Threaded Fasteners for plastic - Infastech

Threaded Fasteners for plastic - Infastech

Threaded Fasteners for plastic - Infastech

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The TORX PLUS ® Drive System is the<br />

ideal drive system <strong>for</strong> screws <strong>for</strong><br />

<strong>plastic</strong>s, since it provides optimum<br />

torque transfer, even when <strong>for</strong>ming or<br />

cutting threads in rein<strong>for</strong>ced <strong>plastic</strong>s.<br />

Its unmatched ability to increase<br />

productivity by outper<strong>for</strong>ming<br />

competing drive systems can lower<br />

assembly costs.<br />

sPeciFicaTions<br />

Drive Sizes • 1IP – 100IP (recess) to fit<br />

screw sizes M0.9 – M24 (#0 – 1")<br />

Styles • Internal, external, low-profile<br />

external, tamper-resistant, TORX PLUS®<br />

Drive/external hex or TORX PLUS Drive/<br />

slotted<br />

Drive Tools • TORX PLUS Drive tools fit<br />

both inch and metric fasteners.<br />

Standard and special tooling is available<br />

from over 3,000 outlets around the<br />

world. For more in<strong>for</strong>mation, please<br />

contact <strong>Infastech</strong>.<br />

t o r X P l u s ® d r i v e s y s t e m<br />

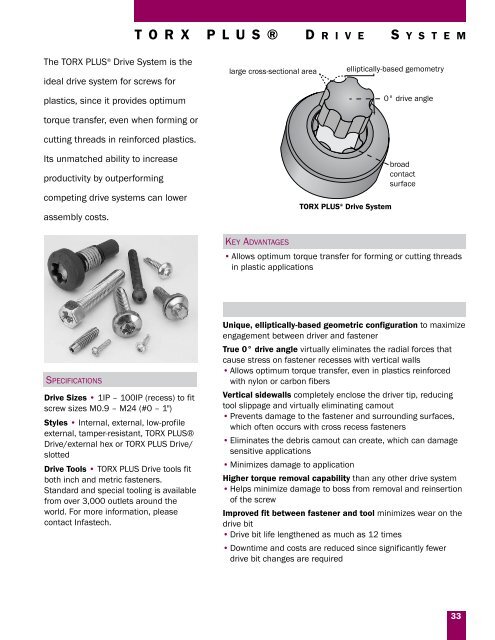

large cross-sectional area<br />

TORX PLUS ® Drive System<br />

elliptically-based gemometry<br />

0° drive angle<br />

broad<br />

contact<br />

surface<br />

Key advanTages<br />

• Allows optimum torque transfer <strong>for</strong> <strong>for</strong>ming or cutting threads<br />

in <strong>plastic</strong> applications<br />

Unique, elliptically-based geometric configuration to maximize<br />

engagement between driver and fastener<br />

True 0° drive angle virtually eliminates the radial <strong>for</strong>ces that<br />

cause stress on fastener recesses with vertical walls<br />

• Allows optimum torque transfer, even in <strong>plastic</strong>s rein<strong>for</strong>ced<br />

with nylon or carbon fibers<br />

Vertical sidewalls completely enclose the driver tip, reducing<br />

tool slippage and virtually eliminating camout<br />

• Prevents damage to the fastener and surrounding surfaces,<br />

which often occurs with cross recess fasteners<br />

• Eliminates the debris camout can create, which can damage<br />

sensitive applications<br />

• Minimizes damage to application<br />

Higher torque removal capability than any other drive system<br />

• Helps minimize damage to boss from removal and reinsertion<br />

of the screw<br />

Improved fit between fastener and tool minimizes wear on the<br />

drive bit<br />

• Drive bit life lengthened as much as 12 times<br />

• Downtime and costs are reduced since significantly fewer<br />

drive bit changes are required<br />

33