Edexcel Level 2 NVQ Diploma in Performing Engineering Operations

Edexcel Level 2 NVQ Diploma in Performing Engineering Operations

Edexcel Level 2 NVQ Diploma in Performing Engineering Operations

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong><br />

<strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF)<br />

Specification<br />

<strong>Edexcel</strong> <strong>NVQ</strong>/competence-based qualifications<br />

For first registration August 2010

Pearson Education Ltd is one of the UK’s largest award<strong>in</strong>g organisations, offer<strong>in</strong>g<br />

academic and vocational qualifications and test<strong>in</strong>g to schools, colleges, employers<br />

and other places of learn<strong>in</strong>g, both <strong>in</strong> the UK and <strong>in</strong>ternationally. Qualifications<br />

offered <strong>in</strong>clude GCSE, AS and A <strong>Level</strong>, <strong>NVQ</strong> and our BTEC suite of vocational<br />

qualifications, rang<strong>in</strong>g from Entry <strong>Level</strong> to BTEC Higher National <strong>Diploma</strong>s. Pearson<br />

Education Ltd adm<strong>in</strong>isters work-based qualifications.<br />

Through <strong>in</strong>itiatives such as onscreen mark<strong>in</strong>g and adm<strong>in</strong>istration, Pearson is lead<strong>in</strong>g<br />

the way <strong>in</strong> us<strong>in</strong>g technology to modernise educational assessment, and to support<br />

teachers and learners.<br />

References to third party material made <strong>in</strong> this specification are made <strong>in</strong> good faith.<br />

We do not endorse, approve or accept responsibility for the content of materials,<br />

which may be subject to change, or any op<strong>in</strong>ions expressed there<strong>in</strong>. (Material may<br />

<strong>in</strong>clude textbooks, journals, magaz<strong>in</strong>es and other publications and websites.)<br />

Authorised by Mart<strong>in</strong> Stretton<br />

Prepared by Andres Vergara<br />

Publications Code N025373<br />

All the material <strong>in</strong> this publication is copyright<br />

© Pearson Education Limited 2012

Contents<br />

Qualification title covered by this specification 1<br />

Key features of the <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g<br />

Eng<strong>in</strong>eer<strong>in</strong>g <strong>Operations</strong> (QCF) 3<br />

What is the purpose of this qualification? 3<br />

Who is this qualification for? 3<br />

What are the benefits of this qualification to the learner and employer? 3<br />

What are the potential job roles for those work<strong>in</strong>g towards this qualification? 3<br />

What progression opportunities are available to learners who achieve this<br />

qualification? 4<br />

What is the qualification structure for the <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong><br />

<strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g <strong>Operations</strong> (QCF)? 5<br />

How is the qualification graded and assessed? 9<br />

Assessment Strategy 9<br />

Types of evidence (to be read <strong>in</strong> conjunction with the assessment strategy<br />

<strong>in</strong> Annexe E) 10<br />

Additional requirements 11<br />

Centre recognition and approval 12<br />

Centre recognition 12<br />

Approvals agreement 12<br />

Quality assurance 12<br />

What resources are required? 12<br />

Unit format 13<br />

Units 15<br />

Unit 1: Work<strong>in</strong>g safely <strong>in</strong> an eng<strong>in</strong>eer<strong>in</strong>g environment 17<br />

Unit 2: Carry<strong>in</strong>g out eng<strong>in</strong>eer<strong>in</strong>g activities efficiently and effectively 27<br />

Unit 3: Us<strong>in</strong>g and communicat<strong>in</strong>g technical <strong>in</strong>formation 41<br />

Unit 4: Produc<strong>in</strong>g mechanical eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>gs us<strong>in</strong>g a CAD system 51<br />

Unit 5: Produc<strong>in</strong>g components us<strong>in</strong>g hand fitt<strong>in</strong>g techniques 63<br />

Unit 6: Produc<strong>in</strong>g mechanical assemblies 79<br />

Unit 7: Form<strong>in</strong>g and assembl<strong>in</strong>g pipework systems 93<br />

Unit 8: Carry<strong>in</strong>g out aircraft detail fitt<strong>in</strong>g activities 107<br />

Unit 9: Install<strong>in</strong>g aircraft mechanical fasteners 123

Unit 10: Produc<strong>in</strong>g aircraft detail assemblies 135<br />

Unit 11: Prepar<strong>in</strong>g and us<strong>in</strong>g lathes for turn<strong>in</strong>g operations 145<br />

Unit 12: Prepar<strong>in</strong>g and us<strong>in</strong>g mill<strong>in</strong>g mach<strong>in</strong>es 159<br />

Unit 13: Prepar<strong>in</strong>g and us<strong>in</strong>g gr<strong>in</strong>d<strong>in</strong>g mach<strong>in</strong>es 173<br />

Unit 14: Prepar<strong>in</strong>g and prov<strong>in</strong>g CNC mach<strong>in</strong>e tool programs 187<br />

Unit 15: Prepar<strong>in</strong>g and us<strong>in</strong>g CNC turn<strong>in</strong>g mach<strong>in</strong>es 199<br />

Unit 16: Prepar<strong>in</strong>g and us<strong>in</strong>g CNC mill<strong>in</strong>g mach<strong>in</strong>es 215<br />

Unit 17: Prepar<strong>in</strong>g and us<strong>in</strong>g CNC mach<strong>in</strong><strong>in</strong>g centres 231<br />

Unit 18: Prepar<strong>in</strong>g and us<strong>in</strong>g <strong>in</strong>dustrial robots 247<br />

Unit 19: Ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g mechanical devices and equipment 261<br />

Unit 20: Assembl<strong>in</strong>g and test<strong>in</strong>g fluid power systems 273<br />

Unit 21: Ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g fluid power equipment 285<br />

Unit 22: Produc<strong>in</strong>g sheet metal components and assemblies 299<br />

Unit 23: Produc<strong>in</strong>g platework components and assemblies 315<br />

Unit 24: Cutt<strong>in</strong>g and shap<strong>in</strong>g materials us<strong>in</strong>g thermal cutt<strong>in</strong>g equipment 327<br />

Unit 25: Prepar<strong>in</strong>g and prov<strong>in</strong>g CNC fabrication mach<strong>in</strong>e tool programs 337<br />

Unit 26: Prepar<strong>in</strong>g and us<strong>in</strong>g CNC fabrication mach<strong>in</strong>ery 349<br />

Unit 27: Prepar<strong>in</strong>g and us<strong>in</strong>g manual metal arc weld<strong>in</strong>g equipment 361<br />

Unit 28: Prepar<strong>in</strong>g and us<strong>in</strong>g manual TIG or plasma-arc weld<strong>in</strong>g<br />

equipment 373<br />

Unit 29: Prepar<strong>in</strong>g and us<strong>in</strong>g manual MIG, MAG and other cont<strong>in</strong>uous wire<br />

weld<strong>in</strong>g equipment 385<br />

Unit 30: Prepar<strong>in</strong>g and us<strong>in</strong>g manual gas weld<strong>in</strong>g equipment 397<br />

Unit 31: Prepar<strong>in</strong>g and us<strong>in</strong>g manual flame braz<strong>in</strong>g and bronze weld<strong>in</strong>g<br />

equipment 409<br />

Unit 32: Produc<strong>in</strong>g electrical or electronic eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>gs us<strong>in</strong>g a<br />

CAD system 421<br />

Unit 33: Wir<strong>in</strong>g and test<strong>in</strong>g electrical equipment and circuits 435<br />

Unit 34: Form<strong>in</strong>g and assembl<strong>in</strong>g electrical cable enclosure and support<br />

systems 449<br />

Unit 35: Assembl<strong>in</strong>g, wir<strong>in</strong>g and test<strong>in</strong>g electrical panels/components<br />

mounted <strong>in</strong> enclosures 461<br />

Unit 36: Assembl<strong>in</strong>g and test<strong>in</strong>g electronic circuits 473<br />

Unit 37: Ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g electrical equipment/systems 489<br />

Unit 38: Ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g electronic equipment/systems 503<br />

Unit 39: Ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g and test<strong>in</strong>g process <strong>in</strong>strumentation and control<br />

devices 519<br />

Unit 40: Wir<strong>in</strong>g and test<strong>in</strong>g programmable controller based systems 531

Unit 41: Us<strong>in</strong>g wood for pattern, modelmak<strong>in</strong>g and other eng<strong>in</strong>eer<strong>in</strong>g<br />

applications 543<br />

Unit 42: Assembl<strong>in</strong>g pattern, model and eng<strong>in</strong>eer<strong>in</strong>g woodwork<br />

components 557<br />

Unit 43: Produc<strong>in</strong>g composite mould<strong>in</strong>gs us<strong>in</strong>g wet lay-up techniques 567<br />

Unit 44: Produc<strong>in</strong>g composite mould<strong>in</strong>gs us<strong>in</strong>g pre-preg lam<strong>in</strong>at<strong>in</strong>g<br />

techniques 581<br />

Unit 45: Produc<strong>in</strong>g composite mould<strong>in</strong>gs us<strong>in</strong>g res<strong>in</strong> <strong>in</strong>fusion techniques 595<br />

Unit 46: Produc<strong>in</strong>g composite assemblies 611<br />

Unit 47: Produc<strong>in</strong>g components by rapid prototyp<strong>in</strong>g techniques 623<br />

Unit 48: Produc<strong>in</strong>g and prepar<strong>in</strong>g sand moulds and cores for cast<strong>in</strong>g 633<br />

Unit 49: Produc<strong>in</strong>g and prepar<strong>in</strong>g molten materials for cast<strong>in</strong>g 645<br />

Unit 50: Produc<strong>in</strong>g cast components by manual means 655<br />

Unit 51: Fettl<strong>in</strong>g, f<strong>in</strong>ish<strong>in</strong>g and check<strong>in</strong>g cast components 665<br />

Unit 52: F<strong>in</strong>ish<strong>in</strong>g surfaces by apply<strong>in</strong>g coat<strong>in</strong>gs or cover<strong>in</strong>gs 677<br />

Unit 53: F<strong>in</strong>ish<strong>in</strong>g surfaces by apply<strong>in</strong>g treatments 689<br />

Unit 54: Carry<strong>in</strong>g out heat treatment of eng<strong>in</strong>eer<strong>in</strong>g materials 701<br />

Unit 55: Carry<strong>in</strong>g out hand forg<strong>in</strong>g of eng<strong>in</strong>eer<strong>in</strong>g materials 713<br />

Unit 56: Stripp<strong>in</strong>g and rebuild<strong>in</strong>g motorsport vehicles (pre-competition) 723<br />

Unit 57: Inspect<strong>in</strong>g a motorsport vehicle dur<strong>in</strong>g a competition 739<br />

Unit 58: Diagnos<strong>in</strong>g and rectify<strong>in</strong>g faults on motorsport vehicle systems<br />

(dur<strong>in</strong>g competition) 751<br />

Unit 59: Carry<strong>in</strong>g out ma<strong>in</strong>tenance activities on motorsport vehicle<br />

electrical equipment 765<br />

Unit 60: Stripp<strong>in</strong>g and rebuild<strong>in</strong>g motorsport eng<strong>in</strong>es (pre-competition) 777<br />

Unit 61: Produc<strong>in</strong>g CAD models (draw<strong>in</strong>gs) us<strong>in</strong>g a CAD system 793<br />

Unit 62: Produc<strong>in</strong>g eng<strong>in</strong>eer<strong>in</strong>g project plans 807<br />

Unit 63: Us<strong>in</strong>g computer software packages to assist with eng<strong>in</strong>eer<strong>in</strong>g<br />

activities 819<br />

Unit 64: Conduct<strong>in</strong>g bus<strong>in</strong>ess improvement activities 831<br />

Unit 65: General mach<strong>in</strong><strong>in</strong>g, fitt<strong>in</strong>g and assembly applications 841<br />

Unit 66: General fabrication and weld<strong>in</strong>g applications 859<br />

Unit 67: General electrical and electronic eng<strong>in</strong>eer<strong>in</strong>g applications 873<br />

Unit 68: General ma<strong>in</strong>tenance eng<strong>in</strong>eer<strong>in</strong>g applications 891<br />

Further <strong>in</strong>formation 904<br />

Useful publications 904<br />

How to obta<strong>in</strong> National Occupational Standards 904

Professional development and tra<strong>in</strong><strong>in</strong>g 905<br />

Annexe A: Progression pathways 907<br />

The <strong>Edexcel</strong> qualification framework for the Eng<strong>in</strong>eer<strong>in</strong>g sector 907<br />

Annexe B: Quality assurance 913<br />

Key pr<strong>in</strong>ciples of quality assurance 913<br />

Quality assurance processes 913<br />

Annexe C: Centre certification and registration 915<br />

What are the access arrangements and special considerations for the<br />

qualification <strong>in</strong> this specification? 915<br />

Annexe D: Additional requirements for qualifications that use the<br />

title <strong>NVQ</strong> with<strong>in</strong> the QCF 917<br />

Annexe E: Assessment Strategy 925

Qualification title covered by this specification<br />

This specification gives you the <strong>in</strong>formation you need to offer the <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF):<br />

Accreditation<br />

start date<br />

Qualification title Qualification<br />

Accreditation<br />

Number (QN)<br />

<strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g <strong>Operations</strong> (QCF) 501/0622/3 01/08/2010<br />

This qualification has been accredited with<strong>in</strong> the Qualifications and Credit Framework (QCF) and is eligible for public fund<strong>in</strong>g as<br />

determ<strong>in</strong>ed by the Department for Education (DfE) under Sections 96 and 97 of the Learn<strong>in</strong>g and Skills Act 2000.<br />

The qualification titles listed above feature <strong>in</strong> the fund<strong>in</strong>g lists published annually by the DfE and the regularly updated website.<br />

They will also appear on the Learn<strong>in</strong>g Aim Reference Application (LARA), where relevant.<br />

You should use the QCF Qualification Accreditation Number (QN), when you wish to seek public fund<strong>in</strong>g for your learners. Each<br />

unit with<strong>in</strong> a qualification will also have a unique QCF reference number, which is listed <strong>in</strong> this specification.<br />

The QCF qualification title and unit reference numbers will appear on the learners’ f<strong>in</strong>al certification document. Learners need to<br />

be made aware of this when they are recruited by the centre and registered with <strong>Edexcel</strong>.<br />

1<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

This title replaces the follow<strong>in</strong>g qualification from 1 st August 2010:<br />

Accreditation<br />

end date<br />

Accreditation<br />

start date<br />

Qualification title Qualification<br />

Accreditation<br />

Number (QN)<br />

<strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g <strong>Operations</strong> 500/2466/8 01/08/2007 31/07/2010<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

2

Key features of the <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong><br />

Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g <strong>Operations</strong> (QCF)<br />

This qualification:<br />

� is nationally recognised<br />

� is based on the Semta National Occupational Standards (NOS). The NOS,<br />

assessment strategy and qualification structure are owned by Semta.<br />

The <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g <strong>Operations</strong><br />

(QCF) has been approved as a component for the Semta Apprenticeship<br />

framework.<br />

What is the purpose of this qualification?<br />

This qualification is appropriate for employees <strong>in</strong> the eng<strong>in</strong>eer<strong>in</strong>g sector<br />

work<strong>in</strong>g across a broad range of areas. It is designed to assess occupational<br />

competence <strong>in</strong> the workplace where learners are required to demonstrate<br />

skills and knowledge to a level required <strong>in</strong> the eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong>dustry.<br />

Who is this qualification for?<br />

There are no entry qualifications or age limits required for this qualification,<br />

unless this is a legal requirement of the process or the environment. This<br />

qualification is for all learners who are capable of reach<strong>in</strong>g the required<br />

standards.<br />

<strong>Edexcel</strong>’s policy is that the qualification should:<br />

� be free from any barriers that restrict access and progression<br />

� ensure equality of opportunity for all wish<strong>in</strong>g to access the qualification.<br />

What are the benefits of this qualification to the learner and employer?<br />

This qualification allows learners to demonstrate competence aga<strong>in</strong>st National<br />

Occupational Standards which are based on the needs of the eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>in</strong>dustry as def<strong>in</strong>ed by Semta, the Sector Skills Council. As such it contributes<br />

to the development of skilled labour <strong>in</strong> the sector. The qualification may<br />

contribute towards the competence element of an Apprenticeship.<br />

What are the potential job roles for those work<strong>in</strong>g towards this<br />

qualification?<br />

� Aerospace eng<strong>in</strong>eer<strong>in</strong>g technician<br />

� Auto electrician<br />

� Electrical eng<strong>in</strong>eer<strong>in</strong>g technician<br />

� Electrician<br />

� Electronic eng<strong>in</strong>eer<strong>in</strong>g technician<br />

� Electronics assembler<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

3

� Eng<strong>in</strong>eer<strong>in</strong>g craft/CNC mach<strong>in</strong>ist<br />

� Eng<strong>in</strong>eer<strong>in</strong>g ma<strong>in</strong>tenance fitter<br />

� Eng<strong>in</strong>eer<strong>in</strong>g ma<strong>in</strong>tenance technician<br />

� Eng<strong>in</strong>eer<strong>in</strong>g operative<br />

� Materials technician<br />

� Mechanical eng<strong>in</strong>eer<strong>in</strong>g technician<br />

� Metals <strong>in</strong>dustry production operative<br />

� Motor vehicle body repairer/ref<strong>in</strong>isher/builder<br />

� Motor vehicle mechanic/technician<br />

� Sheet metal worker<br />

� Welder.<br />

What progression opportunities are available to learners who achieve<br />

this qualification?<br />

This qualification allows learners to demonstrate competence <strong>in</strong> perform<strong>in</strong>g<br />

eng<strong>in</strong>eer<strong>in</strong>g operations at a level required by the eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong>dustry.<br />

Learners can progress across the level and size of the eng<strong>in</strong>eer<strong>in</strong>g<br />

competence and knowledge qualifications and <strong>in</strong>to other occupational areas<br />

such as Team Lead<strong>in</strong>g and Management.<br />

Further <strong>in</strong>formation is available <strong>in</strong> Annexe A.<br />

4<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

What is the qualification structure for the <strong>Edexcel</strong><br />

<strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF)?<br />

Individual units can be found <strong>in</strong> the Units section. The QCF level and credit<br />

value are given on the first page of each unit.<br />

<strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g <strong>Operations</strong><br />

(QCF)<br />

Learners must complete a m<strong>in</strong>imum of 40 credits. Learners must complete all<br />

mandatory units <strong>in</strong> Group M (13 credits) and then choose one of the<br />

follow<strong>in</strong>g pathways:<br />

<strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g <strong>Operations</strong> -<br />

Eng<strong>in</strong>eer<strong>in</strong>g Practices (QCF)<br />

Learners must complete a m<strong>in</strong>imum of three units <strong>in</strong> Group A1*.<br />

*Learners can only choose one unit from 4, 32 and 61.<br />

A total of 40 credits (m<strong>in</strong>imum).<br />

<strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g <strong>Operations</strong> -<br />

Technical Support (QCF)<br />

Learners must complete a m<strong>in</strong>imum of one unit <strong>in</strong> Group B1.<br />

Learners must complete a m<strong>in</strong>imum of two units <strong>in</strong> Group B2.<br />

Learners must complete a m<strong>in</strong>imum of two units <strong>in</strong> Group B3.<br />

A total of 64 credits (m<strong>in</strong>imum).<br />

M – Mandatory units (all pathways)<br />

Learners must complete all units <strong>in</strong> Group M.<br />

Credit value required: m<strong>in</strong>imum 13.<br />

L/600/5781 – Work<strong>in</strong>g safely <strong>in</strong> an eng<strong>in</strong>eer<strong>in</strong>g environment<br />

D/600/5784 – Carry<strong>in</strong>g out eng<strong>in</strong>eer<strong>in</strong>g activities efficiently and effectively<br />

M/600/5790 – Us<strong>in</strong>g and communicat<strong>in</strong>g technical <strong>in</strong>formation<br />

P – Pathways<br />

Learners must choose one pathway.<br />

A – Eng<strong>in</strong>eer<strong>in</strong>g Practices<br />

Learners must complete all units <strong>in</strong> Group M.<br />

Learners must complete a m<strong>in</strong>imum of three units <strong>in</strong> Group A1*.<br />

*Learners can only choose one unit from 4, 32 and 61.<br />

This group represents a pathway.<br />

Credit value required: m<strong>in</strong>imum 27.<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

5

A1 – Optional units (Eng<strong>in</strong>eer<strong>in</strong>g Practices)<br />

Credit value required: m<strong>in</strong>imum 27.<br />

*J/600/5794 – Produc<strong>in</strong>g mechanical eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>gs us<strong>in</strong>g a CAD<br />

system<br />

Barred unit: Y/600/5993 – Produc<strong>in</strong>g CAD models (draw<strong>in</strong>gs) us<strong>in</strong>g a CAD<br />

system.<br />

Barred unit: M/600/5904 – Produc<strong>in</strong>g electrical or electronic eng<strong>in</strong>eer<strong>in</strong>g<br />

draw<strong>in</strong>gs us<strong>in</strong>g a CAD system.<br />

Y/600/5797 – Produc<strong>in</strong>g components us<strong>in</strong>g hand fitt<strong>in</strong>g techniques<br />

H/600/5799 – Produc<strong>in</strong>g mechanical assemblies<br />

T/600/5855 – Form<strong>in</strong>g and assembl<strong>in</strong>g pipework systems<br />

A/600/5856 – Carry<strong>in</strong>g out aircraft detail fitt<strong>in</strong>g activities<br />

F/600/5857 – Install<strong>in</strong>g aircraft mechanical fasteners<br />

J/600/5858 – Produc<strong>in</strong>g aircraft detail assemblies<br />

L/600/5859 – Prepar<strong>in</strong>g and us<strong>in</strong>g lathes for turn<strong>in</strong>g operations<br />

F/600/5860 – Prepar<strong>in</strong>g and us<strong>in</strong>g mill<strong>in</strong>g mach<strong>in</strong>es<br />

J/600/5861 – Prepar<strong>in</strong>g and us<strong>in</strong>g gr<strong>in</strong>d<strong>in</strong>g mach<strong>in</strong>es<br />

R/600/5863 – Prepar<strong>in</strong>g and prov<strong>in</strong>g CNC mach<strong>in</strong>e tool programs<br />

Y/600/5864 – Prepar<strong>in</strong>g and us<strong>in</strong>g CNC turn<strong>in</strong>g mach<strong>in</strong>es<br />

D/600/5865 – Prepar<strong>in</strong>g and us<strong>in</strong>g CNC mill<strong>in</strong>g mach<strong>in</strong>es<br />

H/600/5866 – Prepar<strong>in</strong>g and us<strong>in</strong>g CNC mach<strong>in</strong><strong>in</strong>g centres<br />

M/600/5868 – Prepar<strong>in</strong>g and us<strong>in</strong>g <strong>in</strong>dustrial robots<br />

T/600/5869 – Ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g mechanical devices and equipment<br />

K/600/5870 – Assembl<strong>in</strong>g and test<strong>in</strong>g fluid power systems<br />

F/600/5874 – Ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g fluid power equipment<br />

Y/600/5878 – Produc<strong>in</strong>g sheet metal components and assemblies<br />

R/600/5880 – Produc<strong>in</strong>g platework components and assemblies<br />

H/600/5883 – Cutt<strong>in</strong>g and shap<strong>in</strong>g materials us<strong>in</strong>g thermal cutt<strong>in</strong>g<br />

equipment<br />

M/600/5885 – Prepar<strong>in</strong>g and prov<strong>in</strong>g CNC fabrication mach<strong>in</strong>e tool programs<br />

A/600/5887 – Prepar<strong>in</strong>g and us<strong>in</strong>g CNC fabrication mach<strong>in</strong>ery<br />

J/600/5889 – Prepar<strong>in</strong>g and us<strong>in</strong>g manual metal arc weld<strong>in</strong>g equipment<br />

F/600/5891 – Prepar<strong>in</strong>g and us<strong>in</strong>g manual TIG or plasma-arc weld<strong>in</strong>g<br />

equipment<br />

R/600/5894 – Prepar<strong>in</strong>g and us<strong>in</strong>g manual MIG, MAG and other cont<strong>in</strong>uous<br />

wire weld<strong>in</strong>g equipment<br />

H/600/5897 – Prepar<strong>in</strong>g and us<strong>in</strong>g manual gas weld<strong>in</strong>g equipment<br />

6<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

Y/600/5900 – Prepar<strong>in</strong>g and us<strong>in</strong>g manual flame braz<strong>in</strong>g and bronze weld<strong>in</strong>g<br />

equipment<br />

*M/600/5904 – Produc<strong>in</strong>g electrical or electronic eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>gs us<strong>in</strong>g<br />

a CAD system<br />

Barred unit: Y/600/5993 – Produc<strong>in</strong>g CAD models (draw<strong>in</strong>gs) us<strong>in</strong>g a CAD<br />

system.<br />

Barred unit: J/600/5794 – Produc<strong>in</strong>g mechanical eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>gs us<strong>in</strong>g<br />

a CAD system.<br />

J/600/5908 – Wir<strong>in</strong>g and test<strong>in</strong>g electrical equipment and circuits<br />

J/600/5911 – Form<strong>in</strong>g and assembl<strong>in</strong>g electrical cable enclosure and support<br />

systems<br />

R/600/5913 – Assembl<strong>in</strong>g, wir<strong>in</strong>g and test<strong>in</strong>g electrical panels/components<br />

mounted <strong>in</strong> enclosures<br />

K/600/5917 – Assembl<strong>in</strong>g and test<strong>in</strong>g electronic circuits<br />

A/600/5923 – Ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g electrical equipment/systems<br />

J/600/5925 – Ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g electronic equipment/systems<br />

D/600/5932 – Ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g and test<strong>in</strong>g process <strong>in</strong>strumentation and control<br />

devices<br />

K/600/5934 – Wir<strong>in</strong>g and test<strong>in</strong>g programmable controller based systems<br />

T/600/5936 – Us<strong>in</strong>g wood for pattern, modelmak<strong>in</strong>g and other eng<strong>in</strong>eer<strong>in</strong>g<br />

applications<br />

A/600/5937 – Assembl<strong>in</strong>g pattern, model and eng<strong>in</strong>eer<strong>in</strong>g woodwork<br />

components<br />

J/600/5939 – Produc<strong>in</strong>g composite mould<strong>in</strong>gs us<strong>in</strong>g wet lay-up techniques<br />

L/600/5943 – Produc<strong>in</strong>g composite mould<strong>in</strong>gs us<strong>in</strong>g pre-preg, lam<strong>in</strong>at<strong>in</strong>g<br />

techniques<br />

Y/600/5945 – Produc<strong>in</strong>g composite mould<strong>in</strong>gs us<strong>in</strong>g res<strong>in</strong> <strong>in</strong>fusion techniques<br />

K/600/5948 – Produc<strong>in</strong>g composite assemblies<br />

M/600/5949 – Produc<strong>in</strong>g components by rapid prototyp<strong>in</strong>g techniques<br />

M/600/5952 – Produc<strong>in</strong>g and prepar<strong>in</strong>g sand moulds and cores for cast<strong>in</strong>g<br />

A/600/5954 – Produc<strong>in</strong>g and prepar<strong>in</strong>g molten materials for cast<strong>in</strong>g<br />

J/600/5956 – Produc<strong>in</strong>g cast components by manual means<br />

L/600/5960 – Fettl<strong>in</strong>g, f<strong>in</strong>ish<strong>in</strong>g and check<strong>in</strong>g cast components<br />

R/600/5961 – F<strong>in</strong>ish<strong>in</strong>g surfaces by apply<strong>in</strong>g coat<strong>in</strong>gs or cover<strong>in</strong>gs<br />

H/600/5964 – F<strong>in</strong>ish<strong>in</strong>g surfaces by apply<strong>in</strong>g treatments<br />

T/600/5967 – Carry<strong>in</strong>g out heat treatment of eng<strong>in</strong>eer<strong>in</strong>g materials<br />

A/600/5968 – Carry<strong>in</strong>g out hand forg<strong>in</strong>g of eng<strong>in</strong>eer<strong>in</strong>g materials<br />

T/600/5970 – Stripp<strong>in</strong>g and rebuild<strong>in</strong>g motorsport vehicles (pre-competition)<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

7

F/600/5972 – Inspect<strong>in</strong>g a motorsport vehicle dur<strong>in</strong>g a competition<br />

H/600/5978 – Diagnos<strong>in</strong>g and rectify<strong>in</strong>g faults on motorsport vehicle<br />

systems (dur<strong>in</strong>g competition)<br />

H/600/5981 – Carry<strong>in</strong>g out ma<strong>in</strong>tenance activities on motorsport vehicle<br />

electrical equipment<br />

L/600/5988 – Stripp<strong>in</strong>g and rebuild<strong>in</strong>g motorsport eng<strong>in</strong>es (pre- competition)<br />

*Y/600/5993 – Produc<strong>in</strong>g CAD models (draw<strong>in</strong>gs) us<strong>in</strong>g a CAD system<br />

Barred unit: M/600/5904 – Produc<strong>in</strong>g electrical or electronic eng<strong>in</strong>eer<strong>in</strong>g<br />

draw<strong>in</strong>gs us<strong>in</strong>g a CAD system.<br />

Barred unit: J/600/5794 – Produc<strong>in</strong>g mechanical eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>gs us<strong>in</strong>g<br />

a CAD system.<br />

B – Technical Support<br />

Learners must complete all units <strong>in</strong> Group M.<br />

Learners must complete a m<strong>in</strong>imum of one unit <strong>in</strong> Group B1.<br />

Learners must complete a m<strong>in</strong>imum of two units <strong>in</strong> Group B2.<br />

Learners must complete a m<strong>in</strong>imum of two units <strong>in</strong> Group B3.<br />

This group represents a pathway.<br />

Credit value required: m<strong>in</strong>imum 51.<br />

B1 – Group 1 Optional units (Technical Support)<br />

Credit value required: m<strong>in</strong>imum 11.<br />

J/600/5794 – Produc<strong>in</strong>g mechanical eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>gs us<strong>in</strong>g a CAD<br />

system<br />

M/600/5904 – Produc<strong>in</strong>g electrical or electronic eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>gs us<strong>in</strong>g a<br />

CAD system<br />

Y/600/5993 – Produc<strong>in</strong>g CAD models (draw<strong>in</strong>gs) us<strong>in</strong>g a CAD system<br />

B2 – Group 2 Optional units (Technical Support)<br />

Credit value required: m<strong>in</strong>imum 16.<br />

H/600/5995 – Produc<strong>in</strong>g eng<strong>in</strong>eer<strong>in</strong>g project plans<br />

K/600/5996 – Us<strong>in</strong>g computer software packages to assist with eng<strong>in</strong>eer<strong>in</strong>g<br />

activities<br />

M/600/5997 – Conduct<strong>in</strong>g bus<strong>in</strong>ess improvement activities<br />

B3 – Group 3 Optional units (Technical Support)<br />

Credit value required: m<strong>in</strong>imum 24.<br />

M/600/6003 – General mach<strong>in</strong><strong>in</strong>g, fitt<strong>in</strong>g and assembly applications<br />

T/600/6004 – General fabrication and weld<strong>in</strong>g applications<br />

F/600/6006 – General electrical and electronic eng<strong>in</strong>eer<strong>in</strong>g applications<br />

J/600/6007 – General ma<strong>in</strong>tenance eng<strong>in</strong>eer<strong>in</strong>g applications<br />

8<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

How is the qualification graded and assessed?<br />

The overall grade for the qualification is a ‘pass’. The learner must achieve all<br />

the required units with<strong>in</strong> the specified qualification structure.<br />

To pass a unit the learner must:<br />

� achieve all the specified learn<strong>in</strong>g outcomes<br />

� satisfy all the assessment criteria by provid<strong>in</strong>g sufficient and valid<br />

evidence for each criterion<br />

� show that the evidence is their own.<br />

The qualification is designed to be assessed:<br />

� <strong>in</strong> the workplace or<br />

� <strong>in</strong> conditions resembl<strong>in</strong>g the workplace, as specified <strong>in</strong> the assessment<br />

strategy for the sector, or<br />

� as part of a tra<strong>in</strong><strong>in</strong>g programme.<br />

Assessment Strategy<br />

The Assessment Strategy for this qualification has been <strong>in</strong>cluded <strong>in</strong> Annexe E.<br />

It has been developed by Semta <strong>in</strong> partnership with employers, tra<strong>in</strong><strong>in</strong>g<br />

providers, award<strong>in</strong>g organisations and the regulatory authorities. The<br />

assessment strategy <strong>in</strong>cludes details on:<br />

� criteria for def<strong>in</strong><strong>in</strong>g realistic work<strong>in</strong>g environments<br />

� roles and occupational competence of assessors, expert witnesses,<br />

<strong>in</strong>ternal verifiers and standards verifiers<br />

� quality control of assessment<br />

� evidence requirements.<br />

Evidence of competence may come from:<br />

� current practice where evidence is generated from a current job role<br />

� a programme of development where evidence comes from assessment<br />

opportunities built <strong>in</strong>to a learn<strong>in</strong>g/tra<strong>in</strong><strong>in</strong>g programme whether at or away<br />

from the workplace<br />

� the Recognition of Prior Learn<strong>in</strong>g (RPL) where a learner can<br />

demonstrate that they can meet the assessment criteria with<strong>in</strong> a unit<br />

through knowledge, understand<strong>in</strong>g or skills they already possess without<br />

undertak<strong>in</strong>g a course of learn<strong>in</strong>g. They must submit sufficient, reliable and<br />

valid evidence for <strong>in</strong>ternal and standards verification purposes. RPL is<br />

acceptable for accredit<strong>in</strong>g a unit, several units or a whole qualification<br />

� a comb<strong>in</strong>ation of these.<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

9

It is important that the evidence is:<br />

Valid relevant to the standards for which competence is claimed<br />

Authentic produced by the learner<br />

Current sufficiently recent to create confidence that the same skill,<br />

understand<strong>in</strong>g or knowledge persist at the time of the claim<br />

Reliable <strong>in</strong>dicates that the learner can consistently perform at this<br />

level<br />

Sufficient fully meets the requirements of the standards.<br />

Types of evidence (to be read <strong>in</strong> conjunction with the assessment<br />

strategy <strong>in</strong> Annexe E)<br />

To successfully achieve a unit the learner must gather evidence which shows<br />

that they have met the required standard <strong>in</strong> the assessment criteria.<br />

Evidence can take a variety of different forms <strong>in</strong>clud<strong>in</strong>g the examples below.<br />

Centres should refer to the assessment strategy for <strong>in</strong>formation about which<br />

of the follow<strong>in</strong>g are permissible.<br />

� direct observation of the learner’s performance by their assessor (O)<br />

� outcomes from oral or written question<strong>in</strong>g (Q&A)<br />

� products of the learner’s work (P)<br />

� personal statements and/or reflective accounts (RA)<br />

� outcomes from simulation, where permitted by the assessment<br />

strategy (S)<br />

� professional discussion (PD)<br />

� assignment, project/case studies (A)<br />

� authentic statements/witness testimony (WT)<br />

� expert witness testimony (EPW)<br />

� evidence of Recognition of Prior Learn<strong>in</strong>g (RPL).<br />

The abbreviations may be used for cross-referenc<strong>in</strong>g purposes.<br />

Learners can use one piece of evidence to prove their knowledge, skills and<br />

understand<strong>in</strong>g across different assessment criteria and/or across different<br />

units. It is, therefore, not necessary for learners to have each assessment<br />

criterion assessed separately. Learners should be encouraged to reference<br />

the assessment criteria to which the evidence relates.<br />

Evidence must be made available to the assessor, <strong>in</strong>ternal verifier and<br />

<strong>Edexcel</strong> standards verifier. A range of record<strong>in</strong>g documents is available on<br />

the <strong>Edexcel</strong> website www.edexcel.com. Alternatively, centres may develop<br />

their own.<br />

10<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

Additional requirements<br />

The Jo<strong>in</strong>t Award<strong>in</strong>g Body and the SSC Work<strong>in</strong>g Practices Group have<br />

identified additional requirements that are needed to assess and quality<br />

assure qualifications placed on the QCF that use <strong>NVQ</strong> with<strong>in</strong> their title. These<br />

requirements are shown <strong>in</strong> Annexe D: Additional Requirements for<br />

Qualifications that use the title <strong>NVQ</strong> with<strong>in</strong> the QCF.<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

11

Centre recognition and approval<br />

Centre recognition<br />

Centres that have not previously offered <strong>Edexcel</strong> qualifications need to apply<br />

for and be granted centre recognition as part of the process for approval to<br />

offer <strong>in</strong>dividual qualifications. New centres must complete both a centre<br />

recognition approval application and a qualification approval application.<br />

Exist<strong>in</strong>g centres will be given ‘automatic approval’ for a new qualification if<br />

they are already approved for a qualification that is be<strong>in</strong>g replaced by the<br />

new qualification and the conditions for automatic approval are met. Centres<br />

already hold<strong>in</strong>g <strong>Edexcel</strong> approval are able to ga<strong>in</strong> qualification approval for a<br />

different level or different sector via <strong>Edexcel</strong> onl<strong>in</strong>e.<br />

Approvals agreement<br />

All centres are required to enter <strong>in</strong>to an approvals agreement which is a<br />

formal commitment by the head or pr<strong>in</strong>cipal of a centre to meet all the<br />

requirements of the specification and any l<strong>in</strong>ked codes or regulations.<br />

<strong>Edexcel</strong> will act to protect the <strong>in</strong>tegrity of the award<strong>in</strong>g of qualifications, if<br />

centres do not comply with the agreement. This could result <strong>in</strong> the<br />

suspension of certification or withdrawal of approval.<br />

Quality assurance<br />

Detailed <strong>in</strong>formation on <strong>Edexcel</strong>’s quality assurance processes is given <strong>in</strong><br />

Annexe B.<br />

What resources are required?<br />

Each qualification is designed to support learners work<strong>in</strong>g <strong>in</strong> the Eng<strong>in</strong>eer<strong>in</strong>g<br />

sector. Physical resources need to support the delivery of the qualification<br />

and the assessment of the learn<strong>in</strong>g outcomes and must be of <strong>in</strong>dustry<br />

standard. Centres must meet any specific resource requirements outl<strong>in</strong>ed <strong>in</strong><br />

Annexe E: Assessment Strategy. Staff assess<strong>in</strong>g the learner must meet the<br />

requirements with<strong>in</strong> the overarch<strong>in</strong>g assessment strategy for the sector.<br />

12<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

Unit format<br />

Each unit <strong>in</strong> this specification conta<strong>in</strong>s the follow<strong>in</strong>g sections.<br />

Unit title:<br />

Unit reference number:<br />

Credit value:<br />

Guided learn<strong>in</strong>g hours:<br />

Unit summary:<br />

Assessment requirements/evidence requirements:<br />

Assessment methodology:<br />

Learn<strong>in</strong>g outcomes:<br />

Learn<strong>in</strong>g outcomes state exactly<br />

what a learner should know,<br />

understand or be able to do as a<br />

result of complet<strong>in</strong>g a unit.<br />

Assessment criteria:<br />

Evidence type:<br />

Portfolio<br />

reference:<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

The unit title is accredited on the QCF and this<br />

form of words will appear on the learner’s<br />

Notification of Performance (NOP).<br />

This code is a unique reference number for the unit.<br />

All units have a credit value. The m<strong>in</strong>imum credit value is one, and credits can<br />

only be awarded <strong>in</strong> whole numbers. Learners will be awarded credits when they<br />

achieve the unit.<br />

A notional measure of the substance of a qualification. It <strong>in</strong>cludes an estimate of the<br />

time that might be allocated to direct teach<strong>in</strong>g or <strong>in</strong>struction, together with other<br />

structured learn<strong>in</strong>g time, such as directed assignments, assessments on the job or<br />

supported <strong>in</strong>dividual study and practice. It excludes learner-<strong>in</strong>itiated private study.<br />

This provides a summary of the purpose of the unit.<br />

The assessment/evidence requirements are determ<strong>in</strong>ed<br />

by the SSC. Learners must provide evidence for each<br />

of the requirements stated <strong>in</strong> this section.<br />

This provides a summary of the assessment methodology to be used for the unit.<br />

The assessment criteria of a unit<br />

specify the standard a learner is<br />

expected to meet to demonstrate<br />

that a learn<strong>in</strong>g outcome, or a set of<br />

learn<strong>in</strong>g outcomes, has been<br />

achieved.<br />

The learner<br />

should use this<br />

box to <strong>in</strong>dicate<br />

where the<br />

evidence can<br />

be obta<strong>in</strong>ed eg<br />

portfolio page<br />

number.<br />

Date:<br />

The learner<br />

should give the<br />

date when the<br />

evidence has<br />

been provided.<br />

Learners must reference the type of<br />

evidence they have and where it is<br />

available for quality assurance<br />

purposes. The learner can enter the<br />

relevant key and a reference.<br />

Alternatively, the learner and/or<br />

centre can devise their own<br />

referenc<strong>in</strong>g system.<br />

13

14<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

Units<br />

15

16<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

Unit 1: Work<strong>in</strong>g safely <strong>in</strong> an eng<strong>in</strong>eer<strong>in</strong>g<br />

environment<br />

Unit reference number: L/600/5781<br />

QCF level: 2<br />

Credit value: 5<br />

Guided learn<strong>in</strong>g hours: 33<br />

Unit summary<br />

This unit covers the skills and knowledge needed to prove the competences<br />

required to work safely <strong>in</strong> an eng<strong>in</strong>eer<strong>in</strong>g environment. It will prepare the<br />

learner for entry <strong>in</strong>to the eng<strong>in</strong>eer<strong>in</strong>g or manufactur<strong>in</strong>g sectors, creat<strong>in</strong>g a<br />

progression between education and employment, or it will act as a basis for<br />

the development of additional skills and occupational competences <strong>in</strong> the<br />

work<strong>in</strong>g environment. It covers carry<strong>in</strong>g out the learner’s work activities <strong>in</strong><br />

accordance with <strong>in</strong>structions and by the use of safe work<strong>in</strong>g practices and<br />

procedures.<br />

Assessment requirements/evidence requirements<br />

This unit must be assessed <strong>in</strong> a work environment and must be assessed <strong>in</strong><br />

accordance with the ‘Semta Assessment Strategy’. Detailed <strong>in</strong>formation is<br />

given <strong>in</strong> Annexe E.<br />

Assessment record<strong>in</strong>g<br />

Learners can enter the types of evidence they are present<strong>in</strong>g for assessment<br />

and the submission date aga<strong>in</strong>st each assessment criterion. Alternatively,<br />

centre documentation should be used to record this <strong>in</strong>formation.<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

17

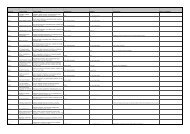

Learn<strong>in</strong>g outcomes and assessment criteria<br />

Date<br />

Portfolio<br />

reference<br />

Learn<strong>in</strong>g outcomes Assessment criteria Evidence<br />

type<br />

1.1 comply with their duties and obligations as def<strong>in</strong>ed<br />

<strong>in</strong> the Health and Safety at Work Act (HASAWA)<br />

1 Work safely <strong>in</strong> an<br />

eng<strong>in</strong>eer<strong>in</strong>g environment<br />

1.2 demonstrate their understand<strong>in</strong>g of their duties and<br />

obligations to health and safety by carry<strong>in</strong>g out all<br />

of the follow<strong>in</strong>g:<br />

– apply<strong>in</strong>g <strong>in</strong> pr<strong>in</strong>ciple their duties and<br />

responsibilities as an <strong>in</strong>dividual under the Health<br />

and Safety at Work Act and other relevant<br />

current legislation<br />

– identify<strong>in</strong>g, with<strong>in</strong> their work<strong>in</strong>g environment,<br />

appropriate sources of <strong>in</strong>formation and guidance<br />

on health and safety issues, to <strong>in</strong>clude:<br />

o eye protection and personal protective<br />

equipment<br />

o COSHH regulations<br />

o risk assessments<br />

– identify<strong>in</strong>g the warn<strong>in</strong>g signs and labels of the<br />

ma<strong>in</strong> groups of hazardous or dangerous<br />

substances<br />

– comply<strong>in</strong>g at all times with the appropriate<br />

statutory regulations and specific regulations<br />

relevant to their work<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

18

Date<br />

Portfolio<br />

reference<br />

Learn<strong>in</strong>g outcomes Assessment criteria Evidence<br />

type<br />

1.3 apply safe work<strong>in</strong>g practices and procedures at all<br />

times<br />

1.4 apply safe work<strong>in</strong>g practices <strong>in</strong> an eng<strong>in</strong>eer<strong>in</strong>g<br />

environment, to <strong>in</strong>clude all of the follow<strong>in</strong>g:<br />

– present themselves <strong>in</strong> the workplace suitably<br />

dressed/prepared for the activities to be<br />

undertaken<br />

– observe personal protection and hygiene<br />

procedures at all times<br />

– act <strong>in</strong> a responsible manner at all times with<strong>in</strong><br />

the work<strong>in</strong>g environment<br />

– ma<strong>in</strong>ta<strong>in</strong> a tidy workplace, with exits and<br />

gangways free from obstructions<br />

– use tools and equipment safely and only for the<br />

purpose <strong>in</strong>tended<br />

– carry out their work activities <strong>in</strong> accordance with<br />

legal requirements and the organisations safety<br />

policies<br />

– take measures to protect others from harm<br />

result<strong>in</strong>g from any work that they are carry<strong>in</strong>g<br />

out<br />

1.5 follow organisational accident and emergency<br />

procedures<br />

19<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

Date<br />

Portfolio<br />

reference<br />

Learn<strong>in</strong>g outcomes Assessment criteria Evidence<br />

type<br />

1.6 comply with all emergency requirements, to<br />

<strong>in</strong>clude:<br />

– identify<strong>in</strong>g the appropriate qualified first aiders<br />

or appo<strong>in</strong>ted person, and the location of first aid<br />

facilities<br />

– identify<strong>in</strong>g the procedures to be followed <strong>in</strong> the<br />

event of <strong>in</strong>jury to themselves or others<br />

– follow<strong>in</strong>g organisational procedures <strong>in</strong> the event<br />

of fire/fire drills and for the evacuation of<br />

premises/work area<br />

– identify<strong>in</strong>g and us<strong>in</strong>g the procedures to be<br />

followed <strong>in</strong> the event of dangerous occurrences<br />

or hazardous malfunctions of equipment,<br />

processes or mach<strong>in</strong>ery<br />

1.7 recognise and control hazards <strong>in</strong> the workplace to<br />

m<strong>in</strong>imise risks<br />

1.8 identify the hazards and risks that are associated<br />

with all of the follow<strong>in</strong>g:<br />

– their work<strong>in</strong>g environment (such as work<strong>in</strong>g at<br />

height, <strong>in</strong> conf<strong>in</strong>ed spaces, hot work)<br />

– the tools and equipment that they use (such as<br />

mach<strong>in</strong>es, power tools, cutt<strong>in</strong>g tools)<br />

– materials and substances that they use (such as<br />

cutt<strong>in</strong>g fluids/oils, hydraulic fluids, fluxes)<br />

– us<strong>in</strong>g work<strong>in</strong>g practices that do not follow laiddown<br />

procedures<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

20

Date<br />

Portfolio<br />

reference<br />

Learn<strong>in</strong>g outcomes Assessment criteria Evidence<br />

type<br />

1.9 use correct manual lift<strong>in</strong>g and carry<strong>in</strong>g techniques<br />

1.10 demonstrate the follow<strong>in</strong>g methods of manual<br />

lift<strong>in</strong>g and carry<strong>in</strong>g techniques:<br />

– lift<strong>in</strong>g alone<br />

plus one more of the follow<strong>in</strong>g:<br />

– with assistance of others<br />

– with mechanical assistance<br />

2.1 describe the roles and responsibilities of themselves<br />

and others under the Health and Safety at Work Act<br />

and other current legislation (such as The<br />

Management of Health and Safety at Work<br />

Regulations; Workplace Health and Safety and<br />

Welfare Regulations; Personal Protective Equipment<br />

at Work Regulations; Manual Handl<strong>in</strong>g <strong>Operations</strong><br />

Regulations; Provision and Use of Work Equipment<br />

Regulations; Display Screen at Work Regulations,<br />

Report<strong>in</strong>g of Injuries, Diseases and Dangerous<br />

Occurrences Regulations)<br />

2 Know how to work safely<br />

<strong>in</strong> an eng<strong>in</strong>eer<strong>in</strong>g<br />

environment<br />

2.2 describe the specific regulations and safe work<strong>in</strong>g<br />

practices and procedures that apply to their work<br />

activities (such as The Electricity at Work<br />

Regulations, Woodwork<strong>in</strong>g Regulations)<br />

2.3 describe the warn<strong>in</strong>g signs for the ma<strong>in</strong> groups of<br />

hazardous substances def<strong>in</strong>ed by Classification,<br />

Packag<strong>in</strong>g and Labell<strong>in</strong>g of Dangerous Substances<br />

Regulations<br />

21<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

Date<br />

Portfolio<br />

reference<br />

Learn<strong>in</strong>g outcomes Assessment criteria Evidence<br />

type<br />

2.4 expla<strong>in</strong> how to locate relevant health and safety<br />

<strong>in</strong>formation for their tasks, and the sources of<br />

expert assistance when help is needed<br />

2.5 expla<strong>in</strong> what constitutes a hazard <strong>in</strong> the workplace<br />

(such as mov<strong>in</strong>g parts of mach<strong>in</strong>ery, electricity,<br />

slippery and uneven surfaces, dust and fumes,<br />

handl<strong>in</strong>g and transport<strong>in</strong>g, contam<strong>in</strong>ants and<br />

irritants, material ejection, fire, work<strong>in</strong>g at height,<br />

environment, pressure/stored energy systems,<br />

volatile or toxic materials, unshielded processes)<br />

2.6 describe their responsibilities for deal<strong>in</strong>g with<br />

hazards and reduc<strong>in</strong>g risks <strong>in</strong> the workplace (such<br />

as hazard spott<strong>in</strong>g and safety <strong>in</strong>spections; the use<br />

of hazard check lists, carry<strong>in</strong>g out risk<br />

assessments, COSHH assessments and safe<br />

systems of work<strong>in</strong>g)<br />

2.7 describe the risks associated with their work<strong>in</strong>g<br />

environment (such as the tools, materials and<br />

equipment that they use, spillages of oil and<br />

chemicals, not report<strong>in</strong>g accidental breakages of<br />

tools or equipment and not follow<strong>in</strong>g laid-down<br />

work<strong>in</strong>g practices and procedures)<br />

2.8 describe the sources of <strong>in</strong>formation for safety (such<br />

as local work procedures, codes of practice or<br />

guidance, the severity of the accident or <strong>in</strong>jury that<br />

the hazard may cause)<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

22

Date<br />

Portfolio<br />

reference<br />

Learn<strong>in</strong>g outcomes Assessment criteria Evidence<br />

type<br />

2.9 describe the control measures that can be used to<br />

elim<strong>in</strong>ate/reduce the hazard (such as lock-off and<br />

permit to work procedures, provision of safe access<br />

and egress, use of guards and fume extraction<br />

equipment, use of personal protective equipment)<br />

2.10 describe the first aid facilities that exist with<strong>in</strong> their<br />

work area and with<strong>in</strong> the organisation <strong>in</strong> general,<br />

and the procedures to be followed <strong>in</strong> the case of<br />

accidents <strong>in</strong>volv<strong>in</strong>g <strong>in</strong>jury<br />

2.11 expla<strong>in</strong> what constitutes dangerous occurrences<br />

and hazardous malfunctions, and why these must<br />

be reported even if no one was <strong>in</strong>jured<br />

2.12 describe the procedures for sound<strong>in</strong>g the<br />

emergency alarms, evacuation procedures and<br />

escape routes to be used, and the need to report<br />

their presence at the appropriate assembly po<strong>in</strong>t<br />

2.13 describe the organisational policy with regard to fire<br />

fight<strong>in</strong>g procedures; the common causes of fire and<br />

what they can do to help prevent them<br />

2.14 describe the personal protective equipment (PPE)<br />

and protective cloth<strong>in</strong>g that is available for their<br />

areas of activity<br />

23<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

Date<br />

Portfolio<br />

reference<br />

Learn<strong>in</strong>g outcomes Assessment criteria Evidence<br />

type<br />

2.15 describe the need to observe personal protection<br />

and hygiene procedures at all times (such as sk<strong>in</strong><br />

care (barrier creams, gloves); eye protection<br />

(safety glasses, goggles, full face masks); hear<strong>in</strong>g<br />

protection (ear plugs, ear defenders); respiratory<br />

protection (fume extraction, face masks, breath<strong>in</strong>g<br />

apparatus, head protection (caps with hair<br />

restra<strong>in</strong>ts, protective helmets); foot protection<br />

(safety footwear); dangers of <strong>in</strong>gestion and the<br />

importance of wash<strong>in</strong>g hands)<br />

2.16 expla<strong>in</strong> how to act responsibly with<strong>in</strong> the work<strong>in</strong>g<br />

environment (such as observ<strong>in</strong>g restricted area<br />

notices, comply<strong>in</strong>g with warn<strong>in</strong>g signs, walk<strong>in</strong>g not<br />

runn<strong>in</strong>g, us<strong>in</strong>g equipment only for its <strong>in</strong>tended<br />

purpose, not <strong>in</strong>terfer<strong>in</strong>g with equipment or process<br />

that are not with<strong>in</strong> their job role, follow<strong>in</strong>g<br />

approved safety procedures at all times)<br />

2.17 describe the methods of manually handl<strong>in</strong>g and<br />

mov<strong>in</strong>g loads (such as push<strong>in</strong>g, pull<strong>in</strong>g, lever<strong>in</strong>g);<br />

how to lift and carry loads safely and correctly<br />

(such as from ground level, waist high, overhead,<br />

reach<strong>in</strong>g over); and the manual and mechanical<br />

lift<strong>in</strong>g and mov<strong>in</strong>g aids available<br />

2.18 describe good housekeep<strong>in</strong>g arrangements (such as<br />

ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g cleanl<strong>in</strong>ess of their work area; removal<br />

of waste materials; storage of materials, tools and<br />

equipment and products; ma<strong>in</strong>tenance of access<br />

and egress (such as clear walkways, emergency<br />

exits))<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

24

Date<br />

Portfolio<br />

reference<br />

Learn<strong>in</strong>g outcomes Assessment criteria Evidence<br />

type<br />

2.19 expla<strong>in</strong> when to act on their own <strong>in</strong>itiative and<br />

when to seek help and advice from others<br />

2.20 expla<strong>in</strong> to whom they should report <strong>in</strong> the event of<br />

problems that they cannot resolve<br />

Learner name:___________________________________ Date: ______________________________<br />

Learner signature: _______________________________ Date: ______________________________<br />

Assessor signature: ______________________________ Date: ______________________________<br />

Internal verifier signature: _________________________ Date: ______________________________<br />

(if sampled)<br />

25<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

26<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

Unit 2: Carry<strong>in</strong>g out eng<strong>in</strong>eer<strong>in</strong>g<br />

activities efficiently and<br />

effectively<br />

Unit reference number: D/600/5784<br />

QCF level: 2<br />

Credit value: 4<br />

Guided learn<strong>in</strong>g hours: 29<br />

Unit summary<br />

This unit covers the skills and knowledge needed to prove the competences<br />

required to cover a broad range of basic activities that will prepare the<br />

learner for entry <strong>in</strong>to the eng<strong>in</strong>eer<strong>in</strong>g or manufactur<strong>in</strong>g sectors. It will<br />

create a progression between education and employment, or will act as a<br />

basis for the development of additional skills and occupational competences<br />

<strong>in</strong> the work<strong>in</strong>g environment.<br />

Assessment requirements/evidence requirements<br />

This unit must be assessed <strong>in</strong> a work environment and must be assessed <strong>in</strong><br />

accordance with the ‘Semta Assessment Strategy’. Detailed <strong>in</strong>formation is<br />

given <strong>in</strong> Annexe E.<br />

Assessment record<strong>in</strong>g<br />

Learners can enter the types of evidence they are present<strong>in</strong>g for<br />

assessment and the submission date aga<strong>in</strong>st each assessment criterion.<br />

Alternatively, centre documentation should be used to record this<br />

<strong>in</strong>formation.<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

27

Learn<strong>in</strong>g outcomes and assessment criteria<br />

Date<br />

Portfolio<br />

reference<br />

Learn<strong>in</strong>g outcomes Assessment criteria Evidence<br />

type<br />

1.1 work safely at all times, comply<strong>in</strong>g with health and<br />

safety legislation, regulations and other relevant<br />

guidel<strong>in</strong>es<br />

1 Work efficiently and<br />

effectively <strong>in</strong> eng<strong>in</strong>eer<strong>in</strong>g<br />

1.2 ensure that they apply all of the follow<strong>in</strong>g checks<br />

and practices at all times dur<strong>in</strong>g the eng<strong>in</strong>eer<strong>in</strong>g<br />

activities:<br />

– adhere to procedures or systems <strong>in</strong> place for risk<br />

assessment, COSHH, personal protective<br />

equipment and other relevant safety regulations<br />

– wear the appropriate personal protective<br />

equipment for the work area and specific activity<br />

be<strong>in</strong>g carried out<br />

– use all tools and equipment safely and correctly,<br />

and only for their <strong>in</strong>tended purpose<br />

– ensure that the work area is ma<strong>in</strong>ta<strong>in</strong>ed and left<br />

<strong>in</strong> a safe and tidy condition<br />

1.3 plan the eng<strong>in</strong>eer<strong>in</strong>g activities before they start<br />

them<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

28

Date<br />

Portfolio<br />

reference<br />

Learn<strong>in</strong>g outcomes Assessment criteria Evidence<br />

type<br />

1.4 prepare for the specific eng<strong>in</strong>eer<strong>in</strong>g activity, by<br />

produc<strong>in</strong>g a work plan which <strong>in</strong>cludes all of the<br />

follow<strong>in</strong>g:<br />

– documentation required (such as draw<strong>in</strong>gs,<br />

technical/reference documents - such as tapp<strong>in</strong>g<br />

drill sizes, imperial to metric conversion books,<br />

component specifications, quality<br />

documentation)<br />

– materials required (such as stock material,<br />

components, part-mach<strong>in</strong>ed components,<br />

cables/wire, weld<strong>in</strong>g consumables)<br />

– equipment required (such as mach<strong>in</strong>e tools to be<br />

used, lift<strong>in</strong>g and handl<strong>in</strong>g equipment, bend<strong>in</strong>g<br />

and form<strong>in</strong>g equipment, anti-static equipment,<br />

test equipment)<br />

– workhold<strong>in</strong>g methods and equipment (such as<br />

mach<strong>in</strong>e or bench vice, clamps, special<br />

workhold<strong>in</strong>g arrangements), where appropriate<br />

– tools required (such as hand tools, portable<br />

power tools, cutt<strong>in</strong>g tools, solder<strong>in</strong>g irons)<br />

– measur<strong>in</strong>g equipment required (such as<br />

mechanical, electrical, pressure, flow, level,<br />

speed, sound)<br />

– the operat<strong>in</strong>g sequence to be followed<br />

– timescale required to complete the eng<strong>in</strong>eer<strong>in</strong>g<br />

operations<br />

29<br />

N025373 – Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012

Date<br />

Portfolio<br />

reference<br />

Learn<strong>in</strong>g outcomes Assessment criteria Evidence<br />

type<br />

1.5 prepare the work area for carry<strong>in</strong>g out the<br />

eng<strong>in</strong>eer<strong>in</strong>g activity<br />

1.6 prepare to carry out the eng<strong>in</strong>eer<strong>in</strong>g activity,<br />

ensur<strong>in</strong>g all of the follow<strong>in</strong>g, as applicable to the<br />

work to be undertaken:<br />

– the work area is free from hazards and is<br />

suitably prepared for the activities to be<br />

undertaken<br />

– any required safety procedures are implemented<br />

– any necessary personal protection equipment is<br />

obta<strong>in</strong>ed, and is <strong>in</strong> a usable condition<br />

– tools and equipment required are obta<strong>in</strong>ed and<br />

checked that they are <strong>in</strong> a safe and usable<br />

condition<br />

– all necessary draw<strong>in</strong>gs, specifications and<br />

associated documents are obta<strong>in</strong>ed<br />

– job <strong>in</strong>structions are obta<strong>in</strong>ed and understood<br />

– the correct materials or components are<br />

obta<strong>in</strong>ed<br />

– appropriate authorisation to carry out the work<br />

is obta<strong>in</strong>ed<br />

1.7 obta<strong>in</strong> all necessary tools and equipment and check<br />

that they are <strong>in</strong> a safe and usable condition<br />

N025373– Specification – <strong>Edexcel</strong> <strong>Level</strong> 2 <strong>NVQ</strong> <strong>Diploma</strong> <strong>in</strong> Perform<strong>in</strong>g Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>Operations</strong> (QCF) – Issue 1 – March 2012 © Pearson Education Limited 2012<br />

30