Spiral Retaining Rings & Wave Springs - Bearing Engineers, Inc.

Spiral Retaining Rings & Wave Springs - Bearing Engineers, Inc.

Spiral Retaining Rings & Wave Springs - Bearing Engineers, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

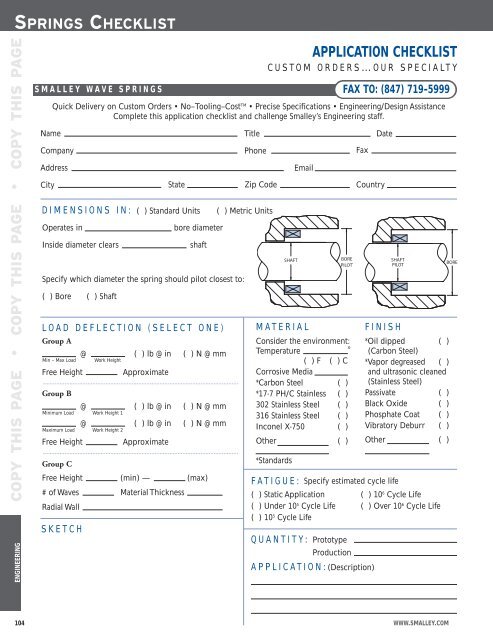

SPRINGS CHECKLIST<br />

COPY THIS PAGE · COPY THIS PAGE · COPY THIS PAGE<br />

ENGINEERING<br />

SMALLEY WAVE SPRINGS<br />

Name<br />

APPLICATION CHECKLIST<br />

CUSTOM ORDERS…OUR SPECIALTY<br />

FAX TO: (847) 719-5999<br />

Quick Delivery on Custom Orders • No–Tooling–Cost TM • Precise Specifications • Engineering/Design Assistance<br />

Complete this application checklist and challenge Smalley’s Engineering staff.<br />

Company<br />

Address<br />

City<br />

DIMENSIONS IN: ( ) Standard Units<br />

Operates in bore diameter<br />

Inside diameter clears shaft<br />

Specify which diameter the spring should pilot closest to:<br />

( ) Bore ( ) Shaft<br />

LOAD DEFLECTION (SELECT ONE)<br />

Group A<br />

@ ( ) lb @ in ( ) N @ mm<br />

Min – Max Load Work Height<br />

Free Height Approximate<br />

Group B<br />

@ ( ) lb @ in ( ) N @ mm<br />

Minimum Load Work Height 1<br />

@ ( ) lb @ in ( ) N @ mm<br />

Maximum Load Work Height 2<br />

Free Height Approximate<br />

Group C<br />

Free Height (min) — (max)<br />

# of <strong>Wave</strong>s<br />

Radial Wall<br />

Material Thickness<br />

SKETCH<br />

104 WWW.SMALLEY.COM<br />

Title<br />

Phone<br />

Email<br />

Fax<br />

State Zip Code Country<br />

( ) Metric Units<br />

MATERIAL<br />

Consider the environment:<br />

Temperature ˚<br />

( ) F<br />

Corrosive Media<br />

( ) C<br />

*Carbon Steel ( )<br />

*17-7 PH/C Stainless ( )<br />

302 Stainless Steel ( )<br />

316 Stainless Steel ( )<br />

<strong>Inc</strong>onel X-750 ( )<br />

Other ( )<br />

*Standards<br />

QUANTITY: Prototype<br />

Production<br />

APPLICATION:(Description)<br />

Date<br />

FINISH<br />

*Oil dipped<br />

(Carbon Steel)<br />

( )<br />

*Vapor degreased ( )<br />

and ultrasonic cleaned<br />

(Stainless Steel)<br />

Passivate ( )<br />

Black Oxide ( )<br />

Phosphate Coat ( )<br />

Vibratory Deburr ( )<br />

Other ( )<br />

FATIGUE: Specify estimated cycle life<br />

( ) Static Application ( ) 106 Cycle Life<br />

( ) Under 105 Cycle Life ( ) Over 106 Cycle Life<br />

( ) 105 Cycle Life