotori vij~anog <strong>kompresora</strong> konfiguracije 5/6<br />

Figure 2. A pair of 5/6 rack generated screw compressor rotors<br />

rotora. Pogon preko vo|enog rotora uzrokuje<br />

zna~ajno pove}anje kontaktnih sila tako da se ovaj<br />

slu~aj mora isklju~iti iz bilo kakvog ozbiljnijeg razmatranja.<br />

Ulje koje se u vij~anom kompresoru ubrizgava izme|u<br />

rotora za podmazivanje, hladjenje i zaptivanje, koristi<br />

se i za podmazivanje le`ajeva. Pri tom je vrlo va`no<br />

uspostaviti odvojen sistem snabdijevanja le`ajeva<br />

uljem i sistem za evakuaciju ulja iz le`ajeva da bi se<br />

gubici usljed trenja smanjili. Ulje se u radni prostor<br />

<strong>kompresora</strong> ubrizgava na onom mjestu na kojem se,<br />

prema termodinamskim prora~unima, temperature<br />

radnog fluida i ulja podudaraju. Polo`aj otvora za<br />

ubrizgavanje ulja je definisan uglom na helikoidi rotora<br />

ali se obi~no postavlja tako da ulje tangencijalno<br />

ulazi u radni prostor kako bi se iskoristilo {to je god<br />

mogu}e vi{e njegove kineti~ke energije.<br />

Kompresor moderne <strong>konstrukcije</strong> treba imati male<br />

gubitke na usisu i potisu. Zato se usisni otvor unutar<br />

ku}i{ta <strong>kompresora</strong> postavlja tako da usisani gas na<br />

svom putu {to manje mijenja smijer kretanja te da<br />

bi imao malu brzinu strujanja. To se posti`e<br />

pove}anjem zapremine usisnog otvora. Veli~ina i<br />

oblik tla~nog otvora definisani su ugra|enim odnosom<br />

pritiska koji }e dati optimalne termodinamske<br />

performanse <strong>kompresora</strong>. Nakon toga se popre~ni<br />

presjek izlaznog toka dodatno pove}ava da bi se<br />

smanjila brzina toka na izlazu i time postigla minimizacija<br />

gubitaka u unutra{njem i izlaznom toku.<br />

Ku}i{te treba da bude pa`ljivo dimenzionisano kako<br />

bi se smanjila te`ina <strong>kompresora</strong> a jedan od na~ina<br />

da se to postigne je ugradnja pre~ke u usisnom<br />

otvoru u cilju pove}anja ~vrsto}a <strong>kompresora</strong> na<br />

vi{im pritiscima.<br />

Vij~ani kompresor je vrlo jednostavna toplotna ma{ina<br />

The oil which is injected into the compressor for<br />

flooding is also used for bearing lubrication but, to<br />

minimise friction losses, the bearing feed and return<br />

system is separate. The position in the compressor<br />

chamber where the oil is injected is set at the<br />

point where thermodynamic calculations show the<br />

gas and oil inlet temperatures to coincide. It is<br />

defined on the rotor helix with the injection hole<br />

located so that the oil enters tangentially in line with<br />

the gate rotor tip in order to recover as much as<br />

possible of the oil kinetic energy.<br />

To minimise flow losses in the suction and discharge<br />

ports, the following features must be included.<br />

The suction port should be positioned in the<br />

housing to let the gas enter with the fewest possible<br />

bends and the gas approach velocity kept low<br />

by making the flow area as large as possible. The<br />

discharge port size is first determined by estimating<br />

the built-in-volume ratio required for optimum thermodynamic<br />

performance. It is then increased in<br />

order to reduce the exit gas velocity and hence<br />

obtain the minimum combination of internal and discharge<br />

flow losses.<br />

The casing should be carefully dimensioned to minimize<br />

its weight and contain reinforcing bars across<br />

the suction port to improve its rigidity at higher<br />

pressures.<br />

- 74 -

![zavarivanje kao metod produ@enja @ivotnog vijeka ku]i[ta toplotnih ...](https://img.yumpu.com/36506092/1/184x260/zavarivanje-kao-metod-produenja-ivotnog-vijeka-kuita-toplotnih-.jpg?quality=85)