Manual for Class D wheeled extinguishers.pdf - Amerex Corporation

Manual for Class D wheeled extinguishers.pdf - Amerex Corporation

Manual for Class D wheeled extinguishers.pdf - Amerex Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

13<br />

2. Argon pressure is too low. Valve is closed. 2. Valve seat has leaked and has pressurized the agent cylinder.<br />

Tamper seal is intact. Pressure in agent and Follow RECHARGE PROCEDURE <strong>for</strong> restoring the<br />

the Argon cylinders. extinguisher to service.<br />

3. Argon pressure is too low. Valve is closed. 3. Leakage in the Argon valve at other than the valve seat.<br />

Tamper seal is intact. No pressure observed Replace with a properly charged Argon cylinder<br />

in the agent cylinder.<br />

4. Unable to remove the agent cylinder cap. 4. Agent cylinder may be pressurized. Make no further attempt<br />

to remove the cap until this is checked. See the RECHARGE<br />

PROCEDURE <strong>for</strong> proper depressurization method.<br />

5. Argon supply hose cut, cracked or abraded. 5. Replace hose assembly with <strong>Amerex</strong> P/N: 06814.<br />

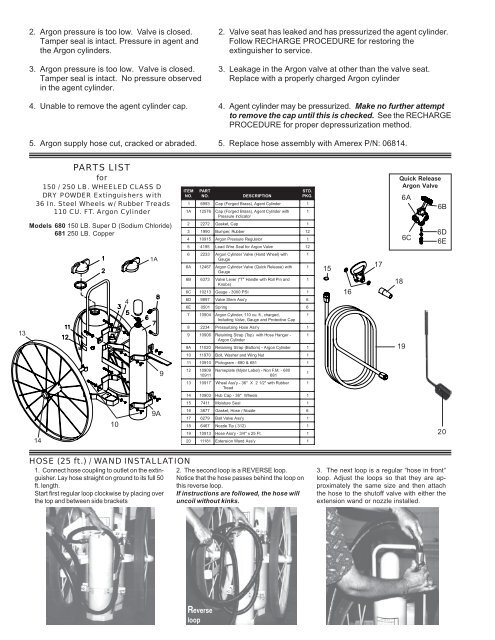

PARTS LIST<br />

<strong>for</strong><br />

150 / 250 LB. WHEELED CLASS D<br />

DRY POWDER Extinguishers with<br />

36 In. Steel Wheels w/ Rubber Treads<br />

110 CU. FT. Argon Cylinder<br />

Models 680 150 LB. Super D (Sodium Chloride)<br />

681 250 LB. Copper<br />

14<br />

10<br />

4<br />

1A<br />

9A<br />

HOSE (25 ft.) / WAND INSTALLATION<br />

1. Connect hose coupling to outlet on the extinguisher.<br />

Lay hose straight on ground to its full 50<br />

ft. length.<br />

Start first regular loop clockwise by placing over<br />

the top and between side brackets<br />

9<br />

ITEM<br />

PART<br />

STD.<br />

NO.<br />

NO. DESCRIPTION<br />

PKG.<br />

1 6993 Cap( Forged<br />

Brass)<br />

, Agent<br />

Cylinder<br />

1<br />

1A12576 Cap<br />

( Forged<br />

Brass)<br />

, Agent<br />

Cylinder<br />

with<br />

Pressure<br />

Indicator<br />

1<br />

2 2272 Gasket, Cap<br />

1<br />

3 1990 Bumper, Rubber<br />

12<br />

4 10915 ArgonPressureRegulator 1<br />

5 4195 LeadWireSeal<strong>for</strong>ArgonValve 12<br />

6 2233 Argon<br />

Cylinder<br />

Valve<br />

( Hand<br />

Wheel)<br />

with<br />

Gauge<br />

1<br />

6A12467 Argon<br />

Cylinder<br />

Valve<br />

( Quick<br />

Release)<br />

with<br />

Gauge<br />

6B6373 Valve<br />

Lever<br />

( " T"<br />

Handle<br />

with<br />

Roll<br />

Pin<br />

and<br />

Knobs)<br />

6C10213 Gauge-3000PSI 1<br />

6D9897 ValveStemAss'y 6<br />

6E0501 Spring 6<br />

7 1 0904<br />

Argon<br />

Cylinder,<br />

110<br />

cu.<br />

ft.<br />

, charged,<br />

Includi<br />

ng<br />

Valve,<br />

Gauge<br />

and<br />

Protective<br />

Cap<br />

1<br />

8 2234 PressurizingHoseAss'y 1<br />

9 10906 Retaining<br />

Strap<br />

( Top)<br />

with<br />

Hose<br />

Hanger<br />

-<br />

Argon<br />

Cylinder<br />

1<br />

9A11020 RetainingStrap( Bottom)<br />

- Argon<br />

Cylinder<br />

1<br />

1011970 Bolt, Washer<br />

and<br />

Wing<br />

Nut<br />

1<br />

1110910 Pictogram-680&681 1<br />

1210909 10911<br />

Nameplate<br />

( Mylar<br />

Label)<br />

- Non<br />

F.<br />

M.<br />

- 680<br />

681<br />

1<br />

1310917 Wheel<br />

Ass'y<br />

- 36"<br />

X 2 1/<br />

2"<br />

with<br />

Rubber<br />

Tread<br />

1<br />

1410903 HubCap-36" Wheels<br />

1<br />

157411 MoistureSeal 1<br />

163877 Gasket, Hose<br />

/ Nozzle<br />

6<br />

176279 BallValveAss'y 1<br />

186 467<br />

NozzleTip( . 312)<br />

1<br />

191 0913<br />

HoseAss'y-3/ 4"<br />

x 25<br />

Ft.<br />

1<br />

2011181 ExtensionWandAss'y 1<br />

2. The second loop is a REVERSE loop.<br />

Notice that the hose passes behind the loop on<br />

this reverse loop.<br />

If instructions are followed, the hose will<br />

uncoil without kinks.<br />

Reverse<br />

loop<br />

1<br />

1<br />

15<br />

16<br />

17<br />

18<br />

Quick Release<br />

Argon Valve<br />

19<br />

6A<br />

6C<br />

6B<br />

6D<br />

6E<br />

20<br />

3. The next loop is a regular “hose in front”<br />

loop. Adjust the loops so that they are approximately<br />

the same size and then attach<br />

the hose to the shutoff valve with either the<br />

extension wand or nozzle installed.