Wheel Loader - Kelly Tractor

Wheel Loader - Kelly Tractor

Wheel Loader - Kelly Tractor

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

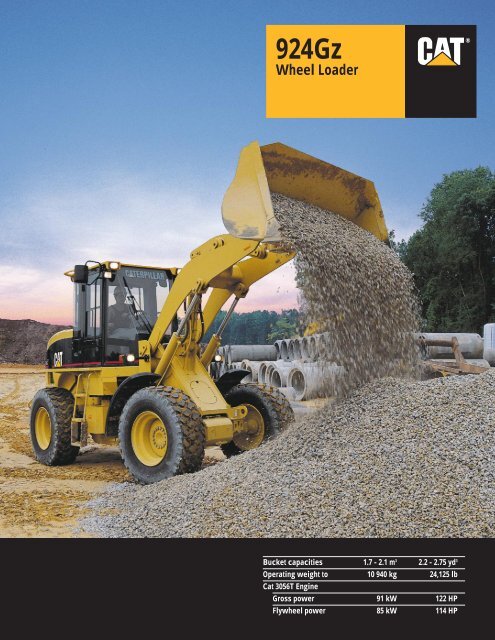

924Gz<strong>Wheel</strong> <strong>Loader</strong>®Bucket capacities 1.7 - 2.1 m 3 2.2 - 2.75 yd 3Operating weight to 10 940 kg 24,125 lbCat 3056T EngineGross power 91 kW 122 HPFlywheel power 85 kW 114 HP

Caterpillar ® Power TrainRugged, dependable Cat components carefully matched to most efficientlyget maximum rimpull to the ground and full power to the loader hydraulics.The 924Gz delivers fast response andaggressive performance in toughapplications. The power train features aCat 3056T diesel engine and power shifttransmission precision-matched to atorque converter and rugged Caterpillaraxles. The system has been carefullytested and balanced to provide optimumperformance and durability in actualoperating conditions.1 - Caterpillar 3056T diesel engine.The six-cylinder, turbocharged 3056Thas a strong reputation for reliability,durability and performance:■ highly efficient combustion chamberincreases power while lowering fuelconsumption, engine emissions andnoise;■ meets all known current worldwideengine emission standards;■ low cylinder pressure rise and lowpeak pressure provide outstandingreliability and durability;■■the normal engine oil changerequirement is only every 500 hoursof operation;engine and cooling system are inseparate compartments for cleaner,quieter operation and easier service.2 - Power shift transmission withstandard Autoshift.Rugged, field-proven Caterpillar 4F/3Rtransmission uses heavy-dutycomponents for durable and reliableoperation. Full power shift capabilityand electronically-controlled Autoshiftsimplify operation. Plus, it’s designedfor easy service and rebuild.■ high-energy friction materials forbetter heat tolerance and thickreaction plates for better heatdissipation;■ electronic Autoshift transmissionincreases operator efficiencies andoptimizes machine performance.Operator can choose auto or manualoperation;■ dampened shifting provides smoothertransition and reduced operatorfatigue;■■■designed with fewer, simpler parts formore reliable operation;simplified removal, disassembly andreassembly for overhaul and rebuild,making it easier to give the 924Gz asecond or third life.a low-speed transmission option withlower gear ratio provides slowertravel speed with high engine speedfor better match with attachments thatdemand high hydraulic flow.4

Hydraulic SystemNew modular system provides improved efficiency, low-effort controls and easy operation.Modular hydraulic system designed by ■ exceptional backdrag performance■ very fast loader cycle times; preserves your initial investment andCaterpillar provides low-effortoperation and greater control:due to a large tilt cylinder and newcheck valves;■ separate steering and implementpumps improve machine response;■ hydraulic system is virtually driftfree.■ load-sensing steering gives priority tothe steering system on demand,making more power available forrimpull, breakout and lift forces;Modular hydraulic control valves add anew dimension of versatility that greatlysimplifies and lowers overall cost of■ system is designed to manage use ofengine power and lower fuelconsumption;reconfiguring the machine for additionalfunctions.■ load-sensing implement hydraulicsprovide exceptional second gearhydraulic-to-rimpull match for betterperformance in tough materials;The standard 924Gz with pin-onimplement comes equipped with a twosectioncontrol valve for lift and tiltfunctions. If new applications place■ simultaneous lift and tilt functionshelp improve productivity;additional hydraulic requirements on themachine, such as adding a Quick■ velocity modulation of lift and tiltfunctions ... the further you pull orpush the lever, the faster the function;Coupler or powered attachments, youcan simply stack additional valvesections (totalling up to four) on the■ low-effort, single-lever implementcontrol;existing ones. There is no need to scrapvalves or change hydraulic lines. Thislowers the cost of machine upgrades.The control valves now featureconvenient ground-level access foreasier modifications to the system.Ride Control Option provides acomfortable ride at all speeds. Thesystem operates automatically or can beturned off with a switch at the operatorstation. The system uses a nitrogen oilaccumulator in the hydraulic lift circuitthat acts like a shock absorber for theloader linkage and bucket. The reactionto movement over rough ground isdampened, reducing fore and aft pitch.Other features include:■ compatibility with Cat biodegradablehydraulic oil;■ pressure taps allow quick diagnosis ofthe whole hydraulic system;■ Caterpillar XT hose & couplingsprovide rugged, reliable performancewith significantly reduced risk ofleaks and blown lines.6

Caterpillar BucketsCaterpillar’s selection of general purpose buckets are an integral part of a machinedesigned to optimize performance.Choice of Buckets. Caterpillar offerstwo general purpose buckets for use onthe 924Gz. Careful match of bucketdesign and machine operatingcharacteristics provide the best digging,loading and carrying performance.General Purpose BucketCaterpillar General PurposeBuckets, available in 1.8 m 3 (2.3 yd 3 .)and 2.1 m 3 (2.75 yd 3 .) capacities, aresuitable for most general applications.Features include:■ improved bucket design with longerfloor for easier flow of material intothe bucket;■ patented Two-Bolt Corner GuardCutting Edge System offers superiorwear resistance, better stability and asimple bolt-on system;■ built-in, replaceable heel wear platesextend bucket life.Ground Engaging Tools includehardened steel cutting edges, choice ofshort or long teeth and a variety of toothadapters. Properly selected, these toolsoptimize performance, improve loadretention and extend the useful life ofCaterpillar buckets.EdgeSegmentTwo-boltCorner GuardTooth TipBolt-onUnitoothBolt-onStraight End BitBolt-onCutting EdgeSharpenedSide BarFor expanded machine versatility,other special purpose buckets are alsoavailable. Contact your CaterpillarDealer for details.Replaceable HeelWear Plates7

Operator StationErgonomic design emphasizes comfort, visibility and easy operation.The G-Series cab is a spacious andcomfortable work environment thatincludes larger windows, more interiorroom, better ergonomics, generousstorage areas and a dramatic reductionin interior sound levels.Access/egress is through a two-doordesign. Both doors open fully and lockflush against the cab. Doors areavailable with solid or sliding glasswindows.Larger windows have more glass areafor exceptional visibility. All glass is flatso replacement panels are readilyavailable and less costly than curvedglass.Interior sound power (dB) has been cutin half compared to former models* by acombination of improved soundinsulation and low-noise components.High-efficiency engine cooling systemhelps reduce exterior sound level. In all,the 924Gz is one of the quietest machinesin its size class.* interior sound pressure measures 3 decibels less thanformer models.Comfortable, low-effort operation ismade possible by:■ pilot hydraulic implement controls;■ padded, adjustable wrist rest;■ remote transmission control option(adds forward/neutral/reverse controlswitch on the implement lever);■ load-sensing, closed-center steeringsystem with flow amplification;■ dual, suspended brake pedals withtransmission neutralizer;■ Tilt console with infinite adjustment.Generous storage space includes alockable compartment, coat hook andmolded compartments designed to hold:■■■lunchbox/cooler;Thermos vacuum bottle;cup or can.Seat options include a basic seat withfully adjustable fore/aft position,seatback angle, bottom cushion height,armrest angle and suspension stiffness.Seat cover is a combination of durable,breathable cloth and vinyl.Other seat options include:■ Cat Contour Series Seat with theaddition of adjustable backrest andlumbar support.■ Cat Contour Series Seat with airsuspension, electrically adjustable.■ basic seat with all vinyl covering.■ basic seat, fabric covering, heatedcushions (thermostatically controlled)and seat-activated parking brakewarning.All seats include a comfortable 75 mm(3 in.) wide retractable seat belt.Customize the cab with:■ 12 VDC converter for powering 12Velectronics;■ radio prep packages for installation ofa radio later;■ sun visor for windshield;■ roll-down sun screen for rear window;■ external mirror package;■ auxiliary lighting packages.8

ServiceabilityImproved access and less maintenance requirements add up to unparalleled ease of service.Easy, wide open access. Gull-wingdoors with pneumatically-assisted liftcylinders effortlessly lift up forexceptional access to major power traincomponents. All filters and servicepoints are within easy reach.Simplified routine service. All servicepoints are accessible from ground leveland are grouped in two locations. Sightgauges allow easy check of radiatorcoolant, hydraulic oil and transmissionoil levels.Swing-out cooling fan allows quick,easy cleaning and service of theradiator. The fan is hydraulically drivenand separated from the enginecompartment. This innovative systemfeatures:■ cooling fan, oil cooler and A/Ccondenser swing away for excellentaccess to radiator;■ high-efficiency fan and shroud;■ low-noise operation;■ simple design for high reliability;■ radiator and coolant hoses remainstationary;■ hydraulic oil cooler is standard;■ uses new Cat Extended Life Coolant/Antifreeze for extended operation(up to 6,000 hr.) between changes.Scheduled Oil Sampling (S•O•S) valvesare factory installed for improved accessto engine, transmission and hydraulicoils. S•O•S valves make oil samplingquicker, cleaner and provides the mostrepresentative oil sample for analysis.Other service features include:■ longer service intervals:- up to 500 hours for engine;- up to 6000 hours for coolant;■ spin-on filters for engine oil,transmission oil and hydraulic oil easyto reach and change with minimal riskof oil spill;■ self-diagnostic transmission and datalink allow quick, easy troubleshootingby service personnel;■ driveshaft is permanently lubricated;■ adjustment-free brakes;■ adjustment-free engine fuel system.9

Environmentally Responsible DesignCaterpillar machines not only help you build a better world, they helpmaintain and preserve the fragile environment.More performance. The 924Gz isdesigned to provide more performancethan ever before in a machine this size.That means more work done in a day,less fuel consumed and minimal impacton our environment.Low exhaust emissions. The Cat 3056Tused in the 924Gz is a low emissionengine designed to meet currentworldwide emission regulations.Quiet operation. Not only is the cabquiet, but spectators outside hear littlenoise too. That is because the remotecooling system allows the 924Gz’sengine to be fully enclosed – less noiseescapes.Extra sound suppression with anoptional package makes the 924Gz evenquieter* so it’s ideal for sound-sensitiveapplications like urban and night work,and when used for snow removal.* exterior sound pressure measures 6 decibels lesscompared to a standard-equipped machine.Ozone protection. To help protect theearth’s ozone layer, the 924Gz’s airconditioning unit uses only R-134arefrigerant which does not containharmful chlorofluorocarbons (CFC’s).Caterpillar biodegradable hydraulic oilcan be used in the 924Gz, providing amore environmentally-sound alternativeto mineral-based oils.Fewer leaks and spills. Lubricant fillersand drains are designed to minimizespills. Cat O-Ring Face Seals, XT Hoseand hydraulic cylinders are all designedto help prevent fluid leaks that can robthe machine performance and causeharm to the environment. Also, the newCat Extended Life Coolant/Antifreezeprovides extended service (up to 6,000hours) so there is less need for fluiddisposal.Longer service intervals. 500-hourengine service intervals and CatExtended Life Coolant/Antifreeze (up to6,000-hour service) mean there is lessdisposal of used fluids.Rebuildable components. Many of themajor components used in the 924Gzare designed for rebuildability. Thatmeans you have high-quality, certifiedrebuilt replacement parts available toyou at a fraction of the cost of new. Plusthere is less scrap for disposal.10

Complete Customer SupportCat dealer services ensure the 924Gz a longer service life and lower operating costs.Your Cat dealer offers a wide range ofservices that can be set up under acustomer support agreement. Choose aplan that can cover everything frommachine and attachment selection toreplacement intervals to get the bestreturn on your machine investment.Selection. Your Cat dealer can help youmake detailed comparisons of machinesyou are considering before you buy.You can compare things like expectedcomponent life, the cost of preventivemaintenance and the true cost of lostproduction.Purchase. Look past initial price.Consider the financing optionsavailable, as well as daily operatingcosts. You can also look at dealerservices that can be included in the costof the machine to yield lower equipmentowning and operating costs over the lifeof the machine.Maintenance. Choose from your Catdealer’s wide range of maintenanceservices for your 924Gz. Repair optionprograms guarantee the cost of repairs.Diagnostic programs such as S•O•S OilAnalysis and Technical Analysis helpyou avoid unscheduled repairs.Replacement. Your Cat dealer can helpyou evaluate the cost involved withrepairing, rebuilding or replacing. Youcan be assured that the choice you makewill be the right one.Product support. Nearly all parts neededto support the 924Gz are alreadyavailable at your dealer’s parts counter.And you can save money withremanufactured parts. You receive thesame warranty and reliability as newparts, but at a cost savings of 40 to 70percent.11

AxlesFixed front, oscillating rear (±12° with17.5 - 25 L-2 tires).Features■ Caterpillar axle with fully-enclosedbrakes and final drives.■ patented Duo-Cone Seals betweenaxle and housing.■ rear wheel can raise or drop a total of:423 mm (16.7 in.) with 17.5 tires, or326 mm (12.8 in) with 20.5 tires.■ conventional differentials standard.■ Limited Slip differentials are optionalon front, rear or both axles.■ rear axle trunnion has remotelubrication fitting.BrakesMeets the following standards:SAE J1473 OCT 90, ISO 3450-1996.Service brake features■ inboard oil-immersed disc brakes onfront and rear axles are standard.■ completely enclosed and sealed.■ adjustment-free.■ separate circuits for front and rear.■ dual pedal braking system.■ switch in cab allows operator to selectautomatic transmission neutralizerwhich activates during braking.■ brakes are fully integrated withhydraulic system, no air systemrequired.Secondary brake features■ Indicator light alerts operator if brakepressure drops.■ continually-charged nitrogenaccumulators provide stopping powerafter loss of engine power.Parking brake features■ mechanical, shoe-type brake.■ mounted on drive line for positivemanual operation.■ application of parking brakeneutralizes the transmission.Final DrivesPlanetary final drives consist of ringgears and planetary carrier assemblies.Features■ ring gears are pressed in and doweledinto axle housing.■ carrier assemblies include planet gearswith full-floating bronze sleevebearings.■ high contact ratio gearset reducesnoise levels during meshing.■ planetary reduction gears are inboardmounted for optimal protection anddurability.<strong>Loader</strong> Hydraulic SystemClosed-center, load-sensing system. Pilot-operated hydraulic implement controls.Implement system, variable displacement pumpOutput at 2300 engine rpm and6900 kPa (1000 psi)with SAE 10W oil at 65°C (150°F) 152 liters/min 39.5 gpmMaximum working pressure: 25 900 kPa 3755 psiLift cylinders, double acting:bore and stroke 107.95 x 755 mm 4.25 x 29.7”Tilt cylinder, double acting:bore and stroke 120.6 x 520 mm 4.75 x 20.5”Hydraulic cycle time SecondsRaise 5.5Dump 1.2Lower, empty, float down 2.7Total 9.4Features■ load-sensing system provides only theflow and pressure needed to move theload.■ variable-displacement piston-typeimplement pump.■ low effort, pilot-operated controls.■ pilot shutoff valve disables implementfunctions for added safety.■ hydraulic couplings with O-Ring FaceSeals.■ standard hydraulic oil cooler tilts outfor easy cleaning of heat exchangers.■ Ride Control system available toreduce machine bounce whentraveling.■ S•O•S oil sampling valve forhydraulic system oil.924Gz specifications13

CabCaterpillar cab and Rollover ProtectiveStructure (ROPS) are standard in NorthAmerica and Europe.Features■ ROPS meets the following criteria:– SAE J1040 MAY94.– ISO 3471-1994.■ also meets the following criteria forFalling Object Protective Structure:– SAE J231 JAN81.– ISO 3449-1992.NoteWhen properly installed and maintained,the cab offered by Caterpillar, when testedwith doors and windows closed as perwork cycle procedures specified inANSI/SAE J1166 May 90, results in anoperator sound exposure Leq (equivalentsound pressure level) of 74 dB(A). Also,when tested as per the static specificationsof 86/662/EEC and dynamic specificationsof 95/27/EC, the respective operator soundpressure levels is 73 dB(A).As manufactured by Caterpillar, thismachine’s exterior sound power levelmeets the criteria spelled out in theEuropean Directives noted on thecertificate of conformance and theaccompanying labeling.TiresTubeless, loader design tires.Choice of■ 17.5 - 25, 12PR (L-2)■ 17.5 - 25, 12PR (L-3)■ 17.5 R25, radial (L-2)■ 17.5 R25, radial (L-3)■ 555/70 R25, radial (L-3)■ 20.5 - 25, 12 PR (L-2)■ 20.5 - 25, 12 PR (L-3)■ 20.5 R25, radial (L-2 )■ 20.5 R25, radial (L-3)■ Other tire choices are available,contact your Cat Dealer for detailsNoteIn certain applications (such as load andcarry work) the loader's productivecapabilities might exceed the tires' tonneskm/h(ton-MPH) capabilities. Caterpillarrecommends that you consult a tiresupplier to evaluate all conditions beforeselecting a tire model.SteeringFull hydraulic power steering. MeetsISO 5010-1992, SAE J1511-FEB94.RatingsMinimum turning radius:(over tire) 5070 mm (16’ 8”)Steering angle, each direction: 40°Steering cylinders, two:bore69.9 mm (2.75 in.)Hydraulic output at 2300 rpm and6900 kPa (1000 psi):106 liters/min (27.7 gpm)Maximum working pressure:20 685 kPa (3000 psi)Features■ center-point frame articulation.■ front and rear wheels track.■ variable displacement piston pumpprovides steering power at all engineand ground speeds.■ tilt steering console.■ high-impact rubber steering stops.■ secondary steering system available tomeet roading regulations in variouscountries, and to meet ISO 5010.Service Refill CapacitiesBucket Controls■ controls can be disabled for roading.Pilot-operated lift and tilt circuits.Liters GallonsLift circuit featuresFuel tank 198 51.5■ four positions: raise, hold, lower Cooling system 42 10.9and float.Crankcase 16 4.2■ can adjust automatic kickout from Transmission 23 6.1horizontal to full lift.Differentials and final drives:Tilt circuit featuresfront 21 5.5■ three positions: tilt back, holdand dump.rear 21 5.5■ two-speed dump for quick dumpingwith bucket and precise load controlHydraulic system(including tank) 133 35with forks or other attachments. Hydraulic tank 73 19■ can adjust automatic bucket positionerto desired loading angle.■ does not require visual spotting.Controls■ choice of low effort single-lever ortwo lever control of lift and tiltcircuits.■ optional third and fourth functionhydraulic circuits available withindividual lever controls for remotehydraulic functions.14 924Gz specifications

◆ B◆ CDimensions with BucketAll dimensions are approximate.◆ Dimensions vary withbucket. Refer to OperatingSpecifications chart on page 16.58 o◆3160 mm(10' 5”)2896 mm(9' 6”)2063 mm(6' 9”)924Gz◆45 o 44 o451mm48 o◆3366 mm(11' 1”)3691 mm(12' 1”)370 mm(1' 2”)624 mm(2' 1”)(1'6”)1778 mm(5' 10”)1400 mm◆(4' 7”)2800 mm(9' 2”)◆◆ A40 o17.5 - 25 20.5 - 2512PR(L-2)12PR(L-2)A 5070 mm (16’ 8”) 5135 mm (16’ 10”)B 1880 mm (6’ 2”) 1880 mm (6’ 2”)C 2356 mm (7’ 9”) 2466 mm (8’ 1”)change in vertical dimension -- +68 mm (+3”)◆<strong>Loader</strong> ClearanceCircle (diameter)924Gz specifications15

Operating SpecificationsRated bucket capacity (§)Struck capacity (§)Bucket widthDump clearance at fulllift and 45° discharge (§)Reach at full liftand 45° discharge (§)Reach at 45° dischargeand 2130 mm (7 ft 0 in) clearance (§)Reach with lift armshorizontal and bucket levelDigging depth (§)Overall lengthOverall height with bucketat full raise (§)<strong>Loader</strong> clearance circle withbucket in carry position (§)Static tipping load straight (§)Static tipping loadfull 40° turn (§)Breakout force (§)Operating weightm 3yd 3m 3yd 3mmft/inmmft/inmmft/inmmft/inmmft/inmminmmft/inmmft/inmmft/inkglbkglbkglbkglbGeneral PurposeWith Bolt-On With Bolt-On With Bolt-OnCutting Edge Teeth & Segments* Teeth*1.8 2.1 1.8 2.1 1.7 2.02.3 2.7 2.3 2.7 2.2 2.61.5 1.7 1.5 1.7 1.4 1.62.0 2.2 2.0 2.2 1.8 2.12550 2550 2585 2585 2585 25858’ 4” 8’ 4” 8’ 6” 8’ 6” 8’ 6” 8’ 6”2760 2691 2656 2587 2656 25879’ 1” 8’ 10” 8’ 9” 8’ 6” 8’ 9” 8’ 6”865 934 969 1037 969 10372’ 10” 3’ 1” 3’ 2” 3’ 5” 3’ 2” 3’ 5”1357 1386 1399 1424 1399 14244’ 5” 4’ 6” 4’ 7” 4’ 8” 4’ 7” 4’ 8”2133 2230 2279 2376 2279 23767’ 0” 7’ 4” 7’ 6” 7’ 10” 7’ 6” 7’ 10”110 118 110 118 85 934” 4.5” 4” 4.5” 3.5” 3.5”6890 6993 7036 7138 7017 712022’ 7” 22’ 11” 23’ 1” 23’ 5” 23’ 0” 23’ 4”4743 4870 4743 4870 4743 487015’ 7” 16’ 0” 15’ 7” 16’ 0” 15’ 7” 16’ 0”11 218 11 276 11 339 11 399 11 339 11 39936’ 10” 37’ 0” 37’ 2” 37’ 5” 37’ 2” 37’ 5”7868 7785 7700 7614 7862 780217,310 17,127 16,940 16,750 17,296 17,1646886 6806 6717 6635 6872 681215,149 14,973 14,777 14,597 15,118 14,9869876 8902 9756 8782 10 660 953521,727 19,584 21,463 19,320 23,452 20,9779907 9960 10 042 10 095 9957 10 01021,795 21,912 22,092 22,209 21,905 22,022Specifications shown are for 924Gz with optional counterweight, standardlubricants, full fuel tank, ROPS cab, 80 kg (176 lb) operator and 17.5 - 25 12PR (L2)tires.Note: Specifications and ratings conform to all applicable standards recommendedby the Society of Automotive Engineers (SAE). SAE Standards J732 JUN92 and J742FEB85 govern loader rating, denoted in the text by (§).* Dimensions are measured to the tip of the bucket teeth to provideaccurate clearance data. SAE standards specifies the cutting edge.16 924Gz specifications

Typical materialdensities-loosekg/m 3 lb/yd 3Basalt 1960 3305Bauxite, Kaolin 1420 2394Claynatural bed 1660 2799dry 1480 2495wet 1660 2799Clay and graveldry 1420 2394wet 1540 2596Decomposed rock75% rock, 25% earth 1960 330550% rock, 50% earth 1720 290025% rock, 75% earth 1570 2647Earthdry, packed 1510 2546wet, excavated 1600 2698kg/m 3 lb/yd 3Granitebroken 1660 2799Gravelpitrun 1930 3254dry 1510 2546dry, 6-50 mm (.2-2") 1690 2849wet, 6-50 mm (.2-2") 2020 3406Gypsumbroken 1810 3052crushed 1600 2698Limestonebroken 1540 2596crushed 1540 2596kg/m 3 lb/yd 3Sanddry, loose 1420 2394damp 1690 2849wet 1840 3102Sand and clayloose 1600 2698Sand and graveldry 1720 2900wet 2020 3416Sandstone 1510 2546Shale 1250 2107Slagbroken 1750 2950Stonecrushed 1600 2698Bucket Size SelectorBucket CapacityMaterial Densityyd 3 m 31400 1600 1800 2000 kg/m 32.25 1.72.3 1.82.6 2.02.75 2.12500 3000 3500 lb/yd 3% = Bucket Fill Factor115% 100% 95%924Gz specifications17

Standard EquipmentStandard equipment may vary. Consult your Caterpillar dealer for specifics.Air cleaner, dry typeAlarm, back-upAlternator, 55-ampAntenna, for radioAntifreeze/coolant, extended-life,protects to minus 36C (-33F)Axle seal guardsBatteries, maintenance-free, 12V,Heavy duty, 900 CCA (two)Brakes: Service - enclosed, sealedParking - mechanical on drive lineBucket positioner, automaticCab, ROPS (sound suppressed andpressurized) with:- ground level door release- heater/defroster- rear window defroster, electric(North American-sourcedmachines only)- personal storage space, cup holder- lighter- coat hook- rear view mirrors (2 inside)- tilt steering console- seat, adjustable suspension(fabric or vinyl)- seat belt, retractable- tinted safety glass- two door cab, fixed glass- wiper and washer, 2-speed plusintermittent, front and rearCounterweightDifferentials, conventional (front/rear)Driveshaft, lubed for lifeElectrical system, 24VEngine, Caterpillar 3056T(Low Emission Diesel)Engine enclosure, lockableEngine fuel priming pumpFenders (front/rear)Hitch, drawbarHorn, front warning (electrical)Hour meter, electricHydraulic diagnostic connectorsHydraulic oil coolerHydraulic control, 2-valve, 1-leverImplement control lever locksImplement positioner, two-positionIndicators:- air cleaner service- coolant level- hydraulic oil level sight gauge- transmission oil level gaugeInstrumentation:- engine coolant temperature gauge- hydraulic oil temperature gauge- torque converter oil temp. gauge- fuel level gaugeLift kickout, automaticLift/tilt kickout neutralizerLighting system: - brake lights- working lights (halogen, flood)includes 2 on front tower, 2 on frontroof and 2 on rear roof<strong>Loader</strong> linkage, z-barLoad-sensing steering systemMufflerRadiator, unit serviceableS•O•S oil sampling valves for engine,transmission and hydraulic systemsStarting aid, thermalSteering stops, cushionedSwing-out, hydraulically-driven fanSwitch, key start & stopTorque converterTransmission, 4F/3R, autoshift, singlelever control and kickdown buttonTransmission neutralizerVandalism protection, lockable servicepointsWarning indicators:- alternator- coolant temperature- engine oil pressure- parking brake- service brake oil pressure- transmission oil temperature18924Gz specifications

Optional EquipmentOptional equipment may vary. Consult your Caterpillar dealer for specifics.Air conditioner (R-134a refrigerant)Alternator, 75-ampAntifreeze/coolant, extended-life,protects to minus 50C (58F)Beacon light, rotating, magnetic-mountBuckets/ground engaging toolsCanopy, ROPSCounterweight, 175 kg (385 lb)Differential, Limited Slip- front axle and/or rear axleDifferential, NoSpin, rear axle onlyElectrical accessories package(12V converter, accessory plugoutlet, wiring)Fenders, roadingGuards:- crankcase- power train- driveshaft- lights (front)- windshield- heavy duty fan guard- vandalism protection (for use withROPS canopy only)Hydraulic control, 2-valve, 2-leverHydraulic control, 3-valve, 2-leverHydraulic control, 3-valve, 3-leverHydraulic third valve (for remotehydraulic functions)Hydraulic oil cooler, heavy dutyLights:- directional, front/rear- flood (auxiliary, cab-mounted)Load check valves (dealer installed)Low speed transmissionMirrors, external (two)Radio prep packages:- for 12V installation, includesspeakers, cable, mounting bracket,hardware, converter, andaccessory plug. Radio not included.- for 24V installation, same as above,but without converter oraccessory plug.Remote Forward/Neutral/ReverseTransmission ControlRide control systemSeats:- Caterpillar Contour Series, fabric- Caterpillar Contour Series, fabric,with air suspensionSliding door windows, (left and right)Sound suppression packageStarting aid, engine coolant heater, 120VSteering, secondarySun screen, rearTires:- bias ply, 17.5 - 25 and 20.5 - 25- radial, 17.5 - 25, 555/70 R25and 20.5 - 25Visor, sun (front)Supplemental SpecificationsChange inOperating WeightChange in Articulated StaticTipping Loadkg lb kg lbAir conditioner +32 +70 +47 +103Canopy, ROPS (less cab) -199 -438 -185 -407Counterweight, 175 kg/385 lb (removal) -175 -385 -294 -647Guard, crankcase +15 +33 +22 +48Guard, driveshaft +43 +95 +12 +26Guard, power train +52 +114 +51 +112Ride Control System +40 +88 +28 +62Secondary steering +37 +81 +50 +110Tires & 1-piece rims, 17.5 - 25, 12PR (L-2) 0 0 0 0Tires & 1-piece rims, 17.5 - 25, 12PR (L-3) +72 +158 +45 +99Tires & 1-piece rims, 17.5 R25, radial (L-2) +40 +88 +25 +55Tires & 1-piece rims, 17.5 R25, radial (L-3) +140 +308 +87 +191Tires & 3-piece rims, 17.5 - 25, 12PR (L-2) +124 +273 +78 +172Tires & 3-piece rims, 17.5 - 25, 12PR (L-3) +196 +431 +123 +270Tires & 3-piece rims, 17.5 R25, radial (L-2) +164 +361 +103 +227Tires & 3-piece rims, 17.5 R25, radial (L-3) +264 +581 +165 +363Tires & 3-piece rims, 555/70 R25, radial (L-3) +516 +1135 +322 +708Tires & 3-piece rims, 20.5 - 25, 12PR (L-2) +412 +906 +257 +565Tires & 3-piece rims, 20.5 - 25, 12PR (L-3) +616 +1355 +385 +847Tires & 3-piece rims, 20.5 R25, radial (L-2) +480 +1056 +300 +660Tires & 3-piece rims, 20.5 R25, radial (L-3) +652 +1434 +407 +895924Gz specifications19

924Gz <strong>Wheel</strong> <strong>Loader</strong>© 2000 CaterpillarPrinted in U.S.A.AEHQ0546-01 (9-2000)Materials and specifications are subject to change without notice.Featured machines in photos may include additional equipment.See your Caterpillar dealer for available options.R