Pallet Jack - Menards

Pallet Jack - Menards

Pallet Jack - Menards

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

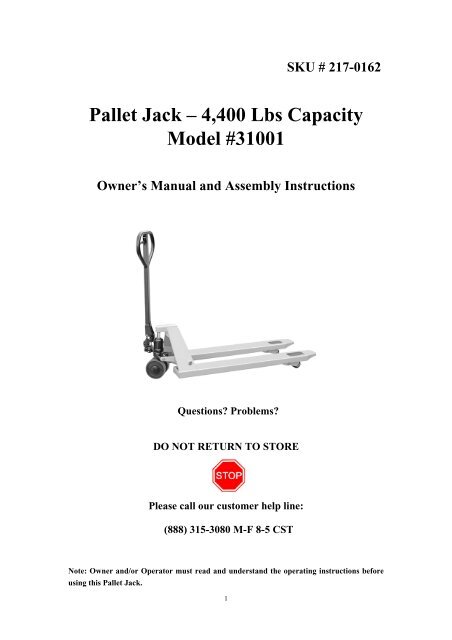

SKU # 217-0162<br />

<strong>Pallet</strong> <strong>Jack</strong> – 4,400 Lbs Capacity<br />

Model #31001<br />

Owner’s Manual and Assembly Instructions<br />

Questions? Problems?<br />

DO NOT RETURN TO STORE<br />

Please call our customer help line:<br />

(888) 315-3080 M-F 8-5 CST<br />

Note: Owner and/or Operator must read and understand the operating instructions before<br />

using this <strong>Pallet</strong> <strong>Jack</strong>.<br />

1

• Handle Assembly Instructions:<br />

1. Important note: The spring of the pallet jack is held in place with a pin (pin B). Do not<br />

remove this pin. Please follow instructions on when this pin should be removed.<br />

2. Pull out pin shaft (part 23). Please refer to Fig. 1.<br />

Fig. 1 Fig. 2<br />

3. Insert handle tube (part 89) into position A. Connect handle tube and the pump body (part<br />

31) via the pin shaft (part 23). Please note the hole in the center of the pin shaft. The chain<br />

(part 10) from the handle will need to be inserted through this hole in step 5. Make sure<br />

that this pin shaft is aligned into the groove of the pump body. Please refer to Fig. 1 and<br />

parts diagram.<br />

4. Insert cotter pin (part 24) through the other end of the pin shaft (part 23).<br />

5. Position chain (part 10) of the handle tube (part 89) over the pressure roller (part 13) and<br />

through the hole in the center of the pin shaft (part 23). Please refer to Fig. 2 and picture<br />

below.<br />

2

Fig. 3 Fig. 4<br />

6. The screw and nut (part 11) at the end of the chain (part 10) should be positioned securely<br />

into the slot of the lever plate (part 52). You may need to manually adjust the lever plate<br />

so that the screw and nut fit into the slot. Tighten the screw once in place. Please refer to<br />

Fig. 2 and Fig. 4<br />

7. Lower the handle to a horizontal position. Pull out pin B. This will engage the spring (part<br />

20). Store pin B in a safe place so that it can be used for future handle replacements. This<br />

step should complete the assembly. Please refer to Fig. 3.<br />

• Final steps before use:<br />

1. After assembly is complete, test the trigger at different positions to make sure the<br />

lowering, neutral and raising operations are fully functional. Please refer to Fig. 5<br />

2. For adjustments to the pallet jack, please refer to the adjustment screw (part 54) seen in<br />

Fig. 4. In the case where the body of the pallet jack lowers automatically after it has been<br />

raised, turn the adjustment screw (part 54) in a counterclockwise direction until desired<br />

action is met. If the body of the pallet jack is unable to be lowered, turn the adjustment<br />

screw (part 54) in a clockwise direction until the pallet jack is able to be lowered<br />

manually.<br />

3. The hex nut (part 53) and adjustment screw (part 54) function as a lock so they will<br />

remain securely locked after any adjustments have been made.<br />

4. The weight capacity of this pallet jack is 4,400 lbs. Please do not exceed the weight<br />

limitation.<br />

Fig. 5<br />

3

WARNING:<br />

• Lower the pallet jack gently. Hasty lowering of the jack may cause damage to the jack<br />

and the cargo.<br />

• Do not overload the pallet jack.<br />

• Do not exceed the weight limitation.<br />

• The center of gravity of the goods should be positioned in the middle of the 2 forks.<br />

Unbalanced loads may cause the pallet jack to overturn.<br />

• Do not use the pallet jack to transport loose or unstable cargo.<br />

• Set the forks to the lowest position when not in use.<br />

• Do not place cargo on the pallet jack for extended periods of time.<br />

• Do not stand on the forks.<br />

• Do not operate the pallet jack on a slope or an uneven surface.<br />

• Do not try to repair the pallet jack without proper training.<br />

4

Limited One-Year Warranty<br />

Great Lakes Tool Mfg., Inc. warrants its products to be free of defects from workmanship and<br />

materials for a period of one year from date of original purchase. We will repair or replace, at our<br />

option, any product covered by this warranty that after inspection is found to be defective in<br />

materials or workmanship during the warranty period.<br />

This warranty does not apply if the product has been misused, abused, subject to an accident,<br />

altered, repaired by others not authorized and is used in commercial or rental applications. Normal<br />

wear and tear is also not covered by this warranty.<br />

To take advantage of this warranty, please contact us at 1-888-315-3080. You will need proof of<br />

purchase and be asked to ship the product back to us freight prepaid.<br />

Under no circumstances shall Great Lakes Tool Mfg., Inc be liable for any indirect, incidental or<br />

consequential damages from the sale or use of this product. Some states do not allow the exclusion<br />

or limitation of incidental or consequential damages. Some states do not allow limitations on the<br />

length of an implied warranty. This warranty provides you with specific legal rights and you may<br />

have other rights that vary from state to state.<br />

5