75 YEARS - Hubbell Power Systems

75 YEARS - Hubbell Power Systems

75 YEARS - Hubbell Power Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

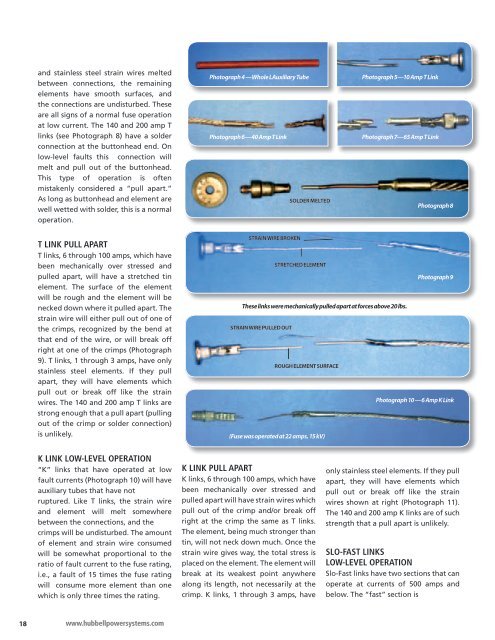

and stainless steel strain wires melted<br />

between connections, the remaining<br />

elements have smooth surfaces, and<br />

the connections are undisturbed. These<br />

are all signs of a normal fuse operation<br />

at low current. The 140 and 200 amp T<br />

links (see Photograph 8) have a solder<br />

connection at the buttonhead end. On<br />

low-level faults this connection will<br />

melt and pull out of the buttonhead.<br />

This type of operation is often<br />

mistakenly considered a “pull apart.”<br />

As long as buttonhead and element are<br />

well wetted with solder, this is a normal<br />

operation.<br />

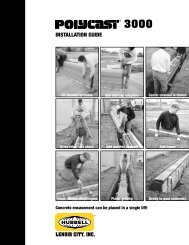

T LINK PULL APART<br />

T links, 6 through 100 amps, which have<br />

been mechanically over stressed and<br />

pulled apart, will have a stretched tin<br />

element. The surface of the element<br />

will be rough and the element will be<br />

necked down where it pulled apart. The<br />

strain wire will either pull out of one of<br />

the crimps, recognized by the bend at<br />

that end of the wire, or will break off<br />

right at one of the crimps (Photograph<br />

9). T links, 1 through 3 amps, have only<br />

stainless steel elements. If they pull<br />

apart, they will have elements which<br />

pull out or break off like the strain<br />

wires. The 140 and 200 amp T links are<br />

strong enough that a pull apart (pulling<br />

out of the crimp or solder connection)<br />

is unlikely.<br />

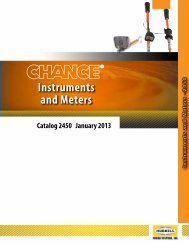

K LINK LOW-LEVEL OPERATION<br />

“K” links that have operated at low<br />

fault currents (Photograph 10) will have<br />

auxiliary tubes that have not<br />

ruptured. Like T links, the strain wire<br />

and element will melt somewhere<br />

between the connections, and the<br />

crimps will be undisturbed. The amount<br />

of element and strain wire consumed<br />

will be somewhat proportional to the<br />

ratio of fault current to the fuse rating,<br />

i.e., a fault of 15 times the fuse rating<br />

will consume more element than one<br />

which is only three times the rating.<br />

18 www.hubbellpowersystems.com<br />

Photograph 4 —Whole LAuxiliary Tube<br />

Photograph 6—40 Amp T Link<br />

STRAIN WIRE BROKEN<br />

K LINK PULL APART<br />

K links, 6 through 100 amps, which have<br />

been mechanically over stressed and<br />

pulled apart will have strain wires which<br />

pull out of the crimp and/or break off<br />

right at the crimp the same as T links.<br />

The element, being much stronger than<br />

tin, will not neck down much. Once the<br />

strain wire gives way, the total stress is<br />

placed on the element. The element will<br />

break at its weakest point anywhere<br />

along its length, not necessarily at the<br />

crimp. K links, 1 through 3 amps, have<br />

Photograph 5—10 Amp T Link<br />

Photograph 7—65 Amp T Link<br />

These links were mechanically pulled apart at forces above 20 lbs.<br />

STRAIN WIRE PULLED OUT<br />

SOLDER MELTED<br />

STRETCHED ELEMENT<br />

ROUGH ELEMENT SURFACE<br />

(Fuse was operated at 22 amps, 15 kV)<br />

Photograph 8<br />

Photograph 9<br />

Photograph 10 —6 Amp K Link<br />

only stainless steel elements. If they pull<br />

apart, they will have elements which<br />

pull out or break off like the strain<br />

wires shown at right (Photograph 11).<br />

The 140 and 200 amp K links are of such<br />

strength that a pull apart is unlikely.<br />

SLO-FAST LINKS<br />

LOW-LEVEL OPERATION<br />

Slo-Fast links have two sections that can<br />

operate at currents of 500 amps and<br />

below. The “fast” section is