Rigid polyurethane foam for refrigerated vehicles and containers

Rigid polyurethane foam for refrigerated vehicles and containers

Rigid polyurethane foam for refrigerated vehicles and containers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2. Insulation <strong>for</strong> the most dem<strong>and</strong>ing<br />

applications<br />

Refrigerated <strong>containers</strong> <strong>and</strong> <strong>vehicles</strong> are generally<br />

run under conditions which dem<strong>and</strong> both optimum<br />

thermal insulation <strong>and</strong> high mechanical strength.<br />

These properties have to be maintained throughout<br />

the service life of the product, which often exceeds<br />

15 years. The specific requirements of shipping<br />

lines, leasing companies, etc., which result from a<br />

number of different influences, are also an important<br />

factor <strong>and</strong> include:<br />

• type of freight transported<br />

• loading <strong>and</strong> unloading conditions<br />

• quality of h<strong>and</strong>ling in different areas<br />

• requirements of the International St<strong>and</strong>ards<br />

Organization (ISO regulations)<br />

• personal preferences <strong>and</strong> company policy<br />

• national transport legislation.<br />

In addition, production costs, durability, corrosion<br />

resistance, low repair <strong>and</strong> maintenance costs (lifecycle<br />

costs) have to be taken into consideration<br />

when producing <strong>refrigerated</strong> <strong>containers</strong> <strong>and</strong> <strong>vehicles</strong>.<br />

Bayer MaterialScience AG works in close cooperation<br />

with its customers here: all our <strong>polyurethane</strong><br />

raw materials are subjected to a lengthy internal<br />

quality assurance procedure in compliance<br />

with strict DIN EN ISO 9001/2000 st<strong>and</strong>ards.<br />

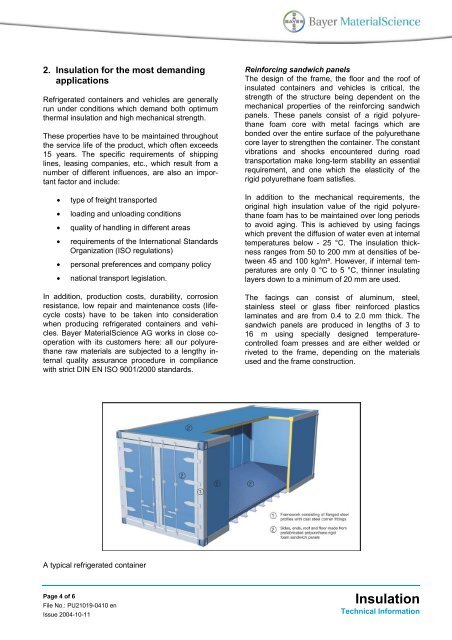

A typical <strong>refrigerated</strong> container<br />

Page 4 of 6<br />

File No.: PU21019-0410 en<br />

Issue 2004-10-11<br />

Rein<strong>for</strong>cing s<strong>and</strong>wich panels<br />

The design of the frame, the floor <strong>and</strong> the roof of<br />

insulated <strong>containers</strong> <strong>and</strong> <strong>vehicles</strong> is critical, the<br />

strength of the structure being dependent on the<br />

mechanical properties of the rein<strong>for</strong>cing s<strong>and</strong>wich<br />

panels. These panels consist of a rigid <strong>polyurethane</strong><br />

<strong>foam</strong> core with metal facings which are<br />

bonded over the entire surface of the <strong>polyurethane</strong><br />

core layer to strengthen the container. The constant<br />

vibrations <strong>and</strong> shocks encountered during road<br />

transportation make long-term stability an essential<br />

requirement, <strong>and</strong> one which the elasticity of the<br />

rigid <strong>polyurethane</strong> <strong>foam</strong> satisfies.<br />

In addition to the mechanical requirements, the<br />

original high insulation value of the rigid <strong>polyurethane</strong><br />

<strong>foam</strong> has to be maintained over long periods<br />

to avoid aging. This is achieved by using facings<br />

which prevent the diffusion of water even at internal<br />

temperatures below - 25 °C. The insulation thickness<br />

ranges from 50 to 200 mm at densities of between<br />

45 <strong>and</strong> 100 kg/m³. However, if internal temperatures<br />

are only 0 °C to 5 °C, thinner insulating<br />

layers down to a minimum of 20 mm are used.<br />

The facings can consist of aluminum, steel,<br />

stainless steel or glass fiber rein<strong>for</strong>ced plastics<br />

laminates <strong>and</strong> are from 0.4 to 2.0 mm thick. The<br />

s<strong>and</strong>wich panels are produced in lengths of 3 to<br />

16 m using specially designed temperaturecontrolled<br />

<strong>foam</strong> presses <strong>and</strong> are either welded or<br />

riveted to the frame, depending on the materials<br />

used <strong>and</strong> the frame construction.<br />

Insulation<br />

Technical In<strong>for</strong>mation