Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8<br />

HigHLigHTS odfjell quarterly magazine<br />

Port captain’s role<br />

in port efficiency<br />

By Odd Magne Vik, Port Captain Sao Paulo, Brazil<br />

Torger Trige, Port Captain Rotterdam, The Netherlands<br />

Jan Harald Otterskred, Port Captain Ulsan, Korea<br />

Jone Abotnes, Port Captain, Singapore<br />

<strong>Odfjell</strong> has port captains in some of the<br />

busiest ports around the world and we<br />

strive to make all activities performed<br />

during a port stay run as time and cost<br />

efficient as possible.<br />

Good communication and team work is<br />

essential in order to optimize the port call.<br />

Vessel, agent, operator, port operator and others<br />

involved in the operation of the vessel have<br />

to work together and communicate closely.<br />

The more vessel and shore can prepare and<br />

make ready in advance the more time can be<br />

saved. This may include having tanks ready<br />

on arrival, good planning of stowage, good<br />

planning and preparation of cleaning and<br />

slop delivery together with other vessel needs<br />

in port. Good, proactive planning in advance<br />

can help to prepare all those involved so that<br />

less unexpected trouble occurs during vessel<br />

operation, and may shorten the rotation. This<br />

saves time and money!<br />

Before the arrival of the vessel, the port<br />

captain will be interested in knowing<br />

whether the vessel’s equipment is working<br />

and fully operational. The captain must as<br />

soon as possible relay any information of<br />

equipment malfunction that may effect the<br />

ship’s efficiency in port.<br />

The rotation in port proposed to the vessel is<br />

based on the vessel’s operation, berth availability,<br />

vessel’s information, tank cleaning<br />

time and other vessels’ schedule. As a port<br />

captain it is viable that we need to exchange<br />

information and evaluate updates with port<br />

and terminals daily. As the berths are always<br />

limited by draft, the captains must communicate<br />

best minimum draft of the ship in its<br />

partly and fully loaded condition. The draft<br />

estimates based on the planned rotation is<br />

vital information for the operation in port<br />

and we welcome captains to forward their<br />

own optimizing suggestions.<br />

Cleaning of cargo tanks which is a cost and<br />

time consuming operation frequently takes<br />

place during port stay. Consequently the<br />

port captain will evaluate in co-operation<br />

with the captain whether such operations<br />

and other cargo operations may be done<br />

safely and simultaneously. We then have<br />

to bear in mind the accumulation of slops<br />

on board compared to going off port limit<br />

for cleaning purposes. The essence here is<br />

time and fuel savings.<br />

In ports where the vessels are calling several<br />

berths, optimizing the rotation in port is<br />

priority number one for the local <strong>Odfjell</strong><br />

Tankers people. Vessels and their operators,<br />

will experience changes in berth sequence<br />

and line-up of barges as a result of that. The<br />

background is obviously that these ports<br />

are very busy and if the next planned berth<br />

is occupied, we would rather change the<br />

rotation and continue operations at another<br />

berth in the rotation in order to move on<br />

and avoid leaving the vessel idle. However,<br />

sometimes it is unavoidable.<br />

If the ship’s port rotation involves multiple<br />

cargoes and berths, it must be considered<br />

whether to apply additional crew for<br />

sampling, tank inspection or special cargo<br />

handling until the ‘peak’ is passed and<br />

operation return to normal.<br />

Besides cargo handling, a lot of other<br />

activities also take place in ‘our’ ports. For<br />

example there are superintendents from<br />

<strong>Odfjell</strong> Ship Management and external ship<br />

management, visits by various purchase<br />

departments, attending service people,<br />

vetting inspections, provisions, stores and<br />

spare parts delivery, bunkering, slop delivery<br />

and so on. In order to make this and the<br />

cargo operation run simultaneously and<br />

smoothly, the flow of information between<br />

the parties is crucial.<br />

The port captain’s main rules are<br />

Communication – Planning – Preparation<br />

– Awareness – Execution – Evaluation. He is<br />

the <strong>Odfjell</strong> representative ashore, there to<br />

serve the captain and his ship, and to ensure<br />

a safe and efficient port stay.<br />

www.odfjell.com<br />

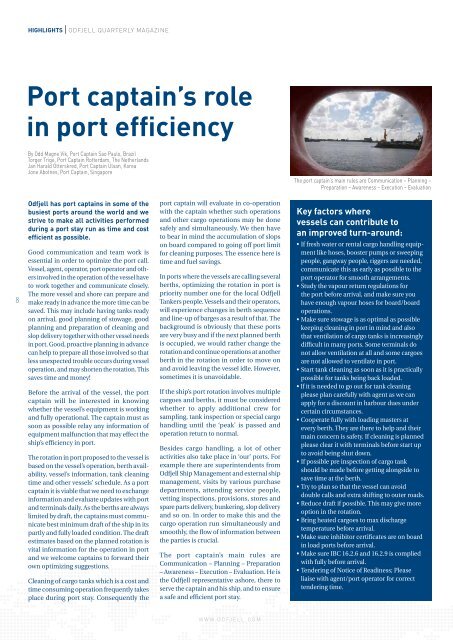

The port captain’s main rules are Communication – Planning –<br />

Preparation – Awareness – Execution – Evaluation<br />

Key factors where<br />

vessels can contribute to<br />

an improved turn-around:<br />

• If fresh water or rental cargo handling equipment<br />

like hoses, booster pumps or sweeping<br />

people, gangway people, riggers are needed,<br />

communicate this as early as possible to the<br />

port operator for smooth arrangements.<br />

• Study the vapour return regulations for<br />

the port before arrival, and make sure you<br />

have enough vapour hoses for board/board<br />

operations.<br />

• Make sure stowage is as optimal as possible<br />

keeping cleaning in port in mind and also<br />

that ventilation of cargo tanks is increasingly<br />

difficult in many ports. Some terminals do<br />

not allow ventilation at all and some cargoes<br />

are not allowed to ventilate in port.<br />

• Start tank cleaning as soon as it is practically<br />

possible for tanks being back loaded.<br />

• If it is needed to go out for tank cleaning<br />

please plan carefully with agent as we can<br />

apply for a discount in harbour dues under<br />

certain circumstances.<br />

• Cooperate fully with loading masters at<br />

every berth. They are there to help and their<br />

main concern is safety. If cleaning is planned<br />

please clear it with terminals before start up<br />

to avoid being shut down.<br />

• If possible pre inspection of cargo tank<br />

should be made before getting alongside to<br />

save time at the berth.<br />

• Try to plan so that the vessel can avoid<br />

double calls and extra shifting to outer roads.<br />

• Reduce draft if possible. This may give more<br />

option in the rotation.<br />

• Bring heated cargoes to max discharge<br />

temperature before arrival.<br />

• Make sure inhibitor certificates are on board<br />

in load ports before arrival.<br />

• Make sure IBC 16.2.6 and 16.2.9 is complied<br />

with fully before arrival.<br />

• Tendering of Notice of Readiness; Please<br />

liaise with agent/port operator for correct<br />

tendering time.