ROTOGRAVURE PRINTING - heimann-hamm.de

ROTOGRAVURE PRINTING - heimann-hamm.de

ROTOGRAVURE PRINTING - heimann-hamm.de

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

pre-press<br />

Galvanic | Color management | Engraving | Cylin<strong>de</strong>r correction | Measuring <strong>de</strong>vices<br />

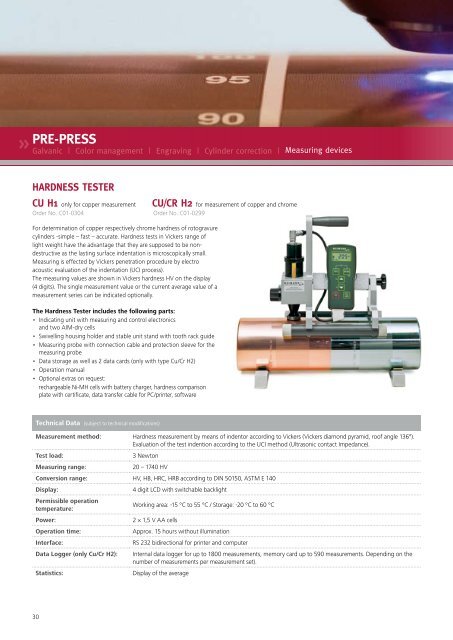

hardness tester<br />

Cu h1 only for copper measurement Cu/Cr h2 for measurement of copper and chrome<br />

Or<strong>de</strong>r No.:C01-0304 Or<strong>de</strong>r No.:C01-0299<br />

For <strong>de</strong>termination of copper respectively chrome hardness of rotogravure<br />

cylin<strong>de</strong>rs -simple – fast – accurate. Hardness tests in Vickers range of<br />

light weight have the advantage that they are supposed to be non<strong>de</strong>structive<br />

as the lasting surface in<strong>de</strong>ntation is microscopically small.<br />

Measuring is effected by Vickers penetration procedure by electro<br />

acoustic evaluation of the in<strong>de</strong>ntation (UCI process).<br />

The measuring values are shown in Vickers hardness HV on the display<br />

(4 digits). The single measurement value or the current average value of a<br />

measurement series can be indicated optionally.<br />

The Hardness Tester inclu<strong>de</strong>s the following parts:<br />

• Indicating unit with measuring and control electronics<br />

and two AIM-dry cells<br />

• Swivelling housing hol<strong>de</strong>r and stable unit stand with tooth rack gui<strong>de</strong><br />

• Measuring probe with connection cable and protection sleeve for the<br />

measuring probe<br />

• Data storage as well as 2 data cards (only with type Cu/Cr H2)<br />

• Operation manual<br />

• Optional extras on request:<br />

rechargeable Ni-MH cells with battery charger, hardness comparison<br />

plate with certificate, data transfer cable for PC/printer, software<br />

Technical Data (subject to technical modifications)<br />

Measurement method: Hardness measurement by means of in<strong>de</strong>ntor according to Vickers (Vickers diamond pyramid, roof angle 136°).<br />

Evaluation of the test in<strong>de</strong>ntion according to the UCI method (Ultrasonic contact Impedance).<br />

Test load: 3 Newton<br />

Measuring range: 20 – 1740 HV<br />

Conversion range: HV, HB, HRC, HRB according to DIN 50150, ASTM E 140<br />

Display: 4 digit LCD with switchable backlight<br />

Permissible operation<br />

temperature:<br />

Power: 2 × 1,5 V AA cells<br />

Working area: -15 °C to 55 °C / Storage: -20 °C to 60 °C<br />

Operation time: Approx. 15 hours without illumination<br />

Interface: RS 232 bidirectional for printer and computer<br />

Data Logger (only Cu/Cr H2): Internal data logger for up to 1800 measurements, memory card up to 590 measurements. Depending on the<br />

number of measurements per measurement set).<br />

Statistics: Display of the average<br />

30