Film Extrusion Guide.pmd - LyondellBasell

Film Extrusion Guide.pmd - LyondellBasell

Film Extrusion Guide.pmd - LyondellBasell

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Rotating Dies<br />

Rotating dies can be used to<br />

randomize transverse film gauge<br />

variation in the bubble. The<br />

constant turning of these dies<br />

distributes any gauge variations<br />

that can be caused by uneven<br />

bubble cooling or melt uniformity<br />

deficiencies.<br />

The randomization of gauge<br />

bands improves the flatness of film<br />

rolls.<br />

Automatic Gauge Adjustment<br />

Automatic gauge adjustment<br />

(Figure 28) can be used with blown<br />

film as another means of attaining<br />

uniform film gauge. Temperature<br />

and/or velocity changes in<br />

segments of the air ring change the<br />

temperature of the melt in that<br />

area. This change leads to a<br />

change in the melt’s drawdown<br />

characteristics and changes the<br />

gauge of the film in that area of the<br />

bubble. Other automatic gauging<br />

systems change overall film<br />

thickness by varying the speed of<br />

the primary nip rolls.<br />

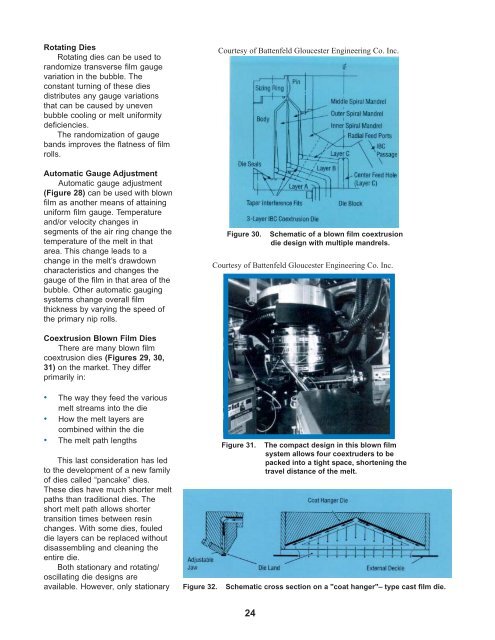

Coextrusion Blown <strong>Film</strong> Dies<br />

There are many blown film<br />

coextrusion dies (Figures 29, 30,<br />

31) on the market. They differ<br />

primarily in:<br />

• The way they feed the various<br />

melt streams into the die<br />

• How the melt layers are<br />

combined within the die<br />

• The melt path lengths<br />

This last consideration has led<br />

to the development of a new family<br />

of dies called “pancake” dies.<br />

These dies have much shorter melt<br />

paths than traditional dies. The<br />

short melt path allows shorter<br />

transition times between resin<br />

changes. With some dies, fouled<br />

die layers can be replaced without<br />

disassembling and cleaning the<br />

entire die.<br />

Both stationary and rotating/<br />

oscillating die designs are<br />

available. However, only stationary<br />

Courtesy of Battenfeld Gloucester Engineering Co. Inc.<br />

Figure 30. Schematic of a blown film coextrusion<br />

die design with multiple mandrels.<br />

Courtesy of Battenfeld Gloucester Engineering Co. Inc.<br />

Figure 31. The compact design in this blown film<br />

system allows four coextruders to be<br />

packed into a tight space, shortening the<br />

travel distance of the melt.<br />

Figure 32. Schematic cross section on a "coat hanger"– type cast film die.<br />

24