FIREX BOARD - Manitoba Green Building Products Directory

FIREX BOARD - Manitoba Green Building Products Directory

FIREX BOARD - Manitoba Green Building Products Directory

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

G<br />

1<br />

The term "proactive fire protection" is used to describe products<br />

and systems which become part of the construction of a building.<br />

These products and systems are tested by independently<br />

approved testing authorities under standard testing conditions.<br />

They are designed to protect the building structure, to restrict<br />

1.2 FIRE TEST STANDARDS - Test on Materials<br />

The standard most commonly referred to in <strong>Building</strong> Codes by<br />

most Asian countries and Hong Kong is the British Standard<br />

(BS 476).<br />

BS 476: Part 4: 1970<br />

Non-combustibility test for materials.<br />

This test classifies materials as either "non-combustible" or<br />

"combustible". It is the most stringent standard for testing the<br />

fire resistance of materials and gives a measure of the heat<br />

and flames generated by the material under standard heating<br />

conditions.<br />

Non-combustible materials can be used without restriction<br />

anywhere in a building. Their use ensures that hazards due to<br />

smoke and toxic gases are minimized and that the fabric of a<br />

1.3 FIRE TEST STANDARDS - Test on Construction of Systems<br />

Fire Testing Method<br />

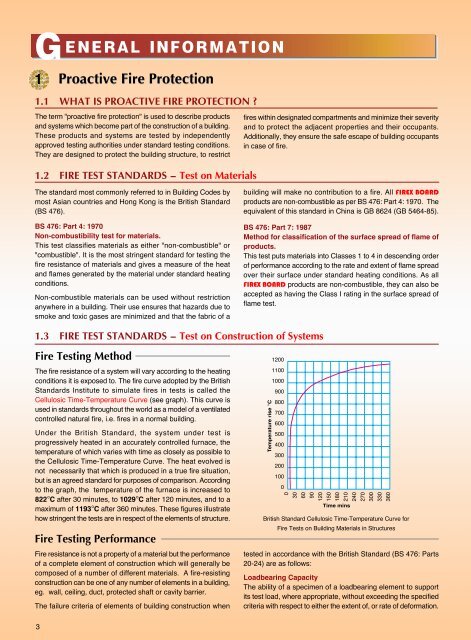

The fire resistance of a system will vary according to the heating<br />

conditions it is exposed to. The fire curve adopted by the British<br />

Standards Institute to simulate fires in tests is called the<br />

Cellulosic Time-Temperature Curve (see graph). This curve is<br />

used in standards throughout the world as a model of a ventilated<br />

controlled natural fire, i.e. fires in a normal building.<br />

Under the British Standard, the system under test is<br />

progressively heated in an accurately controlled furnace, the<br />

temperature of which varies with time as closely as possible to<br />

the Cellulosic Time-Temperature Curve. The heat evolved is<br />

not necessarily that which is produced in a true fire situation,<br />

but is an agreed standard for purposes of comparison. According<br />

to the graph, the temperature of the furnace is increased to<br />

822°C after 30 minutes, to 1029°C after 120 minutes, and to a<br />

maximum of 1193°C after 360 minutes. These figures illustrate<br />

3<br />

ENERAL INFORMATION<br />

Proactive Fire Protection<br />

1.1 WHAT IS PROACTIVE FIRE PROTECTION ?<br />

fires within designated compartments and minimize their severity<br />

and to protect the adjacent properties and their occupants.<br />

Additionally, they ensure the safe escape of building occupants<br />

in case of fire.<br />

how stringent the tests are in respect of the elements of structure. British Standard Cellulosic Time-Temperature Curve for<br />

Fire Testing Performance<br />

Fire resistance is not a property of a material but the performance<br />

of a complete element of construction which will generally be<br />

composed of a number of different materials. A fire-resisting<br />

construction can be one of any number of elements in a building,<br />

eg. wall, ceiling, duct, protected shaft or cavity barrier.<br />

The failure criteria of elements of building construction when<br />

building will make no contribution to a fire. All <strong>FIREX</strong> <strong>BOARD</strong><br />

products are non-combustible as per BS 476: Part 4: 1970. The<br />

equivalent of this standard in China is GB 8624 (GB 5464-85).<br />

BS 476: Part 7: 1987<br />

Method for classification of the surface spread of flame of<br />

products.<br />

This test puts materials into Classes 1 to 4 in descending order<br />

of performance according to the rate and extent of flame spread<br />

over their surface under standard heating conditions. As all<br />

<strong>FIREX</strong> <strong>BOARD</strong> products are non-combustible, they can also be<br />

accepted as having the Class I rating in the surface spread of<br />

flame test.<br />

Temperature rise °C<br />

1200<br />

1100<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

0<br />

30<br />

60<br />

90<br />

120<br />

150<br />

180<br />

210<br />

240<br />

270<br />

300<br />

330<br />

360<br />

Time mins<br />

Fire Tests on <strong>Building</strong> Materials in Structures<br />

tested in accordance with the British Standard (BS 476: Parts<br />

20-24) are as follows:<br />

Loadbearing Capacity<br />

The ability of a specimen of a loadbearing element to support<br />

its test load, where appropriate, without exceeding the specified<br />

criteria with respect to either the extent of, or rate of deformation.