clivia ⢠Armaturen

clivia ⢠Armaturen

clivia ⢠Armaturen

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

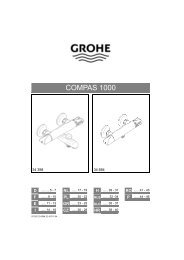

GB<br />

Technical data<br />

Applications<br />

• pressurised storage heaters<br />

• thermally-controlled instantaneous heaters<br />

• hydraulically-controlled instantaneous heaters<br />

Operation with unpressurised storage heaters (open water<br />

heaters) is not possible.<br />

If automatic control does not work optimally, residual dirt<br />

particles or residues from installation are the principal cause.<br />

The diverter should be cleaned as described under<br />

"Maintenance".<br />

Please remember that the automatic control only works<br />

at pressures above 0.5 bar. If this flow pressure is not<br />

available (e.g. in conjunction with instantaneous<br />

heaters), the diverter can be converted into a fully<br />

functional manual diverter by removing spring (A).<br />

For this purpose, remove push button (B) and spring (A), see<br />

"Diverter maintenance".<br />

3<br />

Technical data<br />

• Flow pressure<br />

- min. 0.5 bar<br />

- recommended 1 - 5 bar<br />

• Operating pressure (static pressure) max. 10 bar<br />

• Test pressure<br />

16 bar<br />

If static pressure exceeds 5 bar, a pressure reducing<br />

valve must be fitted.<br />

• Flow rate at 3 bar flow pressure<br />

751 340<br />

- Spout approx. 17 l/min<br />

751 330 approx. 23 l/min<br />

• Temperature<br />

- max. (hot water supply) 80 °C<br />

- recommended (energy economy) 60 °C<br />

• Water connection<br />

hot – left<br />

cold – right<br />

Avoid major pressure differences between the hot and<br />

cold water supply.<br />

• Retaining pressure of automatic diverter according to<br />

EN 817 ≥ 0.5 bar.<br />

These surface-mounted fittings are equipped with nonreturn<br />

valves bearing the DIN-DVGW mark of approval for<br />

intrinsic protection against return flow.<br />

We accept no liability for fittings that are not installed with<br />

the supplied equipment.<br />

Surface-mounted fittings<br />

Installation<br />

See fold-out page II, Fig. [1].<br />

Flush pipes thoroughly before and after installation<br />

(observe DIN EN 806).<br />

• Install the S-unions and screw-mount the mixer.<br />

Hot water connection<br />

left<br />

Cold water connection<br />

right<br />

See the dimensional drawings on fold-out page I.<br />

• Open hot and cold water supply and check<br />

connections for watertightness.<br />

Check function of fitting.<br />

Check operation of automatic diverter<br />

• Actuate lever -<br />

The water supply is released. The water will always<br />

emerge from the bath outlet first of all.<br />

• Press diverter knob -<br />

The flow is diverted from bath spout to shower outlet.<br />

• Close fitting -<br />

The flow is diverted automatically from shower outlet to<br />

bath spout.<br />

Concealed fittings<br />

Final installation<br />

See fold-out page II, Fig. [2].<br />

Flush pipes thoroughly before and after installation<br />

(observe DIN EN 806).<br />

• Remove the mounting template forwards. Cut off the<br />

protruding lower part of the polystyrene sound-insulation<br />

box at the groove above the face of the tiles.<br />

If the lower part of the polystyrene sound-insulation box<br />

does not protrude beyond the face of the tiles, an<br />

extension (30 mm) must be installed.<br />

• Bath-filling and shower mixer version:<br />

Remove plug (C) using a screwdriver. Screw diverter (D)<br />

firmly into position using a socket spanner (32 mm). Fit<br />

spring (A) onto the diverter and attach push button (B).<br />

• Shower mixer version:<br />

Installation of the diverter is not required. Plug (C)<br />

must not be removed under any circumstances.<br />

• Fit sleeve (E).<br />

• Push on escutcheon (F) with foam seal (G) and fasten with<br />

screw (H).<br />

• Fit operating lever provided (I) and tighten from the side<br />

and below with screw (K). Fit marking plate (L).<br />

In order to ensure a perfect seal, it is recommendable to<br />

additionally seal the top edge of the escutcheon with<br />

silicone at the joint to the tile surface.<br />

Open hot and cold water supply and check operation<br />

of the fitting.<br />

Check operation of automatic diverter<br />

• Actuate lever -<br />

The water supply is released. The water will always<br />

emerge from the bath outlet first of all.<br />

• Press diverter knob -<br />

The flow is diverted from bath inlet to shower outlet.<br />

• Close fitting -<br />

The flow is diverted automatically from shower outlet to<br />

bath spout.<br />

If automatic control does not work optimally, residual dirt<br />

particles or residues from installation are the principal cause.<br />

The diverter should be cleaned as described under<br />

"Maintenance".<br />

Please remember that the automatic control only works<br />

at pressures above 0.5 bar. If this flow pressure is not<br />

available (e.g. in conjunction with instantaneous<br />

heaters), the diverter can be converted into a fully<br />

functional manual diverter by removing spring (A).<br />

For this purpose, remove push button (B) and spring (A), see<br />

"Diverter maintenance".