ROTOGRAVURE PRINTING - heimann-hamm.de

ROTOGRAVURE PRINTING - heimann-hamm.de

ROTOGRAVURE PRINTING - heimann-hamm.de

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

pre-press<br />

Galvanic | Color management | Engraving | Cylin<strong>de</strong>r correction | Masuring <strong>de</strong>vices<br />

disCop<br />

Or<strong>de</strong>r No.: B09-0508<br />

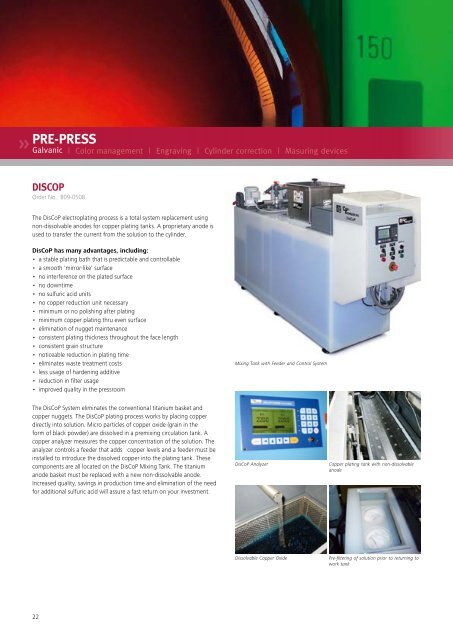

The DisCoP electroplating process is a total system replacement using<br />

non-dissolvable ano<strong>de</strong>s for copper plating tanks. A proprietary ano<strong>de</strong> is<br />

used to transfer the current from the solution to the cylin<strong>de</strong>r.<br />

DisCoP has many advantages, including:<br />

• a stable plating bath that is predictable and controllable<br />

• a smooth 'mirror-like' surface<br />

• no interference on the plated surface<br />

• no downtime<br />

• no sulfuric acid units<br />

• no copper reduction unit necessary<br />

• minimum or no polishing after plating<br />

• minimum copper plating thru even surface<br />

• elimination of nugget maintenance<br />

• consistent plating thickness throughout the face length<br />

• consistent grain structure<br />

• noticeable reduction in plating time<br />

• eliminates waste treatment costs<br />

• less usage of har<strong>de</strong>ning additive<br />

• reduction in filter usage<br />

• improved quality in the pressroom<br />

The DisCoP System eliminates the conventional titanium basket and<br />

copper nuggets. The DisCoP plating process works by placing copper<br />

directly into solution. Micro particles of copper oxi<strong>de</strong> (grain in the<br />

form of black pow<strong>de</strong>r) are dissolved in a premixing circulation tank. A<br />

copper analyzer measures the copper concentration of the solution. The<br />

analyzer controls a fee<strong>de</strong>r that adds copper levels and a fee<strong>de</strong>r must be<br />

installed to introduce the dissolved copper into the plating tank. These<br />

components are all located on the DisCoP Mixing Tank. The titanium<br />

ano<strong>de</strong> basket must be replaced with a new non-dissolvable ano<strong>de</strong>.<br />

Increased quality, savings in production time and elimination of the need<br />

for additional sulfuric acid will assure a fast return on your investment.<br />

22<br />

Mixing Tank with Fee<strong>de</strong>r and Control System<br />

DisCoP Analyzer<br />

Copper plating tank with non-dissolvable<br />

ano<strong>de</strong><br />

Dissolvable Copper Oxi<strong>de</strong> Pre-filtering of solution prior to returning to<br />

work tank<br />

OR<br />

O