Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

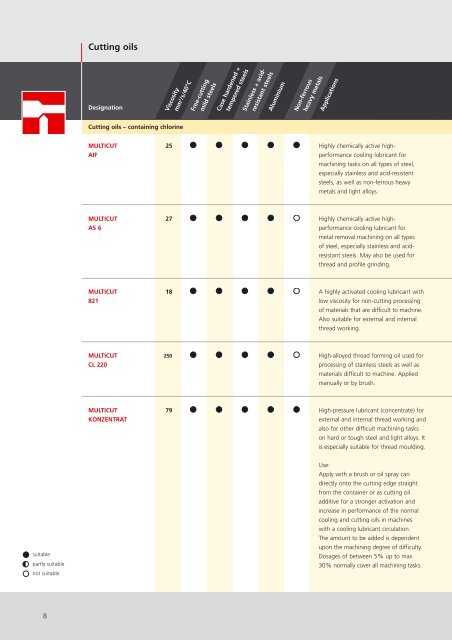

suitable<br />

partly suitable<br />

not suitable<br />

8<br />

Cutting oils<br />

Designation Viscosity<br />

Cutting oils – containing chlorine<br />

MULTICUT<br />

AIF<br />

MULTICUT<br />

AS 6<br />

MULTICUT<br />

821<br />

MULTICUT<br />

CL 220<br />

MULTICUT<br />

KONZENTRAT<br />

25<br />

27<br />

18<br />

250<br />

79<br />

mm 2 /s/40°C<br />

Free-cutting<br />

mild steels<br />

Case hardened +<br />

tempered steels<br />

Stainless + acidresistant<br />

steels<br />

Aluminium<br />

Non-ferrous<br />

heavy metals<br />

Applications<br />

Highly chemically active highperformance<br />

cooling lubricant for<br />

machining tasks on all types of steel,<br />

especially stainless and acid-resistent<br />

steels, as well as non-ferrous heavy<br />

metals and light alloys.<br />

Highly chemically active highperformance<br />

cooling lubricant for<br />

metal removal machining on all types<br />

of steel, especially stainless and acidresistant<br />

steels. May also be used for<br />

thread and profile grinding.<br />

A highly activated cooling lubricant with<br />

low viscosity for non-cutting processing<br />

of materials that are difficult to machine.<br />

Also suitable for external and internal<br />

thread working.<br />

High-alloyed thread forming oil used for<br />

processing of stainless steels as well as<br />

materials difficult to machine. Applied<br />

manually or by brush.<br />

High-pressure lubricant (concentrate) for<br />

external and internal thread working and<br />

also for other difficult machining tasks<br />

on hard or tough steel and light alloys. It<br />

is especially suitable for thread moulding.<br />

Use:<br />

Apply with a brush or oil spray can<br />

directly onto the cutting edge straight<br />

from the container or as cutting oil<br />

additive for a stronger activation and<br />

increase in performance of the normal<br />

cooling and cutting oils in machines<br />

with a cooling lubricant circulation.<br />

The amount to be added is dependent<br />

upon the machining degree of difficulty.<br />

Dosages of between 5% up to max.<br />

30% normally cover all machining tasks.