Blisk Production of the Future - MTU Aero Engines

Blisk Production of the Future - MTU Aero Engines

Blisk Production of the Future - MTU Aero Engines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ISABE-2009-1169<br />

<strong>Blisk</strong> <strong>Production</strong> <strong>of</strong> <strong>the</strong> <strong>Future</strong><br />

Technological and Logistical Aspects <strong>of</strong> <strong>Future</strong>-Oriented Construction and Manufacturing<br />

Processes <strong>of</strong> Integrally Bladed Rotors<br />

Abstract<br />

This paper describes <strong>the</strong> state-<strong>of</strong>-<strong>the</strong>-art in <strong>the</strong><br />

manufacturing technology for integrally bladed<br />

compressor and turbine rotors (blisks) in today’s<br />

engine construction and addresses <strong>the</strong><br />

technological and logistical challenges to be<br />

resolved to ensure flexible and future-oriented<br />

blisk manufacture.<br />

Abbreviations<br />

ECM Electrochemical Machining<br />

PECM Precise Electrochem. Machining<br />

HPC High Performance Cutting<br />

<strong>Blisk</strong> Bladed integrated Disk<br />

IBR Integrated Bladed Rotor<br />

LFW Linear Friction Welding<br />

IHFP Inductive High Frequency Pressure-Welding<br />

LPC Low pressure compressor<br />

AM Adaptive Milling<br />

CMM Coordinate measuring<br />

machine<br />

2. Introduction<br />

Integrally bladed rotors (blisks) are increasingly<br />

being used in modern engine construction.<br />

Meanwhile, advanced compressors for both<br />

commercial and military engines frequently<br />

come as all-blisk designs. Essential benefits<br />

over conventional rotor designs where <strong>the</strong><br />

blades are fitted in slots in <strong>the</strong> disk rim include<br />

weight reductions up to 20 percent and significant<br />

efficiency improvements.<br />

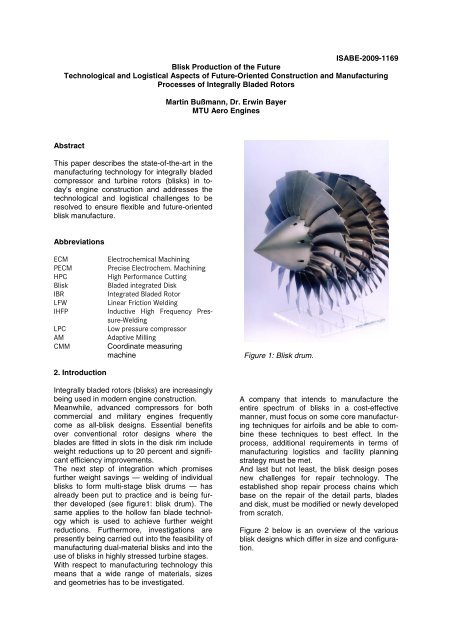

The next step <strong>of</strong> integration which promises<br />

fur<strong>the</strong>r weight savings — welding <strong>of</strong> individual<br />

blisks to form multi-stage blisk drums — has<br />

already been put to practice and is being fur<strong>the</strong>r<br />

developed (see figure1: blisk drum). The<br />

same applies to <strong>the</strong> hollow fan blade technology<br />

which is used to achieve fur<strong>the</strong>r weight<br />

reductions. Fur<strong>the</strong>rmore, investigations are<br />

presently being carried out into <strong>the</strong> feasibility <strong>of</strong><br />

manufacturing dual-material blisks and into <strong>the</strong><br />

use <strong>of</strong> blisks in highly stressed turbine stages.<br />

With respect to manufacturing technology this<br />

means that a wide range <strong>of</strong> materials, sizes<br />

and geometries has to be investigated.<br />

Martin Bußmann, Dr. Erwin Bayer<br />

<strong>MTU</strong> <strong>Aero</strong> <strong>Engines</strong><br />

Figure 1: <strong>Blisk</strong> drum.<br />

A company that intends to manufacture <strong>the</strong><br />

entire spectrum <strong>of</strong> blisks in a cost-effective<br />

manner, must focus on some core manufacturing<br />

techniques for airfoils and be able to combine<br />

<strong>the</strong>se techniques to best effect. In <strong>the</strong><br />

process, additional requirements in terms <strong>of</strong><br />

manufacturing logistics and facility planning<br />

strategy must be met.<br />

And last but not least, <strong>the</strong> blisk design poses<br />

new challenges for repair technology. The<br />

established shop repair process chains which<br />

base on <strong>the</strong> repair <strong>of</strong> <strong>the</strong> detail parts, blades<br />

and disk, must be modified or newly developed<br />

from scratch.<br />

Figure 2 below is an overview <strong>of</strong> <strong>the</strong> various<br />

blisk designs which differ in size and configuration.

1.2 Range<br />

EJ 200<br />

LPC<br />

Ti64<br />

LFW + AM<br />

TP400 Drum<br />

IPC<br />

Ti64<br />

EBW / IFW<br />

HPM<br />

Figure 2: Overview <strong>of</strong> <strong>the</strong> blisk types manufactured by <strong>MTU</strong> <strong>Aero</strong> <strong>Engines</strong>.<br />

3. From <strong>the</strong> strategic approach to <strong>the</strong> present-day<br />

situation at <strong>MTU</strong> <strong>Aero</strong> <strong>Engines</strong><br />

A strategic approach towards market-driven<br />

blisk manufacture was defined by <strong>MTU</strong> <strong>Aero</strong><br />

<strong>Engines</strong> back in 2004.<br />

To be able to manufacture various blisk types<br />

to satisfy <strong>the</strong> demand on <strong>the</strong> commercial and<br />

military markets long-term, several core manufacturing<br />

technologies for <strong>the</strong> production <strong>of</strong> <strong>the</strong><br />

flow duct pr<strong>of</strong>ile must be developed that can be<br />

used in any combination, depending on <strong>the</strong><br />

type <strong>of</strong> blisk involved.<br />

Machining resistance (material)<br />

ECM ECM / / PECM<br />

PECM<br />

HPC<br />

Current current<br />

blisk <strong>Blisk</strong> spectrum<br />

spectrum<br />

HPC<br />

LFW / IHFP<br />

Blade surface area / airfoil length (geometry)<br />

Exc. : Applications <strong>of</strong> airfoiling processes<br />

as referred to two parameters<br />

Figure 3: Core airfoiling processes for blisk<br />

PW6000<br />

HPC<br />

Ti6242<br />

HPM + IFW<br />

EJ 200 Drum<br />

HPC<br />

Ti6242<br />

HPM + IFW<br />

NGPF<br />

HPC<br />

U720;IN718<br />

(PECM)<br />

Focusing on <strong>the</strong>se core technologies makes<br />

sense because <strong>the</strong> production <strong>of</strong> <strong>the</strong> flow duct<br />

accounts for <strong>the</strong> major part <strong>of</strong> <strong>the</strong> manufacturing<br />

costs. In addition, <strong>the</strong> use <strong>of</strong> suitable core<br />

technologies may help reduce raw material<br />

consumption and hence costs.<br />

These core technologies are <strong>the</strong>n supplemented<br />

by hub machining and surface treatment<br />

processes to obtain an optimum process<br />

chain tailored to suit <strong>the</strong> respective type <strong>of</strong><br />

blisk.<br />

If <strong>the</strong>se manufacturing technologies are <strong>the</strong>n<br />

used in conjunction with advanced design and<br />

construction methods a component can be<br />

manufactured that is optimized in terms <strong>of</strong><br />

function, quality and costs.<br />

Based on this approach, a number <strong>of</strong> development<br />

projects were launched which focused<br />

on:<br />

- design to cost<br />

- new or fur<strong>the</strong>r developed joining, milling<br />

and ECM/PECM techniques<br />

- shot peening techniques<br />

- new quality assurance methods<br />

- new repair strategies

The Tool Box Approach in Process Chain Generation<br />

Peripheral Peripheral<br />

processes processes<br />

Niblisk<br />

Tiblisk<br />

Pre-airfoiling processes<br />

Figure 4: Tool box approach<br />

3.1 Design to cost<br />

Airfoiling<br />

Rough-machining Finishing<br />

ECM HPC LFW /<br />

IHFP<br />

ECM /<br />

PECM<br />

HPC<br />

LFW /<br />

IHFP +<br />

AM AM<br />

X X<br />

X<br />

X X<br />

X X<br />

: : : : : :<br />

X<br />

X X<br />

X X<br />

: : : : : :<br />

The primary objective <strong>of</strong> design-to-cost measures<br />

in blisk production is to reduce <strong>the</strong> manufacturing<br />

costs by bringing <strong>the</strong> requirements for<br />

airfoil and annulus surfaces as well as leading<br />

/ trailing edge geometries as closely as possible<br />

in line with <strong>the</strong> fluid mechanical requirements.<br />

In <strong>the</strong> process, <strong>the</strong> friction losses <strong>of</strong><br />

processed surfaces (milled, shot peened,<br />

ground) and/or <strong>the</strong> geometry variations <strong>of</strong> <strong>the</strong><br />

edges must be accounted for in <strong>the</strong> aerodynamic<br />

design as accurately as possible.<br />

TT<br />

Surface- -<br />

treatment<br />

CG<br />

:<br />

X<br />

X<br />

:<br />

Grinding,<br />

etc.<br />

X<br />

:<br />

X<br />

:<br />

Peripheral<br />

processes<br />

-<br />

Post-airfoiling processes / QM<br />

For <strong>the</strong> annulus surfaces, pro<strong>of</strong> could be furnished<br />

that milling marks that extend in <strong>the</strong><br />

direction <strong>of</strong> <strong>the</strong> flow have no adverse effects<br />

whatsoever, as long as <strong>the</strong>ir depth does not<br />

exceed a certain threshold value. This significantly<br />

reduces <strong>the</strong> finish-machining effort.<br />

The results <strong>of</strong> investigations into possible leading<br />

edge geometries on compressor blades<br />

have also revealed technical potential for expanding<br />

<strong>the</strong> acceptance standards.<br />

basic pr<strong>of</strong>ile 1/4 T stub 1/3 T stub 1/8 T concave 1/8 T convex 1/6 T concave<br />

Figure 4: Edge geometries investigated.<br />

∆ω<br />

mittel<br />

∆ω<br />

∆ω<br />

∆ω<br />

0,00%<br />

1/4 1/4 stumpf stub 1/3 1/3 stumpf stub 1/8 1/8 concave konkav 1/8 1/8 convex konvex 1/6 1/6 concave konkav<br />

1-2 Grafiken<br />

3.2 Manufacturing technologies<br />

Edge Kantenform geometries<br />

3.2.1 Joining<br />

Figure 5: Losses ∆ω <strong>of</strong> <strong>the</strong> deviating edge pr<strong>of</strong>iles investigated as compared with a basic pr<strong>of</strong>ile<br />

with constant edge radius.

Linear friction welding (LFW) has proven to be<br />

a suitable method to produce <strong>the</strong> highly<br />

stressed joint between <strong>the</strong> blades and <strong>the</strong> disk<br />

and is now used in production. Fur<strong>the</strong>r development<br />

efforts in this field are mainly targeted<br />

at <strong>the</strong> machine technology to achieve higher<br />

flexibility with respect to <strong>the</strong> various component<br />

geometries to be joined.<br />

Since <strong>the</strong> LFW technique calls for highly engineered<br />

machinery and presupposes certain<br />

geometric conditions regarding <strong>the</strong> components<br />

to be produced, <strong>the</strong> next generation <strong>of</strong><br />

blisk joining techniques is presently being developed:<br />

<strong>the</strong> inductive high-frequency pressure<br />

(IHFP) welding process.<br />

Figure 6: Detail parts and<br />

blisk joined by LFW<br />

Here, <strong>the</strong> energy required to heat <strong>the</strong> materials<br />

to be joined is produced by high-frequency<br />

alternating electromagnetic fields so that <strong>the</strong><br />

complicated machinery needed in <strong>the</strong> LFW<br />

process to produce <strong>the</strong> mechanical vibrations<br />

and high joining forces is no longer required.<br />

Ano<strong>the</strong>r benefit <strong>of</strong> <strong>the</strong> technique is that <strong>the</strong><br />

component proper is subjected to lower<br />

stresses during welding.<br />

1<br />

4<br />

3<br />

2<br />

1= HF generator<br />

2= Welding equipment<br />

3= Hydraulic system<br />

4= CNC control unit<br />

Figures 7 IHFP welding machine<br />

1<br />

Figure 8: section through a IHFP welded joint.<br />

Figure 9: Simulation <strong>of</strong> <strong>the</strong> heating process<br />

during IHFP welding<br />

Presently, <strong>the</strong> technology is being matured for<br />

common joints on titanium materials and crosssections<br />

from <strong>the</strong> fan area to <strong>the</strong> low-pressure<br />

compressor. In <strong>the</strong> process, a capable simulation<br />

<strong>of</strong> coil / alternating field is used which is<br />

particularly suited for <strong>the</strong> component geometry<br />

and significantly reduces parameter testing.<br />

3.2.2 Milling<br />

At <strong>MTU</strong> <strong>Aero</strong> <strong>Engines</strong>, milling is <strong>the</strong> most<br />

commonly used technique to produce blisk<br />

airfoils. In this field, a holistic approach to <strong>the</strong><br />

milling process—machine, setup, milling strategy,<br />

tooling, tool holders, coolant-lubricant,<br />

etc.—helped achieve considerable savings. A<br />

significant contribution came from <strong>the</strong> <strong>MTU</strong>patented<br />

circular stagger milling process.<br />

While with conventional milling <strong>the</strong> angle <strong>of</strong><br />

contact may be up to 180°, this angle is limited<br />

to 30° to 60° with circular milling. This reduces<br />

<strong>the</strong> cutting forces and increases <strong>the</strong> material<br />

removal rate by means larger cutting depths<br />

and higher cutting speeds.

angle <strong>of</strong> contact<br />

angle <strong>of</strong> contact<br />

Figure 10: Angle <strong>of</strong> contact with circular<br />

and conventional milling<br />

Figure 11: Milling on a 5-axis machine<br />

Essential prerequisites for high-performance<br />

machining using <strong>the</strong> circular milling approach<br />

are <strong>the</strong> selection <strong>of</strong> <strong>the</strong> most suitable cutter<br />

material and <strong>the</strong> definition <strong>of</strong> an optimum cutter<br />

geometry. Also, <strong>the</strong> life <strong>of</strong> <strong>the</strong> rough-milling<br />

tools can be more than doubled with an appropriate<br />

edge preparation.<br />

Rounding <strong>of</strong> <strong>the</strong> cutting edge markedly reduces<br />

<strong>the</strong> risk <strong>of</strong> micro-chipping, and <strong>the</strong> cutting<br />

edge normally exhibits a uniform rubbing<br />

wear.<br />

Figure 12: Sharp-edged and rounded edge <strong>of</strong><br />

a rough-milling cutter for blisk machining<br />

These highly dynamic milling processes are<br />

performed using special 5-axis milling machines.<br />

The necessary acceleration can be<br />

achieved by means <strong>of</strong> direct axis drives.<br />

3.2.3 ECM / PECM<br />

So far, <strong>the</strong> advantage <strong>of</strong> electrochemical machining<br />

processes used in <strong>the</strong> production <strong>of</strong><br />

airfoil geometries, i.e. minimum tool wear, has<br />

been <strong>of</strong>fset by <strong>the</strong> drawback <strong>of</strong> inaccurate<br />

contours particularly in <strong>the</strong> edge and radius<br />

areas and a relatively long iteration process.<br />

These disadvantages have now been overcome<br />

by a fur<strong>the</strong>r development <strong>of</strong> <strong>the</strong> process,<br />

<strong>the</strong> so-called precise electrochemical machining<br />

(PECM) technique. A reliable and precise<br />

control <strong>of</strong> this process, which involves very<br />

small gaps between component and vibrating<br />

electrode, has now been made possible by<br />

fur<strong>the</strong>r developments in semiconductor technology<br />

and control systems (precise pulsing<br />

and response times in <strong>the</strong> microsecond range<br />

at high machining currents).<br />

The results <strong>of</strong> trials have shown that, in <strong>the</strong><br />

case <strong>of</strong> materials which are difficult to machine<br />

(nickel-base alloys, nickel PM material), PECM<br />

is distinctly superior to milling in terms <strong>of</strong> machining<br />

speed, tool wear, surface finish, and<br />

process stability <strong>of</strong> <strong>the</strong> geometric features. The<br />

technology has been matured for production<br />

use by <strong>MTU</strong> <strong>Aero</strong> <strong>Engines</strong> and first development<br />

hardware is being machined on prototype<br />

facilities.<br />

Continuous<br />

feed<br />

Part<br />

Part<br />

´Tool<br />

Tool<br />

(-)<br />

(+)<br />

ECM for rough-machining<br />

(electrochemical machining)<br />

• gap > 1 mm<br />

• lower accuracy<br />

• high removal rates<br />

(-)<br />

(+)<br />

Electrolyte<br />

Pulsed<br />

feed<br />

PECM for finishing<br />

(precise electrochemical machining)<br />

•extremely narrow, controlled gap<br />

< 0.1 mm<br />

• pulsed current<br />

• increased accuracy <strong>of</strong> forming<br />

• lower removal rates<br />

Figure 13: ECM / PECM operating principle

ECM premachining<br />

PECM finishing<br />

Figure 14: <strong>Blisk</strong> manufacture by a combination<br />

<strong>of</strong> ECM premachining and PECM finishing –<br />

airfoil geometries and surfaces.<br />

3.2.4 Shot peening<br />

Most <strong>of</strong> <strong>Blisk</strong> blades are subject to controlled<br />

shot peening to increase <strong>the</strong>ir fatigue strength.<br />

Alongside conventional shot peening <strong>MTU</strong><br />

<strong>Aero</strong> <strong>Engines</strong> uses ultra-sound assisted shot<br />

peening which <strong>of</strong>fers <strong>the</strong> advantage <strong>of</strong> minimum<br />

component distortion, since both airfoil<br />

sides are normally compacted simultaneously.<br />

schematic<br />

Figure 15: Test setup for US shot peening<br />

Part<br />

Peening Chamber<br />

Sonotrode<br />

Piezo Shaker<br />

Controller<br />

+ Amplifier<br />

SONATS<br />

Figure 16: Principe <strong>of</strong> US shot peening<br />

Conventional shot peening<br />

Intensity: 0.2 A, coverage: 125 %<br />

US shot peening<br />

Intensity: 0.2 A, coverage 150 %<br />

250µm<br />

Figure 17: Comparison <strong>of</strong> <strong>the</strong> surface texture<br />

achieved by a) conventional and b) US shot<br />

peening<br />

Since US shot peening does not increase <strong>the</strong><br />

roughness <strong>of</strong> <strong>the</strong> airfoil surfaces, in particular<br />

in <strong>the</strong> leading and trailing edge areas, postpeening<br />

finishing processes that had to be<br />

performed after conventional shot peening are<br />

no longer required.

3.2.5 Quality assurance<br />

In this area, optical measuring techniques hold<br />

promise <strong>of</strong> time savings and more reliable<br />

quality statements as compared with conventional<br />

measurements using coordinate measuring<br />

machines (CMM).<br />

In contrast to conventional assembly <strong>of</strong> rotors,<br />

<strong>the</strong> manufacture <strong>of</strong> blisks is subject to particularly<br />

stringent requirements in terms <strong>of</strong> airfoil<br />

location, radius and airfoil pr<strong>of</strong>ile tolerances.<br />

Depending on <strong>the</strong> stability <strong>of</strong> <strong>the</strong> manufacturing<br />

process used, <strong>the</strong>refore, extensive dimensional<br />

inspections must be performed in <strong>the</strong><br />

course <strong>of</strong> in-process and final inspection.<br />

Compared with <strong>the</strong> tactile systems used on<br />

CMMs today’s advanced optical systems <strong>of</strong>fer<br />

great potential <strong>of</strong> reducing <strong>the</strong> inspection effort.<br />

They need far less time to provide complete<br />

models <strong>of</strong> <strong>the</strong> components which can <strong>the</strong>n be<br />

verified by means <strong>of</strong> computation routines, for<br />

example to assess manufacturing deviations in<br />

boundary cases.<br />

In cooperation with <strong>the</strong> measuring system<br />

manufacturers, <strong>MTU</strong> <strong>Aero</strong> <strong>Engines</strong> has succeeded<br />

in improving <strong>the</strong> accuracy <strong>of</strong> <strong>the</strong> systems<br />

also for dimensional inspection <strong>of</strong> leading<br />

and trailing edges, for example.<br />

Figure 18: Dimensional inspection <strong>of</strong> a blisk<br />

Figure 19 : Leading and trailing edges inspected<br />

using optical systems<br />

3.2.6 Repair<br />

Due to <strong>the</strong> integral construction <strong>of</strong> blisks a<br />

variety <strong>of</strong> repair processes needs to be modified<br />

or newly developed. Repairs that go beyond<br />

<strong>the</strong> scope <strong>of</strong> blending, a standard repair<br />

method also for individual blades, involve<br />

processes, such as buildup welding or patching<br />

that call for perfectly matched process<br />

steps, particularly when recoating or subsequent<br />

heat treatments are required.<br />

Repair processes<br />

Figure 20 : Repair categories A, B, C, D<br />

Of <strong>the</strong> repair categories illustrated above, <strong>the</strong><br />

replacement <strong>of</strong> complete airfoils poses <strong>the</strong><br />

most exacting requirements, as this repair<br />

involves <strong>the</strong> use <strong>of</strong> cutting and joining processes<br />

in <strong>the</strong> vicinity <strong>of</strong> critical component<br />

zones. Category A to C repairs are already<br />

used at <strong>MTU</strong> AERO ENGINES, category D is<br />

being developed.<br />

4. <strong>Future</strong> developments<br />

4.1 New designs<br />

The blisk design having become state-<strong>of</strong>-<strong>the</strong>art<br />

in <strong>the</strong> entire compressor area, including <strong>the</strong><br />

high-temperature-resistant high-pressure compressor<br />

stages, <strong>MTU</strong> <strong>Aero</strong> <strong>Engines</strong> is now<br />

working on <strong>the</strong> development <strong>of</strong> fabricated,<br />

high-stressed low-pressure turbine blisks.<br />

Unlike with <strong>the</strong> smaller, integrally cast variants<br />

used, for example, in auxiliary power units<br />

(APUs), <strong>the</strong> special challenge to be overcome<br />

here in manufacturing is <strong>the</strong> material mix <strong>of</strong><br />

forged disks and high-temperature cast blades<br />

and even single-crystal materials.<br />

Figure 21: Design example <strong>of</strong> a fabricated<br />

turbine blisk

4.2 Materials<br />

New engine concepts with enhanced efficiencies<br />

call for <strong>the</strong> use <strong>of</strong> high-strength and hightemperature<br />

alloys. In <strong>the</strong> low-pressure compressor,<br />

<strong>the</strong> simple titanium alloy Ti6V4 is increasingly<br />

being replaced by <strong>the</strong> alloys Ti6242<br />

or Ti6246, and in <strong>the</strong> high-pressure compressor,<br />

<strong>the</strong> modified alloy DA718 with approx. 7 %<br />

more strength is being used instead <strong>of</strong> <strong>the</strong><br />

standard alloy IN718. The last compressor<br />

stages upstream <strong>of</strong> <strong>the</strong> combustion chamber<br />

which are subject to higher <strong>the</strong>rmal stresses<br />

will be made from PM nickel alloys. With <strong>the</strong>se<br />

materials, electrochemical machining processes<br />

are particularly cost-effective.<br />

4.3 Surfaces<br />

To protect blisk blades from erosion by sand<br />

and dust, <strong>MTU</strong> <strong>Aero</strong> <strong>Engines</strong> has developed<br />

new protective coatings which have meanwhile<br />

become <strong>the</strong> standard coatings for airlines operating<br />

in erosive environments. In <strong>the</strong> coating<br />

area, too, poor accessibility <strong>of</strong> <strong>the</strong> blisk calls for<br />

special processes.<br />

Figure 22: <strong>Blisk</strong> airfoils with anti-erosion coating<br />

With aerodynamically optimized compressors,<br />

highest surface finish requirements have to be<br />

satisfied especially in <strong>the</strong> high-pressure compressor<br />

area. To achieve <strong>the</strong> surface finishes<br />

needed blisks with <strong>the</strong>ir special geometrical<br />

constraints have to be processed using o<strong>the</strong>r<br />

and, above all, more cost-effective techniques<br />

than those used on individual blades. In this<br />

field, automated electrochemical process sequences<br />

and o<strong>the</strong>r processes are being tested<br />

at present.<br />

4.4 Quality assurance<br />

<strong>Blisk</strong>s are inspected using <strong>the</strong> standard inspection<br />

methods developed for conventional<br />

disks, such as fluorescent penetrant inspection,<br />

ultrasonic inspection and segregation<br />

etching. For <strong>the</strong> inspection <strong>of</strong> blanks, phased<br />

array technologies are presently being fur<strong>the</strong>r<br />

developed and adapted to suit <strong>the</strong> particular<br />

requirements. Such technologies with <strong>the</strong>ir<br />

high resolution permit production inspection to<br />

be performed quickly and effectively.<br />

4.5 Design<br />

Highly advanced 3D design tools are used in<br />

<strong>the</strong> design <strong>of</strong> <strong>the</strong> blisk blades. Present-day<br />

airfoils are highly twisted, <strong>the</strong> edges frequently<br />

having <strong>the</strong> form <strong>of</strong> an “S”. The blade tips are<br />

hard-faced to protect <strong>the</strong>m against rubbing<br />

wear. These features result in new challenges<br />

for manufacturing technology.<br />

Figure 23 : 3D CAD model <strong>of</strong> a high-pressure<br />

compressor blade<br />

4.6 Industrial production concepts<br />

The manufacturing concept presented here<br />

bases on <strong>the</strong> following prerequisites:<br />

- Tool box concept<br />

The cost-effective and high-quality manufacture<br />

<strong>of</strong> a wide spectrum <strong>of</strong> different blisk types<br />

is possible only by <strong>the</strong> combination <strong>of</strong> various<br />

core manufacturing techniques for airfoiling.<br />

- High investments into <strong>the</strong> special machinery<br />

required are necessary to put <strong>the</strong> tool box concept<br />

in place. Therefore, <strong>the</strong> manufacturing<br />

concept must ensure optimum utilization <strong>of</strong> <strong>the</strong><br />

special machines.<br />

- Owing to <strong>the</strong> integral construction and <strong>the</strong><br />

criticality <strong>of</strong> <strong>the</strong> component and <strong>the</strong> associated<br />

interdependence <strong>of</strong> important quality characteristics<br />

maximum control over an essential<br />

part <strong>of</strong> <strong>the</strong> manufacturing process chain must<br />

be ensured.

- Long response times regarding <strong>the</strong> current<br />

quality situation <strong>of</strong> individual manufacturing<br />

processes must be avoided. A prompt quality<br />

control <strong>of</strong> <strong>the</strong> processes with effective possibilities<br />

to interfere with <strong>the</strong> processes is a must.<br />

Against this background two basic manufacturing<br />

approaches are conceivable:<br />

I) Central concept<br />

Processes that do not form part <strong>of</strong> <strong>the</strong> core<br />

manufacturing techniques are used for <strong>the</strong><br />

entire parts spectrum and are designed to<br />

ensure adequate flexibility <strong>of</strong> machines and<br />

fixtures. Whe<strong>the</strong>r and when a new core manufacturing<br />

technique is included in <strong>the</strong> tool box<br />

depends on <strong>the</strong> parts volume to be processed.<br />

As long as this volume is below a cost-effective<br />

threshold value <strong>the</strong> parts must be processed<br />

using o<strong>the</strong>r methods.<br />

II) Decentral concept<br />

The parts volume for an optimum combination<br />

<strong>of</strong> core manufacturing techniques must be<br />

such that a complete autonomous process<br />

chain is justifiable from <strong>the</strong> economic point <strong>of</strong><br />

view.<br />

pre-stage<br />

parts<br />

Figure 24: Central Concept<br />

p re-stag e<br />

p arts<br />

p re-stag e<br />

p arts<br />

.<br />

.<br />

.<br />

Figure 25: Decentral concept<br />

pre-airfoiling<br />

processes<br />

p re-airfoiling<br />

p ro cesses I<br />

p re-airfoiling<br />

p ro cesses II<br />

.<br />

.<br />

.<br />

rough airfoiling<br />

5. Summary<br />

In advanced engine concepts, blisk construction<br />

makes an important contribution towards<br />

optimizing efficiencies and reducing weight.<br />

Therefore, blisks will find increasing use, also<br />

in <strong>the</strong> turbine area.<br />

To be able to manufacture <strong>the</strong>se critical and<br />

highly stressed engine components in a costeffective<br />

manner, a variety <strong>of</strong> sophisticated<br />

manufacturing and quality techniques is<br />

needed. These have <strong>the</strong>n to be combined into<br />

process chains optimally designed to suit <strong>the</strong><br />

various types <strong>of</strong> blisks to ensure best results in<br />

terms <strong>of</strong> costs and quality.<br />

finish airfoiling<br />

milling PECM<br />

welding<br />

X X<br />

milling X X<br />

ECM X X<br />

airfo ilin g<br />

p ro cess I<br />

airfo ilin g<br />

p ro cess II<br />

.<br />

.<br />

.<br />

post-airfoiling<br />

processes<br />

p o st-airfo ilin g<br />

p ro cesses I<br />

p o st-airfo ilin g<br />

p ro cesses II<br />

.<br />

.<br />

.<br />

quality<br />

inspection<br />

q u ality<br />

in sp ectio n<br />

q u ality<br />

in sp ectio n<br />

.<br />

.<br />

.

![Download PDF [5,37 MB] - MTU Aero Engines](https://img.yumpu.com/21945461/1/190x125/download-pdf-537-mb-mtu-aero-engines.jpg?quality=85)