GUTMANN DECCO | GEALAN S7000IQ - Gutmann AG

GUTMANN DECCO | GEALAN S7000IQ - Gutmann AG

GUTMANN DECCO | GEALAN S7000IQ - Gutmann AG

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

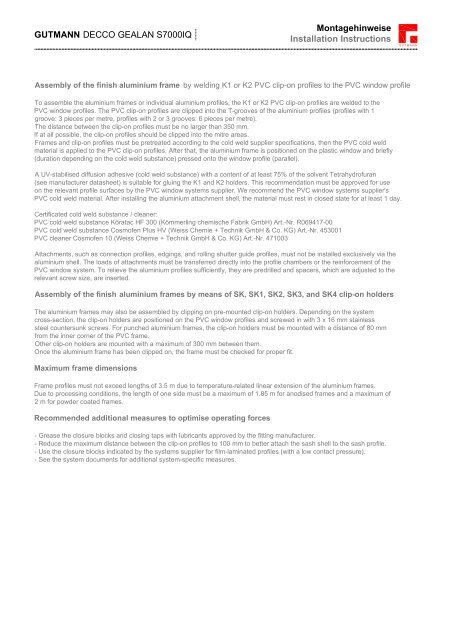

<strong>GUTMANN</strong> <strong>DECCO</strong> <strong>GEALAN</strong> <strong>S7000IQ</strong><br />

Montagehinweise<br />

Installation Instructions<br />

G U T M A N N<br />

Assembly of the finish aluminium frame by welding K1 or K2 PVC clip-on profiles to the PVC window profile<br />

To assemble the aluminium frames or individual aluminium profiles, the K1 or K2 PVC clip-on profiles are welded to the<br />

PVC window profiles. The PVC clip-on profiles are clipped into the T-grooves of the aluminium profiles (profiles with 1<br />

groove: 3 pieces per metre, profiles with 2 or 3 grooves: 6 pieces per metre).<br />

The distance between the clip-on profiles must be no larger than 350 mm.<br />

If at all possible, the clip-on profiles should be clipped into the mitre areas.<br />

Frames and clip-on profiles must be pretreated according to the cold weld supplier specifications, then the PVC cold weld<br />

material is applied to the PVC clip-on profiles. After that, the aluminium frame is positioned on the plastic window and briefly<br />

(duration depending on the cold weld substance) pressed onto the window profile (parallel).<br />

A UV-stabilised diffusion adhesive (cold weld substance) with a content of at least 75% of the solvent Tetrahydrofuran<br />

(see manufacturer datasheet) is suitable for gluing the K1 and K2 holders. This recommendation must be approved for use<br />

on the relevant profile surfaces by the PVC window systems supplier. We recommend the PVC window systems supplier's<br />

PVC cold weld material. After installing the aluminium attachment shell, the material must rest in closed state for at least 1 day.<br />

Certificated cold weld substance / cleaner:<br />

PVC cold weld substance Köratac HF 300 (Kömmerling chemische Fabrik GmbH) Art.-Nr. R069417-00<br />

PVC cold weld substance Cosmofen Plus HV (Weiss Chemie + Technik GmbH & Co. KG) Art.-Nr. 453001<br />

PVC cleaner Cosmofen 10 (Weiss Chemie + Technik GmbH & Co. KG) Art.-Nr. 471003<br />

Attachments, such as connection profiles, edgings, and rolling shutter guide profiles, must not be installed exclusively via the<br />

aluminium shell. The loads of attachments must be transferred directly into the profile chambers or the reinforcement of the<br />

PVC window system. To relieve the aluminium profiles sufficiently, they are predrilled and spacers, which are adjusted to the<br />

relevant screw size, are inserted.<br />

Assembly of the finish aluminium frames by means of SK, SK1, SK2, SK3, and SK4 clip-on holders<br />

The aluminium frames may also be assembled by clipping on pre-mounted clip-on holders. Depending on the system<br />

cross-section, the clip-on holders are positioned on the PVC window profiles and screwed in with 3 x 16 mm stainless<br />

steel countersunk screws. For punched aluminium frames, the clip-on holders must be mounted with a distance of 80 mm<br />

from the inner corner of the PVC frame.<br />

Other clip-on holders are mounted with a maximum of 300 mm between them.<br />

Once the aluminium frame has been clipped on, the frame must be checked for proper fit.<br />

Maximum frame dimensions<br />

Frame profiles must not exceed lengths of 3.5 m due to temperature-related linear extension of the aluminium frames.<br />

Due to processing conditions, the length of one side must be a maximum of 1.85 m for anodised frames and a maximum of<br />

2 m for powder coated frames.<br />

Recommended additional measures to optimise operating forces<br />

- Grease the closure blocks and closing taps with lubricants approved by the fitting manufacturer.<br />

- Reduce the maximum distance between the clip-on profiles to 100 mm to better attach the sash shell to the sash profile.<br />

- Use the closure blocks indicated by the systems supplier for film-laminated profiles (with a low contact pressure).<br />

- See the system documents for additional system-specific measures.