Threaded Fasteners for plastic - Infastech

Threaded Fasteners for plastic - Infastech

Threaded Fasteners for plastic - Infastech

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

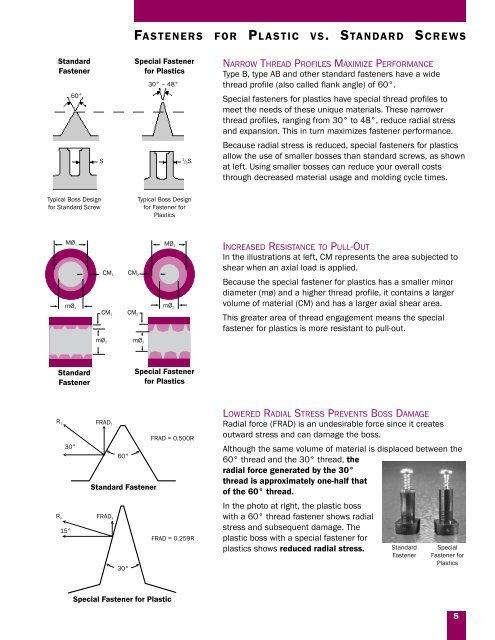

Standard<br />

Fastener<br />

Typical Boss Design<br />

<strong>for</strong> Standard Screw<br />

<strong>Fasteners</strong> For Pl astic vs. standard scre ws<br />

Special Fastener<br />

<strong>for</strong> Plastics<br />

Typical Boss Design<br />

<strong>for</strong> Fastener <strong>for</strong><br />

Plastics<br />

MØ 1 MØ2<br />

mØ1<br />

Standard<br />

Fastener<br />

R 1<br />

R 2<br />

30°<br />

15°<br />

60°<br />

S<br />

CM 1<br />

mØ 1<br />

CM 1<br />

FRAD 1<br />

60°<br />

CM 2<br />

CM 2<br />

mØ 2<br />

Standard Fastener<br />

FRAD 2<br />

30°<br />

30° – 48°<br />

mØ 2<br />

2 /3S<br />

Special Fastener<br />

<strong>for</strong> Plastics<br />

Special Fastener <strong>for</strong> Plastic<br />

FRAD = 0.500R<br />

FRAD = 0.259R<br />

narroW Thread ProFiles maximize PerFormance<br />

Type B, type AB and other standard fasteners have a wide<br />

thread profile (also called flank angle) of 60°.<br />

Special fasteners <strong>for</strong> <strong>plastic</strong>s have special thread profiles to<br />

meet the needs of these unique materials. These narrower<br />

thread profiles, ranging from 30° to 48°, reduce radial stress<br />

and expansion. This in turn maximizes fastener per<strong>for</strong>mance.<br />

Because radial stress is reduced, special fasteners <strong>for</strong> <strong>plastic</strong>s<br />

allow the use of smaller bosses than standard screws, as shown<br />

at left. Using smaller bosses can reduce your overall costs<br />

through decreased material usage and molding cycle times.<br />

increased resisTance To Pull-ouT<br />

In the illustrations at left, CM represents the area subjected to<br />

shear when an axial load is applied.<br />

Because the special fastener <strong>for</strong> <strong>plastic</strong>s has a smaller minor<br />

diameter (mø) and a higher thread profile, it contains a larger<br />

volume of material (CM) and has a larger axial shear area.<br />

This greater area of thread engagement means the special<br />

fastener <strong>for</strong> <strong>plastic</strong>s is more resistant to pull-out.<br />

loWered radial sTress PrevenTs boss damage<br />

Radial <strong>for</strong>ce (FRAD) is an undesirable <strong>for</strong>ce since it creates<br />

outward stress and can damage the boss.<br />

Although the same volume of material is displaced between the<br />

60° thread and the 30° thread, the<br />

radial <strong>for</strong>ce generated by the 30°<br />

thread is approximately one-half that<br />

of the 60° thread.<br />

In the photo at right, the <strong>plastic</strong> boss<br />

with a 60° thread fastener shows radial<br />

stress and subsequent damage. The<br />

<strong>plastic</strong> boss with a special fastener <strong>for</strong><br />

<strong>plastic</strong>s shows reduced radial stress.<br />

Standard<br />

Fastener<br />

Special<br />

Fastener <strong>for</strong><br />

Plastics<br />

5