SUBCOOLED BOILING OF HFE-7100 ... - Eurotherm 2008

SUBCOOLED BOILING OF HFE-7100 ... - Eurotherm 2008

SUBCOOLED BOILING OF HFE-7100 ... - Eurotherm 2008

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5th European Thermal-Sciences Conference, The Netherlands, <strong>2008</strong><br />

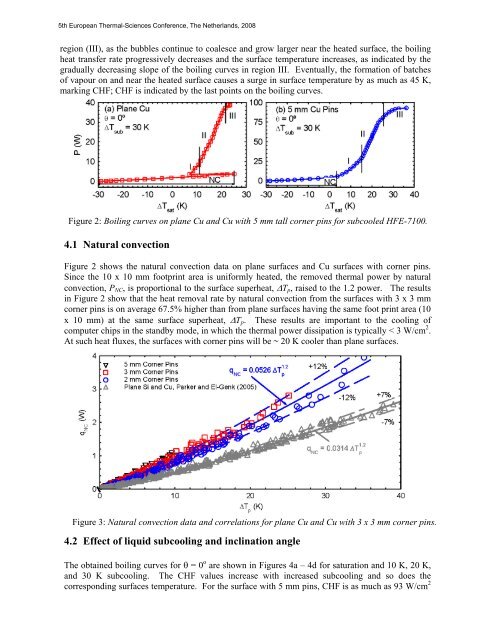

region (III), as the bubbles continue to coalesce and grow larger near the heated surface, the boiling<br />

heat transfer rate progressively decreases and the surface temperature increases, as indicated by the<br />

gradually decreasing slope of the boiling curves in region III. Eventually, the formation of batches<br />

of vapour on and near the heated surface causes a surge in surface temperature by as much as 45 K,<br />

marking CHF; CHF is indicated by the last points on the boiling curves.<br />

Figure 2: Boiling curves on plane Cu and Cu with 5 mm tall corner pins for subcooled <strong>HFE</strong>-<strong>7100</strong>.<br />

4.1 Natural convection<br />

Figure 2 shows the natural convection data on plane surfaces and Cu surfaces with corner pins.<br />

Since the 10 x 10 mm footprint area is uniformly heated, the removed thermal power by natural<br />

convection, PNC, is proportional to the surface superheat, ΔTp, raised to the 1.2 power. The results<br />

in Figure 2 show that the heat removal rate by natural convection from the surfaces with 3 x 3 mm<br />

corner pins is on average 67.5% higher than from plane surfaces having the same foot print area (10<br />

x 10 mm) at the same surface superheat, ΔTp. These results are important to the cooling of<br />

computer chips in the standby mode, in which the thermal power dissipation is typically < 3 W/cm 2 .<br />

At such heat fluxes, the surfaces with corner pins will be ~ 20 K cooler than plane surfaces.<br />

Figure 3: Natural convection data and correlations for plane Cu and Cu with 3 x 3 mm corner pins.<br />

4.2 Effect of liquid subcooling and inclination angle<br />

The obtained boiling curves for θ = 0 o are shown in Figures 4a – 4d for saturation and 10 K, 20 K,<br />

and 30 K subcooling. The CHF values increase with increased subcooling and so does the<br />

corresponding surfaces temperature. For the surface with 5 mm pins, CHF is as much as 93 W/cm 2