Blisk Production of the Future - MTU Aero Engines

Blisk Production of the Future - MTU Aero Engines

Blisk Production of the Future - MTU Aero Engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

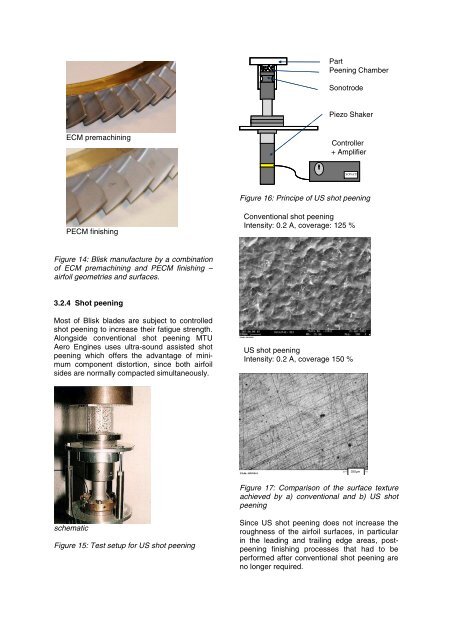

ECM premachining<br />

PECM finishing<br />

Figure 14: <strong>Blisk</strong> manufacture by a combination<br />

<strong>of</strong> ECM premachining and PECM finishing –<br />

airfoil geometries and surfaces.<br />

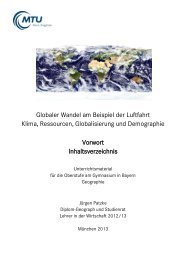

3.2.4 Shot peening<br />

Most <strong>of</strong> <strong>Blisk</strong> blades are subject to controlled<br />

shot peening to increase <strong>the</strong>ir fatigue strength.<br />

Alongside conventional shot peening <strong>MTU</strong><br />

<strong>Aero</strong> <strong>Engines</strong> uses ultra-sound assisted shot<br />

peening which <strong>of</strong>fers <strong>the</strong> advantage <strong>of</strong> minimum<br />

component distortion, since both airfoil<br />

sides are normally compacted simultaneously.<br />

schematic<br />

Figure 15: Test setup for US shot peening<br />

Part<br />

Peening Chamber<br />

Sonotrode<br />

Piezo Shaker<br />

Controller<br />

+ Amplifier<br />

SONATS<br />

Figure 16: Principe <strong>of</strong> US shot peening<br />

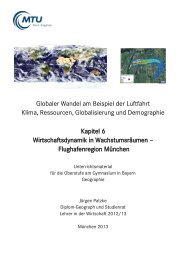

Conventional shot peening<br />

Intensity: 0.2 A, coverage: 125 %<br />

US shot peening<br />

Intensity: 0.2 A, coverage 150 %<br />

250µm<br />

Figure 17: Comparison <strong>of</strong> <strong>the</strong> surface texture<br />

achieved by a) conventional and b) US shot<br />

peening<br />

Since US shot peening does not increase <strong>the</strong><br />

roughness <strong>of</strong> <strong>the</strong> airfoil surfaces, in particular<br />

in <strong>the</strong> leading and trailing edge areas, postpeening<br />

finishing processes that had to be<br />

performed after conventional shot peening are<br />

no longer required.

![Download PDF [5,37 MB] - MTU Aero Engines](https://img.yumpu.com/21945461/1/190x125/download-pdf-537-mb-mtu-aero-engines.jpg?quality=85)