Download as PDF (899 KB) - Makino Europe GmbH

Download as PDF (899 KB) - Makino Europe GmbH

Download as PDF (899 KB) - Makino Europe GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

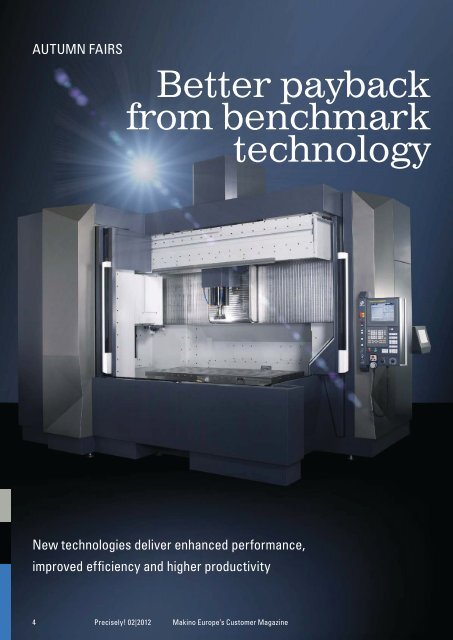

AUTUMN FAIRS<br />

4<br />

Precisely! 02|2012<br />

Better payback<br />

from benchmark<br />

technology<br />

New technologies deliver enhanced performance,<br />

improved efficiency and higher productivity<br />

<strong>Makino</strong> <strong>Europe</strong>’s Customer Magazine

F8: the vertical machining centre<br />

with front doors open<br />

Autumn trade fairs are traditionally the time when technology<br />

and service providers in the machine tool industry serve up<br />

their latest wares. This year, <strong>Makino</strong> launches a number of new<br />

machines that offer users an outstanding return on investment<br />

through higher productivity.<br />

F8/F9: e<strong>as</strong>y access to the spindle and the part<br />

F8/F9: a machine of extremes<br />

A new vertical machining centre<br />

(VMCs) from <strong>Makino</strong>, the F8/F9, is big<br />

and strong, yet accurate at the same<br />

time. The size and strength of the<br />

F8/F9 is illustrated by a few key<br />

characteristics: 17,000 kg in weight,<br />

a 2,500 kg payload, an 800 mm Y-axis<br />

stroke, roller guides, permanent sup-<br />

port and guidance of all axes (no floating<br />

axis), a short force loop (only<br />

600 mm from spindle to Z-axis supports<br />

and guides), and a 10,000 rpm 426 Nm<br />

spindle. All this leads to low vibration<br />

levels in performing powerful cutting<br />

operations and stability in machining<br />

difficult-to-cut materials. The accuracy<br />

of the machining performance is b<strong>as</strong>ed<br />

on several related factors: the thermo-<br />

symmetric design, core-cooled ball<br />

screws and an optional core-cooled<br />

20,000 rpm spindle, resulting in thermal<br />

stability, which ensures sustained<br />

accuracy during long hours of machining<br />

and minimizes spindle growth in a<br />

Z-axis direction.<br />

Balanced benefits<br />

This excellent balance of strength, size<br />

and accuracy brings key benefits for<br />

the user. The F8/F9 performs demanding<br />

roughing and boring operations at<br />

high MRRs while still reducing cutter<br />

consumption and the problems caused<br />

by chip clogging. The fact that jobs<br />

can be completely or nearly finished<br />

on an F8/F9 is a formula for enhanced<br />

productivity. After all, the good sur-<br />

face quality of finished pieces, minimal<br />

blending error between different<br />

tools, high pitch accuracy and certain<br />

±5 µm accuracy in parting lines reduce<br />

or eliminate the need for further manual<br />

operations. Moreover, he ergo-<br />

nomic design of the F8/F9 reduces non-<br />

cutting times and facilitates loading<br />

and unloading of large parts, inspection<br />

of parts and tools, and access for<br />

manual operations. L<strong>as</strong>t but not le<strong>as</strong>t,<br />

the combination of strength, size and<br />

accuracy means the F8/F9 is a highly<br />

flexible VMC suitable for a wide variety<br />

of applications, such <strong>as</strong> pl<strong>as</strong>tic<br />

injection moulding, cold and hot forging,<br />

mould b<strong>as</strong>e machining and parts<br />

machining, <strong>as</strong> well <strong>as</strong> materials, e.g.<br />

steel, stainless steel and titanium.<br />

5<br />

www.makino.eu

U3: e<strong>as</strong>y guide maintenance<br />

U3: cost-effective wire EDM<br />

The latest addition to <strong>Makino</strong>‘s wire<br />

EDM portfolio, the U3, bo<strong>as</strong>ts a unique<br />

0.4µm/3-p<strong>as</strong>s capability that speeds<br />

up punch and die cutting: under<br />

standard machining conditions the<br />

<strong>Makino</strong> U3 delivers a surface finish of<br />

Ra 0.4 µm with just three p<strong>as</strong>ses. That<br />

naturally reduces machining time and<br />

also lowers the cost of consumables<br />

<strong>as</strong> less wire is required.<br />

The U3 comes with numerous features<br />

to speed up wire EDM operations. The<br />

Pico Precision Guides automatically<br />

thread initial start holes <strong>as</strong> small <strong>as</strong><br />

0.4 mm in diameter with minimal risk<br />

of failure while a high-pressure twinjet<br />

system and improved pecking feed<br />

system deliver even more accurate,<br />

6<br />

Precisely! 02|2012<br />

high-speed wire threading. By melting<br />

the wire to form a burrless pointed tip,<br />

the thermal cutter further improves the<br />

reliability of wire threading. What is<br />

more, the U3’s new guide maintenance<br />

system eliminates the need for lengthy<br />

realignment procedures if guides have<br />

to be reinstalled. A machine of this qual-<br />

ity – with the same fixed-table design<br />

concept <strong>as</strong> <strong>Makino</strong>‘s well-known UP<br />

Series – offers an excellent return on<br />

investment for shops specialising in<br />

precision metal tooling or die stamping.<br />

Upgraded a61nx-5E<br />

Designed to boost productivity by<br />

reducing work-setting operations, the<br />

new a61nx-5E horizontal machining<br />

centre (HMC) is particularly suited to<br />

machining aircraft parts, e.g. complex<br />

impeller blades, and high-performance<br />

a61nx-5E: pallet change sequence<br />

<strong>Makino</strong> <strong>Europe</strong>’s Customer Magazine<br />

aluminium cutting. <strong>Makino</strong> h<strong>as</strong> added<br />

a 4th and a 5th direct drive axis to the<br />

successful a61nx and introduced a new<br />

automated pallet changer to make<br />

horizontal work settings possible in a<br />

rotary table 5-axis HMC. The standard<br />

specs version is designed for high-accuracy<br />

cutting, the aluminium specs<br />

option for high-performance aluminium<br />

cutting with a high-power 24,000 rpm,<br />

80 kW spindle achieving an MRR of up<br />

to 5,000 cm 3 /min. Another spindle option<br />

– 14,000 rpm, 240 Nm – is extreme-<br />

ly suitable for machining titanium, and<br />

in particular aerospace parts.<br />

Besides high speed and accuracy, the<br />

machine‘s other outstanding nding features<br />

are its ergonomic design, , re<strong>as</strong>suring<br />

reliability and power-saving ving Eco mode.<br />

The new machine concept ept not only<br />

enables it to be operated d more e<strong>as</strong>ily<br />

and quickly but also allows ows for larger<br />

workpieces and longer-length length tools.<br />

At the same time, the latest test Pro.5 High<br />

Performance Control unit it comes with<br />

an improved touchscreen n and icons<br />

for f<strong>as</strong>ter input, and a tool ol data<br />

screen for simple tool management.<br />

anagement.<br />

The machine‘s reliability is b<strong>as</strong>ed,<br />

among other things, on the he<br />

spindle head‘s w<strong>as</strong>hing coolant<br />

and flat surface to prevent nt chip<br />

contamination during auto- uto-<br />

matic tool changing, and a choice<br />

of two disposal devices for optimum<br />

chip evacuation. L<strong>as</strong>t but t far from<br />

le<strong>as</strong>t, the machine‘s standard ndard Eco Eco<br />

mode reduces power consumption<br />

onsumption<br />

by up to 30%.

<strong>Makino</strong>‘s new<br />

small-sized HMC<br />

A strikingly small HMC<br />

Visitors to the <strong>Makino</strong> booth will be<br />

surprised at how small this HMC is.<br />

Most would expect a machine of this<br />

size to be a VMC. But now <strong>Makino</strong><br />

h<strong>as</strong> broken the mould by developing<br />

an HMC of unparalleled compactness<br />

(WxDxH: 1,110 x 2,000 x 2,150<br />

mm; footprint 2.2 m2 ). Since this new<br />

machine benefits from the superior<br />

chip evacuation of HMCs, it is ideal<br />

for parts‘ production, especially <strong>as</strong> it<br />

offers four table options to suit a wide<br />

range of components. components. High machine<br />

dynamics and excellent accuracy are<br />

A20:<br />

20-metre X-axis travel<br />

the machine‘s strengths. The cutting<br />

performance h<strong>as</strong> been tested in alu-<br />

minium at 335 cc/min. and in S55/C<br />

steel at 40 cc/min. The repeatability<br />

of the linear axis h<strong>as</strong> been me<strong>as</strong>ured<br />

at ±0.002 mm and the indexing repeat-<br />

ability of the rotary axis at ±2 sec. In<br />

other words, the machine‘s unmatched<br />

compactness, machining accuracy,<br />

cutting capability and competitive<br />

price make it a very interesting proposition<br />

for series production of automotive<br />

or industrial components and<br />

high-precision parts for the medical<br />

and watch industries – particularly<br />

<strong>as</strong> the machine‘s e<strong>as</strong>y accessibility<br />

makes various automation configurations<br />

possible.<br />

EDBV3 & A4-A20:<br />

aerospace highlights<br />

Though not on view at the autumn fairs,<br />

one newcomer to the <strong>Makino</strong> portfo-<br />

lio, the EDBV3, will particularly in-<br />

terest jet engine manufacturers. Designed<br />

<strong>as</strong> a more efficient solution for<br />

drilling cooling holes and fan-shape<br />

machining in blades and vanes, the<br />

EDBV3 combines a number of new<br />

technologies that reduce machining<br />

time in such operations – by drilling<br />

cooling holes seven times f<strong>as</strong>ter than<br />

existing EDM drilling technology –<br />

and make continuous single setup<br />

machining possible. The result is an<br />

innovative, efficiency-enhancing<br />

sinker EDM machine that will enable<br />

manufacturers to meet the growing<br />

demand for jet engines.<br />

What is more, <strong>Makino</strong>‘s new generation<br />

of large-size HMCs, the A4-A20,<br />

is ideally suited for producing highquality<br />

aluminium structural parts<br />

for the aerospace industry. The key<br />

features are enhanced machine<br />

dynamics with axes acceleration of<br />

0.8 g, a powerful spindle (120 kW) and<br />

a modular design with X-axis travel<br />

ranging from 4 to 20 metres.<br />

For further information on all these<br />

technologies ple<strong>as</strong>e consult your local<br />

<strong>Makino</strong> representative, visit the <strong>Makino</strong><br />

booth at one of the autumn fairs,<br />

or contact us at precisely@makino.eu<br />

7<br />

www.makino.eu