Infobox0810 Agnati upgrades - Vonderheiden

Infobox0810 Agnati upgrades - Vonderheiden

Infobox0810 Agnati upgrades - Vonderheiden

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Infobox 08/ 2010<br />

Successful <strong>upgrades</strong> of single facer <strong>Agnati</strong> S 90 and Master<br />

Hydraulic Soft Touch System Package<br />

Glue dam package and web edge detection<br />

Exchange of existing pneumatic- against hydraulic-system<br />

After many successful <strong>upgrades</strong> of several<br />

types of single facers from Peters, Langston,<br />

Simon and MHI, the company<br />

<strong>Vonderheiden</strong> add two new single facers,<br />

<strong>Agnati</strong> S 90 and Master to their product<br />

portfolio. By this upgrade the users will<br />

achieve better quality and higher<br />

availability, combined with less glue<br />

consumption and reduced waste.<br />

The conventional paper gap system on an<br />

<strong>Agnati</strong> single facer requires frequent gap<br />

adjustment and frequent calibration by the<br />

operator.<br />

Occurring inaccuracies are mostly<br />

compensated by increased glue<br />

application and higher glue consumption is<br />

the result.<br />

The company <strong>Vonderheiden</strong> upgraded an<br />

<strong>Agnati</strong> S90 and Master single facer<br />

successfully in two customer sites from<br />

pneumatic glue gap setting to proven<br />

hydraulic Softtouch-system.<br />

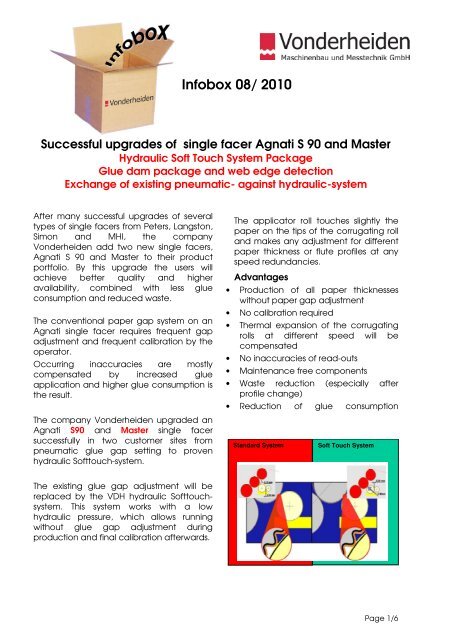

The existing glue gap adjustment will be<br />

replaced by the VDH hydraulic Softtouchsystem.<br />

This system works with a low<br />

hydraulic pressure, which allows running<br />

without glue gap adjustment during<br />

production and final calibration afterwards.<br />

The applicator roll touches slightly the<br />

paper on the tips of the corrugating roll<br />

and makes any adjustment for different<br />

paper thickness or flute profiles at any<br />

speed redundancies.<br />

Advantages<br />

• Production of all paper thicknesses<br />

without paper gap adjustment<br />

• No calibration required<br />

• Thermal expansion of the corrugating<br />

rolls at different speed will be<br />

compensated<br />

• No inaccuracies of read-outs<br />

• Maintenance free components<br />

• Waste reduction (especially after<br />

profile change)<br />

• Reduction of glue consumption<br />

Standard System Soft Touch System<br />

Page 1/6

Direct drive for single facer glue<br />

unit<br />

In order to use the sofftouch system<br />

successfully , the speed of the applicator<br />

roll must be adjustable in relation to the<br />

corrugating roll speed.<br />

Up to now the S90 glue unit is mechanical<br />

driven by a clutch and cardan shaft.<br />

These components are sensitive to failure,<br />

but even more critical is non-adjustabilitiy<br />

of the speed ratio of the relative speed<br />

applicator to corrugating roll.<br />

Therefore the existing system had to be<br />

replaced by a servo drive, which was due<br />

to the restrictive available space a difficult<br />

task. This problem was due to precise<br />

engineering solved and finally installed.<br />

One of the customer has two S90´s in<br />

his corrugator and has a very good<br />

comparison from old to new system.<br />

Right after the start-up a direct<br />

comparison was run (same order,<br />

same paper, same glue) and they are<br />

very pleased with the results (ECT,<br />

operator friendliness).<br />

The result about savings in glue<br />

consumption couldn´t be submitted at<br />

this stage, but we will inform you<br />

immediately after the availability of<br />

these data.<br />

Due to the positive experiences the<br />

second machine of this customer will<br />

be upgraded soon.<br />

New glue dams<br />

The existing glue dams didn’t seal very<br />

well, plus the holders and fixation are<br />

relatively instable. The existing rubber<br />

glue dam sealing leads to an inexact<br />

glue edge, which can transfer the glue<br />

to corrugating- and press-/calander<br />

roll, causing production and quality<br />

problems.<br />

As done on other single facers too, the<br />

existing glue dam system was<br />

replaced by state-of-the-art bronze<br />

glue dams, improved sealing together<br />

with stronger levers.<br />

Page 2/6

The glue dam package can be seen as first step into improving the machine.<br />

The new glue dam modification can be done separately without any other upgrade<br />

and immediately a much smaller and more accurate glue edge will be the result.<br />

By doing only this single modification the user should not loose his vision of the<br />

required result and that his key problem must be solved sustainable.<br />

Page 3/6

Existing, undefined New , accurate glue line<br />

Page 4/6

Improved glue dam positioning<br />

What are the advantages of improved<br />

glue dams if the positioning isn’t<br />

reliable and accurate?<br />

Within the existing pneumatic system<br />

there’s always remaining air in the<br />

tubes, which leads to an inexact and<br />

uncontrolled positioning of the glue<br />

dams.<br />

In order to get rid of this problem VDH<br />

replaced the pneumatic by new<br />

electronic motors and achieve a very<br />

precise positioning.<br />

Web edge detection<br />

After doing all these improvements to<br />

the machine it only remained the<br />

weak point of a proper functioning<br />

web edge detection.<br />

Due to the tough environment (steam,<br />

dust, moisture etc.) all known available<br />

systems can’t guarantee any<br />

precision, which again leads to wrong<br />

positioning.<br />

In order to overcome this problem the<br />

customers decided to install the<br />

newest BHS technology.<br />

The BHS light grid has one sender and<br />

receiver, which are protected behind<br />

special glass, which prevents dust<br />

contamination. The accuracy of this<br />

system is with ± 1 mm much better<br />

than conventional systems.<br />

There are no moving parts or no<br />

sensors, which must follow the web<br />

edge.<br />

Additional advantages are the<br />

reduction of required maintenance<br />

and reduced calibration.<br />

Due to the immediate detection of the<br />

actual web edge the glue dams will<br />

follow immediately into the new<br />

position.<br />

Receiver<br />

Sender<br />

Page 5/6

As reported both users are very satisfied with the results of the modifications done.<br />

Shortly there will further single facers upgraded.<br />

Naturally all described <strong>upgrades</strong> can be done separately, but it must be understood<br />

that the final planned achievement must be reached and that the <strong>upgrades</strong> must<br />

solve the problem sustainable !!!<br />

Summary of the described <strong>upgrades</strong>:<br />

.<br />

1. Hydraulic Softtouch package<br />

2. Glue dam package<br />

a. Direct drive for glue unit<br />

b. New glue dams by improved design and bronze material<br />

c. Improved glue dam positioning by new motor<br />

3. Web edge detection by BHS light grid<br />

----------------------------------------------------------------------------------------------------------------------------------------<br />

<strong>Vonderheiden</strong> Maschinenbau und Messtechnik GmbH<br />

Tel.: +49 (0)40-589 55-0<br />

Fax: +49 (0)40-589 55-21<br />

info@vonderheiden.com<br />

http://www.vonderheiden.com<br />

24h-Hotline Electrical & Mechanical<br />

+49 (0)160- 714 09 00<br />

Page 6/6