Threaded Fasteners for plastic - Infastech

Threaded Fasteners for plastic - Infastech

Threaded Fasteners for plastic - Infastech

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

s u c c e s s w i t h F a s t e n e r s F o r P l a s t i c s<br />

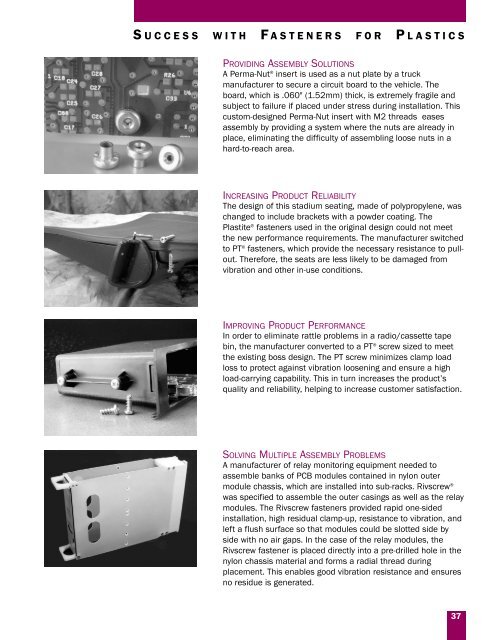

Providing assembly soluTions<br />

A Perma-Nut ® insert is used as a nut plate by a truck<br />

manufacturer to secure a circuit board to the vehicle. The<br />

board, which is .060" (1.52mm) thick, is extremely fragile and<br />

subject to failure if placed under stress during installation. This<br />

custom-designed Perma-Nut insert with M2 threads eases<br />

assembly by providing a system where the nuts are already in<br />

place, eliminating the difficulty of assembling loose nuts in a<br />

hard-to-reach area.<br />

increasing ProducT reliabiliTy<br />

The design of this stadium seating, made of polypropylene, was<br />

changed to include brackets with a powder coating. The<br />

Plastite ® fasteners used in the original design could not meet<br />

the new per<strong>for</strong>mance requirements. The manufacturer switched<br />

to PT ® fasteners, which provide the necessary resistance to pullout.<br />

There<strong>for</strong>e, the seats are less likely to be damaged from<br />

vibration and other in-use conditions.<br />

imProving ProducT PerFormance<br />

In order to eliminate rattle problems in a radio/cassette tape<br />

bin, the manufacturer converted to a PT ® screw sized to meet<br />

the existing boss design. The PT screw minimizes clamp load<br />

loss to protect against vibration loosening and ensure a high<br />

load-carrying capability. This in turn increases the product’s<br />

quality and reliability, helping to increase customer satisfaction.<br />

solving mulTiPle assembly Problems<br />

A manufacturer of relay monitoring equipment needed to<br />

assemble banks of PCB modules contained in nylon outer<br />

module chassis, which are installed into sub-racks. Rivscrew ®<br />

was specified to assemble the outer casings as well as the relay<br />

modules. The Rivscrew fasteners provided rapid one-sided<br />

installation, high residual clamp-up, resistance to vibration, and<br />

left a flush surface so that modules could be slotted side by<br />

side with no air gaps. In the case of the relay modules, the<br />

Rivscrew fastener is placed directly into a pre-drilled hole in the<br />

nylon chassis material and <strong>for</strong>ms a radial thread during<br />

placement. This enables good vibration resistance and ensures<br />

no residue is generated.<br />

37