Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

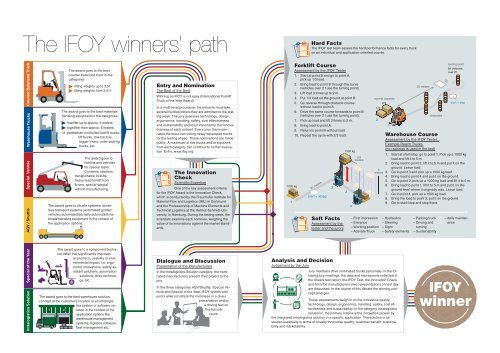

<strong>The</strong> <strong>IFOY</strong> winners’ path<br />

Hard Facts<br />

<strong>The</strong> <strong>IFOY</strong> test team assess the hard performance facts for every truck<br />

on an individual and application-oriented course.<br />

Counter Balanced Truck<br />

Special of the Year AGV / Shuttle Special Vehicle Warehouse Trucks<br />

Intralogistics Solution<br />

<strong>The</strong> award goes to the best<br />

counter balanced truck in the<br />

categories<br />

lifting weights up to 3,5 t<br />

lifting weights from 3,51 t<br />

<strong>The</strong> award goes to the best materials<br />

handling equipment in the categories<br />

lowlifter up to approx. 6 meters<br />

highlifter from approx. 6 meters<br />

i.e. pedestrian-controlled lowlift trucks,<br />

lift trucks, tow tractors,<br />

tugger trains, order-picking<br />

trucks, etc.<br />

<strong>The</strong> award goes to<br />

forklifts and vehicles<br />

for special tasks:<br />

Container stackers,<br />

transportable forklifts,<br />

heavy-load forklift from<br />

8 tons, special special<br />

vehicle manufacturing.<br />

<strong>The</strong> award goes to shuttle systems, driverless<br />

transport systems (automated guided<br />

vehicle), automated/partially automated materials<br />

handling equipment in the context of<br />

the application options.<br />

<strong>The</strong> award goes to a component/technical<br />

detail that significantly improves<br />

economics, usability or environmental<br />

impact, i.e. ergonomic<br />

innovations, safety assistant<br />

solutions, automation<br />

solutions, drive technology,<br />

etc.<br />

<strong>The</strong> award goes to the best warehouse solution<br />

concept at the customer’s location or an intralogistics<br />

system or software solution<br />

in the context of the<br />

application options like<br />

warehouse management<br />

systems, logistics software,<br />

fleet management etc.<br />

Entry and Nomination<br />

<strong>The</strong> Best of the Best<br />

Winning an <strong>IFOY</strong> is not easy (International Forklift<br />

Truck of the Year Award).<br />

In a multi-level procedure, the entrants must take<br />

several hurdles before they are admitted to the testing<br />

week. <strong>The</strong> jury assesses technology, design,<br />

ergonomics, handling, safety, cost effectiveness<br />

and sustainability and most importantly, the innovativeness<br />

of each entrant. Every juror then nominates<br />

the most convincing newly developed trucks<br />

for the testing phase. <strong>The</strong>se nominations are made<br />

public. A maximum of five trucks and/or solutions<br />

from each category can continue to further evaluation.<br />

Entry: www.ifoy.org<br />

<strong>The</strong> Innovation<br />

Check<br />

Scientific Expertise<br />

One of the key assessment criteria<br />

for the <strong>IFOY</strong> Award is the Innovation Check,<br />

which is conducted by the Fraunhofer Institute for<br />

Material Flow and Logistics (IML) in Dortmund<br />

and the Professorship of Machine Elements and<br />

Technical Logistics at the Helmut-Schmidt-University,<br />

in Hamburg. During the testing week, the<br />

scientists examine each nominee, weighing the<br />

value of its innovations against the market standards.<br />

Dialogue and Discussion<br />

Presentation of the Manufacturers<br />

In the Intralogistics Solution category, the nominated<br />

manufacturers present their project to the<br />

jury.<br />

In the three categories AGV/Shuttle, Special Vehicle<br />

and Special of the Year, <strong>IFOY</strong> testers and<br />

jurors alike scrutinize the nominees in a (live-)<br />

presentation and/or<br />

a driving test on<br />

the test parcours.<br />

1000 kg<br />

1<br />

Forklift Course<br />

Assessment by the <strong>IFOY</strong> Tester<br />

1. Start at point B and go to point A,<br />

pick up 1/3 load.<br />

2. Bring load to point B through the curve<br />

(vehicles over 2 t use the turning point).<br />

3. Lift load 3 times up to 2 m.<br />

4. Put 1/3 load on the ground at point B.<br />

5. Go reverse through obstacle course<br />

without load to point A.<br />

6. Drive the same course forwards to point B<br />

(vehicles over 2 t use the turning point).<br />

7. Pick up load and lift 3 times to 2 m.<br />

8. Bring load to point A.<br />

9. Return to point B without load.<br />

10. Repeat the cycle with 2/3 load.<br />

35 meters<br />

start + stopp<br />

Analysis and Decision<br />

Judgement by the Jury<br />

3<br />

Soft Facts<br />

Assessment by the<br />

tester and the jurors<br />

1500 kg<br />

5,5<br />

meters<br />

normal capacity<br />

2/3<br />

1/3<br />

Jury members drive nominated trucks personally. in the following<br />

jury meetings, the data and impressions collected in<br />

the drivers test report, the <strong>IFOY</strong> Test, the Innovation Check<br />

and from the manufacturers (live-) presentations on test day<br />

are discussed. In the course of this debate the winning concept<br />

emerges.<br />

<strong>The</strong>se assessments weigh in on the innovative quality,<br />

technology, design, ergonomics, handling, safety, cost effectiveness<br />

and sustainability. In the category intralogistics<br />

solutions“, the primary criteria is the innovation proven by<br />

the integrated intralogistics solution in a specific application. <strong>The</strong> solution is assessed<br />

especially in terms of novelty/innovative quality, customer benefit, sustainability<br />

and marketability.<br />

2<br />

4<br />

A<br />

5<br />

meters<br />

– First impression<br />

– Entrance<br />

– Working position<br />

– Activate Truck<br />

25 meters<br />

obstacles<br />

Warehouse Course<br />

Assessment by the <strong>IFOY</strong> Tester,<br />

Example Reach Trucks<br />

(no rackings is used in the test)<br />

– Hydraulics<br />

– Steering<br />

– Sight<br />

– Safety elements<br />

– Parking truck<br />

– Driving and<br />

turning<br />

– Sustainability<br />

B<br />

turning point<br />

for vehicles<br />

over 2t<br />

start + stop<br />

1. Start at start/stop, go to point 1. Pick up a 1000 kg<br />

load and lift it to 5 m.<br />

2. Bring load to point 2, lift it to 5 m and put it on the<br />

ground. Leave load.<br />

3. Go to point 3 and pick up a 1500 kg load.<br />

4. Bring load to point 4 and put it on the ground.<br />

5. Go to point 2, pick up a 1000 kg load and lift it to 5 m.<br />

6. Bring load to point 1, lift it to 5 m and put it on the<br />

ground level where it originally was. Leave load.<br />

7. Go to point 4, pick up a 1500 kg load.<br />

8. Bring the load to point 3, put it on the ground.<br />

9. Go to start/stop and stop there.<br />

– daily maintanance