a study on fine grinding process in jet mill - ePrints@USM

a study on fine grinding process in jet mill - ePrints@USM

a study on fine grinding process in jet mill - ePrints@USM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

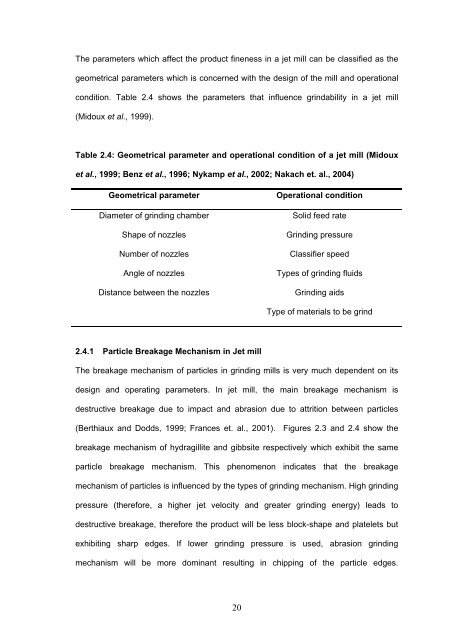

The parameters which affect the product <strong>f<strong>in</strong>e</strong>ness <strong>in</strong> a <strong>jet</strong> <strong>mill</strong> can be classified as the<br />

geometrical parameters which is c<strong>on</strong>cerned with the design of the <strong>mill</strong> and operati<strong>on</strong>al<br />

c<strong>on</strong>diti<strong>on</strong>. Table 2.4 shows the parameters that <strong>in</strong>fluence gr<strong>in</strong>dability <strong>in</strong> a <strong>jet</strong> <strong>mill</strong><br />

(Midoux et al., 1999).<br />

Table 2.4: Geometrical parameter and operati<strong>on</strong>al c<strong>on</strong>diti<strong>on</strong> of a <strong>jet</strong> <strong>mill</strong> (Midoux<br />

et al., 1999; Benz et al., 1996; Nykamp et al., 2002; Nakach et. al., 2004)<br />

Geometrical parameter Operati<strong>on</strong>al c<strong>on</strong>diti<strong>on</strong><br />

Diameter of <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> chamber Solid feed rate<br />

Shape of nozzles Gr<strong>in</strong>d<strong>in</strong>g pressure<br />

Number of nozzles Classifier speed<br />

Angle of nozzles Types of <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> fluids<br />

Distance between the nozzles Gr<strong>in</strong>d<strong>in</strong>g aids<br />

2.4.1 Particle Breakage Mechanism <strong>in</strong> Jet <strong>mill</strong><br />

Type of materials to be gr<strong>in</strong>d<br />

The breakage mechanism of particles <strong>in</strong> <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> <strong>mill</strong>s is very much dependent <strong>on</strong> its<br />

design and operat<strong>in</strong>g parameters. In <strong>jet</strong> <strong>mill</strong>, the ma<strong>in</strong> breakage mechanism is<br />

destructive breakage due to impact and abrasi<strong>on</strong> due to attriti<strong>on</strong> between particles<br />

(Berthiaux and Dodds, 1999; Frances et. al., 2001). Figures 2.3 and 2.4 show the<br />

breakage mechanism of hydragillite and gibbsite respectively which exhibit the same<br />

particle breakage mechanism. This phenomen<strong>on</strong> <strong>in</strong>dicates that the breakage<br />

mechanism of particles is <strong>in</strong>fluenced by the types of <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> mechanism. High <strong>gr<strong>in</strong>d<strong>in</strong>g</strong><br />

pressure (therefore, a higher <strong>jet</strong> velocity and greater <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> energy) leads to<br />

destructive breakage, therefore the product will be less block-shape and platelets but<br />

exhibit<strong>in</strong>g sharp edges. If lower <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> pressure is used, abrasi<strong>on</strong> <strong>gr<strong>in</strong>d<strong>in</strong>g</strong><br />

mechanism will be more dom<strong>in</strong>ant result<strong>in</strong>g <strong>in</strong> chipp<strong>in</strong>g of the particle edges.<br />

20

![[Consumer Behaviour] - ePrints@USM](https://img.yumpu.com/21924816/1/184x260/consumer-behaviour-eprintsusm.jpg?quality=85)