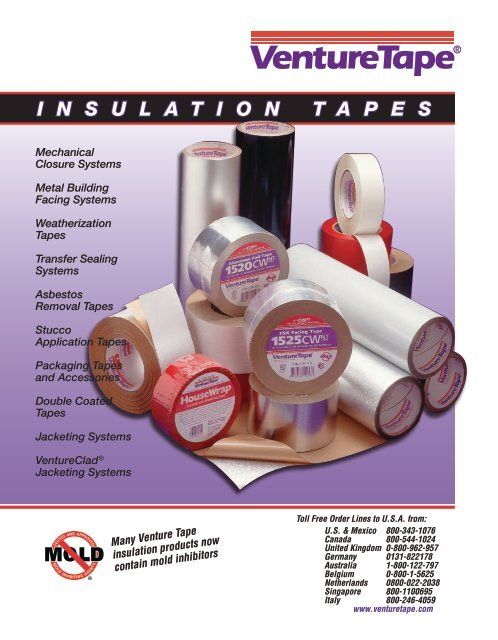

I N S U L A T I O N T A P E S - Venture Tape

I N S U L A T I O N T A P E S - Venture Tape

I N S U L A T I O N T A P E S - Venture Tape

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

I N S U L A T I O N T A P E S<br />

Mechanical<br />

Closure Systems<br />

Metal Building<br />

Facing Systems<br />

Weatherization<br />

<strong>Tape</strong>s<br />

Transfer Sealing<br />

Systems<br />

Asbestos<br />

Removal <strong>Tape</strong>s<br />

Stucco<br />

Application <strong>Tape</strong>s<br />

Packaging <strong>Tape</strong>s<br />

and Accessories<br />

Double Coated<br />

<strong>Tape</strong>s<br />

Jacketing Systems<br />

<strong>Venture</strong>Clad ®<br />

Jacketing Systems<br />

Many <strong>Venture</strong> <strong>Tape</strong><br />

insulation products now<br />

contain mold inhibitors<br />

Toll Free Order Lines to U.S.A. from:<br />

U.S. & Mexico 800-343-1076<br />

Canada 800-544-1024<br />

United Kingdom 0-800-962-957<br />

Germany 0131-822178<br />

Australia 1-800-122-797<br />

Belgium 0-800-1-5625<br />

Netherlands 0800-022-2038<br />

Singapore 800-1100695<br />

Italy 800-246-4059<br />

www.venturetape.com

The headquarters of <strong>Venture</strong> <strong>Tape</strong> Corp. houses research and development, product testing laboratories, sales,<br />

customer service and product training. Expanded to 234,000 square feet, it contains our specially designed,<br />

state-of-the-art manufacturing facility. Planned for peak efficiency, this plant features the industry’s latest<br />

developments in process equipment and controls, as well as custom machinery available to no other tape<br />

manufacturer.<br />

is a team of highly qualified professionals<br />

working together to provide our customers<br />

with the highest quality products and the greatest economic value. Our mission is to seek<br />

continuous improvement in everything that we do. We are operating our business in a way<br />

that safeguards the well-being of our people, our customers and our neighbors.<br />

We strive to give you, our customers, the latest, best and most innovative<br />

technology which will allow you to stay in the forefront in your industry at a cost that gives<br />

you maximum economic value.<br />

<strong>Venture</strong> <strong>Tape</strong> Corp.<br />

30 Commerce Road<br />

Rockland, Massachusetts 02370 U.S.A.<br />

Tel 781-331-5900<br />

800-343-1076 (U.S.A.)<br />

Fax: 781-871-0065<br />

www.venturetape.com<br />

Printed in U.S.A. 6/09<br />

Most <strong>Venture</strong> <strong>Tape</strong> products are shipped from<br />

stock, from warehouses in:<br />

Rockland, MA<br />

Atlanta, GA<br />

Houston, TX<br />

City of Industry, CA<br />

Chicago, IL<br />

Milwaukee, WI<br />

Portland, OR<br />

Canada<br />

Australia<br />

United Kingdom<br />

Singapore<br />

Netherlands<br />

Italy

Contents Page Contents<br />

Page<br />

Mechanical Closure Systems ......................5<br />

1500 Waterproof Cloth Duct ........................ 5<br />

1501 Utility Grade Coated Cloth Duct ......... 5<br />

1502 Metalized Cloth Duct .......................... 5<br />

1556 Pro Grade Waterproof Cloth Duct ....... 5<br />

1557 Premium Cloth Duct .......................... 5<br />

1513CW 1mil (25 µ) Aluminum Foil ................. 5<br />

1514CW Foil/Kraft Insulation............................ 5<br />

1517CW 1.2 mil (30 µ) Aluminum Foil ............. 5<br />

3243 2 mil High Temp. Aluminum Foil ....... 6<br />

1521CW High Tack 1.5 mil (38 µ)<br />

Aluminum Foil ................................... 6<br />

3531 1.5 mil (38 µ) Rubber Based<br />

Aluminum Foil ................................... 6<br />

2521CW High Tack 1.5 mil (38 µ) Aluminum<br />

Foil Self Wound ................................. 6<br />

1520CW 2 mil (50 µ) Aluminum Foil ................ 6<br />

2520CW 2 mil (50 µ) Aluminum Foil<br />

Self Wound ........................................ 6<br />

6520CW 2 mil (50 µ) Aluminum Foil<br />

Self Wound ........................................ 6<br />

3520CW 2 mil (50 µ) HVAC Aluminum Foil ..... 6<br />

3530 2 mil (50 µ) Rubber Based<br />

Aluminum Foil ................................... 7<br />

1580 & 1580P UL-181B-FX Listed Duct Joint<br />

Sealing <strong>Tape</strong> ....................................... 7<br />

1581A UL-181A Printed 2 mil (50 µ)<br />

Aluminum Foil Ductboard .................. 7<br />

1511CW 1.5 mil (38 µ) White Aluminum Foil ... 7<br />

1519CW 3 mil (75 µ) Aluminum Foil Duct ....... 7<br />

2519CW 3 mil (75 µ) Aluminum Foil Duct<br />

Self Wound ........................................ 7<br />

6519CW 3 mil (75 µ) Aluminum Foil Duct<br />

Self Wound ........................................ 7<br />

1525CW FSK Facing......................................... 7<br />

3525 FSK Rubber Based Facing <strong>Tape</strong> .......... 9<br />

1599B UL-181B-FX Flexible Duct Closure .... 9<br />

1528CW & SQ FSK Vapor Seal Disks & Squares ....... 9<br />

1529CW Polyethylene Reinforced Foil <strong>Tape</strong> ...... 9<br />

3529HT Polyethylene Reinforced Foil <strong>Tape</strong> ...... 9<br />

1538CW WMP-DW Reinforced Black<br />

Polypropylene Facing <strong>Tape</strong> ................ 9<br />

1540CW ASJ Facing ......................................... 9<br />

1542CW & SQ ASJ Vapor Seal Disks & Squares ....... 9<br />

1555CW Cryogenic Vapor Barrier <strong>Tape</strong> ............. 9<br />

1585CW-2 Sheathing ........................................ 10<br />

1585CW-P2 Printed Red Sheathing ..................... 10<br />

1506R 5 mil (125 µ) Vinyl Seal ................... 10<br />

1506CW 6 mil (150 µ) Vinyl Seal ................... 10<br />

1507 3 mil (75 µ) Line Set <strong>Tape</strong> ................ 10<br />

1509 Polyfoam <strong>Tape</strong> .................................. 10<br />

1510R 10 mil (250 µ) Vinyl Seal ................. 10<br />

1570CW Tedlar® Facing; White ..................... 10<br />

1571CW Tedlar® Facing; Gray ....................... 10<br />

Asbestos removal/Weatherization Products ... 11<br />

1500 Waterproof Cloth Duct ......................11<br />

1501 Utility Grade Coated Cloth Duct .......11<br />

912 Black Polyethylene <strong>Tape</strong> ...................11<br />

919 PE Butt Strip/ Splicing .....................11<br />

923 Clear PE Removable .........................11<br />

523 Removable Double Coated<br />

1 mil (25 µ) PET ...............................11<br />

581 Double Coated Cloth ........................11<br />

921CW Clear Polyethylene ...........................11<br />

Jacketing Systems ................................ 12<br />

1527 Non-Adhesive FSK ........................... 12<br />

2537 White Polypropylene/Kraft ............... 12<br />

1541 Non-Adhesive ASJ ........................... 12<br />

1541S Non-Adhesive ASJ w/ SSL ............... 12<br />

1574CW <strong>Venture</strong>Guard® Facing <strong>Tape</strong> ............ 12<br />

1577CW <strong>Venture</strong>Clad® Facing <strong>Tape</strong> .............. 12<br />

1578CW <strong>Venture</strong>Clad® Facing <strong>Tape</strong> .............. 12<br />

1579CW <strong>Venture</strong>Clad Plus® Facing <strong>Tape</strong> ...... 12<br />

1555U <strong>Venture</strong>Wrap Laminate .................. 13<br />

1577CW <strong>Venture</strong>Clad® Pre-cut Sheets .......... 13<br />

Metal Building Facing Systems ................. 15<br />

1531CW WMP®-10 PP Facing ...................... 15<br />

1532CW Reinforced White Vinyl <strong>Tape</strong> ............. 15<br />

1535CW WCF®-50 Facing <strong>Tape</strong> .................... 15<br />

1537CW WMP®-VR PP Facing ..................... 15<br />

1545CW VRP®-3 Vinyl Facing ...................... 15<br />

1547CW WMP®-VR-R Facing ....................... 15<br />

1549CW FSK HD Facing................................. 15<br />

1551CW WMP®-50 Polypropylene Facing .... 15<br />

1558HT 2 mil (50 µ) White Aluminum Foil .... 16<br />

1562CW WMP®-F Facing ............................. 16<br />

1565CW VR-RHD Metal Building Facing ........ 16<br />

1567CW VRV Metal Building Facing .............. 16<br />

1568CW VR-R Metal Building Facing ............. 16<br />

1582CW Arenashield Reinforced<br />

Aluminum Foil Facing ...................... 16<br />

1583CW Gymguard Reinforced Metalized<br />

White PP Facing............................... 16<br />

442B&W Woven Copolymer Patch <strong>Tape</strong> .......... 16<br />

442BLL Woven Copolymer Patch <strong>Tape</strong> .......... 17<br />

450 Woven PE Sealing ............................ 17<br />

460 Series Embossed Vinyl, White, Black, Gray 17<br />

600 Series Double Coated Foam <strong>Tape</strong>/Rubber ... 17<br />

700 Series Double Coated Foam <strong>Tape</strong>/Acrylic ... 17<br />

1700 Series Vinyl Foam Sealant .......................... 17<br />

Stucco <strong>Tape</strong>s ..................................... 18<br />

1499 Stucco Mask <strong>Tape</strong>, Red .................... 18<br />

1592 Stucco Seal EIFS <strong>Tape</strong> ...................... 18<br />

Packaging & Accessory <strong>Tape</strong>s .................. 18<br />

100 General Purpose Masking ................ 18<br />

200 Carton Sealing ................................. 18<br />

200P Printed Carton Sealing ..................... 18<br />

201 2 Inch (5.1 cm) <strong>Tape</strong> Applicator ....... 18<br />

203 3 Inch (7.6 cm) <strong>Tape</strong> Applicator ....... 18<br />

205 Strapping ......................................... 18<br />

Double Coated & Transfer Sealing Systems ... 19<br />

510 Double Coated PET/Rubber ............. 19<br />

512/60 Double Coated PET/Rubber ............. 19<br />

514CW Double Coated PET/Acrylic .............. 19<br />

518 Double Coated PET/Acrylic .............. 19<br />

592CW SSL 2 mil (50 µ) Acrylic Transfer ..... 19<br />

594CW SST 4 mil (100 µ) Acrylic Transfer ... 19<br />

5170 0.5 mil (12 µ) Double Coated PET ... 19<br />

1163/ms74 Double Coated 0.5 mil (12 µ)<br />

Ultra High Peel PET ......................... 19<br />

3604 Double Faced Polyester <strong>Tape</strong> ........... 21<br />

3683FR Fire Retardant Double Coated Tissue 21<br />

3693FLE FR Fire Retardant Double Coated<br />

Film w/ Finger Lift Edge ................... 21<br />

3694FLE FR FRFire Retardant Double Coated<br />

Film w/ Finger Lift Edge ................... 21<br />

3697FLE FR Double Coated, Fire Retardant<br />

Film <strong>Tape</strong> ......................................... 21<br />

3802(R) High Performance Transfer <strong>Tape</strong> ....... 21<br />

1153 High Performance Scrim<br />

Transfer <strong>Tape</strong> .................................... 21<br />

KEY<br />

ASJ — All Service Jacket<br />

CW — Cold Weather Adhesive Formulation<br />

DC — Double Coated<br />

FLE — Finger Lift Edge<br />

FR — Fire Retardant<br />

FSK — Foil/Scrim/Kraft<br />

HD — Heavy Duty<br />

HT — High Tack<br />

µ — Micron<br />

ms — Moisture Stable (liner)<br />

PE — Polyethylene<br />

PET — Polyester<br />

PP — Polypropylene<br />

R — Rubber Based Adhesive Formulation<br />

S — Strips<br />

SSL — Self Sealing Lap<br />

SST — Self Sealing Tab

About <strong>Venture</strong> Quality…<br />

ISO 9001:2000 Status<br />

<strong>Venture</strong> <strong>Tape</strong> is committed to providing the highest<br />

level of customer service. We strive to keep<br />

our customers up to date on order status, product<br />

availability, quotations, new products, quality, and<br />

other relevant issues. Honesty and integrity are the<br />

hallmarks of <strong>Venture</strong> <strong>Tape</strong> and the cornerstones of<br />

our permanent customer satisfaction commitment.<br />

This commitment to our customers has allowed<br />

<strong>Venture</strong> <strong>Tape</strong> to achieve ISO 9001:2000 status at<br />

its global facilities and insures product consistency<br />

worldwide. Beginning with product development, carrying<br />

through materials procurement, manufacturing,<br />

and delivery, we strive to match our products closely<br />

to customer needs. and meet our customers expectations<br />

every time. Our goal is always clear: Supply<br />

products which help solve problems.<br />

In addition to our extensive internal capabilities,<br />

<strong>Venture</strong> <strong>Tape</strong> welcomes customer input. Providing<br />

samples, application specific testing, and on-site<br />

consultation allows us to see our products in use<br />

and gives us an understanding of field performance,<br />

assuring that our products meet the most important<br />

specification of all: they work.<br />

Consult <strong>Venture</strong> <strong>Tape</strong> specialists for recommendations<br />

on product selection, specialized development<br />

and testing, and innovative answers to insulation<br />

challenges.<br />

About <strong>Venture</strong> Adhesives...<br />

Rubber-Based Adhesives<br />

Our tapes that indicate the use of rubber-based<br />

adhesives are fabricated with a premium formulation<br />

characterized by extreme aggressiveness,<br />

high-peel and high shear strengths. They show<br />

exceptionally good adhesion to low surface energy<br />

substrates such as polyethylene and polypropylene.<br />

They are generally recommended for interior use<br />

due to inherently low UV resistance. They are not<br />

recommended for use where temperatures may<br />

exceed 200°F (93°C).<br />

Although rubber-based adhesives form a superior<br />

bond, caution should be taken where resistance to<br />

temperatures above 180°F (82°C), UV exposure,<br />

solvents and weathering are required. <strong>Venture</strong><br />

acrylic formulations perform better in these circumstances.<br />

Acrylic Adhesives<br />

<strong>Venture</strong> <strong>Tape</strong> products specifying Acrylic Adhesives<br />

are uniformly manufactured with a specially<br />

developed formulation which combines exceptionally<br />

high shear strength with both high tack and<br />

cold stick properties, so important in working under<br />

less-than-ideal conditions. The bond strength of<br />

the products in this aggressive, high temperature<br />

adhesive family actually increases after application,<br />

through self cross-linking of its acrylic polymers.<br />

Cold Weather (CW) Acrylics<br />

Our tapes constructed with Cold Weather Acrylic<br />

Adhesives are formulated specially for handling<br />

in adverse conditions. A breakthrough in adhesive<br />

technology, these tapes retain their superior tack<br />

in cold, humid, even damp conditions, yet are heat<br />

stable up to 250°F (121°C). They are field tested<br />

and recommended for application in conditions as<br />

low as –10°F (–23°C). As with our other acrylic<br />

formulae, bond strength increases after adhesion,<br />

due to self cross-linking properties.<br />

Revolutionary New CW Plus!<br />

In 1990, <strong>Venture</strong> <strong>Tape</strong> introduced new CW Plus, an<br />

acrylic adhesive formula with 50% greater adhesion.<br />

It also features the amazing capability of being<br />

applied effectively at temperatures as low as –25°F<br />

(–32°C). CW Plus is currently limited in use to<br />

several ASJ products.<br />

Limited Warranty<br />

Products sold by <strong>Venture</strong> <strong>Tape</strong> Corp. are warranted upon delivery<br />

to be of the quality set forth in the specifications. <strong>Venture</strong> <strong>Tape</strong><br />

Corp. makes no other representations or warranties, expressed<br />

or implied, including but not limited to, the implied warranties<br />

of merchantability and fitness for a particular purpose. Should a<br />

product sold by <strong>Venture</strong> <strong>Tape</strong> Corp. not be as warranted, <strong>Venture</strong><br />

<strong>Tape</strong> Corp.’s sole obligation shall be, at its sole option, to repair,<br />

correct or replace the products, or, at <strong>Venture</strong> <strong>Tape</strong> Corp.’s sole<br />

discretion,to refund amounts paid for such product upon its<br />

return to a location designated by <strong>Venture</strong> <strong>Tape</strong> Corp. No product<br />

may be returned to <strong>Venture</strong> <strong>Tape</strong> Corp. without prior written approval.<br />

Any return must be shipped within 14 days of delivery.<br />

<strong>Venture</strong> <strong>Tape</strong> Corp. shall in no event have any responsibility for<br />

any damages beyond the cost of the product, either for labor,<br />

expense or other damages of any sort including special, incidental<br />

or consequential damages incurred by the buyer or user.<br />

Determination of the suitability of the product to its application<br />

and product installation are solely the responsibility of the buyer.<br />

VENTURE TAPE CORP. MAKES NO OTHER REPRESENTATIONS<br />

OR WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING<br />

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF<br />

MERCHANTABILITY AND FITNESS FOR A PARTICULAR<br />

PURPOSE. SHOULD A PRODUCT SOLD BY VENTURE TAPE<br />

CORP. NOT BE AS WARRANTED, VENTURE TAPE CORP.’S SOLE<br />

OBLIGATION SHALL BE, AT ITS SOLE OPTION, TO REPAIR,<br />

CORRECT OR REPLACE THE PRODUCTS, OR, AT VENTURE<br />

TAPE CORP.’S SOLE DISCRETION, TO REFUND AMOUNTS PAID<br />

FOR SUCH PRODUCT UPON ITS RETURN TO A LOCATION<br />

DESIGNATED BY VENTURE TAPE CORP. NO PRODUCT MAY<br />

BE RETURNED TO VENTURE TAPE CORP. WITHOUT PRIOR<br />

WRITTEN APPROVAL. ANY RETURN MUST BE SHIPPED<br />

WITHIN 14 DAYS OF DELIVERY. VENTURE TAPE CORP. SHALL<br />

IN NO EVENT HAVE ANY RESPONSIBILITY FOR ANY DAMAGES<br />

BEYOND THE COST OF THE PRODUCT, EITHER FOR LABOR,<br />

EXPENSE OR OTHER DAMAGES OF ANY SORT INCLUD-<br />

ING SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES<br />

INCURRED BY THE BUYER OR USER. DETERMINATION OF<br />

THE SUITABILITY OF THE PRODUCT TO ITS APPLICATION AND<br />

PRODUCT INSTALLATION ARE SOLELY THE RESPONSIBILITY<br />

OF THE BUYER.

Waterproof<br />

Cloth Duct <strong>Tape</strong><br />

1500<br />

Utility Grade<br />

Coated Cloth<br />

Duct <strong>Tape</strong><br />

1501<br />

Metalized Cloth<br />

Duct <strong>Tape</strong><br />

1502<br />

12 mil Pro Grade<br />

Waterproof Cloth<br />

Duct <strong>Tape</strong><br />

1556<br />

A high strength premium quality polyethylene coated<br />

cotton cloth tape coated with an aggressive high<br />

tack natural rubber adhesive system. Adheres well<br />

to sheet metal ducts and conforms well to corners<br />

and irregular surfaces. Will not curl when unwound,<br />

tears readily.<br />

Colors: Silver, Black, White<br />

Primary use: Vapor sealing sheet metal ducts;<br />

general purpose, heavy duty service.<br />

Thickness: 10 mils (254 µ)<br />

Adhesion: 50 oz./inch width (5.47 N/2.5 cm)<br />

Elongation: 18%<br />

Tensile: 23 lbs./inch width (40.3 N/2.5 cm)<br />

Widths: Silver – 2, 3 inches (5.1, 7.6 cm)<br />

Black – 2 inches (5.1 cm)<br />

White – 2 inches (5.1 cm)<br />

Length: 60 yards (55m) on 3 inch (7.6 cm) core<br />

An economical, polyethylene coated cotton cloth<br />

duct tape with a natural rubber, pressure sensitive<br />

adhesive system. High tack, adheres well to metal<br />

surfaces, conforms well to corners and irregular<br />

surfaces.<br />

Color: Silver<br />

Primary use: Sealing sheet metal ducts and general<br />

purpose industrial applications.<br />

Thickness: 9 mils (229 µ)<br />

Adhesion: 45 oz./inch width (4.9 N/2.5 cm)<br />

Elongation: 16%<br />

Tensile: 24 lbs./inch width (42 N/2.5 cm)<br />

Widths: 2 inches (5.1 cm)<br />

Length: 60 yards (55 m) on 3 inch (7.6 cm) core<br />

A high quality metalized polyethylene cloth tape<br />

coated with a natural rubber pressure sensitive<br />

adhesive system. This tape has high tack, high peel<br />

and adheres well to fiber ductboard, flexible duct<br />

and sheet metal duct. Conforms well to corners and<br />

irregular surfaces.<br />

Color: Metalized<br />

Primary use: Vapor sealing of fiber ductboard, flexible<br />

duct, sheet metal ductwork and general industrial<br />

purposes.<br />

Thickness: 10 mils (250 µ)<br />

Adhesion: 55 oz./inch width (15.6 N/2.5 cm)<br />

Elongation: 11%<br />

Tensile: 36 lbs./inch width (163 N/2.5 cm)<br />

Widths: 2, 3 inches (5.1, 7.6 cm)<br />

Length: 60 yards (55 m) on 3 inch (7.6 cm) core<br />

A high strength, premium quality polyethylene coated<br />

cotton cloth tape coated with an aggressive, high<br />

tack, natural rubber pressure sensitive adhesive<br />

system. Adheres well to sheet metal duct and<br />

conforms well to corners and irregular surfaces.<br />

Colors: Silver, Black<br />

Primary use: Vapor sealing sheet metal ductwork and<br />

general purpose heavy duty service. Also used for<br />

hanging poly sheeting.<br />

Thickness: 12 mils (305 µ)<br />

Adhesion: 70 oz./inch width (19.8 N/2.5 cm)<br />

Elongation: 15%<br />

Tensile: 25 lbs./inch width (65.5 N/2.5 cm)<br />

Widths: Silver – 2 inches ( 5.1 cm)<br />

Black – 2 inches (5.1 cm)<br />

Length: 60 yards (55m) on 3 inch (7.6 cm) core<br />

Premium Cloth<br />

Duct <strong>Tape</strong><br />

1557<br />

Mechanical Closure Systems<br />

1 mil (25 micron)<br />

Aluminum Foil<br />

<strong>Tape</strong><br />

1513CW<br />

Foil/Kraft<br />

Insulation <strong>Tape</strong><br />

1514CW<br />

1.2 mil (30 micron)<br />

Aluminum Foil <strong>Tape</strong><br />

1517CW<br />

A high strength, premium quality polyethylene coated<br />

cloth tape coated with an aggressive, high tack<br />

natural rubber pressure sensitive adhesive system.<br />

This tape adheres particularly well to sheet metal<br />

duct, and conforms well to corners and irregular<br />

surfaces.Does not curl when unwound.<br />

Colors: Silver, Black<br />

Primary use: Vapor sealing of sheet metal ductwork<br />

and general purpose heavy duty service. Excellent for<br />

hanging poly sheeting.<br />

Thickness: 13 mils (325 µ)<br />

Adhesion: 69 oz./inch width (19.6 N/2.5 cm)<br />

Elongation: 18%<br />

Tensile: 41 lbs./inch width (117 N/2.5 cm)<br />

Widths: 2 inches (5.1 cm)<br />

Length: 60 yards (55 m) on 3 inch (7.6 cm) core<br />

A high strength 1 mil (25 µ) aluminum foil tape<br />

coated with <strong>Venture</strong>’s CW cold weather acrylic<br />

adhesive. High quick stick at normal temperatures;<br />

excellent performance at low temperatures and high<br />

humidity.<br />

Primary use: Vapor sealing for foil faced insulation<br />

products.<br />

Thickness: 2.3 mils (58 µ) (exclusive of liner)<br />

Adhesion: 64 oz./inch width (18.1 N/2.5 cm)<br />

Elongation: 7%<br />

Tensile: 13 lbs./inch width (58.9 N/2.5 cm)<br />

Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

An aluminum foil/kraft tape laminate coated with<br />

<strong>Venture</strong>’s CW cold weather acrylic adhesive. High<br />

quick stick at normal temperatures; excellent<br />

performance at low temperatures and high humidity.<br />

Primary use: Closure system for fiberglass and foil<br />

faced mineral wool insulation systems.<br />

Thickness: 2.6 mils (65 µ) (exclusive of liner)<br />

Adhesion: 80 oz./inch width (22.6 N/2.5 cm)<br />

Elongation: 5%<br />

Tensile: 18 lbs./inch width (81.5 N/2.5 cm)<br />

Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

A high strength 1.2 mil (30 µ) aluminum foil tape<br />

coated with <strong>Venture</strong>’s CW cold weather acrylic<br />

adhesive system. This adhesive combines high<br />

quick stick at normal temperatures with excellent<br />

performance at low temperatures and high humidity.<br />

Primary use: Vapor sealing tape for foil faced<br />

insulation products.<br />

Thickness: 2.6 mils (65 µ) (exclusive of liner)<br />

Adhesion: 80 oz./inch width (22.6 N/2.5 cm)<br />

Elongation: 5%<br />

Tensile: 18 lbs./inch width (81.5 N/2.5 cm)<br />

Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

Conforms to British Standard BS 476:<br />

Part 7, Class 1; Part 6, Class 0.<br />

Conforms to German Standard DIN A-2.<br />

Certificate of Fire Approval No. SAS F000578<br />

EC Type Examination (Type Approval)<br />

Certificate No. MED 0050397<br />

Toll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,<br />

from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-4059<br />

5

Mechanical Closure Systems<br />

2 mil Aluminum Foil<br />

High Temperature<br />

<strong>Tape</strong><br />

3243<br />

High Tack 1.5 mil<br />

(38 micron)<br />

Aluminum Foil <strong>Tape</strong><br />

1521CW<br />

1.5 mil (38 micron)<br />

Rubber Based<br />

Aluminum Foil<br />

3531<br />

High Tack 1.5 mil<br />

38 Micron Aluminum<br />

Foil <strong>Tape</strong> Self Wound<br />

2521CW<br />

6<br />

A 2 mil (50 micron) aluminum foil coated with a high<br />

shear, high heat resistant acrylic adhesive system.<br />

Dead soft foil conforms well to irregular surfaces.<br />

Primary use: Can be used in most flue pipe and<br />

chimney pipe applications in temperatures up to<br />

450°F.<br />

Thickness: 3.8 mils (96.5 µ) (exclusive of liner)<br />

Adhesion: 85 oz./inch width (24.1 N/2.5 cm)<br />

Elongation: 4.4%<br />

Tensile: 27 lbs./inch width (122 N/2.5 cm)<br />

Widths: 3 inches (7.6 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

A special 1.5 mil (38 µ) high strength aluminum foil<br />

tape with a higher tack, special CW cold weather<br />

acrylic adhesive system. This formulation combines<br />

extremely high quick stick at normal temperatures<br />

with superior performance at low temperatures and<br />

high humidity.<br />

Primary use: Thinner material allows for superior<br />

conformability in vapor sealing of fiberglass<br />

ductboard and FSK systems.<br />

Thickness: 3.0 mils (75 µ) (exclusive of liner)<br />

Adhesion: 98 oz./inch width (27.7 N/2.5 cm)<br />

Elongation: 4.4%<br />

Tensile: 21 lbs./inch width (95 N/2.5 cm)<br />

Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Lengths: 50, 100 yards (46, 91 m) on 3 inch (7.6 cm) core<br />

U.S. Coast Guard Approval No: 164.112/63/0<br />

for interior finish.<br />

A 1.5 mil (38 µ) high strength aluminum foil coated<br />

with an aggressive, high tack rubber based adhesive<br />

system. The foil conforms well to both fibrous and<br />

sheet metal ducts, providing an excellent vapor<br />

seal. Conforms well around corners and to irregular<br />

surfaces.<br />

Primary use: Used for vapor sealing of FSK faced<br />

thermal insulation systems.<br />

Thickness: 3.0 mils (75 µ)<br />

Adhesion: 150 oz./inch width (42.5 N/2.5 cm)<br />

Elongation: 4.4%<br />

Tensile: 21 lbs./inch width (95 N/2.5 cm)<br />

Widths: 2, 2½, 3 inches (5.1, 6.4, 7.6 cm)<br />

Length: 50 yards (46 m) on a 3 inch (7.6 cm) core<br />

Conforms to British Standard BS 476: Parts 6 & 7<br />

A special 1.5 mil (38 µ) high strength aluminum<br />

foil tape with a high tack CW cold weather acrylic<br />

adhesive. 2521CW is release coated and self wound,<br />

with no release liner for ease of use. Extremely<br />

high quick stick at normal temperatures; superior<br />

performance at low temperatures and high humidity.<br />

Primary use: Masking material on acrylic and<br />

polycarbonate aircraft windows. Also used as<br />

a sealing system in refrigerated appliances and<br />

microwave ovens as well as a variety of other<br />

industrial applications.<br />

Thickness: 3.0 mils (75 µ)<br />

Adhesion: 85 oz./inch width (24.1 N/2.5 cm)<br />

Elongation: 4.4%<br />

Tensile: 21 lbs./inch width (95 N/2.5 cm)<br />

Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Length: 60 yards (55 m) on 3 inch (7.6 cm) core<br />

2 mil (50 micron)<br />

Aluminum Foil <strong>Tape</strong><br />

1520CW<br />

2 mil (50 micron)<br />

Aluminum Foil <strong>Tape</strong><br />

Self-Wound<br />

2520CW<br />

2 mil (50 micron)<br />

Aluminum Foil <strong>Tape</strong><br />

Self-Wound<br />

6520<br />

2 mil (50 micron)<br />

HVAC Aluminum Foil<br />

<strong>Tape</strong><br />

3520CW<br />

A 2 mil (50 µ) high strength aluminum foil coated<br />

with special cold weather acrylic adhesive system<br />

that combines superior quick stick at normal<br />

temperatures with superior low temperature<br />

performance at freezing (32°F or 0°C). The ultimate<br />

in cold weather tapes. Recommended for use at<br />

normal and high temperatures also.<br />

Primary use: Improved vapor sealing of fiberglass<br />

ductboard, ductwrap and FSK systems.<br />

Thickness: 3.5 mils (88 µ) (exclusive of liner)<br />

Adhesion: 96 oz./inch width (27.1 N/2.5 cm)<br />

Elongation: 4.4%<br />

Tensile: 27 lbs./inch width (122 N/2.5 cm)<br />

Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Lengths: 50, 100 yards (46, 91 m) on 3 inch (7.6 cm) core<br />

U.S. Coast Guard Approval No: 164.112/63/0<br />

for interior finish.<br />

Conforms to British Standard BS 476:<br />

Part 7, Class 1; Part 6, Class 0.<br />

A 2 mil (50 µ) high strength aluminum foil coated<br />

with an aggressive, high temperature acrylic<br />

adhesive. 2520CW is release coated and self wound,<br />

with no release liner for ease of use. Superior quick<br />

stick at normal temperatures; superior high and low<br />

temperature performance.<br />

Primary use: Masking material on acrylic and polycarbonate<br />

aircraft windows. Also used as a sealing<br />

system in refrigerated appliances and microwave<br />

ovens as well as a variety of other industrial applications.<br />

Thickness: 3.5 mils (88 µ)<br />

Adhesion: 85 oz./inch width (24.1 N/2.5 cm)<br />

Elongation: 4.4%<br />

Tensile: 27 lbs./inch width (122 N/2.5 cm)<br />

Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Length: 60 yards (55 m) on 3 inch (7.6 cm) core<br />

A 2 mil (50 µ) high strength, non-silicone releasecoated,<br />

self-wound aluminum foil, coated with<br />

an aggressive, high temperature acrylic adhesive<br />

system. The foil conforms well to both fibrous and<br />

sheet metal ducts, providing an excellent vapor seal.<br />

The malleable foil also conforms well around corners<br />

and to irregular surfaces. The acrylic adhesive<br />

system performs excellently at low temperatures.<br />

Primary use: Masking material on acrylic and polycarbonate<br />

aircraft windows. Also, used as a sealing<br />

system in refrigerated appliances and microwave<br />

ovens as well as a variety of other industrial applications.<br />

Thickness: 4 mils (102 µ)<br />

Adhesion: 80 oz./inch width (22.7 N/2.5 cm)<br />

Elongation: 4.4%<br />

Tensile: 27 lbs./inch width (113 N/2.5 cm)<br />

Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Length: 60 yards (55 m) on 3 inch (7.6 cm) core<br />

High strength, 2 mil (50 µ) foil coated with an<br />

aggressive, high temperature acrylic adhesive<br />

system. Bonds well to both fibrous and metal ducts,<br />

providing an excellent vapor seal. Malleable foil<br />

conforms well on corners and to irregular surfaces.<br />

The special cold weather adhesive combines superior<br />

quick stick at normal temperatures with superior<br />

low temperature performance down to freezing. The<br />

ultimate for cold weather, with excellent at normal<br />

and high temperatures.<br />

Primary use: Vapor sealing fiberglass ductboard and<br />

sheet metal ducts. Also used on FSK systems.<br />

Thickness: 3.7 mils (90 µ)<br />

Adhesion: 100 oz./inch width (28.3 N/2.5 cm)<br />

Elongation: 5%<br />

Tensile: 34 lbs./inch width (154 N/2.5 cm)<br />

Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core

2 mil (50 micron)<br />

Rubber Based<br />

Aluminum Foil<br />

3530<br />

UL-181B-FX Listed<br />

Duct Joint Sealing<br />

<strong>Tape</strong><br />

1580 & 1580P<br />

UL-181A Printed 2 mil<br />

(50 micron) Aluminum<br />

Foil Ductboard <strong>Tape</strong><br />

1581A-CW<br />

White Aluminum<br />

Foil <strong>Tape</strong><br />

1511CW<br />

A 2.0 mil, high strength aluminum foil coated with an<br />

aggressive, high tack rubber based adhesive system.<br />

The foil conforms well to both fibrous and sheet<br />

metal ducts, providing an excellent vapor seal. The<br />

malleable foil also conforms well around corners and<br />

to irregular surfaces.<br />

Primary use: Vapor sealing sheet metal ducts; general<br />

purpose, heavy duty service. Can also be used<br />

on all FSK insulation systems<br />

Thickness: 3.7 mils (90 µ)<br />

Adhesion: 150 oz./inch width (42.5 N/2.5 cm)<br />

Elongation: 5%<br />

Tensile: 34 lbs./inch width (154 N/2.5 cm)<br />

Widths: 2, 2½, 3 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

Conforms to British Standard BS 476:<br />

Parts 6 & 7<br />

Heavy duty, high strength aluminum foil with specially<br />

formulated adhesive system. Performance and<br />

materials guaranteed to meet or exceed UL-181B-FX<br />

quality standards, and assures against this tape being<br />

a conductor of any flame.<br />

Also available unprinted<br />

Primary use: Superior vapor sealing of metal duct.<br />

Thickness: 17.0 mils (177.8 µ) (exclusive of liner)<br />

Adhesion: 160 oz./inch width (45.3 N/2.5 cm)<br />

Elongation: 5%<br />

Tensile: 20 lbs./inch width (62.8 N/2.5 cm)<br />

Widths: 2, 3 inches (5.1, 7.6 cm)<br />

Length: 100’ on 3 inch (7.6 cm) core<br />

Heavy duty, high strength aluminum foil with<br />

specially formulated acrylic adhesive system.<br />

Performance and materials guaranteed to meet<br />

or exceed UL-181A-P and UL-181B-FX quality<br />

standards, and assures against this tape being a<br />

conductor of any flame. Superior adhesion and<br />

conformance for fibrous ductboard systems.<br />

Primary use: Vapor sealing sheet metal ducts; taping<br />

fiberglass ductboard & flexible duct.<br />

Thickness: 4.0 mils (100 µ) (exclusive of liner)<br />

Adhesion: 85 oz./inch width (24.2 N/2.5 cm)<br />

Shear Adhesion:<br />

5 lb. weight–24 hours+ 40°F/6 hours<br />

10 lb. weight–>120 hours+ 73.4°F/120 hours<br />

1 lb. weight–>6 hours+ 150°F/6 hours<br />

Elongation: 4.3%<br />

Tensile: 25 lbs./inch width (113.2 N/2.5 cm)<br />

Widths: 2½, 3 inches (6.4, 7.6 cm)<br />

Length: 60 yards (55 m) on 3 inch (7.6 cm) core<br />

A 1.5 mil (38 µ) white aluminum foil coated with an<br />

aggressive cold weather acrylic adhesive system<br />

which offers superior quick stick at below zero<br />

and elevated temperatures. Zero temper, dead<br />

soft aluminum foil conforms well to smooth and<br />

embossed surfaces.<br />

Primary use: Matching lap joint and vapor seal for both<br />

smooth and satin foil faced board. For use on Thermax ®<br />

and Atlas ® products.<br />

Conforms to: British Standards Class 1, BS 47776: Part 7 &<br />

U.S. Coast Guard Approval No: 164.112/63/0<br />

for interior finish.<br />

Thickness: 3.5 mils (88 µ) (exclusive of liner)<br />

Adhesion: 100 oz./inch width (28.3 N/2.5 cm)<br />

Elongation: 5%<br />

Tensile: 34 lbs./inch width (154 N/2.5 cm)<br />

Widths: 2, 3, 4, 5 inches (5.1, 7.6, 10.2, 12.7 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

3 mil (75 micron)<br />

Aluminum Foil<br />

Duct <strong>Tape</strong><br />

1519CW<br />

Mechanical Closure Systems<br />

3 mil (75 micron)<br />

Aluminum Foil Duct<br />

<strong>Tape</strong> Self Wound<br />

2519CW<br />

3 mil (75 micron)<br />

Aluminum Foil <strong>Tape</strong><br />

Self Wound<br />

6519CW<br />

FSK<br />

Facing <strong>Tape</strong><br />

1525CW<br />

High strength, 3 mil (75 µ) aluminum foil tape coated<br />

with 2 mils (50 µ) of an aggressive, high temperature<br />

acrylic adhesive system. Conforms well to corners<br />

and irregular surfaces. Superior adhesion to both<br />

fibrous and metal ducts, providing an excellent vapor<br />

seal.<br />

Primary use: Moisture and vapor barrier for duct<br />

systems. For roofing applications, flashing, joints<br />

and insulation. Used as a protective layer during<br />

welding.<br />

Thickness: 5.0 mils (125 µ) (exclusive of liner)<br />

Adhesion: 96 oz./inch width (27.1 N/2.5 cm)<br />

Elongation: 5%<br />

Tensile: 27.8 lbs./inch width (125.9 N/2.5 cm)<br />

Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

High strength, 3 mil (75 µ) aluminum foil tape coated<br />

with 2 mils (50 µ) of an aggressive, high temperature<br />

acrylic adhesive system. 2519CW is release coated<br />

and self wound, with no release liner for ease of<br />

use. Conforms well, with superior adhesion to both<br />

fibrous and metal ducts. Provides an excellent vapor<br />

seal. Meets L-T-80B and Mil-T-23397B.<br />

Primary use: Masking material on acrylic and polycarbonate<br />

aircraft windows. Also used as a sealing<br />

system in refrigerated appliances and microwave<br />

ovens as well as a variety of other industrial applications.<br />

Thickness: 5.0 mils (125 µ)<br />

Adhesion: 85 oz./inch width (24.1 N/2.5 cm)<br />

Elongation: 5%<br />

Tensile: 27.8 lbs./inch width (125.9 N/2.5 cm)<br />

Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 10.2 cm)<br />

Length: 60 yards (55 m) on 3 inch (7.6 cm) core<br />

A 3 mil (75 micron) high strength, non-silicone<br />

release-coated, self-wound aluminum foil, coated<br />

with an aggressive, high temperature acrylic<br />

adhesive system. The foil conforms well to both<br />

fibrous and sheet metal ducts, providing an excellent<br />

vapor seal. The malleable foil also conforms well<br />

around corners and to irregular surfaces.<br />

Primary use: Masking material on acrylic and polycarbonate<br />

aircraft windows. Also, used as a sealing<br />

system in refrigerated appliances and microwave<br />

ovens as well as a variety of other industrial applications.<br />

Thickness: 5.0 mils (125 µ) total<br />

Adhesion: 80 oz./inch width (22.7 N/2.5 cm)<br />

Elongation: 5%<br />

Tensile: 27.8 lbs./inch width (133.4 N/2.5 cm)<br />

Widths: 2, 3 inches (5.1, 7.6 cm)<br />

Length: 60 yards (55 m) on 3 inch (7.6 cm) core<br />

Tridirectionally reinforced with 2 x 3/sq.in. (2.5 x<br />

2.5 cm) fiberglass scrim, U.L. listed Foil/Scrim/Kraft<br />

lamination. Coated with a special cold weather<br />

acrylic adhesive system which combines very high<br />

quick stick at normal temperatures with superior low<br />

temperature performance. Recommended for use<br />

down to 10°F (–12°C). Conforms well to both fibrous<br />

ductboard and blankets. The ultimate in cold weather<br />

tapes. Meets ASTM C1136.<br />

Primary use: Vapor seal on FSK faced fiberglass<br />

ductboard and blanket systems.<br />

Thickness: 6.5 mils (165 µ) (exclusive of liner)<br />

Adhesion: 92 oz./inch width (26.0 N/2.5 cm)<br />

Elongation: 2%<br />

Tensile: 40 lbs./inch width (178 N/2.5 cm)<br />

Widths: 2, 3, 4, 5 inches (5.1, 7.6, 10.2, 12.7 cm)<br />

Length: 50, 100 yards (46, 91 m) on 3 inch (7.6 cm) core<br />

Conforms to British Standard Class 1<br />

BS 476: Part 7<br />

Toll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,<br />

from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-4059<br />

7

<strong>Venture</strong><strong>Tape</strong> ® 1599B UL181B-FX Listed<br />

Flexible Duct Closure <strong>Tape</strong><br />

• Half tHe Cost of<br />

cloth duct tape<br />

• Ul181B-fX listed<br />

• Higher adhesion and<br />

tack than traditional<br />

cloth duct tapes<br />

• Can be used on metal &<br />

metal connections<br />

• excellent UV resistance<br />

• long-life CW acrylic<br />

adhesive; superior<br />

performance in extreme<br />

environments; from<br />

-35°f to 260°f<br />

•<br />

2 inch x 120 yard rolls

FSK Rubber Based<br />

Facing <strong>Tape</strong><br />

3525<br />

UL-181B-FX 3 mil (75<br />

micron) Printed Flexible<br />

Duct Closure <strong>Tape</strong><br />

1599B<br />

FSK<br />

Vapor Seal<br />

Disks & Squares<br />

1528CW & SQ<br />

Polyethylene<br />

Reinforced Foil <strong>Tape</strong><br />

1529CW<br />

Polyethylene<br />

Reinforced Foil <strong>Tape</strong><br />

3529HT<br />

Tridirectionally reinforced with 2 x 3/sq.in. fiberglass<br />

scrim, U.L. listed foil/scrim/kraft lamination. This<br />

tape conforms well to both fiberglass board and<br />

blankets. Coated with an aggressive, high tack rubber<br />

based adhesive system.<br />

Primary use: Used as a vapor seal on FSK faced<br />

fiberglass insulation.<br />

Thickness: 6.5 mils (165 µ)<br />

Adhesion: 125 oz./inch width (35.4 N/2.5 cm)<br />

Elongation: 2%<br />

Tensile: 40 lbs./inch width (178 N/2.5 cm)<br />

Widths: 2, 3, 4, 5 inches (5.1, 7.6, 10.2, 12.7 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

A polypropylene film with an acrylic, CW cold weather<br />

adhesive system. Will perform well in either sub-zero<br />

cold or abnormally warm temperatures. UL listed.<br />

Meets or exceeds all state building codes requiring<br />

UL181B-FX.<br />

Colors: Silver, Black, Clear<br />

Primary use: Sealing flexible air ducts and air<br />

connectors.<br />

Thickness: 3.0 mils (10.0762 mm)<br />

Adhesion:<br />

To stainless steel: 41 oz./inch width (11.4 N/2.5 cm)<br />

To backing: 31 oz./inch width (8.6 N/2.5 cm)<br />

Elongation: 150%<br />

Tensile: 22 lbs./inch width (99.4 N/2.5 cm)<br />

Width: 2, 3 inches (5.1, 7.6 cm)<br />

Length: 120 yards (110 m) on<br />

3 inch (7.6 cm) core<br />

Die cut disks and squares, on release paper liner<br />

for ease of application. Same U.L. listed material as<br />

No. 1525, with 2 x 3/sq.in. (2.5 x 2.5 cm) diagonal<br />

reinforced Foil/Scrim/ Kraft lamination. 500 per roll.<br />

Cold weather adhesive formula.<br />

Primary use: Provides vapor seal over washers<br />

and pins used in mounting insulation. seals small<br />

punctures and tears.Tremendous labor savings over<br />

hand cut tape sections.<br />

1528CW Kiss-Cut Disks<br />

2 ½ inch (6.4 cm) diameter<br />

1528CW/SQ Kiss-Cut Squares<br />

3 x 3 inch (2.5 x 2.5 cm) square<br />

Thickness: 6.5 mils (165 µ) (exclusive of liner)<br />

Adhesion: 92 oz./inch width (26.0 N/2.5 cm)<br />

Elongation: 2%<br />

Tensile: 45 lbs./inch width (203.8 N/2.5 cm)<br />

Quantity: 500 disks/squares on 3 inch (7.6 cm) core<br />

A tridirectionally reinforced, hand tearable, expanded<br />

polyethylene foil tape coated with acrylic adhesive<br />

which exhibits superior quick stick at high and<br />

low temperatures. Resistant to moisture, it is<br />

recommended for use in conditions of high humidity.<br />

Meets AS 1530 -Part 3.<br />

Primary use: Vapor seal for reinforced aluminum<br />

faced fiberglass or mineral wool thermal insulation.<br />

Thickness: 5 mils (0.127mm)<br />

Adhesion: 72 oz./inch width (20.3 N/2.5 cm)<br />

Elongation: 21.3%<br />

Tensile: 16.1 lbs./inch width (71.6 N/2.5 cm)<br />

Width: 2, 3 inches (5.1, 7.6 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

A tri-directionally reinforced expanded polyethylene<br />

foil tape coated with a high performance rubber<br />

pressure sensitive adhesive. Hand tearable with<br />

superior resistance to moisture, and is recommended<br />

for use in high humidity applications. Provides easy<br />

application and superior performance and durability<br />

over a wide range of temperatures and environmental<br />

conditions.<br />

Primary use: Primarily used as a vapor seal for<br />

reinforced aluminum faced fiberglass or mineral wool<br />

thermal insulation.<br />

Thickness: 5 mils (0.127mm)<br />

Adhesion: 100 oz./inch width (27.8 N/2.5 cm)<br />

Elongation: 21.3%<br />

Tensile: 24 lbs./inch width (106.8 N/2.5 cm)<br />

Width: 2, 3 inches (5.1, 7.6 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

ASJ<br />

Facing <strong>Tape</strong><br />

1540CW Plus<br />

ASJ Vapor Seal<br />

Disks & Squares<br />

1542CW<br />

Plus & SQ<br />

Cryogenic Vapor<br />

Barrier <strong>Tape</strong><br />

<strong>Venture</strong>Wrap<br />

1555CW<br />

Mechanical Closure Systems<br />

WMP-DW Reinforced<br />

Black Polypropylene<br />

Facing <strong>Tape</strong><br />

1538CW<br />

A tridirectionally reinforced, black, polypropylene/<br />

skrim /kraft lamination coated with a special CW<br />

cold weather acrylic adhesive which exhibits<br />

superior quick stick at high and low; 10°F<br />

(-12°C) temperatures. Resistant to moisture, it is<br />

recommended for use in conditions of high humidity.<br />

Colors: Black, Gray<br />

Primary use: Vapor seal and closure system on<br />

Lamtec WMP-DW faced thermal insulation.<br />

Thickness: 7.5 mils (0.191 mm)<br />

Adhesion: 68 oz./inch width (19.2 N/2.5 cm)<br />

Tensile: 40 lbs./inch width (181 N/2.5 cm)<br />

Width: 3 inches (7.6 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

All Service Jacket <strong>Tape</strong>. White Kraft/Scrim/Foil<br />

lamination with 4 x 4/sq.in. (2.5 x 2.5 cm)<br />

tridirectional scrim reinforcement. Special cold<br />

weather acrylic adhesive system that combines<br />

superior quick stick at normal temperatures with<br />

superior low temperature performance down<br />

to –25°F (–32°C). Excellent at normal and high<br />

temperatures also.<br />

Primary use: Closure system and vapor seal on All<br />

Service Jacket faced duct and piping systems.<br />

Thickness: 11.5 mils (287 µ) (exclusive of liner)<br />

*Adhesion: 92 oz./inch width (26.0 N/2.5 cm)<br />

Elongation: 2%<br />

Tensile: 40 lbs./inch width (181 N/2.5 cm)<br />

Widths: 2, 3, 4, 5 inches<br />

(5.1, 7.6, 10.2, 12.7 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

Pre-cut disks and squares on release paper liner.<br />

Same U.L. listed material as No. 1540 with 4 x 4/<br />

sq.in. (2.5 x 2.5 cm) diagonally reinforced White<br />

Kraft/Scrim/Foil lamination. 500 per roll. With special<br />

CW cold weather adhesive system.<br />

Primary use: Vapor seal over washers and pins used<br />

in mounting insulation. Easily handled, prepared<br />

product saves time in application.<br />

1542CW Kiss-Cut Disks<br />

2 ½ inch (6.4 cm) diameter<br />

1542CW/SQ Kiss-Cut Squares<br />

3 x 3 inch (2.5 x 2.5 cm) square<br />

Thickness: 11.5 mils (287 µ) (exclusive of liner)<br />

*Adhesion: 92 oz./inch width (26.0 N/2.5 cm)<br />

Elongation: 2%<br />

Tensile: 40 lbs./inch width (181 N/2.5 cm)<br />

Quantity: 500 disks/ squares on 3 inch (7.6 cm) core<br />

A three ply laminate made with a 1 mil aluminum<br />

foil with 0.5 mil polyester film on both sides and<br />

coated with a special cold weather acrylic pressure<br />

sensitive adhesive system which combines superior<br />

quick stick at normal temperatures with superior low<br />

temperature performance below freezing.<br />

Colors: Silver and White<br />

Primary use: This tape is primarily used a low<br />

temperature vapor barrier joint closure system.<br />

Thickness: 4 mils (102 µ)<br />

Adhesion: 60 oz./inch width (17 N/2.5 cm)<br />

Elongation: 50%<br />

Tensile: 15 lbs./inch width (68 N/2.5 cm)<br />

Widths: 2, 3 inch (5.1, 7.6 cm)<br />

Length: 50 yards (46m) on 3 inch (7.6 cm) core<br />

Toll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,<br />

from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-4059<br />

9

Mechanical Closure Systems<br />

Sheathing<br />

<strong>Tape</strong><br />

1585CW-2<br />

Printed<br />

Sheathing <strong>Tape</strong><br />

1585CW-P2<br />

5 mil (125 micron)<br />

Vinyl Seal <strong>Tape</strong><br />

1506R<br />

6 mil (150 micron)<br />

Vinyl Seal <strong>Tape</strong><br />

1506CW<br />

10<br />

A thin, strong, polypropylene film tape coated with<br />

<strong>Venture</strong>’s aggressive CW cold weather acrylic adhesive<br />

system. Excellent performance characteristics at<br />

elevated temperatures and down to 10°F (–12°C).<br />

Colors: Red, White, Pink, Clear<br />

Primary use: Closure system and vapor seal on all<br />

exterior sheathing; plywood, OSB, Dens Glass Gold®<br />

and other house wrap products, including Tyvek®<br />

and Typar®. Also used as an interior barrier repair<br />

tape, and for air tightness on door and window<br />

flanges, sill plates, corners and joints. Seam tape on<br />

polyethylene.<br />

Thickness: 3 mils (76 µ)<br />

Adhesion (Tyvek): 28 oz./inch width (7.95 N/2.5 cm)<br />

Elongation: 136%<br />

Tensile: 20 lbs./inch width (90.6 N/2.5 cm)<br />

Widths: 1 7 ∕8, 2½, 3 inches (4.8, 6.4, 7.6 cm)<br />

Lengths: 55, 72 yards (50, 66 m) on 3 inch (7.6 cm) core<br />

Same product as No. 1585CW-2, but imprinted with<br />

copy reading, “No. 1585CW-P2 Sheathing <strong>Tape</strong>, See<br />

CCMC Evaluation Report No. 11362-R,” <strong>Venture</strong>’s<br />

logo and address listed.<br />

Color: Red<br />

Primary use: Closure system and vapor seal on<br />

Tyvek® faced thermal insulation requiring notice of<br />

specification, and other housewraps. Repairs rips<br />

and tears in the facing. Polyethylene seaming.<br />

Thickness: 3.1 mils (78 µ)<br />

Adhesion: 43 oz./inch width (12.0 N/2.5 cm)<br />

Elongation: 136%<br />

Tensile: 20 lbs./inch width (90.6 N/2.5 cm)<br />

Width: 2 1 ∕3 inches (60 mm)<br />

Length: 72 yards (66 m) on 3 inch (7.6 cm) core<br />

Thin, strong and conformable vinyl film tape coated<br />

with <strong>Venture</strong>’s special rubber based adhesive<br />

designed to adhere well to PVC fittings.<br />

Colors: Black, White<br />

Primary use: Sealing longitudinal and circumferential<br />

joints in pipe coverings and vessels. Seals 45°, 90°<br />

joints, T’s and valves in PVC materials.<br />

Thickness: 5 mils (125 µ)<br />

Adhesion: Peel—29 oz./inch width (8.0 N/2.5 cm)<br />

Elongation: 150%<br />

Tensile: 15 lbs./inch width (67.9 N/2.5 cm)<br />

Widths: 1, 1½, 2 inches (2.5, 3.8, 5.1 cm)<br />

Length: 36 yards (33 m) on 11/2 inch (3.8 cm) core<br />

*Not recommended for outdoor use.<br />

Thin, strong and conformable copolymer film tape<br />

coated with <strong>Venture</strong>’s special, high grade, U.V.<br />

resistant CW cold weather acrylic adhesive system.<br />

Also resistant to solvents.<br />

Color: White<br />

Primary use: Sealing longitudinal and circumferential<br />

joints in PVC pipe coverings and vessels. Seals 45°,<br />

90° joints, T’s and valves in PVC materials.<br />

Thickness: 6 mils (150 µ)<br />

Adhesion: Peel—64 oz./inch width (18.1 N/2.5 cm)<br />

Elongation: 500%<br />

Tensile: 18 lbs./inch width (81.5 N/2.5 cm)<br />

Widths: 1, 1 ½, 2 inches (2.5, 3.8, 5.1 cm)<br />

Length: 36 yards (33 m) on 11/2 inch (3.8 cm) core<br />

Polypropylene<br />

Line Set <strong>Tape</strong>;<br />

Black, Metalized & White<br />

1507<br />

Polyfoam<br />

<strong>Tape</strong><br />

1509<br />

10 mil (250 micron)<br />

Vinyl Seal <strong>Tape</strong><br />

1510R<br />

Tedlar ®<br />

Facing <strong>Tape</strong><br />

1570CW (White)<br />

1571CW (Gray)<br />

A polypropylene film with an acrylic adhesive system.<br />

<strong>Venture</strong>’s special adhesive formula will perform well<br />

from sub-zero to tropical temperatures. Waterproof<br />

weatherproof and UV resistant, it is ideal for outdoor<br />

use in any climate.<br />

Colors: Black, Metalized (Silver) & White<br />

Primary use: For taping line sets. Works well on<br />

black foam pipe used in line sets. Metalized used<br />

for reflective insulation. White used on white foam<br />

insulation or line set.<br />

Thickness: 3 mils (75 µ)<br />

Adhesion: 31 oz./inch width (8.6 N/2.5 cm)<br />

Elongation: 150%<br />

Tensile: 22 lbs./inch width (99.4 N/2.5 cm)<br />

Widths: 2 inches (5.1 cm)<br />

Length: 60 yards (55 m) on 3 inch (7.6 cm) core<br />

A high density cross linked polyethylene foam tape<br />

coated on one side with rubber based adhesive,<br />

which allows for excellent quick stick sealing and<br />

high shear properties. Good resistance to humidity,<br />

mild acids, oil and grease. Adheres well to textured<br />

and irregular surfaces.<br />

Colors: Black, White<br />

Primary use: Used for condensation control on<br />

plumbing pipes and as lap tape on pipe insulation:<br />

also sound vibration dampening.<br />

Thickness: 1/8 inch (3.2 mm) (exclusive of liner)<br />

Peel Adhesion: 100 oz./inch width (28.3 N/2.5 cm)<br />

Elongation: 300%<br />

Tensile: 6 lbs./inch width (27.2 N/2.5 cm)<br />

Width: 2 inches (5.1 cm)<br />

Length: 10 yards (9.1 m) on 3 inch (7.6 cm) core<br />

A tough, conformable, specially formulated vinyl<br />

film tape coated with <strong>Venture</strong>’s special rubber based<br />

adhesive which is designed to adhere well to PVC<br />

fittings. This tape is particularly resistant to moisture,<br />

acids, alkalis, and oils, and is highly abrasion<br />

resistant as well.<br />

Color: White<br />

Primary use: Application of premolded high impact<br />

PVC insulation fitting covers.<br />

Thickness: 10 mils (250 µ)<br />

Adhesion: 29 oz./inch width (8.0 N/2.5 cm)<br />

Elongation: 325%<br />

Tensile: 31 lbs./inch width (140.4 N/2.5 cm)<br />

Widths: 1, 1½, 2 inches (2.5, 3.8, 5.1 cm)<br />

Length: 33.33 yards (30.4 m) on 11/2 inch (3.8 cm) core<br />

A thin, strong Tedlar® (polyvinyl fluoride) film tape.<br />

<strong>Venture</strong>’s special cold weather acrylic adhesive<br />

system together with this facing tape make for an<br />

exceptional product for high performance below<br />

freezing.<br />

Colors: White, Gray<br />

Primary use: Closure system and vapor seal for<br />

Tedlar ® / fiberglass lamination faced thermal insulation,<br />

rigid foam insulation board, and rigid foam or<br />

fiberglass pipe insulation. Extremely high resistance<br />

to U.V. rays, weathering and most chemicals, makes<br />

this an outstanding tape for solar or chemical plant<br />

application.<br />

Thickness: 3 mils (75 µ)<br />

Adhesion: 68 oz./inch width (19.2 N/2.5 cm)<br />

Elongation: 130%<br />

Tensile: 11 lbs./inch width (49.8 N/2.5 cm)<br />

Widths: 2, 3 inches (5.1, 7.6 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core

Waterproof<br />

Cloth Duct <strong>Tape</strong><br />

1500<br />

Utility Grade<br />

Coated Cloth<br />

Duct <strong>Tape</strong><br />

1501<br />

Black<br />

Polyethylene<br />

<strong>Tape</strong><br />

912<br />

Polyethylene<br />

Splicing <strong>Tape</strong><br />

919<br />

Ruggedly structured cotton fabric tape with<br />

polyethylene coated face. Aggressive, high tack<br />

natural rubber adhesive conforms and bonds to<br />

nearly any surface. Unwinds flat, tears readily.<br />

Colors: Silver, Black, White<br />

Primary use: Vapor sealing sheet metal ducts;<br />

general purpose, heavy duty service.<br />

Thickness: 10 mils (254 µ)<br />

Adhesion: 50 oz./inch width (5.47 N/2.5 cm)<br />

Elongation: 18%<br />

Tensile: 23 lbs./inch width (40.3 N/2.5 cm)<br />

Widths: Silver – 2, 3 inches (5.1, 7.6 cm)<br />

Black – 2 inches (5.1 cm)<br />

White – 2 inches (5.1 cm)<br />

Length: 60 yards (55m) on 3 inch (7.6 cm) core<br />

An economical, polyethylene coated cotton cloth<br />

duct tape with a natural rubber, pressure sensitive<br />

adhesive system. High tack, adheres well to metal<br />

surfaces, conforms well to corners and irregular<br />

surfaces.<br />

Color: Silver<br />

Primary use: Sealing sheet metal ducts and general<br />

purpose industrial applications.<br />

Thickness: 9 mils (229 µ)<br />

Adhesion: 45 oz./inch width (4.9 N/2.5 cm)<br />

Elongation: 16%<br />

Tensile: 24 lbs./inch width (42 N/2.5 cm)<br />

Widths: 2 inches (5.1 cm)<br />

Length: 60 yards (55 m) on 3 inch (7.6 cm) core<br />

A black polyethylene surface protection tape coated<br />

with a specially formulated removable acrylic<br />

pressure sensitive adhesive (PSA).<br />

Color: Black<br />

Primary use: Weatherseal for poly sheeting and<br />

sealing ink containers<br />

Thickness: 5.8 mils (147.3 µ)<br />

Adhesion: 24 oz./inch width (6.8 N/2.5 cm)<br />

Elongation: 250%<br />

Tensile: 13 lbs./inch width (58.8 N/2.5 cm)<br />

Widths: 2, 3 inches (5.1, 7.6 cm)<br />

Length: 36 yards (33 m) on 3 inch (7.6 cm) core<br />

A thick, strong polyethylene tape coated with an<br />

aggressive, premium quality, synthetic rubber based<br />

adhesive system.<br />

Colors: Clear, Black<br />

Primary use: Poly film splicing and sealing.<br />

Thickness: 8.3 mils (208 µ)<br />

Adhesion: 40 oz./inch width (11.3 N/2.5 cm)<br />

Elongation: 400%<br />

Tensile: 19 lbs./inch width (85.9 N/2.5 cm)<br />

Widths: 2, 3 inches (5.1, 7.6 cm)<br />

Length: 36 yards (33 m) on 3 inch (7.6 cm) core<br />

Asbestos Removal/ Weatherization Products<br />

Clear Polyethylene<br />

Removable <strong>Tape</strong><br />

923<br />

Removable Double<br />

Coated 1 mil (25 micron)<br />

Polyester <strong>Tape</strong><br />

523<br />

Double Coated<br />

Cloth <strong>Tape</strong><br />

581<br />

Clear<br />

Polyethylene<br />

<strong>Tape</strong><br />

921CW<br />

A 5 mil (125 µ) clear polyethylene film coated<br />

with a specially formulated, high tack, removable<br />

acrylic adhesive system. The adhesive will adhere to<br />

polyethylene and remove cleanly, in most instances,<br />

from drywall and painted surfaces. Reduces most<br />

costly repainting and repair of damage often incurred<br />

when using permanent adhesive tapes.<br />

Color: Clear<br />

Primary use: Hanging poly sheeting, especially during<br />

asbestos removal projects in finished areas.<br />

Thickness: 6.2 mils (157 µ)<br />

Adhesion: 24 oz./inch width (6.8 N/2.5 cm)<br />

Elongation: 250%<br />

Tensile: 12.5 lbs./inch width (56.6 N/2.5 cm)<br />

Widths: 1, 1½, 2, 3, 4 inches (2.5, 3.8, 5.1, 7.6, 10.2 cm)<br />

Length: 36 yards (33 m) on 3 inch (7.6 cm) core<br />

Controlled high/low tack acrylic adhesives set on<br />

polyester film. Removes cleanly without residue.<br />

Resists U.V., moisture, solvents, mild acids, oil and<br />

grease.<br />

Color: Clear<br />

Primary use: Where removability without damage is<br />

required, such as hanging poly barrier sheeting on<br />

asbestos removal projects. Removes cleanly from<br />

drywall.<br />

Thickness: 3.75 mils (93 µ) (exclusive of liner)<br />

Adhesion: 24 hrs. (to polyester)<br />

High Tack—80 oz./inch width (22.5 N/2.5 cm)<br />

Low Tack—16 oz./inch width (3.4 N/2.5 cm)<br />

Elongation: 100%<br />

Tensile: 16 lbs./inch width (72.5 N/2.5 cm)<br />

Widths: 1, 1½, 2, 3 inches (2.5, 3.8, 5.1, 7.6 cm)<br />

Lengths: 36, 60 yards (33, 55 m) on 3 inch (7.6 cm) core<br />

A tightly woven cotton/polyester blend fabric coated<br />

on both sides with an extremely aggressive, premium<br />

grade rubber-based adhesive system. Flexibility<br />

and thickness enhance sealing ability to rough and<br />

textured surfaces.<br />

Color: White<br />

Primary use: Mounting poly sheet to materials such<br />

as brick and cinder block. Splicing sheet for pressurized<br />

environments.<br />

Thickness: 11 mils (275 µ) (exclusive of liner)<br />

Adhesion: 190 oz./inch width (53.7 N/2.5 cm)<br />

Elongation: 29%<br />

Tensile: 12 lbs./inch width (54.3 N/2.5 cm)<br />

Widths: 1½, 1¾, 2, 3, 4 inches (3.8, 4.4, 5.1, 7.6, 10.2<br />

cm)<br />

Lengths: 25, 36 yards (23, 33 m) on 3 inch (7.6 cm) core<br />

A 5 mil (125 µ) thin, strong and conformable<br />

transparent polyethylene film tape with a very high<br />

shear, UV resistant cold weather acrylic adhesive<br />

with excellent holding properties and cold stick.<br />

Excellent resistance to moisture, acids, chemicals,<br />

alkalis, oils, abrasion and weathering.<br />

Color: Clear<br />

Primary use: Weather seal for applying plastic storm<br />

windows, door jams, window casings in low temperature<br />

environment. Also used for film can sealing,<br />

ink container sealing and splicing polyethylene film.<br />

Thickness: 6.2 mils (157 µ)<br />

Adhesion: 75 oz./inch width (21.2 N/2.5 cm)<br />

Elongation: 250%<br />

Tensile: 12.5 lbs./inch width (56.6 N/2.5 cm)<br />

Sizes: 1” x 45 feet, 2” x 25 feet, 2” x 108 feet<br />

(2.5 cm x 13.7 m, 5.1 cm x 7.6 m, 5.1 cm x 33 m)<br />

Toll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,<br />

from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-4059<br />

11

Jacketing Systems<br />

Non-Adhesive FSK<br />

Facing<br />

1527<br />

White Polypropylene/<br />

Kraft<br />

2537<br />

Non-Adhesive ASJ<br />

Facing<br />

1541<br />

Non-Adhesive ASJ<br />

Facing Sheets w/<br />

Self Sealing Lap <strong>Tape</strong><br />

1541S<br />

12<br />

Uncoated flame resistant Aluminum Foil/Fiberglass<br />

Scrim/Kraft lamination used for facing thermal<br />

insulation.<br />

Scrim: 2 x 3/sq.in. (2,5 x 2.5 cm) tridirectional pattern.<br />

Primary use: Vapor barrier paper over plain fiberglass<br />

and other insulation products.<br />

Thickness: 3.5 mils (88 µ)<br />

Elongation: 2%<br />

Tensile: 40 lbs./inch width (181 N/2.5 cm)<br />

Widths: 42, 48, 50, 54, 71 inches<br />

(107, 122, 127, 137, 180 cm)<br />

Lengths: 200, 600, 900 feet<br />

(61, 183, 274 m) on 3 inch (7.6 cm) core<br />

Uncoated PSK barrier material. Scrim: 5 x 5/sq.in.<br />

(2,5 x 2.5 cm) Meets ASTM C1136.<br />

Primary use: Vapor barrier PSK to go over all types<br />

of insulation materials.<br />

Widths: 42, 54, 78 inch<br />

Lengths: 150, 200, 300 feet<br />

(46, 61, 91 m) on 3 inch (7.6 cm) core<br />

Uncoated All Service Jacketing barrier material<br />

consisting of flame resistant, high intensity white<br />

kraft paper, fiberglass yarn reinforcement and<br />

aluminum foil lamination.Scrim: 5 x 5/sq.in. (2,5 x<br />

2.5 cm) tridirectional pattern. Meets ASTM C1136.<br />

Primary use: Vapor barrier paper for all types of<br />

insulation materials.<br />

Widths: 3, 23½, 35½, 48, 71 inches<br />

(7.6, 59.7, 90.2, 122, 180 cm)<br />

Lengths: 200, 600, 900 feet<br />

(61, 183, 274 m) on 3 inch (7.6 cm) core<br />

Precut ASJ sheets with SSL applied. Jacketing meets<br />

ASTM C1136.<br />

Primary use: Applied over all types of pipe insulation<br />

as a vapor retarder.<br />

Thickness: .009 inch<br />

Tensile: 50 lbs./inch width (113 N/2.5 cm)<br />

Sizes: All pipe sizes available.<br />

<strong>Venture</strong>Guard ®<br />

Chemical Resistant<br />

Jacketing System<br />

1574CW<br />

<strong>Venture</strong>Clad ®<br />

5-Ply Laminated<br />

Foil/Film Facing<br />

1577CW<br />

<strong>Venture</strong>Clad ® 3-Ply<br />

Laminated Foil/Film<br />

Facing <strong>Tape</strong><br />

1578CW<br />

<strong>Venture</strong>Clad Plus ®<br />

13-Ply Laminated<br />

Foil/Film Facing<br />

1579CW<br />

A self adhesive, chemical resistant vapor barrier,<br />

performance alternative to stainless steel for insulation<br />

and jacketing applications. Installs quickly and easily<br />

with no special tools, resulting in significant time,<br />

labor and material cost savings. <strong>Venture</strong>Guard ®<br />

exceeds most building code requirements, can be<br />

used for new construction or repair. Hypalon ® type<br />

backing exhibits superior strength, flexibility, elasticity<br />

and resistance to chemicals, UV and ozone. Apply<br />

from 10° to 302°F (-12° to 150°C).<br />

Primary use: Alternative to metal jacketing on piping<br />

and insulation in chemical, oil & gas refining and<br />

processing, transportation and marine industries.<br />

Thickness: 26.6 mils (675 µ) (exclusive of liner)<br />

Adhesion: 50 oz./inch width (14.3 N/2.5 cm)<br />

Elongation: 1000%<br />

Tensile: 25 lbs./inch width (113 N/2.5 cm)<br />

Width: 4, 20, 35½ inches (10, 50, 90 cm)<br />

Length: 25 yards (23 m) on 3 inch (7.6 cm) core<br />

A five-ply laminate; three layers of aluminum foil (core<br />

and outer layers), and two layers of polyester film,<br />

coated with a special cold weather acrylic adhesive<br />

system. High quick stick at normal temperatures<br />

coupled with superior performance below freezing.<br />

Highly puncture and tear resistant, flame retardant.<br />

Zero permeability, low weight, fast, clean safe<br />

installation. Apply at –10 to 248°F (–23 to 120°C).<br />

Colors: White, Natural Aluminum, Black, Stucco<br />

Embossed, White Stucco Embossed, Black Embossed<br />

and Tedlar<br />

Primary use: Facing system and vapor seal on foam<br />

glass, mineral fiber, nitrile rubber, and foam insulation,<br />

on interior/exterior piping & duct.<br />

Thickness: 6 mils ( 152.4 µ) (exclusive of liner)<br />

Adhesion: 55 oz./inch width (15.6 N/2.5 cm)<br />

Tensile: 68 lbs./inch width (306 N/2.5 cm)<br />

Width: 23½, 35½, 46, 60 inches (60, 120, 152 cm)<br />

Length: 50 yards (46 m) on 3 inch (7.6 cm) core<br />

A three-ply laminate; two layers of aluminum foil<br />

(outer layers), and a layer of polyester film, coated<br />

with a special cold weather acrylic adhesive system.<br />

High quick stick at normal temperatures coupled<br />

with superior performance below freezing. Highly<br />

puncture and tear resistant, flame retardant. Zero<br />

permeability, low weight, fast, clean safe installation.<br />

Apply at –10 to 248°F (–23 to 120°C).<br />

Primary use: Adjunct to #1577CW to facilitate sealing<br />

bends. Also used as a low temperature vapor barrier<br />

joint closure system.<br />

Thickness: 3.3 mils (83 µ) (exclusive of liner)<br />

Adhesion: 60 oz./inch width (17 N/2.5 cm)<br />

Tensile: 34 lbs./inch width (153 N/2.5 cm)<br />

Width: 2, 3 inches (5.1, 7.6 cm)<br />

Length: 55 yards (50.6 m) on 3 inch (7.6 cm) core<br />

A thirteen-ply laminate (six aluminum foil, four<br />

polyester film on scrim reinforced core), with special<br />

CW cold weather acrylic adhesive system allowing<br />

superior performance to10°F (–12°C). Highly puncture<br />

and tear resistant, as well as flame retardant. Zero<br />

permeability, low weight, fast, clean safe installation.<br />

Maximum continuous use to 300°F (149°C). Also<br />

available without adhesive (NA).<br />

Colors: White, Natural Aluminum, Stucco Embossed<br />

Primary use: Facing system and vapor seal on foam<br />

glass, mineral fiber, nitrile rubber, rigid and semirigid<br />

foam insulation, interior or exterior.<br />

Total Thickness: 15.5 mils (380 µ) (exclusive of liner)<br />

Adhesion: 100 oz./inch width (28.4 N/2.5 cm)<br />

Tensile: 160 lbs./inch width (720 N/2.5 cm)<br />

Puncture ASTM D-1000): 80 lbs (360n)<br />

Elongation: 35%<br />

Widths: 2, 4, 23½, 35½ inches (5, 10, 58, 90 cm)<br />

Length: 25 yards (23 m) on 3 inch (7.6 cm) core

<strong>Venture</strong>Wrap<br />

Laminate<br />

1555U<br />

A three ply laminate constructed of a 1 mil aluminum<br />

foil with 0.5 mil polyester film on both sides.<br />

Colors: Silver, White<br />

Primary use: Primarily used as a low temperature<br />

vapor barrier in cryogenic applications on pipe<br />

insulation.<br />

Thickness: 2.4 mils (61 µ)<br />

Elongation: 49%<br />

Tensile: 12,500 psi (86 mPa)<br />

Widths: 35 ½”<br />

Length: 250 yards (229 m) on 3 inch (7.6 cm) core<br />

<strong>Venture</strong>Clad ®<br />

Pre-Cut Sheets<br />

1577CW ®<br />

Jacketing Systems<br />

Sizes: All pipe sizes available<br />

Colors: Silver, White Embossed<br />

What is <strong>Venture</strong>Clad ® Jacketing?<br />

Primary use: Pre-jacketing of insulation in a shop or<br />

in the field prior to installation.<br />

<strong>Venture</strong>Clad ® jacketing is a zero permeability, self adhesive jacketing product<br />

which delivers significant advantages over traditional jacketing techniques.<br />

•<br />

•<br />

•<br />

Application Temperature<br />

as low as -30˚ F<br />

Zero Permeability<br />

UL 723/ASTM-E-84<br />

Flame and Smoke<br />

•<br />

•<br />

•<br />

No Primers, Activators, or Heat Guns<br />

Required<br />

Ideal Internal or External Use<br />

Neat, Clean, and Dependable Material<br />

The above application shows a chiller that was insulated in a mechanical room with rubber<br />

insulation and covered with <strong>Venture</strong>Clad ® 1577CW (White)<br />

Toll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,<br />

from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-4059<br />

13

Metal Building Facing Systems Matching Guide<br />

1529CW 1545CW<br />

1535CW<br />

1531CW<br />

1549CW 1567CW<br />

1531CW Black<br />

1558CW<br />

450 Black 1568CW<br />

1537CW<br />

1562CW<br />

450 Clear 1582CW<br />

1537CW Black<br />

460 White<br />

1583CW 1551CW<br />

1547CW<br />

1584CW<br />

Toll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,<br />

from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-4059

WMP ® -10<br />

Polypropylene<br />

Facing <strong>Tape</strong><br />

1531CW<br />

VSF-HD Reinforced<br />

Vinyl Facing <strong>Tape</strong><br />

1532CW<br />

WCF ® -50<br />

Facing <strong>Tape</strong><br />

1535CW<br />

WMP ® -VR<br />

Polypropylene<br />

Facing <strong>Tape</strong><br />

1537CW<br />

White metalized polypropylene/scrim/kraft laminated<br />

facing tape. 4 x 4/sq.in. (2.5 x 2.5 cm) Tridirectional<br />

scrim reinforcement. CW acrylic adhesive.<br />

Colors: Black, White<br />

Primary use: Closure system and vapor seal on<br />

Lamtec WMP ® -10 faced thermal insulation.<br />

Thickness: 7.0 mils (175 µ) (exclusive of liner)<br />