implantaten und Aufbau - BEGO

implantaten und Aufbau - BEGO

implantaten und Aufbau - BEGO

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

Originalia – Materials Science<br />

7<br />

In-vitro corrosion current measurement between<br />

titanium implants and superstructures made<br />

of titanium, gold and cobalt chrome alloys<br />

M. Gente, J. Dati, P. Günter, S. Pruss, S. Rickmeyer, S. Vittur<br />

Marburg<br />

When a tooth is lost, the resulting gap can be<br />

closed with a bridge. Although the adjoining<br />

teeth may have no hard tissue defects, or only<br />

minor defects, they will inevitably be damaged<br />

during construction of the bridge. Placement of<br />

an implant is therefore the more favourable solution.<br />

Furthermore, implants can be used in<br />

isolation for tooth replacement, which is why<br />

they are becoming increasingly popular in spite<br />

of their high cost. Nevertheless, account must<br />

be taken of the effect that the implant material<br />

will have on other metals in the mouth as regards<br />

corrosion. In this context, corrosion means<br />

the gradual degradation of a material due<br />

to the influence of other materials in its surro<strong>und</strong>ings.<br />

The implant and the respective metal<br />

superstructures form a galvanic cell. The<br />

aim of this paper is to investigate the corrosion<br />

currents between a titanium implant and various<br />

metallic superstructure materials.<br />

Materials and method<br />

The aim was to investigate the corrosion currents<br />

between an implant (Semados S 3.75 L13<br />

LOT 902621, Bego Implant Systems, Bremen)<br />

and the superstructures made of a cast, highgold<br />

alloy (Degunorm, Degussa Hanau), prefabricated<br />

superstructures made of commercially<br />

pure titanium (Sub-Tec titanium abutment S<br />

5.5, LOT 901728, Bego Implant Systems, Bremen)<br />

and prefabricated CoCrMo superstructures<br />

(Sub-Tec Wirobond ® MI abutment 5.5, LOT<br />

902286, Bego Implant Systems, Bremen). The<br />

compositions of the alloys, as stated by the manufacturers,<br />

are given in Table 1.<br />

As it was not possible to prepare the surface of<br />

the cylindrical superstructures evenly using<br />

abrasive paper, a uniform finish was ensured by<br />

sandblasting all the superstructures with an<br />

abrasive of grit size 110 µm (Korox, <strong>BEGO</strong>, Bremen),<br />

at a pressure of 2 bar, until a matt surface<br />

was produced. The superstructures were then<br />

Corrosion currents were investigated between titanium implants and superstructures<br />

made of various dental metals (CoCrMo alloy Wirobond, grade 4<br />

purity titanium and high-gold alloy Degunorm) when in electrical contact.<br />

The electrolytes used were unbuffered normal saline solution with a pH of 6<br />

and also with a pH of 2.3, created by the addition of lactic acid. The pairing<br />

of titanium implant and cobalt-chrome superstructure displayed the lowest<br />

corrosion current density, at approx. 3 nA/cm 2 in both solutions. The corrosion<br />

current density measured with superstructures made of titanium or<br />

high-gold alloy was significantly higher, at up to 100 nA/cm 2 and 180 nA/cm 2<br />

respectively. The results of this investigation indicate that CoCrMo superstructures<br />

can be used on implants at least as safely as titanium or high-gold<br />

precious-metal alloys.<br />

stored in dry air for 7 days so that passivation<br />

layers could form again.<br />

The wires required for voltage measurement<br />

were attached to the implant and the superstructure.<br />

To prevent the copper of the wires<br />

from going into solution, the connection points<br />

were carefully covered with light-curing composite<br />

(Grandio Flow A1, VOCO, Cuxhaven). Fig.<br />

1 shows an implant and Fig. 2 shows a CoCr superstructure<br />

with the sealed connection point.<br />

For the investigation, two test-tubes were set<br />

up as shown in Fig. 3. The test-tubes were<br />

sealed airtight using Parafilm to prevent evaporation.<br />

A salt bridge connects the two vessels; a<br />

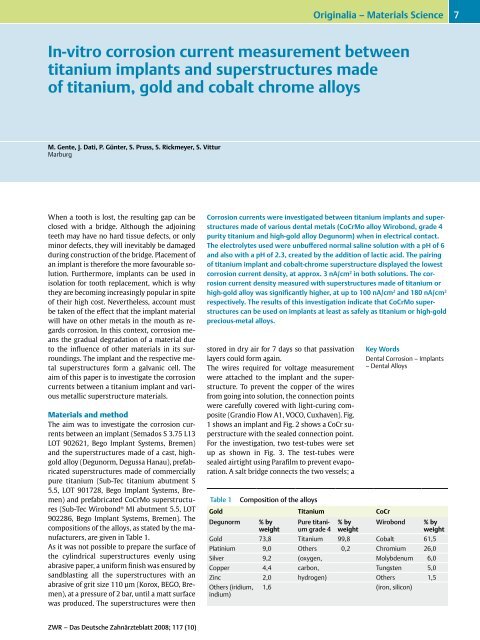

Table 1<br />

Composition of the alloys<br />

Key Words<br />

Dental Corrosion – Implants<br />

– Dental Alloys<br />

Gold Titanium CoCr<br />

Degunorm % by Pure titanium<br />

% by Wirobond<br />

weight<br />

grade 4<br />

weight<br />

% by<br />

weight<br />

Gold 73,8 Titanium 99,8 Cobalt 61,5<br />

Platinium 9,0 Others 0,2 Chromium 26,0<br />

Silver 9,2 (oxygen, Molybdenum 6,0<br />

Copper 4,4 carbon, Tungsten 5,0<br />

Zinc 2,0 hydrogen) Others 1,5<br />

Others (iridium,<br />

indium)<br />

1,6 (iron, silicon)<br />

ZWR ̶ Das Deutsche Zahnärzteblatt 2008; 117 (10)

![Folleto del curso [3449823B/pdf] - BEGO](https://img.yumpu.com/49168777/1/184x260/folleto-del-curso-3449823b-pdf-bego.jpg?quality=85)

![Folleto del curso [1975602B/pdf] - BEGO](https://img.yumpu.com/35748327/1/190x190/folleto-del-curso-1975602b-pdf-bego.jpg?quality=85)